YOU SEARCHED BY...

SEARCH BY...

International Buyers' Guide

Country

- Al Kuwayt(1)

- Algeria(1)

- Argentina(1)

- Australia(2)

- Austria(5)

- Belgium(8)

- Brazil(4)

- Bulgaria(1)

- Canada(15)

- China(26)

- Denmark(10)

- Estonia(1)

- Finland(3)

- France(11)

- Germany(68)

- Greece(3)

- Hong Kong(1)

- India(29)

- Indonesia(1)

- Iran(1)

- Ireland(3)

- Israel(4)

- Italia (64)

- Japan(8)

- Lithuania(2)

- Malaysia(3)

- Mexico(1)

- New Zealand(3)

- Pakistan(3)

- Peru(1)

- Poland(1)

- Portugal(4)

- Russia(2)

- Saudi Arabia(1)

- Singapore(1)

- Slovenia(1)

- South Africa(1)

- South Korea(4)

- Spain(8)

- Sri Lanka(1)

- Sweden(7)

- Switzerland(11)

- Taiwan(10)

- Thailand(4)

- The Czech Republic(4)

- The Netherlands(5)

- Turkey(31)

- United Kingdom(20)

- United States(347)

- Vietnam(1)

International Buyers' Guide

Omya International AG

Company Headquarters

42 Baslerstrasse

Oftringen, AG 4665

Switzerland

International Buyers' Guide

Raw Materials

Content From Omya International AG

-

Omya's contribution to circular economy: together for a sustainable future

...White Papers / Tech Papers Released on 06.17.2020

-

Calcium Carbonate designed for PP spunmelt and dry-laid nonwovens

...White Papers / Tech Papers Released on 03.16.2020

-

Fibers & Nonwovens

Omya Calcium Carbonate for PP Spunmelt and Dry-Laid NonwovensLiterature / Brochures Released on 02.25.2020

Related Content

-

-

Associations | Shows/Events

-

Nonwoven Network to Install Ultrasonic Tea Packaging Machine

Machine can package 100 bags per minute09.21.21

-

Kimberly-Clark Adds to Board

Deirdre Mahlan and Jaime Ramirez will serve on the company's Audit Committee09.16.21

-

Harald Stini Resigns from Tenowo

Salvatore Musso temporarily takes over sole management of the company09.16.21

-

-

Wipes

Wipes Makers Ditch Plastics

Legislative demands and changing consumer preferences have created a need for alternative raw materials in many wipes marketsKaren McIntyre, Editor 09.01.21

-

-

Adult Incontinence

Ontex Launches Subscription-Based Incontinence Products Brand

A Lovely Day aims to diminish the taboo of incontinence08.31.21

-

Electronics | Machinery and Equipment

Optima Develops Fuel Cell Production Lines

Company provides machine solutions for all process stages involved in manufacturing membrane electrode assembly08.30.21

-

Associations | Shows/Events

INDA Offers On-Demand World of Wipes Conference Program

Thirty-one speaker presentations available for purchase08.30.21

-

Kimberly-Clark Announces Executive Leadership Changes

Tristram Wilkinson named president of the company's Asia Pacific consumer business08.26.21

-

Geotextile/Agrotextile

Confidence Infrastructure Invests in Two Needlepunch Geotextile Fabric Lines

Lines will cater to increasing demand of geotextiles in Bangladesh and international markets08.26.21

-

Ahlstrom-Munksjö Announces Name Change of Notes Issuer Spa Holdings 3 Oy

Business name registered as Ahlstrom-Munksjö Holding 3 Oy08.23.21

-

Feminine Hygiene

Always, Thrive Global Launch Period Tracker and Wellness App

By registering and engaging with the app, users can spark donations of period products08.19.21

-

Medical | Meltblown | Mergers and Acquisitions | North America

Precision ADM Acquires Canadian Meltblown Nonwovens Producer

Roswell DHT and Precision will produce 100% compostable nonwoven fabrics for use in PPE08.16.21

