02.08.19

IDEA 2019, the world’s preeminent event for nonwovens and engineered fabrics, will be held March 25-28 at Miami Beach Convention Center in Miami Beach, FL. The INDA-organized event will attract 7000 attendees and more than 500 exhibitors representing the entire nonwovens industry supply chain. The exhibitors will display game-changing technologies, innovations , materials and machinery giving nonwovens executives the chance to source all of their companies’ needs in one place.

IDEA exhibitors are already planning their booths for the three-day event. Below is a look at what some exhibitors plan to bring to the show.

Avgol

Booth 928

Avgol, a global leader in the manufacture of high-performance nonwoven fabric solutions, is to showcase its Forward Innovative Thinking (FIT) family of nonwoven technologies at IDEA 2019.

Developed to respond to consumer needs and desires, FIT technologies and chemistries address softness, skin wellness, barrier and fluid management complexities in hygiene applications, including the baby diaper, adult incontinence and feminine hygiene products markets.

Avgol’s FIT strategy represents the company’s commitment to harnessing expertise to anticipate the needs of consumers. It includes the creation of high-performance technologies that are designed to be modular in nature and can be used alone, or in combination, to provide a palette of solutions for product designers.

The family includes beneFIT, comfortFIT and enhanceFIT as well as Waveform 3D—a new process that enables the modification of nonwoven fabrics to extend innovation capabilities and enhance performance and comfort for consumers.

Nick Carter, director of Market Business Intelligence and Intellectual Property at Avgol, says: “IDEA is a premier event in the nonwovens and engineered fabrics sector and an excellent platform for Avgol to inform and educate delegates on our latest market-leading and pioneering technologies.

“We look forward to demonstrating how our FIT technologies can offer a truly tailored solution for enhanced performance and end-user comfort.”

Aurizon Ultrasonics

Booth 820

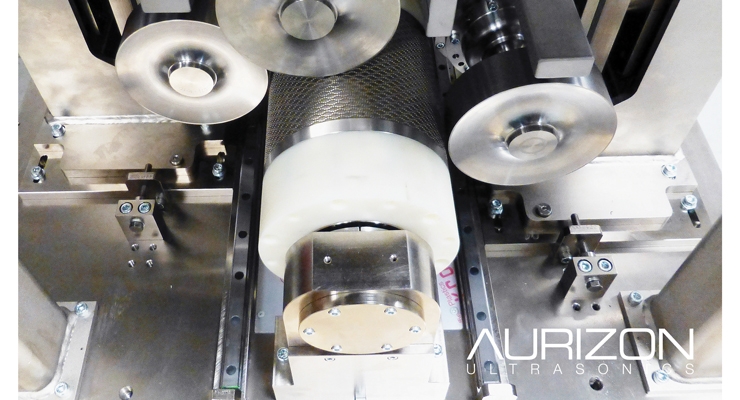

Aurizon Ultrasonics makes high power ultrasonic systems for a variety of nonwoven processing applications including bonding, elastic entrapment, feature attachment, embossing, sheet lamination and cutting.

Many nonwoven product manufacturers use adhesives for these steps, but Aurizon is proving that there is a better way to produce elasticized fabric – ultrasonic technology.

In the past, Aurizon Ultrasonics exclusively provided rotary sonotrodes with their technology. However, in 2019 they are expanding their offerings by including the option of fixed blade horn technology. This technology can reduce equipment cost by leveraging an increased blade width as compared to rotary. It is not suitable as a replacement for all rotary horn applications, yet there are many less demanding applications where it is an effective solution such as material lamination and edge sealing.

The company’s patented technology provides a solid foundation for delivering increased productivity, reduced costs, and a more sustainable process. Additionally, ultrasonic technology has aesthetic benefits including odorless, softer, more breathable fabric and the potential for using lighter materials and reduced elastic decitex. Elasticized fabric created by ultrasonic methods has more drape, bend and crush conformability than products using adhesive.

Dilo Group

Booth 522

Dilo is a leading equipment supplier of complete lines for staple fiber nonwoven fabric production.

The most recent machine concepts from DiloGroup companies DiloTemafa, DiloSpinnbau and DiloMachines will be promoted with the emphasis on new equipment components which improve product quality, increase line capacity and furthermore enable new opportunities in nonwoven production.

