02.08.19

There has been a distinct global shift over the past five years towards more sustainable products and processes as organizations around the world seek to meet the needs of the present without compromising the ability of future generations to meet their own.

Businesses must now find ways to reconcile economic growth with environmental protection and social responsibility – balancing people, planet and profit.

This has had a significant impact across almost all markets and is now becoming a major focus for producers, retailers and consumers of nonwovens alike. Nick Carter, director, Market Business Intelligence and Intellectual Property, at Avgol, explains the drivers behind sustainability in the market, the increased need for sustainable and eco-conscious practices and how Avgol is putting sustainability at the forefront, supported by its Forward Innovative Thinking (‘FIT’) strategy.

“Nonwovens is an indispensable sector of textiles, producing a variety of invaluable products, many of which are disposable, that are vital to consumers’ daily lives. As a result of increased consumer awareness, and some concern about the impact of disposable products, sustainability in the nonwovens industry is now paramount. Product developers are mpw looking to create the effective, environmentally conscious solutions demanded by the market.

“With the global consumption of sustainable nonwovens valued in 2017 at $14.1 billion and predicted to grow at a rate of 6.4% annually between now and 2022, this is clearly a high-growth area representing the potential for significant business benefits of adapting sustainable practices.”

Carter continues: “As sustainability rightly comes to the forefront, it’s important to retain focus on delivering products that truly address key consumer concerns and deliver exceptional performance in areas like skin wellness, comfort and effective fluid management.”

Avgol is passionate about developing visionary products and solutions that are produced as sustainably as possible and deliver relevant, timely and tangible value to its customers.

To achieve this, the company is driving forward with its dynamic new FIT strategy of innovation, representing the company’s commitment to harnessing its expertise to anticipate the needs of consumers and create high performance technologies for the baby diaper, adult incontinence and feminine hygiene markets.

Avgol’s continuing research and development work supports sustainability through thoughtful design, pushing the boundaries of new technologies to meet the ever-evolving needs of global consumers.

Carter continues: “When it comes to a product’s sustainability, it’s important to consider every stage of the development and production process, as well as transport and logistics. By taking a holistic, innovation-focused approach to sustainability we can reduce environmental impact while simultaneously obtaining the same or even better product performance.

“We are focused on understanding where we can implement more sustainable practices throughout every stage of the process, from research and development right through to delivery to customers. By developing high-performance fabrics with enhanced capabilities, we can reduce product complexity, allowing for fewer total components and potentially removing entire production and supply streams while harnessing our expertise to anticipate the evolving needs of customers.

“At the manufacturing stage, Avgol is using less oil-based resin to develop products, resulting in less resin in the waste stream and enabling more products to be made from the same amount of raw material. For a business that is regularly challenged on its sustainability credentials, it is clear how this strategy delivers benefits in terms of both resource efficiency and carbon footprint reduction. Fundamentally it is about achieving more from less,” Carter explains.

“We are developing lightweight, high-performance solutions, such as recently launched beneFIT Control. We not only bring our customers added value with leading edge solutions but also deliver sustainability benefits when it comes to product shipping. Our revolutionary lightweight fabrics offer the potential for more packable diapers, adult incontinence and feminine hygiene products, reducing packing requirements, improving logistics and improving the product’s overall carbon footprint as more can be packed in each shipment.”

“It is imperative that the nonwovens industry continues to employ more sustainable practices across the lifecycle of products to respond to consumer demand, deliver business benefits and to deliver global environmental benefits. Avgol’s progressive, solution-centric FIT strategy will help to fulfil its mission to develop sustainable nonwovens that contribute to the life and wellbeing of hundreds of millions of babies, mothers and senior citizens around the globe.”

Breathable Nonwovens

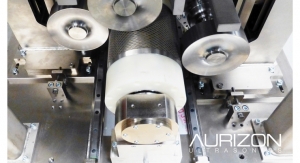

In January, Avgol launched a range of breathable fabrics which exceed the performance of current commercially available spunmelt SMS materials.

The development is in line with Avgol’s Forward Innovative Thinking (“FIT”) strategy for new product innovation.

Carter, says: “The enhanceFIT family is being developed to meet evolving product designer needs for lighter weight fabrics, having improved elasticity, barrier and breathable performance properties. This family is based on multiple technology platforms that allows Avgol to tailor fabric performance for the needs of specific markets, including hygiene, medical and industrial applications.”

enhanceFIT Breathe is the first in a line of new fabric solutions resulting from Avgol’s recent developments in new assets and technology. The fabrics demonstrate enhanced uniformity with corresponding improvements in barrier, appearance and coverage in materials less than 25 gsm, without relying on cumbersome submicron filament fabrication methods. In practical applications, downgauged fabrics are now available that have previously required higher basis weights to achieve air permeability specifications.