-

Product Improvement/Innovation | Wipes

LifeSavers: Personal Care Wipes Function as an Early Warning Device

Newly developed wipes detect abnormal glucose levels in urineTara Olivo, associate editor 08.13.21

-

Machinery and Equipment | Shows/Events

Andritz to Exhibit Nonwovens Production Technologies at Techtextil Russia

Company will highlight air-through bonding, needlepunch, spunlace, spunbond and other technologies08.10.21

-

Medical

Berry to Add Second Site In India

Investment focuses on healthcare, does not involve nonwovens08.09.21

-

Machinery and Equipment

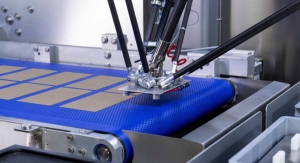

2021 Machinery & Equipment Review

A look at the latest technological developments from the major suppliers of nonwovens related machineryTara Olivo, Associate Editor 08.04.21

-

Meltblown | Spunbond/Spunmelt

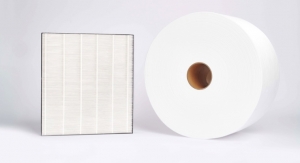

MAG HEPA-Grade Meltblown Targets Beauty and Medical Industry

Taiwanese company produces 100 tons of nonwovens per month08.02.21

-

North America | Western Europe

EDANA, INDA Launch Industry Standards

Nonwovens standard procedures offer harmonized language for the U.S. and Europe08.02.21

-

Associations | Shows/Events | Wipes

World of Wipes Draws 475 to Atlanta

Event was the first in-person conference in the nonwovens industry in 500 days07.20.21

-

Wipes

Unicharm to Launch Organic Cotton Based Baby Wipe in Taiwan

Mamy Poko Premium Baby Wipes certified by Oeko-Tex and FSC Certification07.19.21

-

Associations | Contracts/Awards | Shows/Events | Wipes

Scott 24 Hour Sanitizing Wipes Wins WOW Innovation Award

Pre-saturated wipes quickly disinfect and maintain surface sanitization for 24 hours07.15.21

-

Chemicals/Adhesives

Nippon Shokubai Earns Biomass Certification for SAP

The use of bio-based SAP will contribute to the reduction of CO2 emissions throughout the product life cycle07.13.21

-

Diaper, Baby | Feminine Hygiene | Pacific Rim

Daio Paper Launches Medium Term Business Plan

Japanese hygiene specialist looks to expand its overseas businesses sharplyKaren McIntyre, editor 07.08.21

-

Meltblown | Spunbond/Spunmelt

Jofo Completes SAAF Purchase

Acquisition gives company first spunmelt operation outside of China07.08.21

-

-

Wipes

WOW Conference Expected to Attract 400 Attendees

50 companies will exhibit products and services during two evening receptions07.07.21

-

Associations | Shows/Events | Wipes

World of Wipes to Focus on Sustainability, Covid-19 Consumer Wipes Buying Trends

Event will be held next week in AtlantaTara Olivo, associate editor 07.07.21

-

Shows/Events

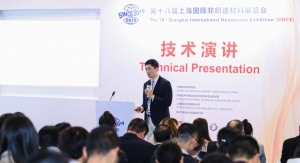

Groz-Beckert Reports Success at ITMA Asia + CITME 2021

Company welcomed nearly 3,600 visitors in-person and virtually during the trade fair07.07.21

-

Wipes

Innovation Award To Be Presented at WOW

Companies to vie for honor at Atlanta conference in July07.06.21

-

Facilities/Capacity | Meltblown | Spunbond/Spunmelt

PFNonwovens Announces South African Expansion

$40 million investment will add 40 jobs, additional capacity to site06.22.21

-

Flame Retardance | Home Products | Legal/Regulatory

Beckmann Converting Solutions Meet New Federal Flammability Standard

Company offers fire barrier fabrics for furniture manufacturers through its Sandel International division06.21.21