DiloTemafa has introduced versions of the Baltromix bale opener and the card willow which are particularly suited to the processing of longer fibers at highest throughput. Longer cleaning intervals and shorter cleaning times also result from the design changes. The DON dosing opener remains as an intermediate between fiber preparation and the card feeder and provides a fine opening stage.

DiloSpinnbau has a new “Unifeed” card feeder (VRS-P) which combines the principle of volumetric charged feeding with the characteristics of a chute feeder but without the conventional overhead trunk which allows for lower ceiling height requirement. The fiber flock matt is condensed by a vacuum delivery apron to give better uniformity of mass distribution. The distribution over the working width is controlled by additional flaps. This feeder can be adapted for medium/fine to coarse and medium to long staple fibers.

The “VectorQuadroCard” incorporates a modular transfer group between breast and main section. The quick change facility of this roller group provides different carding options. The delivery system is also flexible to provide parallel laid, random or condensed web. The preopener section on this card has four worker/stripper pairs with five pairs on the main cylinder. Emphasis is on high throughput with good web quality.

DiloMachines has a new horizontal crosslapper version “DLSC” which allows web infeed speeds up to 200 m/min depending on fiber specification. Such infeed speeds will prevent the lapper being the line bottleneck. The DLSC works in conjunction with the proven CV1A web regulation system for improved felt evenness and the potential for fiber savings. A further increase of the drive power within the three-apron-layering technology as well as the application of carbon fiber reinforced parts enables these major improvements. A web guiding system (“extended web guide”) can be added to avoid web wrinkles at lapper reversals.

Mahlo

Booth 636

Mahlo will be exhibiting its QMS-12 Web Gauging System for the on-line measurement of web basis weight, thickness, density, moisture, coating add on, and air permeability. In addition, new sensor technologies for measuring web composition and fiber ratio will also be on display, as well as features such as Roll Reporting and Data Management for real time evaluation, analysis, and archiving of critical web parameters.

Martin Automatic

Booth 1964

Leading American manufacturer of high-performance splicing, rewinding, web transport and web tension control, Martin Automatic, will be exhibiting at the upcoming IDEA19 trade show in Miami, FL. Speaking for the company, Mike Jelinsky, sales engineer for Martin Automatic, says, “Nonwovens are a significant segment within Martin’s global markets and IDEA19 creates an arena to continue our involvement with established and emerging nonwoven customers and applications. The expo allows us to share our expertise in handling a variety of materials, and to highlight the cost and production efficiency improvements that our automation can bring.”

Visitors will be able to discuss Martin’s advanced web transport and web tension technologies, and the company’s solutions for non-stop splicing, unwinding and rewinding of nonwovens from 20mm to 4M wide supplied on reels up to 2.4M diameter. Designed to be practical, and reliable with industry leading lowest cost of ownership, Martin equipment is easy to use and easy to maintain for provides long-term performance and profitability.

Nordfab

Booth 1071

Nordfab Quick-Fit ducting allows fast installation without special tools, rivets, screws or welding. The QF rolled edge on ducting components is quickly connected with the unique Quick-Fit Clamp, cutting installation and downtime by more than 45%. The Quick-Fit Clamp allows easy adjustment of ducting layouts during installation as well as easy removal for cleaning, reconfiguring, or relocation.

Quick-Fit ducting is ideal for most dust, mist and fume collection applications. Ducting is available in galvanized or stainless steel, various gauges to suit applications such as highly abrasive dusts, and diameters from 3” to 72”.

Nordfab Ducting offers two free software tools, one CAD-based and one SketchUp-based, to make it easier to create layouts of ducting for an installation.

Optima Nonwovens

Booth 1050

IDEA is the most important trade show for Optima Nonwovens in 2019. In line with this, the company will present a multitude of new ideas and solutions to help machine users overcome their everyday challenges: rising labor costs, more complex packaging processes, and changing market demands. Visitors to the trade show can discover how the OPAL line management software, a cobot and augmented reality can help with this at several stations. With the aid of three characters, the company will demonstrate typical applications for these new technologies. The courage to develop new, digital solutions is also underlined by the trade show’s slogan: “Your Production of the Future: Smart. Efficient. Flexible.”