Earlier in 2018, Avgol introduced the beneFIT range, developed through Avgol’s Forward Innovative Thinking (FIT) strategy, which harnesses the company’s expertise in creating high-performance technologies for the baby diaper, adult incontinence and feminine hygiene markets with the needs of the consumer at the forefront.

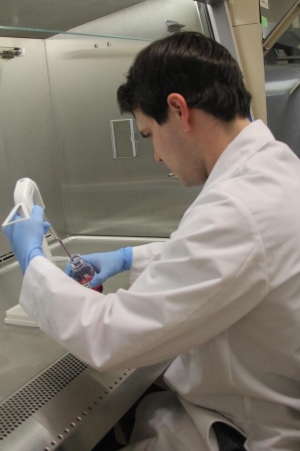

The strategy forms the basis of Avgol’s continuing research and development into revolutionary solutions that meet the ever-growing needs of the global hygiene market. In fact, the nonwovens producer has collaborated with the Biotechnology Center of Excellence at Alamance Community College (ACC) in North Carolina to run efficacy trials using beneFIT Control.

Biotechnology degree students at ACC undertook hundreds of tests of fabric samples to which Avgol’s beneFIT Control technology had been applied, to demonstrate the solution’s antimicrobial efficacy. In one particular test, 10 different fabric samples were used, exposed to two different bacterial strains – E.coli and Staphylococcus, as part of the range of standard and newly developed evaluations performed by Avgol and its partners to confirm antimicrobial efficacy in disposable applications. When checked after 24 hours of incubation there was a significant reduction of bacterial growth due to direct exposure to the samples infused with Avgol’s antimicrobial solution.

Michelle Sabaoun, Department Head – Biotechnology at Alamance Community College, says, “Partnering with industry-leader Avgol has been absolutely invaluable to our biotechnology program and our students. Running the trials provides a real-world application of the skills students have mastered throughout their degree courses and gives graduates of our program a competitive advantage upon entering the workforce.

“The fact that Avgol, as a global leader in nonwoven textiles, bypassed a number of major research universities closer to its North Carolina facilities and chose to partner with ACC speaks volumes about the quality of our Biotechnology program. It is the longest-running two-year Biotechnology degree program in the USA and is widely recognized for its 700+ hours of hands-on laboratory training, as well as the quality of its graduates. We thank Avgol for the wonderful opportunity and look forward to our partnership continuing into the future.”

Businesses must now find ways to reconcile economic growth with environmental protection and social responsibility – balancing people, planet and profit.

This has had a significant impact across almost all markets and is now becoming a major focus for producers, retailers and consumers of nonwovens alike. Nick Carter, director, Market Business Intelligence and Intellectual Property, at Avgol, explains the drivers behind sustainability in the market, the increased need for sustainable and eco-conscious practices and how Avgol is putting sustainability at the forefront, supported by its Forward Innovative Thinking (‘FIT’) strategy.

“Nonwovens is an indispensable sector of textiles, producing a variety of invaluable products, many of which are disposable, that are vital to consumers’ daily lives. As a result of increased consumer awareness, and some concern about the impact of disposable products, sustainability in the nonwovens industry is now paramount. Product developers are mpw looking to create the effective, environmentally conscious solutions demanded by the market.

“With the global consumption of sustainable nonwovens valued in 2017 at $14.1 billion and predicted to grow at a rate of 6.4% annually between now and 2022, this is clearly a high-growth area representing the potential for significant business benefits of adapting sustainable practices.”

Carter continues: “As sustainability rightly comes to the forefront, it’s important to retain focus on delivering products that truly address key consumer concerns and deliver exceptional performance in areas like skin wellness, comfort and effective fluid management.”

Avgol is passionate about developing visionary products and solutions that are produced as sustainably as possible and deliver relevant, timely and tangible value to its customers.

To achieve this, the company is driving forward with its dynamic new FIT strategy of innovation, representing the company’s commitment to harnessing its expertise to anticipate the needs of consumers and create high performance technologies for the baby diaper, adult incontinence and feminine hygiene markets.

Avgol’s continuing research and development work supports sustainability through thoughtful design, pushing the boundaries of new technologies to meet the ever-evolving needs of global consumers.

