Tara Olivo, Associate Editor12.07.18

The use of nonwovens in the interior and exterior of vehicles continues to grow, and today over 40 automotive parts are made with these types of fabrics. Nonwovens can be up to 30% lighter than traditional materials they replace and can make a car more than 2kg lighter, according to the international nonwovens association EDANA.

In vehicles, nonwovens are used for temperature and sound insulation, seating, liners for the roof and wheel arches, as well as linings and carpets.

Today, many nonwovens producers are growing their lineups of innovations in order to cater to the growing electric vehicle market. Market trends such as “green” mobility and autonomous driving are also providing growth opportunities for nonwovens producers, according to Gerhard Klier, sales director Technical Products, Sandler. “Lightweight, yet highly functional components continue to be in high demand,” he says. “At the same time, these new mobility concepts entail new requirements on the utilized materials. For example, the noise level in electric cars is different to that of cars with combustion engines. Therefore, new materials are needed. All of this creates opportunities for further development of our products and innovation.”

Geographically, Sandler is seeing growth in all areas in Europe and the U.S., was well as in Asia, especially China, Klier says. Overall, the use of nonwovens in automotive applications continues to increase, and in markets such as Asia, which are still developing, high growth rates are creating high demand, he adds.

In order to respond to demand around the globe, Sandler is working with local partners and sales representatives as well as operating sales offices in Shanghai, China, and New Delhi, India. “In this way, we are attainable to our customers and potential buyers directly on site, eliminating cultural and language barriers from the start. It goes without saying that this also gives us in-depth knowledge of local requirements and enables us to give even more sound advice to our customers,” Klier explains.

Due to major growth expected in Asia, Autoneum is also focusing on electric vehicles.

“By 2025, Asia will be home to more than half of the global middle class and account for half of the global automobile production, one third of which will be in China alone. Autoneum wants to participate in this growth and aims to significantly increase its sales in Asia,” says Anahid Rickmann, head Corporate Communications & Responsibility, Autoneum.

According to Rickmann, more e-cars are sold in China than in the rest of the world combined. “And just recently, the Chinese government set itself the target of selling seven million e-cars by 2025 and it lifted the JV regulations for foreign electric vehicle manufacturers. This will further accelerate the market for this vehicle segment,” she says.

Autoneum has a large presence in China, with a total of 10 sites in the country, with the two most recent plants opening this year in Pinghu (Zhejiang Province) and Shenyang Tiexi (Liaoning Province). Both plants have begun production of lightweight multifunctional components for noise and heat.

The continued strong customer demand for lightweight components for acoustic and thermal management made it necessary to further expand Autoneum’s production capacities in China, the company says.

Using state-of-the-art production processes, Autoneum Pinghu manufactures underbody systems made of Ultra-Silent for European, U.S.-American and Chinese customers. These textile underbodies will be installed, among others, in various hybrid models and a fully electric vehicle of a new Chinese car manufacturer. When operating at full capacity, around 5.5 million underbody components made of Ultra-Silent will be produced in Pinghu each year and delivered just-in-time to the local production facilities of customers. With Ultra-Silent, Autoneum offers the lightest underbody systems for vehicles available on the market: Compared with equivalent components made of plastic they are up to 50% lighter, fully recyclable, reduce noise and thanks to improved aerodynamics, they help to reduce a vehicle’s fuel consumption and emissions.

During the Pinghu plant opening, Autoneum CEO Martin Hirzel stated: “With our two new plants in China we are continuing our strategy-driven expansion course in this important growth market. In order to be able to offer our customers industry-leading components, we are investing heavily in sustainable production processes as well as in innovative technologies and materials. At the same time we are supporting the expansion of electromobility in China with the regional market launch of multifunctional components for a diverse range of drive systems.”

At the Shenyang Tiexi production facility, around 7.5 million carpet systems, inner dashes, floor insulators and heatshields will be produced annually for German and Swedish vehicle manufacturers on a site measuring 23000 square meters.

Autoneum sees significant growth potential in new forms of mobility such as electromobility and self-driving cars. Rickmann says the company is prepared for this transformation and is investing accordingly in innovative products and technologies in acoustic and thermal management for the vehicle of the future. Today, Autoneum offers an optimized product portfolio for electric vehicles of existing and new car manufacturers with innovative technologies such as Tune-It for carpet systems and Hybrid-Acoustics ECO+ for inner dashes and floor insulators.

With Tune-It for needlepunch carpets, Autoneum offers automotive manufacturers a technology that makes the car of tomorrow lighter, more comfortable and environmentally friendly – while delivering ideal acoustic performance at the same time.

Tune-It is based on an innovative fiber combination in the carpet backing with which, for the first time, sound insulation and absorption can be tuned to the specific needs and geometry of the passenger cabin across the entire surface of the carpet. According to Autoneum, because of this technology, it is now possible to define the optimum insulation and absorption performance already during the development phase of new vehicle models by means of computer-aided simulations. As a result, needlepunch carpets based on Tune-It provide ideal noise protection in the passenger cabin. In addition, given a weight advantage of up to 25% compared to standard needlepunch carpets, components based on Tune-It also support reduced fuel consumption and less vehicle emissions.

The environmental footprint of this carpet technology that consists of 100% PET is also reflected in the fact that Tune-It based components are fully recyclable. Compared to conventional carpet molding, where non-recyclable production waste can reach a share of 30%, off-cuts produced during the manufacture of Tune-It can be processed into pellets and completely returned into the carpet manufacturing process in the form of fibers.

Meanwhile, Freudenberg Performance Materials is seeing by far the strongest growth, according to Dr. Frank Heislitz, CEO, Freudenberg Performance Materials. Growth has been slower in Europe and rather modest in the U.S., he adds.

Earlier this year, Freudenberg Far Eastern Spunweb, a Freudenberg Performance Materials and Far Eastern Spunweb company, made plans to build an additional production line at the Tayuan Tao-Yuan site in Taiwan. This expansion of capacity will enable the company to meet growing demand in the traditional automotive and carpet markets of Asia.