“Our three characters – Tom, an operations manager, Lisa, a plant manager, and Carl, a machine operator, will demonstrate the daily challenges in the production of paper hygiene products before the eyes of the visitors,” says Oliver Rebstock, managing director at Optima Nonwovens. These include the increasing complexity of packaging processes, an ever faster time to market, and varying market demands. “Not only do the machines, markets, and packaging processes change, but so too do the people who stand in front of the machine,” adds Rebstock. From the points of view of Tom, Lisa, and Carl, they have very different requirements and thus there is a demand for customized solutions by Optima. “The Smart Services complement the already existing Optima services,” explains Rebstock. Some of Optima’s strengths include a well-developed network of subsidiaries that offer local support, reliable spare parts delivery, and on-site inspections by Optima experts.

OPAL gives operations managers an overview of the performance indicators and reduces machine downtime.

Operations managers are interested in having a comprehensive overview of production, in order to quickly identify weak points and to use human resources in an appropriate way. Therefore, Optima Nonwovens will present the OPAL line management software at IDEA. The system records performance indicators such as overall equipment effectiveness (OEE) and leads to an increase in production quality and transparency, productivity, less machine downtime, and the best use of production capacities. This information can be presented worldwide on any imaginable output device.

Plant managers are confronted with rising labor costs and have to adjust their production quickly and flexibly to new market demands. Optima is supporting them using a cobot, a robot which can operate in the machine’s surrounding area. Visitors will also be introduced to an extended modularity concept that enables production to respond flexibly to new requirements, making investment in machines long-term and future-proof.

Total Care Asset Management (TCAM) addresses machine operators’ needs. Flexible consumer behavior requires small lot sizes and frequent format changes. With TCAM, which belongs to the Optima smart services, they receive the right information at the right time on the right output device to avoid any errors. Information about machine status can be displayed in the same way as maintenance manuals and training materials, for example, using augmented reality glasses. The augmented reality glasses can show useful digital information about the real environment of the wearer. In addition, the system can be used for remote support. Service employees at Optima can switch to the customer’s augmented reality glasses live and help them to change format parts. Another positive effect is that new employees can be trained more quickly, the error rate falls, and therefore downtimes also fall. These measures raise productivity for Optima’s customers.

Sandler

Booth 902

At IDEA, Sandler AG invites visitors to the garden of (green) developments. The nonwovens manufacturer will showcase its broad range of material for hygiene products, wipes and technical applications, among them nonwovens that take account of sustainability. In baby care, feminine care and incontinence products, Sandler offers nonwovens that combine functionality and comfort in use. Efficient, even softer nonwovens for intake layers contribute to optimum fluid management. Particularly smooth product variants are ideal for use as tampon covers. A new generation of nonwovens for elastic closure systems combine improved extensibility and high stability in processing. The focus of this year’s trade fair participation, however, will be on nonwovens for topsheet applications.

Sandler developed a nonwoven composite for use in diapers in cooperation with a customer, that is particularly smooth yet voluminous at the same time. Special embossing creates a topographical structure on the materials surface, which enhances fluid handling as well as comfort in use: moisture collects at the lower points; the bulky sections keep moist parts of the material away from the skin, thus preventing skin irritation. Owing to its low basis weight this new development is ideal for thin, lightweight product structures for hygiene applications—for increased comfort and discretion in use.

Another multi-layer nonwoven offers a structured and perforated alternative for topsheets: The embossing pattern dubbed “canyon” renders the topsheet bulkier, while also increasing stability and creating an individual look. This structure forms grooves on the topsheet’s surface, which help quickly transport fluid away from the body and into the absorbent core. In this way, the nonwovens contribute to preventing skin irritation and support a sense of safety during use.

Sandler topsheet materials made with cotton also contribute to comfort in use—soft, reliably functional and manufactured using an increased share of renewable raw materials.

In the wipes market, Sandler is developing more sustainable product solutions even for single-use products. Made from a special, certified viscose fiber, Sandler’s new substrates are biodegradable and also available as FSC certified variants. They offer the established Sandler quality—highly absorbent, tear-resistant and better for the environment. The PEFC-certified substrate, bio textile by sandler is made exclusively from viscose fibers sourced from European forests—sustainable raw materials with a reduced carbon footprint. Newly developed nonwovens made from viscose and cellulose acetate fibers are soft and gentle on the skin. They are biodegradable and compostable. Wipes substrates made from the lactic-acid based raw material PLA and product variants with a share of cotton complete the range of nonwoven substrates made with raw materials from renewable sources.