-

Machinery and Equipment | Shows/Events

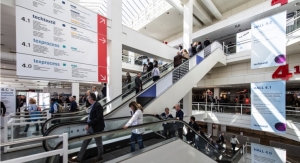

Swiss Textile Machinery Companies Report Successful ITMA Asia + CITME Exhibition

Exhibitors welcome return to in-person customer contact06.18.21

-

Adult Incontinence

Ontex to Pilot Smart Diaper Program in EU

Orizon sensor technology to be tested in nursing homes06.17.21

-

Associations | Shows/Events

EDANA Hosts Successful International Nonwovens Symposium

Nearly 200 industry professionals joined the virtual event06.14.21

-

-

China | Facilities/Capacity | Spunlace | Wipes

Zhejiang Saintyear Orders Second Andritz Spunlace Line

Start-up scheduled for the third quarter of 202206.11.21

-

Contracts/Awards | Machinery and Equipment

Montalvo Receives Exporter of the Year Award

Company honored by the Maine International Trade CenterTara Olivo, associate editor 06.09.21

-

-

Diaper, Baby | Feminine Hygiene | Green/Sustainability

Natural Hygiene: Innovation Continues

Brands are putting their own spin on what makes an eco-friendly productTara Olivo, Associate Editor 06.03.21

-

Filtration | Medical | Meltblown | Product Improvement/Innovation

KNH Launches HEPA Grade Meltblown

Nonwovens will supply the high-end filtration marketTara Olivo, associate editor 06.01.21

-

INDA Launches Updated Nonwoven Material Sampler

178-page publication contains 124 material swatchesKaren McIntyre, editor 05.25.21

-

-

Medical | Meltblown | Western Europe

Dutch PPE Solutions Starts Meltblown Production

Joint venture between Royal DSM and VDL Groep makes Europe less dependent on supplies from overseasTara Olivo, associate editor 05.13.21

-

Associations | Shows/Events

EDANA Opens Up Registration for International Nonwovens Symposium

Virtual event will be held June 9-10Tara Olivo, associate editor 05.07.21

-

-

Facilities/Capacity | South Africa

Andritz Installs Stitchbonding Line in South Africa

Line supplied to Romatex will produce Maliwatt products used in a wide range of applicationsTara Olivo, associate editor 05.06.21

-

Associations | Shows/Events

Virtual Outlook Conference a Success

Over 590 key stakeholders joined the nonwoven personal care products event04.28.21

-

Ontex Adds to Executive Management Committee

Peter Vanneste named chief financial officer, Vincent Crepy named chief supply chain officer04.28.21

-

Facilities/Capacity | Machinery and Equipment | Needlepunch | Western Europe

Andritz to Supply Elliptical Cylinder Pre-Needler in France

Machine supplied to Amarande will process shoddy and natural fibers for the production of heavy feltsTara Olivo, associate editor 04.19.21

-

Russ Torres Named Group President of Kimberly-Clark North America

Torres succeeds Kim UnderhillTara Olivo, associate editor 04.14.21

-

Aries Face Masks Meet ASTM Standards

Coverings proven effective for workplace safetyKaren McIntyre, editor 04.13.21

-

-

Meltblown | Spunbond/Spunmelt

Spunmelt Nonwovens Surge

New lines are popping up all over the globe to help ease shortages for medical fabrics and other key applicationsKaren McIntyre, Editor 04.12.21

-

Associations | Shows/Events | Wipes

Asia Wipes Summit Held Successfully in Shanghai

Event focused on the sustainable development of wipesTara Olivo, associate editor 04.12.21

-

Wipes

Wipes Manufacturers Meet Demand Surge

Line investments and increased partnerships will increase output of disinfectant wipesKaren McIntyre, Editor 04.01.21

-

Tenowo Appoints Managing Director

Salvatore Musso will lead sales and marketing for the companyTara Olivo, associate editor 04.01.21