With the new production line, Freudenberg will increase annual production of nonwovens in Tayuan Tao-Yuan by around 11,000 metric tons.

Freudenberg currently supplies these two markets in Asia with primary and secondary carrier materials for automotive carpet moldings and inlay mats, as well as dry running mats, carpets and carpet tiles. The high-performance materials are easy to form and thus contribute to economical processing. In addition, their high dimensional stability ensures a precise fit and they are extremely durable.

This capacity expansion will also enable Freudenberg to develop the company’s regional position. “Asia is important for FPM’s automotive business as it is the region with the largest absolute growth in this industry. Car production is increasing and the new mobility market – for which Freudenberg offers also innovative solutions – is growing,” says Heislitz.

Construction of the new production line is expected to be complete in 2020.

The main growth driver for Freudenberg in the automotive market is innovation. “The automotive market requires new solutions in three fields in which Freudenberg is particularly strong: lightweight (e.g. CO2 reduction), new mobility and sustainability (e.g. recyclable materials),” Heislitz says.

Freudenberg’s nonwovens based on Lutraflor technology for automotive carpets, insert mats and interior and trunk linings, can provide weight savings of up to 40% compared to conventional automotive carpets. Another weight-saving innovation from Freudenberg is its unique multilayer composite for molded underbody panels and wheel liners, which enables weight savings of 15 to 40% compared to conventional products. Weight savings can also be found with its Evolon microfilament textiles, automotive acoustic pads and headliner facing materials, which are not only used for headliners but also for trunk liners and seat backs, Heislitz says.

Also, beginning this year, Freudenberg is one of the first companies worldwide to manufacture gas diffusion layers (GDL) completely in-house with its own production facilities. GDL are essential component of fuel cells. They ensure that the hydrogen fuel is converted into power as efficiently as possible. “Freudenberg’s gas diffusion layers help to improve the efficiency of fuel cells,” explains Heislitz. “Their high uniformity in structure and thickness increases electrical and thermal conductivity and improves the transport of gases and liquids in the fuel cell. Further strengths of Freudenberg’s gas diffusion layers compared with other products are superior downstream processing and exceptional surface properties.”

Freudenberg’s gas diffusion layers for e-cars are indispensable components for new mobility vehicles, he adds.

Investments Around the World

While Asia has been an important market for investment recently, some nonwovens producers are looking elsewhere around the world.

Early in 2018, Fibertex Nonwovens continued its global expansion through the acquisition of the Brazilian nonwovens producer Duci, based in an industrial district west of Sao Paulo. Fibertex Nonwovens generates annual revenue of about DKK 1.4 billion, or $233 million, and currently has production facilities in Denmark, France, the Czech Republic, Turkey, the U.S. and South Africa. Duci was founded in 2001 and generates revenue of nearly DKK 115 million, or just under $20 million.

Duci manufactures spunlaced nonwovens, a technology Fibertex already uses at its sites in France and Turkey.

Duci’s potential in the automotive industry was attractive to Fibertex Nonwovens. An average European car contains about 30 square meters of advanced nonwovens, and Fibertex Nonwovens has managed to capture a market leading position as supplier of materials in everything from headliners, seats and parcel trays to exterior applications used in wheel housings, motor insulation and underbodies.

In September Fibertex Nonwovens announced it was increasing the Duci plant’s production capacity by 20% to accommodate growing demand for special-purpose products for the automotive and other industries. The Denmark-based nonwovens producer has already significantly increased its sales to a number of South American customers.

“The process of taking over the factory in Brazil has far exceeded our expectations. Our South American customers have given us a really warm welcome, and we’re already facing an urgent lack of capacity,” Fibertex Nonwovens CEO Jørgen Bech Madsen said at the time of the capacity announcement. “We’ve been planning to expand capacity since acquiring Duci, but the need has arisen faster than we anticipated, and we will begin to upgrade the existing production line immediately. We know from previous experience in expanding our other factory sites that an upgrade can increase our output capacity by 20%. In addition, we will accelerate planning for other expansion projects.”

Estimated at close to DKK 15 million, the investment is expected to be fully implemented by the summer of 2019. Bech Madsen explains that Fibertex Nonwovens has already sold the extra capacity to the growing Brazilian market, which is the world’s sixth-largest and accounts for more than half of the entire South American market. The spunlacing technology made by Fibertex Nonwovens in Brazil is manufactured by just one other company in South America. Fibertex already makes this type of nonwoven at sites in France and Turkey, and its experience in this segment was a key factor in its success.

The latest investment news from Tenowo, a nonwovens producer based in Hof, Germany, is an expansion into Mexico. This summer the company announced the formation of Tenowo de Mexico, S. de R.L. de C.V., which initially includes the establishment of a sales office and warehouse in the city of San Luis Potosí, Mexico.

The new entity is jointly owned by Tenowo Inc. in the U.S. and Tenowo GmbH in Germany. It was established in response to increased demand for Tenowo’s automotive products in the Mexican market and will house materials manufactured both in the U.S. and Germany.

At the time of the announcement, Chris Peart, president and CEO of Tenowo, Inc., said that the location provides Tenowo with a footprint in a fast-growing geographic part of its market and is hopefully the first step towards further expansion. “San Luis Potosí is a thriving city in the heart of the Bajio region of Mexico and has access to four major ports,” he said. “In addition, it is within a few hours of the major automotive manufacturing hubs in Mexico. It is the ideal location for our needs.”