Especially for applications in household cleaning Sandler will present wipes substrates made from recycled polyester fibers, which also contribute to conserving resources. An embossing design dubbed “square” further enhances cleaning properties. Rows of small squares enlarge the nonwoven’s surface for optimized dirt removal while also rendering the wipe substrate more voluminous for a softer, fluffier feel.

For disinfection applications, Sandler will showcase a new fine perforation, which is effective in two ways: Firstly, the enlarged surface increases dirt collection for optimum cleaning results. Secondly, fluids accumulate in the material and are quickly released during use—a prerequisite for ideal disinfection.

Product variants featuring increased stability further add to the product range.

Technical Absorbents

Booth 1241

This year the International Engineered Fabrics Conference and Exposition (IDEA), Technical Absorbents will again be exhibiting as the event makes its way back to the newly renovated Miami Beach Convention Centre. It will be concentrating on the promotion of its SAF superabsorbent fabrics and will be bringing along a number of new samples.

The Technical Absorbents stand – number 1241 – will be SAF branded as the company continues to raise the profile of its fibrous superabsorbents in the industry.

“IDEA has always been a great event for us,” explains commercial director Paul Rushton. “2019 is an exciting year for Technical Absorbents and SAF. Our development team has developed a number of new superabsorbent fabric technologies and we are keen to demonstrate these in Miami.

“Our washable nonwoven fabric range has been expanded. These are suitable for hygiene and other garments that require moisture management for either comfort and/or evaporative cooling. We now have a range of gsm variants to better suit individual product design requirements.

“Our first unique, fully maceratable, 100% SAF fabric was launched towards the end of 2018. This range has now also been further developed with fabrics ranging from 240-420gsm. These are suitable for applications that require higher levels of absorbency, including hygiene and medical.

“Finally, we also now have a complete range of ultra-thin, low basis-weight carded, hot air-through and airlaid nonwovens. These are ideal for products that require a soft, discrete absorbent core that still offers high levels of absorbency performance.

“We hope that we can share our new fabric portfolio with more people at IDEA, and create some exciting new ideas for their use.”

Zimmer Austria

Booth 413

Zimmer Austria will present several coating systems at IDEA. These high quality multipurpose coating machines and complete lines for application with liquid pastes, lacquers and foams include the Magnoroll, Triplexcoat, Magnoject and Rotary.Screen.

Magnoroll is a multipurpose coating machine equipped with various modules for universal applications, for example magnetic low-add-on systems, direct roll coating, screen coating with magnet roll rods or magnet blade squeegee knife coating.

IDEA exhibitors are already planning their booths for the three-day event. Below is a look at what some exhibitors plan to bring to the show.

Avgol

Booth 928

Avgol, a global leader in the manufacture of high-performance nonwoven fabric solutions, is to showcase its Forward Innovative Thinking (FIT) family of nonwoven technologies at IDEA 2019.

Developed to respond to consumer needs and desires, FIT technologies and chemistries address softness, skin wellness, barrier and fluid management complexities in hygiene applications, including the baby diaper, adult incontinence and feminine hygiene products markets.

Avgol’s FIT strategy represents the company’s commitment to harnessing expertise to anticipate the needs of consumers. It includes the creation of high-performance technologies that are designed to be modular in nature and can be used alone, or in combination, to provide a palette of solutions for product designers.

The family includes beneFIT, comfortFIT and enhanceFIT as well as Waveform 3D—a new process that enables the modification of nonwoven fabrics to extend innovation capabilities and enhance performance and comfort for consumers.

Nick Carter, director of Market Business Intelligence and Intellectual Property at Avgol, says: “IDEA is a premier event in the nonwovens and engineered fabrics sector and an excellent platform for Avgol to inform and educate delegates on our latest market-leading and pioneering technologies.

“We look forward to demonstrating how our FIT technologies can offer a truly tailored solution for enhanced performance and end-user comfort.”

