David R. Roisum, Finishing Technologies, Inc.06.01.18

Last time we talked about the challenges of measuring bulk or thickness. Here we will talk about why bulk can be lost if the nonwoven is tender. Worse yet, any loss will be nonuniform. In short, the average nonwoven thickness will decrease and the variation of thickness will increase. The common operation that will likely do this, almost guaranteed to do this, is the winder.

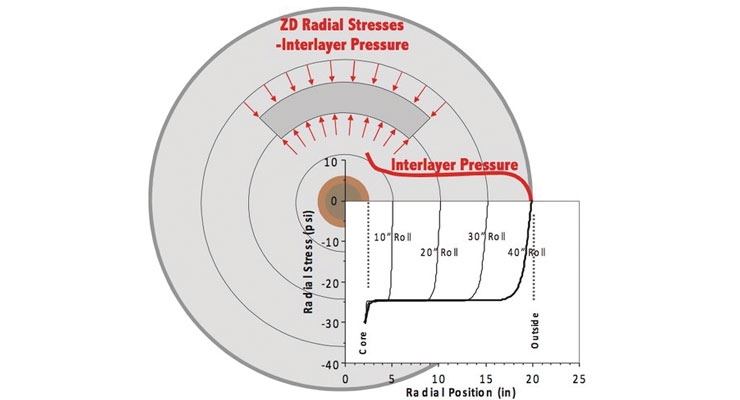

What do we mean by tender? Scientists call behavior like this ‘creep.’ It is the slow, steady and permanent change in length (when in tension), width (when in tension due to necking) and/or bulk (when under Z-direction pressure). We will focus on pressure because that is the easiest to understand and may be the larger concern for many. The first thing we need to know is what the pressure is on each of the layers in the winding roll. While the exact numbers depend on the details, the trend is the same for all winders, run under all settings and for all nonwovens and in fact all materials of any kind. In short, pressure is guaranteed by the laws of winding physics. The only substantial difference in materials is that, for example, the pressures in a roll of newspaper, perhaps 50 psi, is greater than nonwovens, which is greater than tissue which is less than one psi of pressure. Even though this is less for our products, nonwovens are extremely tender compared to newspaper which is also changed and damaged during winding.

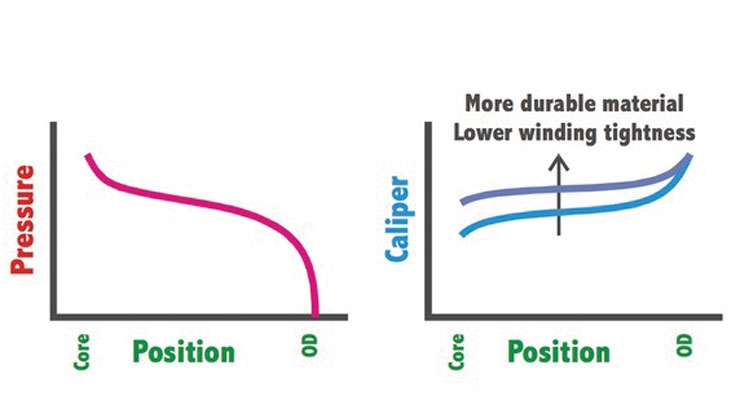

As seen in Figure 1, the pressure is highest at the core, medium in the middle and low, in fact zero, at the outside of the roll. So what happens if the pressure in the roll is enough to cause creep, as it almost always will be? Where pressure is highest, near the core, the bulk or thickness will be permanently less. As seen in Figure 2, the loss at the core will be greater than the loss in the middle which is greater than the loss at the outside.

While is it true that some of this will be recovered elastically as soon as the material is unwound and some will be recovered with time, known as memory, there will be a measureable permanent loss. The permanent loss of bulk may range from less than 5% on newspaper to an incredible 50% on tender nonwovens. Worse yet, it is nonuniform. Customers who sample material from the top will see bulky material and those who get it from the bottom will see crushed material. The longer the material sits in the roll, the worse it gets. Yet, even if you unwound immediately you would suffer from permanent and nonuniform bulk loss. The higher the temperature of storage, the worse it gets. Yet, even if you store at room temperature you would suffer from permanent and nonuniform bulk loss.