Tenowo has made other investments at other sites around the world. New stitchbonding capacity at its U.S. plant in North Carolina will serve the seating market in the U.S., as well as in South America and Mexico. Additionally, capacity for tailor made stitchbonded nonwovens will come onstream in 2019 at its U.S. and Germany sites, which are used for wire harnessing tapes. Meanwhile, in Mittweida, Germany, Tenowo dedicated additional capacity for decorative nonwovens used for headliners and interior trim. The company also added capacity for its Multiknit brands used in seating, which provide good air permeability and ecological advantages in terms of sustainability. In Hof and Reichenbach, Tenowo developed new high-end filter media for automotive applications. Finally, in China, Tenowo has worked up to capacity, which has paved the way for further steps to expand its presence in Asia.

Detlev Käppel, director, sales for Tenowo, says all three of the company’s major regions—the Americas, Europe and Asia—are important to the company. “We can serve our customers domestically and are therefore independent on political decisions which may influence the global markets and supply chain,” he says. “That gives us the edge over many of our competitors. Tenowo considers all markets as vital for us but we can’t ignore that China, which represents the biggest automotive market worldwide in terms of manufactured units and is a vanguard in E-mobility.”

Meanwhile, EcoTechnilin, a British-owned company with a factory in France and an R&D center in the U.K., recently opened a new facility in Poland with a complete line for nonwovens dedicated to the automotive businesses ready to help Tier 1 to grow their business in Eastern Europe. The line is a complete, high-capacity needlepunch eXcelle line from Andritz Nonwoven. The line has a production capacity of about 1000 kg/h and produces nonwovens made of natural fibers, glass fibers and polypropylene from 300 to 2,400 gsm for the automotive industry.

Andritz has delivered the opening and blending equipment, an eXcelle card for a width of 2.5 meters and a profile crosslapper in combination with Andritz technology for pre-needling and needling of heavyweight nonwovens.

EcoTechnilin also operates two Andritz lines in France.

As a leading provider of natural fiber solutions, EcoTechnilin is currently able to produce more than 10,000 tons of nonwoven mats per year. The company has developed a range of materials for many applications in the transport industry (automotive, aircraft, buses, railway, etc.), the construction industry, furniture, geotextiles, and others. With this new line in Poland, the company will substantially increase its production.

Other investments from EcoTechnilin include the purchase of a complete line for the impregnation of tape, fabrics and nonwovens with thermoset resin bio or petro based resin. Additionally, a line to produce the flax tape, the unidirectional 100% flax based product, gives the best mechanical performance ever, according to Karim Behlouli, managing director at EcoTechnilin.

Various factors are helping natural fibers gain ground in automotive components, according to Behlouli. For EcoTechnilin, one reason is that its new hybrid technology can give more flexibility to Tier 1 automotive companies, and they can produce very complex products made from natural fibers. Behlouli says the company’s new range of products also solve the problem of VOCs, odor and mildew. Another benefit of natural fibers is that they contribute to a very good life cycle analysis compared to other solutions.

Something New

Innovation has been key to growth for nonwovens producers invested in the automotive market, as makers of auto parts continue to demand light yet durable materials.

Among the latest developments from Sandler are new fine filter media for use in activated carbon filters. “With these new nonwovens, the functionality of activated carbon filters and the optimum particle filtration provided by nonwoven media can be combined in a durable, efficient product,” says Sandler’s Klier.

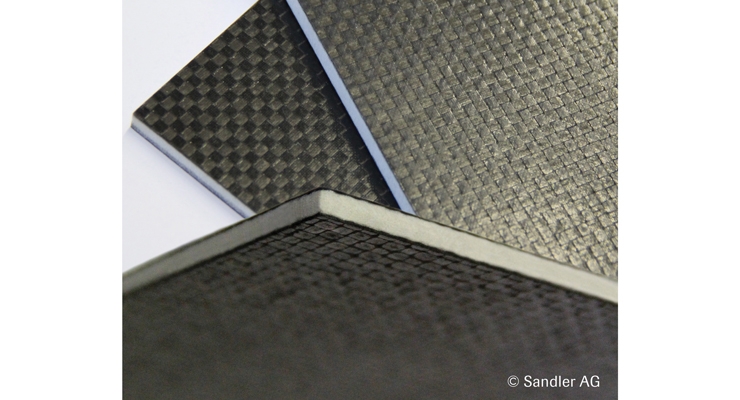

Sandler is also developing composite materials. Self-supporting nonwoven panels are equipped on one or both sides with a cover layer of carbon- or glass-fiber reinforced plastic. “The resulting sandwich materials can be processed into lightweight components, which offer high mechanical functionality—in favor of lightweight designs,” Klier says.

TWE Group, based in Emsdetten, Germany, produces nonwovens that are found virtually everywhere in a vehicle, from the underbody to the roof lining and from the boot to the engine compartment. In order to respond to some of the upcoming megatrends such as emission and weight reductions and electric vehicles, the company has developed various new and innovative materials, according to Willi Lauk, business unit director Automotive, TWE Group. “We are currently in discussion with OEM’s and we do supply those materials already in different projects as either first prototypes or even pre-serial parts, where we are close to a nomination.”

As these products are not yet in serial production, TWE is staying mum on the details at this point in time.

In India, Autotech Nonwovens, a producer of needlepunch, has developed new designs for its headliner fabrics, and has also started supplying in new segments including luggage board and seating back fabrics.

Ankit Desai, director, Autotech Nonwovens, expects the company’s primary market, India, to continue its growth momentum as new buyers enter the market as well as existing owners of vehicles looking for product upgrades to a higher segment, e.g. towards mid-segment sedans and SUVs.

“We believe that as the average Indian car buyer looks for value added products and higher value cars, our premium products, including printed headliners, are seeing increasing interest from OEMs,” Desai says. “Many OEMs would have not considered such a product some years ago, however as customer demand graduates towards premium hatchbacks, sedans and SUVs, we expect this premiumization shift to continue.”

Made in America

U.S. companies are also focusing on innovation in the automotive market.

Monadnock Non-Wovens produces meltblown nonwovens for the automotive market at its site in Mount Pocono, PA.