Aurizon Ultrasonics

Booth 820

Aurizon Ultrasonics makes high power ultrasonic systems for a variety of nonwoven processing applications including bonding, elastic entrapment, feature attachment, embossing, sheet lamination and cutting.

Many nonwoven product manufacturers use adhesives for these steps, but Aurizon is proving that there is a better way to produce elasticized fabric – ultrasonic technology.

In the past, Aurizon Ultrasonics exclusively provided rotary sonotrodes with their technology. However, in 2019 they are expanding their offerings by including the option of fixed blade horn technology. This technology can reduce equipment cost by leveraging an increased blade width as compared to rotary. It is not suitable as a replacement for all rotary horn applications, yet there are many less demanding applications where it is an effective solution such as material lamination and edge sealing.

The company’s patented technology provides a solid foundation for delivering increased productivity, reduced costs, and a more sustainable process. Additionally, ultrasonic technology has aesthetic benefits including odorless, softer, more breathable fabric and the potential for using lighter materials and reduced elastic decitex. Elasticized fabric created by ultrasonic methods has more drape, bend and crush conformability than products using adhesive.

Dilo Group

Booth 522

Dilo is a leading equipment supplier of complete lines for staple fiber nonwoven fabric production.

The most recent machine concepts from DiloGroup companies DiloTemafa, DiloSpinnbau and DiloMachines will be promoted with the emphasis on new equipment components which improve product quality, increase line capacity and furthermore enable new opportunities in nonwoven production.

DiloTemafa has introduced versions of the Baltromix bale opener and the card willow which are particularly suited to the processing of longer fibers at highest throughput. Longer cleaning intervals and shorter cleaning times also result from the design changes. The DON dosing opener remains as an intermediate between fiber preparation and the card feeder and provides a fine opening stage.

DiloSpinnbau has a new “Unifeed” card feeder (VRS-P) which combines the principle of volumetric charged feeding with the characteristics of a chute feeder but without the conventional overhead trunk which allows for lower ceiling height requirement. The fiber flock matt is condensed by a vacuum delivery apron to give better uniformity of mass distribution. The distribution over the working width is controlled by additional flaps. This feeder can be adapted for medium/fine to coarse and medium to long staple fibers.

The “VectorQuadroCard” incorporates a modular transfer group between breast and main section. The quick change facility of this roller group provides different carding options. The delivery system is also flexible to provide parallel laid, random or condensed web. The preopener section on this card has four worker/stripper pairs with five pairs on the main cylinder. Emphasis is on high throughput with good web quality.

DiloMachines has a new horizontal crosslapper version “DLSC” which allows web infeed speeds up to 200 m/min depending on fiber specification. Such infeed speeds will prevent the lapper being the line bottleneck. The DLSC works in conjunction with the proven CV1A web regulation system for improved felt evenness and the potential for fiber savings. A further increase of the drive power within the three-apron-layering technology as well as the application of carbon fiber reinforced parts enables these major improvements. A web guiding system (“extended web guide”) can be added to avoid web wrinkles at lapper reversals.

Mahlo

Booth 636

Mahlo will be exhibiting its QMS-12 Web Gauging System for the on-line measurement of web basis weight, thickness, density, moisture, coating add on, and air permeability. In addition, new sensor technologies for measuring web composition and fiber ratio will also be on display, as well as features such as Roll Reporting and Data Management for real time evaluation, analysis, and archiving of critical web parameters.

Martin Automatic

Booth 1964

Leading American manufacturer of high-performance splicing, rewinding, web transport and web tension control, Martin Automatic, will be exhibiting at the upcoming IDEA19 trade show in Miami, FL. Speaking for the company, Mike Jelinsky, sales engineer for Martin Automatic, says, “Nonwovens are a significant segment within Martin’s global markets and IDEA19 creates an arena to continue our involvement with established and emerging nonwoven customers and applications. The expo allows us to share our expertise in handling a variety of materials, and to highlight the cost and production efficiency improvements that our automation can bring.”

Visitors will be able to discuss Martin’s advanced web transport and web tension technologies, and the company’s solutions for non-stop splicing, unwinding and rewinding of nonwovens from 20mm to 4M wide supplied on reels up to 2.4M diameter. Designed to be practical, and reliable with industry leading lowest cost of ownership, Martin equipment is easy to use and easy to maintain for provides long-term performance and profitability.