-

Adult Incontinence

-

Associations | Shows/Events

INDEX Postponed to October

Organizers also announce virtual optionTara Olivo, associate editor 03.22.21

-

Ettore Paolini Named VP of Service at Andritz Nonwoven, GM of Andritz Diatec

He has 20 years’ experience in the hygiene machinery sectorTara Olivo, associate editor 03.19.21

-

Associations | Shows/Events | Wipes

World of Wipes Returns as In-Person Event

Wipes conference to be held in Atlanta July 12-15Tara Olivo, associate editor 03.18.21

-

Associations | China | Shows/Events

ANEX+SINCE to be Held in July

Nonwovens exhibitions will take place at the Shanghai World Expo Exhibition and Convention CentreTara Olivo, associate editor 03.15.21

-

Hygiene Film/Components | Medical

A New Solution for Defense Against Infectious Agents

Gowfense by Texol is the protective laminate for disposable gownsTara Olivo, associate editor 03.15.21

-

Wipes

Clorox Ramps Up Wipes Output

Company expects wipes growth to continue beyond pandemic's endKaren McIntyre, editor 03.12.21

-

Filtration | Product Improvement/Innovation

Ahlstrom-Munksjö Forms Partnership with Virgis Filter and Webasto

Filtration solution developed to protect indoor environments from Covid-19Tara Olivo, associate editor 03.11.21

-

Adult Incontinence

Ontex’s Smart Diapers Use Printed Sensors to Improve Adult Care

New solution helps increase the wellbeing of all affected by continence care, including patients, professional caregivers, institutions and familiesDavid Savastano, editor, Printed Electronics Now 03.10.21

-

A solution for defense against infectious agents

Gowfense by Texol is the protective laminate for disposable gowns

-

Medical | Mergers and Acquisitions

-

Shows/Events

Cinte Techtextil China to Hold Hybrid Exhibition in China

Visitors will be able to attend in person or online at June eventKaren McIntyre, editor 03.09.21

-

Feminine Hygiene

Adult Incontinence Products Industry Continues to Grow

New players, new product formats increase competition in the marketTara Olivo, Associate Editor 03.04.21

-

Medical

FPInnovations Develops Biodegradable Mask

In addition to the mask filtering materials, the elastic ear loops and nose pieces are biodegradableTara Olivo, associate editor 03.04.21

-

Legal/Regulatory | North America

Non-Regulatory Face Mask Standard Approved

ASTM F3502 establishes design, labeling, fit and usage requirements for facial coveringsKaren McIntyre, editor 02.25.21

-

Filtration | Shows/Events

Filtech Announces New Dates

Filtration event will be held March 8-10, 2022, in Cologne, Germany02.16.21

-

P&G Adds to Board

B. Marc Allen is the chief strategy officer and SVP of strategy and corporate development at Boeing02.10.21

-

Medical

Artofix's N95-Type Mask Approved by Health Canada

Company can produce close to 100,000 masks per week02.09.21

-

-

Shows/Events

-

-

Machinery and Equipment

Lemu Group Engineers Mask-Making Machine

Converting equipment can provide growth opportunities while assisting in the fight against COVID-1901.21.21

-

Shows/Events

Techtextil, Texprocess Postponed to 2022

Events will take place in the second quarter of next year01.19.21

-

Filtration | Market Data

Freedonia Tracks Filtration Market

Nonwovens demand for filtration applications is expected to climb 2.7% annually01.14.21

-

-

Diaper, Baby

Trends in Diapers: Sustainability, Natural Ingredients or Other Features?