According to Keith Hayward, managing director, Monadnock, the automotive industry in North America is just coming off a peak demand over the last few years. “There is a significant movement to larger SUV’s and trucks that presents extra engineering challenges in order to make the vehicles quieter, lighter and more energy efficient,” he says. “As ever there is an emphasis on cost and weight reduction.”

Polypropylene nonwovens, in general, offer weight reduction and improved acoustical performance, Hayward says. A new development from Monadnock is its HPAM High Performance Acoustic Media for the automotive industry. HPAM is a fine fiber, polypropylene meltblown, lofted nonwoven that significantly improves sound absorption at lower frequencies in cars and trucks. HPAM enables vehicles to maintain or reduce interior noise levels, reduce weight and lower costs.

For Monadnock, which also produces and supplies nonwovens for air and liquid filtration, face masks, sorbents and vacuum bags, the automotive market is an attractive one for the company. “It is a highly competitive, consistent and large market,” Hayward comments. “This means there are numerous opportunities for the companies offering something genuinely better value than established products, better performance at no extra cost or those offering environmentally attractive propositions.”

Conover, NC-based Dalco Nonwovens, which produces needlepunch for automotive applications and other markets, continues to see nonwovens be readily accepted in the automotive world due to their custom-ability for the many uses a vehicle may need – durability, sound absorption, hydrophobicity, moldability and aesthetics. According to Gale Shipley, automotive sales manager at Dalco, one good example is the use of dilour nonwovens verses tufted carpet. “Both products are color matched, durable, and visually pleasing; however, the nonwoven is less costly. In addition, it can also be easily merged with a sound absorption layer.”

Dalco’s and its sister company Global Felt Technologies’ (GFT) needlepunch nonwovens are used not only as the base for the dilour operation but the sound absorption-layer as well.

Benefits of Dalco’s and GFT’s needlepunch nonwovens are exemplified in the automotive parts having increased rigidity for underbody aerodynamics and durability, ease of molding into shapes while maintaining strength due to the mechanical bonding in the “Z” direction, enhanced acoustical characteristics, and safety cushioning for passengers (protection over metal framing), Shipley says. Many of these characteristics can be engineered through polymer and denier selection as well as merging with other technologies such as spunbond and films.

Dalco and GFT focus on automotive markets throughout the U.S., from Michigan and the midwest, through the south, and as far away as California. “Although the SAAR (seasonally adjusted annual rate) appears to have plateaued and the industry is preparing for a downturn, more vehicles are continuing to utilize nonwovens for a variety of expanding applications. In addition, larger vehicles are requiring larger underbody shields, larger wheel well liners, larger sound absorption layers, etc., thus sustaining our growth,” Shipley says.

Sustainable From the Inside Out

In the automotive market, sustainability means more than just electric cars. Today, nonwovens producers are implementing sustainable solutions from the raw materials they use to their manufacturing operations.

The trend of environmental sustainability is clearly visible, says TWE’s Lauk. “OEM’s are looking more and more for sustainable materials and try to replace other materials that do not meet those criteria,” he says.

For instance, TWE’s Caliweb material will be used as a replacement for foam in certain areas of the car, such as in seats and roof linings directly behind the leather or other visual materials. Caliweb is an enmeshed polyester nonwoven with vertically positioned fibers. According to Lauk, it has very good resilience, excellent draping capability, therefore wrinkle-free optics possible, smooth surface due to meshing, the composite itself is completely recyclable and it has no emissions, no odor or fogging effects.

According to Sandler’s Klier, environmental sustainability continues to be in high demand in the automotive industry. “With the supply of fossil fuels being increasingly depleted and CO2 emissions damaging our environment, reducing the fuel consumption remains a vital topic in automotive engineering,” he comments. “Current trends, such as electromobility, are a prime example of the industry’s efforts to reduce the environmental impact. Naturally, the topic also continues to be a focus of product development at Sandler.”

Being lightweight, high-performance materials, nonwovens contribute to reducing the total weight of a car, thus helping to lower fuel consumption and reduce CO2 emissions, he adds. As such, Sandler focuses on reducing component weights while still offering high functionality, for example, with its sawasorb advanced nonwovens. Sawasorb features excellent sound absorption throughout the frequency range at low product thickness. They are therefore ideal for narrow installation spaces, such as in door side panels, dashboard or boot.

The majority of Sandler’s nonwovens for the automotive industry are single-polymer materials, made of 100% polyester, which are fully recyclable after use. Where it is possible, Sandler partly uses recycled fibers, made from PET drinking bottles, for example, in manufacturing these nonwovens, Klier says. Further, nonwoven edge trims from production are sent directly for reprocessing and are reused in production, supporting closed material cycles.

“Apart from the utilized raw materials, our nonwovens also support environmental protection during use,” Klier says. “Absorbers for application in engine covers for example, not only dampen engine noise, they also function as heat insulators and slow the cooling-off of the engine. Thereby, cold starts are prevented, and fuel consumption is reduced.”

According to Autoneum’s Rickmann, the environmental sustainability of car parts is becoming more important in the automotive industry. On the one hand, the company invests decisively in making its production processes more eco-efficient. It is expanding its recycling capacities and globally implementing energy, waste and water efficiency measures to achieve ambitious environmental targets set in its new Corporate Responsibility Strategy 2025. On the other hand, the company offers a wide range of lightweight components for noise and heat protection, some of which stand out due to their high content of recycled fibers and materials. “These components can make an important contribution to the weight reduction of vehicles, which in turn leads to lower fuel consumption and CO2 emissions. Hence, we support our customers not only in fulfilling tightening environmental regulations, but also in satisfying consumer demand for more environmentally friendly cars,” Rickmann concludes.

While Monadnock’s HPAM material is made with 100% virgin polypropylene, Hayward says that it is lighter than competitive products in the market, which is critical for fuel economy. Further, the nonwoven is fully recyclable at the end of its useful life unlike alternatives that are made with both polyester and polypropylene rendering, them practically impossible to recycle, he adds. Additionally, HPAM is made with 100% renewable electricity through an investment in Green-e certified renewable wind power energy certificates.