Nordfab

Booth 1071

Nordfab Quick-Fit ducting allows fast installation without special tools, rivets, screws or welding. The QF rolled edge on ducting components is quickly connected with the unique Quick-Fit Clamp, cutting installation and downtime by more than 45%. The Quick-Fit Clamp allows easy adjustment of ducting layouts during installation as well as easy removal for cleaning, reconfiguring, or relocation.

Quick-Fit ducting is ideal for most dust, mist and fume collection applications. Ducting is available in galvanized or stainless steel, various gauges to suit applications such as highly abrasive dusts, and diameters from 3” to 72”.

Nordfab Ducting offers two free software tools, one CAD-based and one SketchUp-based, to make it easier to create layouts of ducting for an installation.

Optima Nonwovens

Booth 1050

IDEA is the most important trade show for Optima Nonwovens in 2019. In line with this, the company will present a multitude of new ideas and solutions to help machine users overcome their everyday challenges: rising labor costs, more complex packaging processes, and changing market demands. Visitors to the trade show can discover how the OPAL line management software, a cobot and augmented reality can help with this at several stations. With the aid of three characters, the company will demonstrate typical applications for these new technologies. The courage to develop new, digital solutions is also underlined by the trade show’s slogan: “Your Production of the Future: Smart. Efficient. Flexible.”

“Our three characters – Tom, an operations manager, Lisa, a plant manager, and Carl, a machine operator, will demonstrate the daily challenges in the production of paper hygiene products before the eyes of the visitors,” says Oliver Rebstock, managing director at Optima Nonwovens. These include the increasing complexity of packaging processes, an ever faster time to market, and varying market demands. “Not only do the machines, markets, and packaging processes change, but so too do the people who stand in front of the machine,” adds Rebstock. From the points of view of Tom, Lisa, and Carl, they have very different requirements and thus there is a demand for customized solutions by Optima. “The Smart Services complement the already existing Optima services,” explains Rebstock. Some of Optima’s strengths include a well-developed network of subsidiaries that offer local support, reliable spare parts delivery, and on-site inspections by Optima experts.

OPAL gives operations managers an overview of the performance indicators and reduces machine downtime.

Operations managers are interested in having a comprehensive overview of production, in order to quickly identify weak points and to use human resources in an appropriate way. Therefore, Optima Nonwovens will present the OPAL line management software at IDEA. The system records performance indicators such as overall equipment effectiveness (OEE) and leads to an increase in production quality and transparency, productivity, less machine downtime, and the best use of production capacities. This information can be presented worldwide on any imaginable output device.

Plant managers are confronted with rising labor costs and have to adjust their production quickly and flexibly to new market demands. Optima is supporting them using a cobot, a robot which can operate in the machine’s surrounding area. Visitors will also be introduced to an extended modularity concept that enables production to respond flexibly to new requirements, making investment in machines long-term and future-proof.

Total Care Asset Management (TCAM) addresses machine operators’ needs. Flexible consumer behavior requires small lot sizes and frequent format changes. With TCAM, which belongs to the Optima smart services, they receive the right information at the right time on the right output device to avoid any errors. Information about machine status can be displayed in the same way as maintenance manuals and training materials, for example, using augmented reality glasses. The augmented reality glasses can show useful digital information about the real environment of the wearer. In addition, the system can be used for remote support. Service employees at Optima can switch to the customer’s augmented reality glasses live and help them to change format parts. Another positive effect is that new employees can be trained more quickly, the error rate falls, and therefore downtimes also fall. These measures raise productivity for Optima’s customers.

Sandler

Booth 902

At IDEA, Sandler AG invites visitors to the garden of (green) developments. The nonwovens manufacturer will showcase its broad range of material for hygiene products, wipes and technical applications, among them nonwovens that take account of sustainability. In baby care, feminine care and incontinence products, Sandler offers nonwovens that combine functionality and comfort in use. Efficient, even softer nonwovens for intake layers contribute to optimum fluid management. Particularly smooth product variants are ideal for use as tampon covers. A new generation of nonwovens for elastic closure systems combine improved extensibility and high stability in processing. The focus of this year’s trade fair participation, however, will be on nonwovens for topsheet applications.