New niche brands penetrate the disposable baby diaper marketNatalia Richer, Diaper Testing International 01.06.21

-

Diaper, Baby

Baby Diapers: A Changing Market

New brands, new marketing efforts have changed the way manufacturers speak to parentsKaren McIntyre, Editor 01.06.21

-

The Private Label Market

Innovation, e-commerce push store brands to a new levelTara Olivo, Associate Editor 01.06.21

-

China | Medical | Middle East/North Africa | Spunbond/Spunmelt

Jofo Finalizes SAAF Acquisition

Chinese manufacturer buys 70% stake in Saudi nonwovens producer12.30.20

-

Green/Sustainability

Fibertex PC Continues to Roll Out Circular Products

Company's complete nonwovens portfolio now available as certified ISCC Plus12.21.20

-

China

Jofo Focuses on Expansion

A string of acquisitions, investments has transformed company into a global player12.17.20

-

Absorbent Core | Hygiene Film/Components

Hygiene Suppliers Go Natural

Demand for safer ingredients, transparency guide innovation in a highly competitive marketKaren McIntyre, Editor 12.11.20

-

Diaper, Baby

EWG Verified Diapers Launch Nationwide

Collaboration with Healthynest offers full analysis of ingredients12.10.20

-

Associations

-

Machinery and Equipment | Mergers and Acquisitions

Andritz to Buy Laroche

Deal enhances scope of supply in spunlace, wetlaid and needlepunch machinery12.04.20

-

-

Filtration | Nanotechnology

Applied Nanoscience to Commence U.S.-based Production of NanoFense Formulation

Company awarded a PPE Manufacturing Grant to aid in the global fight against Covid-1912.01.20

-

Wipes

Diamond Wipes Expands HandyClean Steridol Wipes Range

Adds 80-count soft pack and individually wrapped disinfecting wipes11.19.20

-

Facilities/Capacity | Medical | North America

United Sewing Automation Produces U.S.-Sourced and Manufactured PPE Face Masks

Mt. Airy, NC, facility gets a visit from U.S. Representative Patrick McHenry11.17.20

-

Education | Hygiene Film/Components

Avery Dennison Publishes White Paper on ISO-Certified Diaper Materials

White paper released in conjunction with World Prematurity Day11.16.20

-

50 Years of Nonwovens

In 1970 Disposable Soft Goods started covering a new industry focused on disposable markets. Today, the magazine, now known as Nonwovens Industry, continues toKaren McIntyre, Editor 11.12.20

-

-

Apparel | China | Green/Sustainability

Texon Achieves Two Industry Accreditations

Dongguan, China, site earns SATRA Laboratory Accreditation Status and is certified to the Global Recycled Standard11.12.20

-

-

Green/Sustainability | Wipes

-

Wipes

Sani Professional Products Demonstrate Efficacy Against SARS-CoV-2

Test results for three products have been submitted to the EPA10.14.20

-

Market Data | Medical

Smithers Tracks Market Boom for Medical Nonwovens

Data shows a 19.2% increase in demand due to Covid-19 pandemic10.14.20

-

Maxcess Opens New Global HQ in Illinois

Also appoints Alexander Haid to lead its European operations10.13.20

-

-

-

Omya Receives Inaugural INDEX People's Prize

Omyafiber video received most likes on INDEX's Linkedin page10.08.20

-

China

Chinese Nonwovens Outlook

As hygiene products continue to evolve in sophistication and design, nonwovens manufacturers continue to invest in new technologiesKaren McIntyre, Editor 10.08.20

-

Contracts/Awards | Shows/Events

EDANA Announces INDEX Innovation Award Winners

Companies honored across seven categories in virtual ceremony10.07.20

-

Green/Sustainability

Berry's Biesheim, France, Facility Achieves ISCC Plus Certification

With certification Berry can produce nonwovens substituting a percentage part or 100% of the virgin resin with certified circular polymers10.02.20

-

Green/Sustainability | Spunbond/Spunmelt

Sabic, Fibertex Personal Care Partner to Make Recycled Nonwoven

Fabrics made using recycled plastics from the Trucircle portfolio10.01.20

-

-

China International Public Health Security Epidemic Prevention & Protection Material Fair

GUANGZHOU INTERNATIONAL SOURCING CENTRE

-

Diaper, Baby | R&D/Basic Research

Diaper Testing International Releases Report on Walmart Diaper Brands

Features analysis on two exclusive baby diaper brands All Good and Rascal + Friends06.29.20

-

-