For their part, Dalco and GFT have, at plant level, developed processes to the end result of being 98.5% landfill free in its fiber, plastic, and paper waste. Additionally, Shipley says, the companies have been partnering with their customers and fiber suppliers to create a close loop recycling system.

“However,” she adds, “in the past few months, the automotive OEM’s have been plagued by a growing concern regarding increased fiber prices resulting from anti-dumping legislation and tariffs. These battles are forcing OEM’s to look at alternative channels to maintain their competitive price points sometimes at the negation of recyclability. These OEM’s concerns are in addition to the steel and aluminum tariffs.”

In vehicles, nonwovens are used for temperature and sound insulation, seating, liners for the roof and wheel arches, as well as linings and carpets.

Today, many nonwovens producers are growing their lineups of innovations in order to cater to the growing electric vehicle market. Market trends such as “green” mobility and autonomous driving are also providing growth opportunities for nonwovens producers, according to Gerhard Klier, sales director Technical Products, Sandler. “Lightweight, yet highly functional components continue to be in high demand,” he says. “At the same time, these new mobility concepts entail new requirements on the utilized materials. For example, the noise level in electric cars is different to that of cars with combustion engines. Therefore, new materials are needed. All of this creates opportunities for further development of our products and innovation.”

Geographically, Sandler is seeing growth in all areas in Europe and the U.S., was well as in Asia, especially China, Klier says. Overall, the use of nonwovens in automotive applications continues to increase, and in markets such as Asia, which are still developing, high growth rates are creating high demand, he adds.

In order to respond to demand around the globe, Sandler is working with local partners and sales representatives as well as operating sales offices in Shanghai, China, and New Delhi, India. “In this way, we are attainable to our customers and potential buyers directly on site, eliminating cultural and language barriers from the start. It goes without saying that this also gives us in-depth knowledge of local requirements and enables us to give even more sound advice to our customers,” Klier explains.

Due to major growth expected in Asia, Autoneum is also focusing on electric vehicles.

“By 2025, Asia will be home to more than half of the global middle class and account for half of the global automobile production, one third of which will be in China alone. Autoneum wants to participate in this growth and aims to significantly increase its sales in Asia,” says Anahid Rickmann, head Corporate Communications & Responsibility, Autoneum.

According to Rickmann, more e-cars are sold in China than in the rest of the world combined. “And just recently, the Chinese government set itself the target of selling seven million e-cars by 2025 and it lifted the JV regulations for foreign electric vehicle manufacturers. This will further accelerate the market for this vehicle segment,” she says.

Autoneum has a large presence in China, with a total of 10 sites in the country, with the two most recent plants opening this year in Pinghu (Zhejiang Province) and Shenyang Tiexi (Liaoning Province). Both plants have begun production of lightweight multifunctional components for noise and heat.

The continued strong customer demand for lightweight components for acoustic and thermal management made it necessary to further expand Autoneum’s production capacities in China, the company says.

Using state-of-the-art production processes, Autoneum Pinghu manufactures underbody systems made of Ultra-Silent for European, U.S.-American and Chinese customers. These textile underbodies will be installed, among others, in various hybrid models and a fully electric vehicle of a new Chinese car manufacturer. When operating at full capacity, around 5.5 million underbody components made of Ultra-Silent will be produced in Pinghu each year and delivered just-in-time to the local production facilities of customers. With Ultra-Silent, Autoneum offers the lightest underbody systems for vehicles available on the market: Compared with equivalent components made of plastic they are up to 50% lighter, fully recyclable, reduce noise and thanks to improved aerodynamics, they help to reduce a vehicle’s fuel consumption and emissions.

During the Pinghu plant opening, Autoneum CEO Martin Hirzel stated: “With our two new plants in China we are continuing our strategy-driven expansion course in this important growth market. In order to be able to offer our customers industry-leading components, we are investing heavily in sustainable production processes as well as in innovative technologies and materials. At the same time we are supporting the expansion of electromobility in China with the regional market launch of multifunctional components for a diverse range of drive systems.”

At the Shenyang Tiexi production facility, around 7.5 million carpet systems, inner dashes, floor insulators and heatshields will be produced annually for German and Swedish vehicle manufacturers on a site measuring 23000 square meters.

Autoneum sees significant growth potential in new forms of mobility such as electromobility and self-driving cars. Rickmann says the company is prepared for this transformation and is investing accordingly in innovative products and technologies in acoustic and thermal management for the vehicle of the future. Today, Autoneum offers an optimized product portfolio for electric vehicles of existing and new car manufacturers with innovative technologies such as Tune-It for carpet systems and Hybrid-Acoustics ECO+ for inner dashes and floor insulators.

With Tune-It for needlepunch carpets, Autoneum offers automotive manufacturers a technology that makes the car of tomorrow lighter, more comfortable and environmentally friendly – while delivering ideal acoustic performance at the same time.

Tune-It is based on an innovative fiber combination in the carpet backing with which, for the first time, sound insulation and absorption can be tuned to the specific needs and geometry of the passenger cabin across the entire surface of the carpet. According to Autoneum, because of this technology, it is now possible to define the optimum insulation and absorption performance already during the development phase of new vehicle models by means of computer-aided simulations. As a result, needlepunch carpets based on Tune-It provide ideal noise protection in the passenger cabin. In addition, given a weight advantage of up to 25% compared to standard needlepunch carpets, components based on Tune-It also support reduced fuel consumption and less vehicle emissions.

The environmental footprint of this carpet technology that consists of 100% PET is also reflected in the fact that Tune-It based components are fully recyclable. Compared to conventional carpet molding, where non-recyclable production waste can reach a share of 30%, off-cuts produced during the manufacture of Tune-It can be processed into pellets and completely returned into the carpet manufacturing process in the form of fibers.

