Tara Olivo, associate editor06.01.21

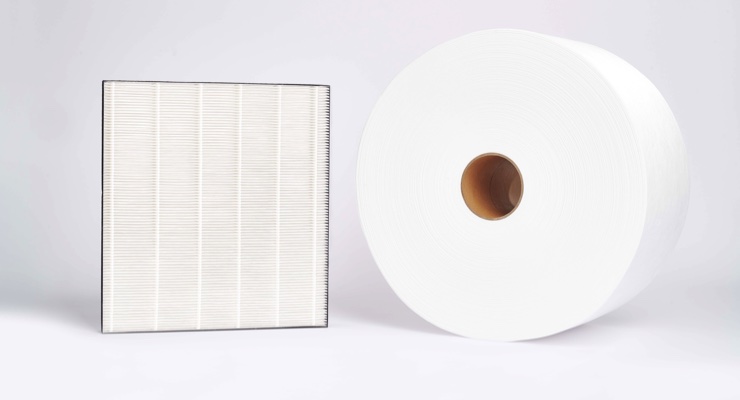

KNH has been dedicated to meltblown technology for more than 20 years, which is widely applied in the medical and personal protective filter material. KNH has officially entered the high-end filtration market by launching the HEPA grade meltblown nonwovens with high efficiency and high permeability.

KNH is the first manufacturer of air through and meltblown nonwovens in Taiwan. The main nonwoven products it produces are air through, thermal bond, airlaid, spunlace, meltblown and calender bond. It has served customers all around the world and produces more than 20,000 tons of nonwovens per year. Due to the impact of Covid-19, KNH expanded meltblown production lines in 2020 to meet the high demand from worldwide customers. This year, KNH launched the HEPA grade meltblown nonwoven with high efficiency and high permeability to supply the high-end filtration market.

Compared with the general meltblown nonwovens, KNH HEPA Meltblown nonwovens can meet the requirements of high-efficiency filtration H10-H14, with the lower air resistance and higher performance. The efficiency can be achieved up to 99.995%; the air resistance can be decreased around 30-40%. Therefore, KNH HEPA Meltblown nonwovens can also provide medical and personal protection filters with more breathable, comfortable, and protective options.

Established in 1969, KNH's plants are based throughout the China. It focuses on nonwoven production and OEM for the international well-known brands with a global vision.

KNH is the first manufacturer of air through and meltblown nonwovens in Taiwan. The main nonwoven products it produces are air through, thermal bond, airlaid, spunlace, meltblown and calender bond. It has served customers all around the world and produces more than 20,000 tons of nonwovens per year. Due to the impact of Covid-19, KNH expanded meltblown production lines in 2020 to meet the high demand from worldwide customers. This year, KNH launched the HEPA grade meltblown nonwoven with high efficiency and high permeability to supply the high-end filtration market.

Compared with the general meltblown nonwovens, KNH HEPA Meltblown nonwovens can meet the requirements of high-efficiency filtration H10-H14, with the lower air resistance and higher performance. The efficiency can be achieved up to 99.995%; the air resistance can be decreased around 30-40%. Therefore, KNH HEPA Meltblown nonwovens can also provide medical and personal protection filters with more breathable, comfortable, and protective options.

Established in 1969, KNH's plants are based throughout the China. It focuses on nonwoven production and OEM for the international well-known brands with a global vision.