Carter continues: “When it comes to a product’s sustainability, it’s important to consider every stage of the development and production process, as well as transport and logistics. By taking a holistic, innovation-focused approach to sustainability we can reduce environmental impact while simultaneously obtaining the same or even better product performance.

“We are focused on understanding where we can implement more sustainable practices throughout every stage of the process, from research and development right through to delivery to customers. By developing high-performance fabrics with enhanced capabilities, we can reduce product complexity, allowing for fewer total components and potentially removing entire production and supply streams while harnessing our expertise to anticipate the evolving needs of customers.

“At the manufacturing stage, Avgol is using less oil-based resin to develop products, resulting in less resin in the waste stream and enabling more products to be made from the same amount of raw material. For a business that is regularly challenged on its sustainability credentials, it is clear how this strategy delivers benefits in terms of both resource efficiency and carbon footprint reduction. Fundamentally it is about achieving more from less,” Carter explains.

“We are developing lightweight, high-performance solutions, such as recently launched beneFIT Control. We not only bring our customers added value with leading edge solutions but also deliver sustainability benefits when it comes to product shipping. Our revolutionary lightweight fabrics offer the potential for more packable diapers, adult incontinence and feminine hygiene products, reducing packing requirements, improving logistics and improving the product’s overall carbon footprint as more can be packed in each shipment.”

“It is imperative that the nonwovens industry continues to employ more sustainable practices across the lifecycle of products to respond to consumer demand, deliver business benefits and to deliver global environmental benefits. Avgol’s progressive, solution-centric FIT strategy will help to fulfil its mission to develop sustainable nonwovens that contribute to the life and wellbeing of hundreds of millions of babies, mothers and senior citizens around the globe.”

Breathable Nonwovens

In January, Avgol launched a range of breathable fabrics which exceed the performance of current commercially available spunmelt SMS materials.

The development is in line with Avgol’s Forward Innovative Thinking (“FIT”) strategy for new product innovation.

Carter, says: “The enhanceFIT family is being developed to meet evolving product designer needs for lighter weight fabrics, having improved elasticity, barrier and breathable performance properties. This family is based on multiple technology platforms that allows Avgol to tailor fabric performance for the needs of specific markets, including hygiene, medical and industrial applications.”

enhanceFIT Breathe is the first in a line of new fabric solutions resulting from Avgol’s recent developments in new assets and technology. The fabrics demonstrate enhanced uniformity with corresponding improvements in barrier, appearance and coverage in materials less than 25 gsm, without relying on cumbersome submicron filament fabrication methods. In practical applications, downgauged fabrics are now available that have previously required higher basis weights to achieve air permeability specifications.

Earlier in 2018, Avgol introduced the beneFIT range, developed through Avgol’s Forward Innovative Thinking (FIT) strategy, which harnesses the company’s expertise in creating high-performance technologies for the baby diaper, adult incontinence and feminine hygiene markets with the needs of the consumer at the forefront.

The strategy forms the basis of Avgol’s continuing research and development into revolutionary solutions that meet the ever-growing needs of the global hygiene market. In fact, the nonwovens producer has collaborated with the Biotechnology Center of Excellence at Alamance Community College (ACC) in North Carolina to run efficacy trials using beneFIT Control.

Biotechnology degree students at ACC undertook hundreds of tests of fabric samples to which Avgol’s beneFIT Control technology had been applied, to demonstrate the solution’s antimicrobial efficacy. In one particular test, 10 different fabric samples were used, exposed to two different bacterial strains – E.coli and Staphylococcus, as part of the range of standard and newly developed evaluations performed by Avgol and its partners to confirm antimicrobial efficacy in disposable applications. When checked after 24 hours of incubation there was a significant reduction of bacterial growth due to direct exposure to the samples infused with Avgol’s antimicrobial solution.

Michelle Sabaoun, Department Head – Biotechnology at Alamance Community College, says, “Partnering with industry-leader Avgol has been absolutely invaluable to our biotechnology program and our students. Running the trials provides a real-world application of the skills students have mastered throughout their degree courses and gives graduates of our program a competitive advantage upon entering the workforce.

“The fact that Avgol, as a global leader in nonwoven textiles, bypassed a number of major research universities closer to its North Carolina facilities and chose to partner with ACC speaks volumes about the quality of our Biotechnology program. It is the longest-running two-year Biotechnology degree program in the USA and is widely recognized for its 700+ hours of hands-on laboratory training, as well as the quality of its graduates. We thank Avgol for the wonderful opportunity and look forward to our partnership continuing into the future.”