04.06.17

DuPont Protection Solutions announced the 50th anniversary of DuPont Tyvek, a unique nonwoven material that has enabled new dimensions of protection, security and safety in a wide variety of industries and applications. To mark this major milestone, celebratory events will be held throughout the year to not only pay tribute to the past, but to focus on the future. In addition, a series of communications and special activities are planned to inform, inspire and involve customers, end-users and others around the world during this celebration year and beyond.

“We are proud of the role Tyvek has played during the past 50 years in making a world of greater good possible,” says Christian Marx, global business director for DuPont Tyvek. “From helping to protect medical personnel during the West Africa Ebola crisis, to serving as a weather barrier for the pavilion housing the Liberty Bell in Philadelphia along with countless homes and commercial buildings around the globe, to helping protect the health of millions of patients around the world by maintaining the sterility of medical devices and supplies, Tyvek provides the trusted protection people need to accomplish bigger things. We are pleased to celebrate the past but remain focused on the future, collaborating worldwide to innovate with Tyvek and help solve the challenges of the next half century and beyond.”

Lightweight and durable, Tyvek is breathable, yet resistant to water, abrasion, bacterial penetration and aging, making it ideal for a wide variety of applications across diverse industries. One of the most commonly known applications is in construction where products in the family of building envelope solutions, such as Tyvek HomeWrap, Tyvek CommercialWrap, DuPont Flashing Systems and Tyvek Protec, are used to create more comfortable, energy-efficient buildings with fewer chances for moisture damage caused by water buildup.

DuPont is a global leader with Tyvek protective garments providing superior protection for workers in industrial and cleanroom applications and for first responders. Companies around the world use more than 200 million Tyvek garments per year. Tyvek garments have been used to support emergency response efforts across the globe, including the U.S. Deepwater Horizon oil spill cleanup; the Japan 2011 tsunami cleanup and Fukushima nuclear plant remediation; and for protection of workers in West Africa in addressing the Ebola crisis.

"We are committed to innovation in the development of protective apparel garments and accessories and we are launching several new products in our Tyvek and Tychem product range in 2017 to meet market needs,” says David Domnisch, global marketing manager for Tyvek Protective Apparel.

Beyond protecting homes and workers, Tyvek also is widely used to help protect patients in healthcare settings. Since its introduction to the medical device industry more than 45 years ago, Tyvek has been recognized as a standard of excellence for sterile device packaging. Tyvek earned this distinction because it provides excellent microbial barrier, strength and protection for medical devices and pharmaceutical applications. Tyvek for medical packaging also helped enable the development of new sterilization methods, such as low-temperature gas plasma sterilization.

Other applications for Tyvek include: industrial packaging, active packaging and other specialty applications; cargo covers for pharmaceuticals and perishables; envelopes used by the U.S. Postal Service; and graphics as a substrate for tags, labels, banners, wristbands, maps and the creation of works of art and consumer products.

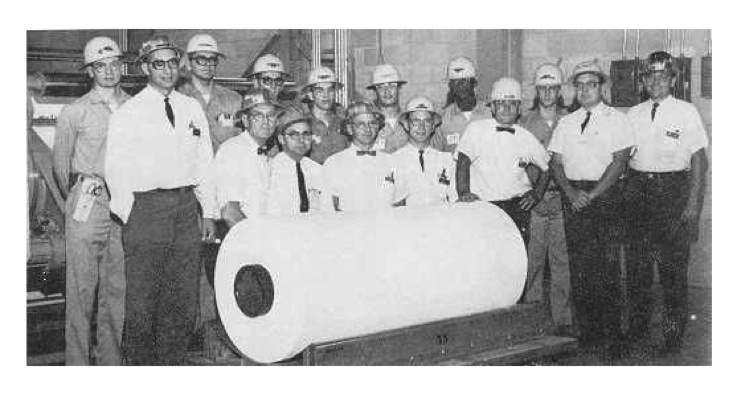

The history of Tyvek began in 1955 when DuPont researcher Jim White made a chance discovery of a new fiber source. A program to develop the new material was set up and a year later DuPont submitted a patent proposal for strong yarn linear polyethylene. It took several more years for research teams to perfect the complex manufacturing process, which was based on the flash-spinning technology invented by DuPont scientist Herbert Blades. In 1965, the new engineered sheet structure was registered under the trademark name Tyvek, and in April 1967 DuPont began commercial production.

“We are proud of the role Tyvek has played during the past 50 years in making a world of greater good possible,” says Christian Marx, global business director for DuPont Tyvek. “From helping to protect medical personnel during the West Africa Ebola crisis, to serving as a weather barrier for the pavilion housing the Liberty Bell in Philadelphia along with countless homes and commercial buildings around the globe, to helping protect the health of millions of patients around the world by maintaining the sterility of medical devices and supplies, Tyvek provides the trusted protection people need to accomplish bigger things. We are pleased to celebrate the past but remain focused on the future, collaborating worldwide to innovate with Tyvek and help solve the challenges of the next half century and beyond.”

Lightweight and durable, Tyvek is breathable, yet resistant to water, abrasion, bacterial penetration and aging, making it ideal for a wide variety of applications across diverse industries. One of the most commonly known applications is in construction where products in the family of building envelope solutions, such as Tyvek HomeWrap, Tyvek CommercialWrap, DuPont Flashing Systems and Tyvek Protec, are used to create more comfortable, energy-efficient buildings with fewer chances for moisture damage caused by water buildup.

DuPont is a global leader with Tyvek protective garments providing superior protection for workers in industrial and cleanroom applications and for first responders. Companies around the world use more than 200 million Tyvek garments per year. Tyvek garments have been used to support emergency response efforts across the globe, including the U.S. Deepwater Horizon oil spill cleanup; the Japan 2011 tsunami cleanup and Fukushima nuclear plant remediation; and for protection of workers in West Africa in addressing the Ebola crisis.

"We are committed to innovation in the development of protective apparel garments and accessories and we are launching several new products in our Tyvek and Tychem product range in 2017 to meet market needs,” says David Domnisch, global marketing manager for Tyvek Protective Apparel.

Beyond protecting homes and workers, Tyvek also is widely used to help protect patients in healthcare settings. Since its introduction to the medical device industry more than 45 years ago, Tyvek has been recognized as a standard of excellence for sterile device packaging. Tyvek earned this distinction because it provides excellent microbial barrier, strength and protection for medical devices and pharmaceutical applications. Tyvek for medical packaging also helped enable the development of new sterilization methods, such as low-temperature gas plasma sterilization.

Other applications for Tyvek include: industrial packaging, active packaging and other specialty applications; cargo covers for pharmaceuticals and perishables; envelopes used by the U.S. Postal Service; and graphics as a substrate for tags, labels, banners, wristbands, maps and the creation of works of art and consumer products.

The history of Tyvek began in 1955 when DuPont researcher Jim White made a chance discovery of a new fiber source. A program to develop the new material was set up and a year later DuPont submitted a patent proposal for strong yarn linear polyethylene. It took several more years for research teams to perfect the complex manufacturing process, which was based on the flash-spinning technology invented by DuPont scientist Herbert Blades. In 1965, the new engineered sheet structure was registered under the trademark name Tyvek, and in April 1967 DuPont began commercial production.