Sandler developed a nonwoven composite for use in diapers in cooperation with a customer, that is particularly smooth yet voluminous at the same time. Special embossing creates a topographical structure on the materials surface, which enhances fluid handling as well as comfort in use: moisture collects at the lower points; the bulky sections keep moist parts of the material away from the skin, thus preventing skin irritation. Owing to its low basis weight this new development is ideal for thin, lightweight product structures for hygiene applications—for increased comfort and discretion in use.

Another multi-layer nonwoven offers a structured and perforated alternative for topsheets: The embossing pattern dubbed “canyon” renders the topsheet bulkier, while also increasing stability and creating an individual look. This structure forms grooves on the topsheet’s surface, which help quickly transport fluid away from the body and into the absorbent core. In this way, the nonwovens contribute to preventing skin irritation and support a sense of safety during use.

Sandler topsheet materials made with cotton also contribute to comfort in use—soft, reliably functional and manufactured using an increased share of renewable raw materials.

In the wipes market, Sandler is developing more sustainable product solutions even for single-use products. Made from a special, certified viscose fiber, Sandler’s new substrates are biodegradable and also available as FSC certified variants. They offer the established Sandler quality—highly absorbent, tear-resistant and better for the environment. The PEFC-certified substrate, bio textile by sandler is made exclusively from viscose fibers sourced from European forests—sustainable raw materials with a reduced carbon footprint. Newly developed nonwovens made from viscose and cellulose acetate fibers are soft and gentle on the skin. They are biodegradable and compostable. Wipes substrates made from the lactic-acid based raw material PLA and product variants with a share of cotton complete the range of nonwoven substrates made with raw materials from renewable sources.

Especially for applications in household cleaning Sandler will present wipes substrates made from recycled polyester fibers, which also contribute to conserving resources. An embossing design dubbed “square” further enhances cleaning properties. Rows of small squares enlarge the nonwoven’s surface for optimized dirt removal while also rendering the wipe substrate more voluminous for a softer, fluffier feel.

For disinfection applications, Sandler will showcase a new fine perforation, which is effective in two ways: Firstly, the enlarged surface increases dirt collection for optimum cleaning results. Secondly, fluids accumulate in the material and are quickly released during use—a prerequisite for ideal disinfection.

Product variants featuring increased stability further add to the product range.

Technical Absorbents

Booth 1241

This year the International Engineered Fabrics Conference and Exposition (IDEA), Technical Absorbents will again be exhibiting as the event makes its way back to the newly renovated Miami Beach Convention Centre. It will be concentrating on the promotion of its SAF superabsorbent fabrics and will be bringing along a number of new samples.

The Technical Absorbents stand – number 1241 – will be SAF branded as the company continues to raise the profile of its fibrous superabsorbents in the industry.

“IDEA has always been a great event for us,” explains commercial director Paul Rushton. “2019 is an exciting year for Technical Absorbents and SAF. Our development team has developed a number of new superabsorbent fabric technologies and we are keen to demonstrate these in Miami.

“Our washable nonwoven fabric range has been expanded. These are suitable for hygiene and other garments that require moisture management for either comfort and/or evaporative cooling. We now have a range of gsm variants to better suit individual product design requirements.

“Our first unique, fully maceratable, 100% SAF fabric was launched towards the end of 2018. This range has now also been further developed with fabrics ranging from 240-420gsm. These are suitable for applications that require higher levels of absorbency, including hygiene and medical.

“Finally, we also now have a complete range of ultra-thin, low basis-weight carded, hot air-through and airlaid nonwovens. These are ideal for products that require a soft, discrete absorbent core that still offers high levels of absorbency performance.

“We hope that we can share our new fabric portfolio with more people at IDEA, and create some exciting new ideas for their use.”

Zimmer Austria

Booth 413

Zimmer Austria will present several coating systems at IDEA. These high quality multipurpose coating machines and complete lines for application with liquid pastes, lacquers and foams include the Magnoroll, Triplexcoat, Magnoject and Rotary.Screen.

Magnoroll is a multipurpose coating machine equipped with various modules for universal applications, for example magnetic low-add-on systems, direct roll coating, screen coating with magnet roll rods or magnet blade squeegee knife coating.