Meanwhile, Freudenberg Performance Materials is seeing by far the strongest growth, according to Dr. Frank Heislitz, CEO, Freudenberg Performance Materials. Growth has been slower in Europe and rather modest in the U.S., he adds.

Earlier this year, Freudenberg Far Eastern Spunweb, a Freudenberg Performance Materials and Far Eastern Spunweb company, made plans to build an additional production line at the Tayuan Tao-Yuan site in Taiwan. This expansion of capacity will enable the company to meet growing demand in the traditional automotive and carpet markets of Asia.

With the new production line, Freudenberg will increase annual production of nonwovens in Tayuan Tao-Yuan by around 11,000 metric tons.

Freudenberg currently supplies these two markets in Asia with primary and secondary carrier materials for automotive carpet moldings and inlay mats, as well as dry running mats, carpets and carpet tiles. The high-performance materials are easy to form and thus contribute to economical processing. In addition, their high dimensional stability ensures a precise fit and they are extremely durable.

This capacity expansion will also enable Freudenberg to develop the company’s regional position. “Asia is important for FPM’s automotive business as it is the region with the largest absolute growth in this industry. Car production is increasing and the new mobility market – for which Freudenberg offers also innovative solutions – is growing,” says Heislitz.

Construction of the new production line is expected to be complete in 2020.

The main growth driver for Freudenberg in the automotive market is innovation. “The automotive market requires new solutions in three fields in which Freudenberg is particularly strong: lightweight (e.g. CO2 reduction), new mobility and sustainability (e.g. recyclable materials),” Heislitz says.

Freudenberg’s nonwovens based on Lutraflor technology for automotive carpets, insert mats and interior and trunk linings, can provide weight savings of up to 40% compared to conventional automotive carpets. Another weight-saving innovation from Freudenberg is its unique multilayer composite for molded underbody panels and wheel liners, which enables weight savings of 15 to 40% compared to conventional products. Weight savings can also be found with its Evolon microfilament textiles, automotive acoustic pads and headliner facing materials, which are not only used for headliners but also for trunk liners and seat backs, Heislitz says.

Also, beginning this year, Freudenberg is one of the first companies worldwide to manufacture gas diffusion layers (GDL) completely in-house with its own production facilities. GDL are essential component of fuel cells. They ensure that the hydrogen fuel is converted into power as efficiently as possible. “Freudenberg’s gas diffusion layers help to improve the efficiency of fuel cells,” explains Heislitz. “Their high uniformity in structure and thickness increases electrical and thermal conductivity and improves the transport of gases and liquids in the fuel cell. Further strengths of Freudenberg’s gas diffusion layers compared with other products are superior downstream processing and exceptional surface properties.”

Freudenberg’s gas diffusion layers for e-cars are indispensable components for new mobility vehicles, he adds.

Investments Around the World

While Asia has been an important market for investment recently, some nonwovens producers are looking elsewhere around the world.

Early in 2018, Fibertex Nonwovens continued its global expansion through the acquisition of the Brazilian nonwovens producer Duci, based in an industrial district west of Sao Paulo. Fibertex Nonwovens generates annual revenue of about DKK 1.4 billion, or $233 million, and currently has production facilities in Denmark, France, the Czech Republic, Turkey, the U.S. and South Africa. Duci was founded in 2001 and generates revenue of nearly DKK 115 million, or just under $20 million.

Duci manufactures spunlaced nonwovens, a technology Fibertex already uses at its sites in France and Turkey.

Duci’s potential in the automotive industry was attractive to Fibertex Nonwovens. An average European car contains about 30 square meters of advanced nonwovens, and Fibertex Nonwovens has managed to capture a market leading position as supplier of materials in everything from headliners, seats and parcel trays to exterior applications used in wheel housings, motor insulation and underbodies.

In September Fibertex Nonwovens announced it was increasing the Duci plant’s production capacity by 20% to accommodate growing demand for special-purpose products for the automotive and other industries. The Denmark-based nonwovens producer has already significantly increased its sales to a number of South American customers.

“The process of taking over the factory in Brazil has far exceeded our expectations. Our South American customers have given us a really warm welcome, and we’re already facing an urgent lack of capacity,” Fibertex Nonwovens CEO Jørgen Bech Madsen said at the time of the capacity announcement. “We’ve been planning to expand capacity since acquiring Duci, but the need has arisen faster than we anticipated, and we will begin to upgrade the existing production line immediately. We know from previous experience in expanding our other factory sites that an upgrade can increase our output capacity by 20%. In addition, we will accelerate planning for other expansion projects.”

Estimated at close to DKK 15 million, the investment is expected to be fully implemented by the summer of 2019. Bech Madsen explains that Fibertex Nonwovens has already sold the extra capacity to the growing Brazilian market, which is the world’s sixth-largest and accounts for more than half of the entire South American market. The spunlacing technology made by Fibertex Nonwovens in Brazil is manufactured by just one other company in South America. Fibertex already makes this type of nonwoven at sites in France and Turkey, and its experience in this segment was a key factor in its success.

The latest investment news from Tenowo, a nonwovens producer based in Hof, Germany, is an expansion into Mexico. This summer the company announced the formation of Tenowo de Mexico, S. de R.L. de C.V., which initially includes the establishment of a sales office and warehouse in the city of San Luis Potosí, Mexico.

The new entity is jointly owned by Tenowo Inc. in the U.S. and Tenowo GmbH in Germany. It was established in response to increased demand for Tenowo’s automotive products in the Mexican market and will house materials manufactured both in the U.S. and Germany.

At the time of the announcement, Chris Peart, president and CEO of Tenowo, Inc., said that the location provides Tenowo with a footprint in a fast-growing geographic part of its market and is hopefully the first step towards further expansion. “San Luis Potosí is a thriving city in the heart of the Bajio region of Mexico and has access to four major ports,” he said. “In addition, it is within a few hours of the major automotive manufacturing hubs in Mexico. It is the ideal location for our needs.”