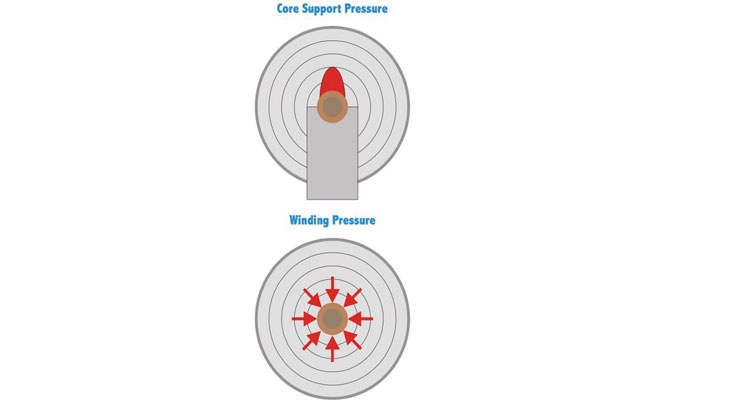

If this were not messy enough, we have one additional inevitable complication: gravity. When supporting a roll by the core during winding or unwinding, the pressures of the core lifting the inside of the roll can be quite large. Even if the winding/unwinding time is short, the very large pressures may permanently crush material above the core. So notice that the pressures due to winding and the pressures due to core support are in the same place as seen in Figure 3. We need to know which is largest because they have quite different solutions. In the former case it is wind looser and in the latter case it is wind smaller rolls on larger cores. The difference can be seen by measuring bulk loss on a trial small sized roll. If bulk loss is similar, it is winding. If bulk loss is reduced, part of it is crushed by roll weight.

So, what should we do? Wind looser by reducing the winder TNT’s (Tension, Nip and Torque) settings to the extent possible which may be some limitation of the winder or, more likely, making rolls too soft to store and ship. In future products we should consider DFM (design for manufacturability). Here we treat the winder as a customer as fully as we do the end-use customer. Otherwise, we may risk designing a material that can not be safely stored in a wound roll and thus must be stored in a stack or box.

What do we mean by tender? Scientists call behavior like this ‘creep.’ It is the slow, steady and permanent change in length (when in tension), width (when in tension due to necking) and/or bulk (when under Z-direction pressure). We will focus on pressure because that is the easiest to understand and may be the larger concern for many. The first thing we need to know is what the pressure is on each of the layers in the winding roll. While the exact numbers depend on the details, the trend is the same for all winders, run under all settings and for all nonwovens and in fact all materials of any kind. In short, pressure is guaranteed by the laws of winding physics. The only substantial difference in materials is that, for example, the pressures in a roll of newspaper, perhaps 50 psi, is greater than nonwovens, which is greater than tissue which is less than one psi of pressure. Even though this is less for our products, nonwovens are extremely tender compared to newspaper which is also changed and damaged during winding.

As seen in Figure 1, the pressure is highest at the core, medium in the middle and low, in fact zero, at the outside of the roll. So what happens if the pressure in the roll is enough to cause creep, as it almost always will be? Where pressure is highest, near the core, the bulk or thickness will be permanently less. As seen in Figure 2, the loss at the core will be greater than the loss in the middle which is greater than the loss at the outside.

While is it true that some of this will be recovered elastically as soon as the material is unwound and some will be recovered with time, known as memory, there will be a measureable permanent loss. The permanent loss of bulk may range from less than 5% on newspaper to an incredible 50% on tender nonwovens. Worse yet, it is nonuniform. Customers who sample material from the top will see bulky material and those who get it from the bottom will see crushed material. The longer the material sits in the roll, the worse it gets. Yet, even if you unwound immediately you would suffer from permanent and nonuniform bulk loss. The higher the temperature of storage, the worse it gets. Yet, even if you store at room temperature you would suffer from permanent and nonuniform bulk loss.

If this were not messy enough, we have one additional inevitable complication: gravity. When supporting a roll by the core during winding or unwinding, the pressures of the core lifting the inside of the roll can be quite large. Even if the winding/unwinding time is short, the very large pressures may permanently crush material above the core. So notice that the pressures due to winding and the pressures due to core support are in the same place as seen in Figure 3. We need to know which is largest because they have quite different solutions. In the former case it is wind looser and in the latter case it is wind smaller rolls on larger cores. The difference can be seen by measuring bulk loss on a trial small sized roll. If bulk loss is similar, it is winding. If bulk loss is reduced, part of it is crushed by roll weight.

So, what should we do? Wind looser by reducing the winder TNT’s (Tension, Nip and Torque) settings to the extent possible which may be some limitation of the winder or, more likely, making rolls too soft to store and ship. In future products we should consider DFM (design for manufacturability). Here we treat the winder as a customer as fully as we do the end-use customer. Otherwise, we may risk designing a material that can not be safely stored in a wound roll and thus must be stored in a stack or box.