Tenowo has made other investments at other sites around the world. New stitchbonding capacity at its U.S. plant in North Carolina will serve the seating market in the U.S., as well as in South America and Mexico. Additionally, capacity for tailor made stitchbonded nonwovens will come onstream in 2019 at its U.S. and Germany sites, which are used for wire harnessing tapes. Meanwhile, in Mittweida, Germany, Tenowo dedicated additional capacity for decorative nonwovens used for headliners and interior trim. The company also added capacity for its Multiknit brands used in seating, which provide good air permeability and ecological advantages in terms of sustainability. In Hof and Reichenbach, Tenowo developed new high-end filter media for automotive applications. Finally, in China, Tenowo has worked up to capacity, which has paved the way for further steps to expand its presence in Asia.

Detlev Käppel, director, sales for Tenowo, says all three of the company’s major regions—the Americas, Europe and Asia—are important to the company. “We can serve our customers domestically and are therefore independent on political decisions which may influence the global markets and supply chain,” he says. “That gives us the edge over many of our competitors. Tenowo considers all markets as vital for us but we can’t ignore that China, which represents the biggest automotive market worldwide in terms of manufactured units and is a vanguard in E-mobility.”

Meanwhile, EcoTechnilin, a British-owned company with a factory in France and an R&D center in the U.K., recently opened a new facility in Poland with a complete line for nonwovens dedicated to the automotive businesses ready to help Tier 1 to grow their business in Eastern Europe. The line is a complete, high-capacity needlepunch eXcelle line from Andritz Nonwoven. The line has a production capacity of about 1000 kg/h and produces nonwovens made of natural fibers, glass fibers and polypropylene from 300 to 2,400 gsm for the automotive industry.

Andritz has delivered the opening and blending equipment, an eXcelle card for a width of 2.5 meters and a profile crosslapper in combination with Andritz technology for pre-needling and needling of heavyweight nonwovens.

EcoTechnilin also operates two Andritz lines in France.

As a leading provider of natural fiber solutions, EcoTechnilin is currently able to produce more than 10,000 tons of nonwoven mats per year. The company has developed a range of materials for many applications in the transport industry (automotive, aircraft, buses, railway, etc.), the construction industry, furniture, geotextiles, and others. With this new line in Poland, the company will substantially increase its production.

Other investments from EcoTechnilin include the purchase of a complete line for the impregnation of tape, fabrics and nonwovens with thermoset resin bio or petro based resin. Additionally, a line to produce the flax tape, the unidirectional 100% flax based product, gives the best mechanical performance ever, according to Karim Behlouli, managing director at EcoTechnilin.

Various factors are helping natural fibers gain ground in automotive components, according to Behlouli. For EcoTechnilin, one reason is that its new hybrid technology can give more flexibility to Tier 1 automotive companies, and they can produce very complex products made from natural fibers. Behlouli says the company’s new range of products also solve the problem of VOCs, odor and mildew. Another benefit of natural fibers is that they contribute to a very good life cycle analysis compared to other solutions.

Something New

Innovation has been key to growth for nonwovens producers invested in the automotive market, as makers of auto parts continue to demand light yet durable materials.

Among the latest developments from Sandler are new fine filter media for use in activated carbon filters. “With these new nonwovens, the functionality of activated carbon filters and the optimum particle filtration provided by nonwoven media can be combined in a durable, efficient product,” says Sandler’s Klier.

Sandler is also developing composite materials. Self-supporting nonwoven panels are equipped on one or both sides with a cover layer of carbon- or glass-fiber reinforced plastic. “The resulting sandwich materials can be processed into lightweight components, which offer high mechanical functionality—in favor of lightweight designs,” Klier says.

TWE Group, based in Emsdetten, Germany, produces nonwovens that are found virtually everywhere in a vehicle, from the underbody to the roof lining and from the boot to the engine compartment. In order to respond to some of the upcoming megatrends such as emission and weight reductions and electric vehicles, the company has developed various new and innovative materials, according to Willi Lauk, business unit director Automotive, TWE Group. “We are currently in discussion with OEM’s and we do supply those materials already in different projects as either first prototypes or even pre-serial parts, where we are close to a nomination.”

As these products are not yet in serial production, TWE is staying mum on the details at this point in time.

In India, Autotech Nonwovens, a producer of needlepunch, has developed new designs for its headliner fabrics, and has also started supplying in new segments including luggage board and seating back fabrics.

Ankit Desai, director, Autotech Nonwovens, expects the company’s primary market, India, to continue its growth momentum as new buyers enter the market as well as existing owners of vehicles looking for product upgrades to a higher segment, e.g. towards mid-segment sedans and SUVs.

“We believe that as the average Indian car buyer looks for value added products and higher value cars, our premium products, including printed headliners, are seeing increasing interest from OEMs,” Desai says. “Many OEMs would have not considered such a product some years ago, however as customer demand graduates towards premium hatchbacks, sedans and SUVs, we expect this premiumization shift to continue.”

Made in America

U.S. companies are also focusing on innovation in the automotive market.

Monadnock Non-Wovens produces meltblown nonwovens for the automotive market at its site in Mount Pocono, PA.

According to Keith Hayward, managing director, Monadnock, the automotive industry in North America is just coming off a peak demand over the last few years. “There is a significant movement to larger SUV’s and trucks that presents extra engineering challenges in order to make the vehicles quieter, lighter and more energy efficient,” he says. “As ever there is an emphasis on cost and weight reduction.”

Polypropylene nonwovens, in general, offer weight reduction and improved acoustical performance, Hayward says. A new development from Monadnock is its HPAM High Performance Acoustic Media for the automotive industry. HPAM is a fine fiber, polypropylene meltblown, lofted nonwoven that significantly improves sound absorption at lower frequencies in cars and trucks. HPAM enables vehicles to maintain or reduce interior noise levels, reduce weight and lower costs.

For Monadnock, which also produces and supplies nonwovens for air and liquid filtration, face masks, sorbents and vacuum bags, the automotive market is an attractive one for the company. “It is a highly competitive, consistent and large market,” Hayward comments. “This means there are numerous opportunities for the companies offering something genuinely better value than established products, better performance at no extra cost or those offering environmentally attractive propositions.”

Conover, NC-based Dalco Nonwovens, which produces needlepunch for automotive applications and other markets, continues to see nonwovens be readily accepted in the automotive world due to their custom-ability for the many uses a vehicle may need – durability, sound absorption, hydrophobicity, moldability and aesthetics. According to Gale Shipley, automotive sales manager at Dalco, one good example is the use of dilour nonwovens verses tufted carpet. “Both products are color matched, durable, and visually pleasing; however, the nonwoven is less costly. In addition, it can also be easily merged with a sound absorption layer.”

Dalco’s and its sister company Global Felt Technologies’ (GFT) needlepunch nonwovens are used not only as the base for the dilour operation but the sound absorption-layer as well.

Benefits of Dalco’s and GFT’s needlepunch nonwovens are exemplified in the automotive parts having increased rigidity for underbody aerodynamics and durability, ease of molding into shapes while maintaining strength due to the mechanical bonding in the “Z” direction, enhanced acoustical characteristics, and safety cushioning for passengers (protection over metal framing), Shipley says. Many of these characteristics can be engineered through polymer and denier selection as well as merging with other technologies such as spunbond and films.

Dalco and GFT focus on automotive markets throughout the U.S., from Michigan and the midwest, through the south, and as far away as California. “Although the SAAR (seasonally adjusted annual rate) appears to have plateaued and the industry is preparing for a downturn, more vehicles are continuing to utilize nonwovens for a variety of expanding applications. In addition, larger vehicles are requiring larger underbody shields, larger wheel well liners, larger sound absorption layers, etc., thus sustaining our growth,” Shipley says.

Sustainable From the Inside Out

In the automotive market, sustainability means more than just electric cars. Today, nonwovens producers are implementing sustainable solutions from the raw materials they use to their manufacturing operations.

The trend of environmental sustainability is clearly visible, says TWE’s Lauk. “OEM’s are looking more and more for sustainable materials and try to replace other materials that do not meet those criteria,” he says.

For instance, TWE’s Caliweb material will be used as a replacement for foam in certain areas of the car, such as in seats and roof linings directly behind the leather or other visual materials. Caliweb is an enmeshed polyester nonwoven with vertically positioned fibers. According to Lauk, it has very good resilience, excellent draping capability, therefore wrinkle-free optics possible, smooth surface due to meshing, the composite itself is completely recyclable and it has no emissions, no odor or fogging effects.

According to Sandler’s Klier, environmental sustainability continues to be in high demand in the automotive industry. “With the supply of fossil fuels being increasingly depleted and CO2 emissions damaging our environment, reducing the fuel consumption remains a vital topic in automotive engineering,” he comments. “Current trends, such as electromobility, are a prime example of the industry’s efforts to reduce the environmental impact. Naturally, the topic also continues to be a focus of product development at Sandler.”

Being lightweight, high-performance materials, nonwovens contribute to reducing the total weight of a car, thus helping to lower fuel consumption and reduce CO2 emissions, he adds. As such, Sandler focuses on reducing component weights while still offering high functionality, for example, with its sawasorb advanced nonwovens. Sawasorb features excellent sound absorption throughout the frequency range at low product thickness. They are therefore ideal for narrow installation spaces, such as in door side panels, dashboard or boot.

The majority of Sandler’s nonwovens for the automotive industry are single-polymer materials, made of 100% polyester, which are fully recyclable after use. Where it is possible, Sandler partly uses recycled fibers, made from PET drinking bottles, for example, in manufacturing these nonwovens, Klier says. Further, nonwoven edge trims from production are sent directly for reprocessing and are reused in production, supporting closed material cycles.

“Apart from the utilized raw materials, our nonwovens also support environmental protection during use,” Klier says. “Absorbers for application in engine covers for example, not only dampen engine noise, they also function as heat insulators and slow the cooling-off of the engine. Thereby, cold starts are prevented, and fuel consumption is reduced.”

According to Autoneum’s Rickmann, the environmental sustainability of car parts is becoming more important in the automotive industry. On the one hand, the company invests decisively in making its production processes more eco-efficient. It is expanding its recycling capacities and globally implementing energy, waste and water efficiency measures to achieve ambitious environmental targets set in its new Corporate Responsibility Strategy 2025. On the other hand, the company offers a wide range of lightweight components for noise and heat protection, some of which stand out due to their high content of recycled fibers and materials. “These components can make an important contribution to the weight reduction of vehicles, which in turn leads to lower fuel consumption and CO2 emissions. Hence, we support our customers not only in fulfilling tightening environmental regulations, but also in satisfying consumer demand for more environmentally friendly cars,” Rickmann concludes.

While Monadnock’s HPAM material is made with 100% virgin polypropylene, Hayward says that it is lighter than competitive products in the market, which is critical for fuel economy. Further, the nonwoven is fully recyclable at the end of its useful life unlike alternatives that are made with both polyester and polypropylene rendering, them practically impossible to recycle, he adds. Additionally, HPAM is made with 100% renewable electricity through an investment in Green-e certified renewable wind power energy certificates.

For their part, Dalco and GFT have, at plant level, developed processes to the end result of being 98.5% landfill free in its fiber, plastic, and paper waste. Additionally, Shipley says, the companies have been partnering with their customers and fiber suppliers to create a close loop recycling system.

“However,” she adds, “in the past few months, the automotive OEM’s have been plagued by a growing concern regarding increased fiber prices resulting from anti-dumping legislation and tariffs. These battles are forcing OEM’s to look at alternative channels to maintain their competitive price points sometimes at the negation of recyclability. These OEM’s concerns are in addition to the steel and aluminum tariffs.”