03.02.18

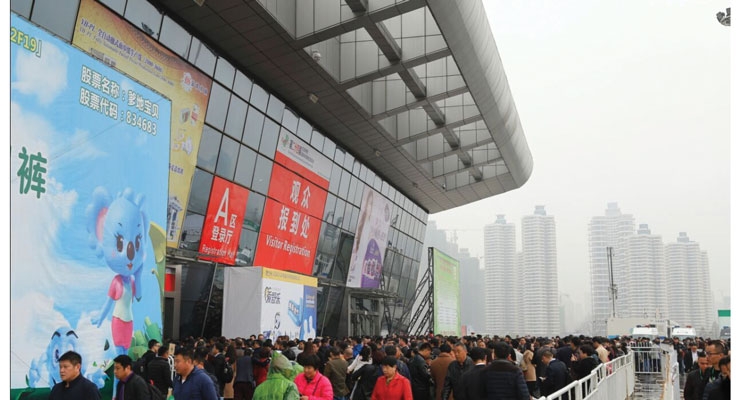

After more than 20 years of careful cultivation, the China International Disposable Paper Expo (CIDPEX), organized by the China National Household Paper Industry Association (CNHPIA), has become a well-known annual industry event, attracting tens of thousands of domestic and foreign exhibitors and visitors every year. More than 1000 tissue paper and disposable hygiene product brands from China and abroad will be showcased during the event, which will take place April 18-20 at the Nanjing International Expo Center, Jiangsu, China.

With the proportion of overseas exhibitors and visitors improving, internationalized services will be provided through the whole exhibition process. CNHPIA will provide English registration information, traffic guide and a visa invitation letter to help overseas visitors get to the exhibition venue more conveniently. An English show directory with general information and exhibitor profiles will be provided onsite. Another highlight of CIDPEX 2018 is the conference on April 17, one day before the exhibition. Insightful analysis and practical solutions will be provided on the latest hot topics in the industry. All speeches at the CIDPEX 2018 conference will be given in both Chinese and English with simultaneous interpretation.

This show preview will introduce the highlights and some important exhibitors of each pavilion. More information can be found on CNHPIA’s website, www.cnhpia.org.

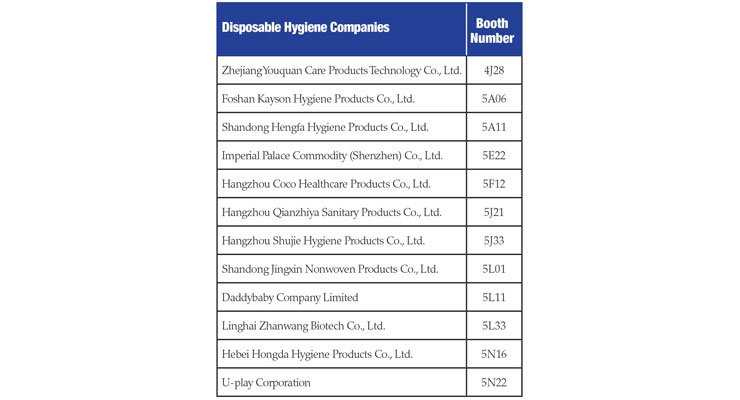

Disposable Hygiene Products Pavilion

Many disposable hygiene products enterprises have added new and differentiated products to their offerings. Well-known brands such as Via, Daddybaby, Baby Energy and COCO will show-off high-quality products at the exhibition. Tampons appeared at CIDPEX for the first time in 2017, and will be an important part of this year’s event. Further, pure cotton continues to gain in popularity in China and is being used more in sanitary napkins, diapers, wet wipes, etc. The industry is also paying attention to pregnant women, and manufacturers have developed a series of products around this special group.

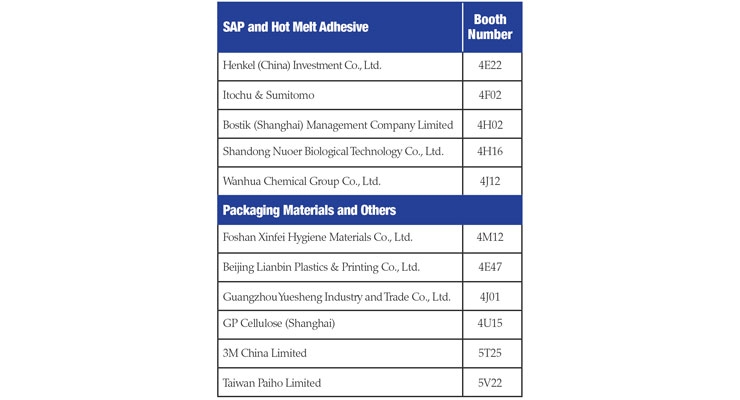

Raw Material Pavilion

Raw material providers will bring their new solutions to help make differentiated finished products with excellent performance. Visitors will find technology improvements in all kinds of raw materials, including hot melt adhesives, closing systems, packing materials, SAP, nonwovens and other raw materials. For example, Henkel (China) will launch its new product, the Technomelt Ultra Cool hot melt adhesive, which can be used at ultra low temperatures. Shandong Rongtai will bring its latest elastic and three-dimensional cotton nonwovens for sanitary napkins and diapers.

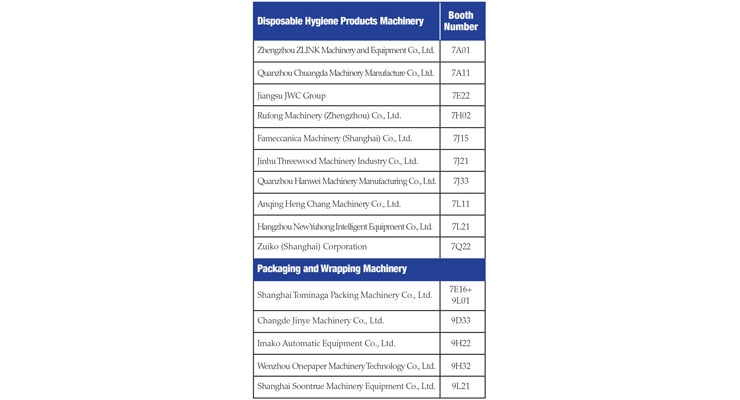

Machinery Pavilion

In the machinery pavilion, hundreds of machines will be demonstrated onsite and visitors will see the latest in new technologies and machinery improvements. Well-known machinery companies will be in attendance, including A.Celli, Andritz, Valmet, Toscotec, Kawanoe Zoki, Fabio Perini, Baosuo, Dechangyu, Soontrue, Fameccanica and Hengchang, among others.

Bostik Brings Adhesives

Bostik is a leading global adhesive specialist for construction, consumer and industrial markets and will be participating at CIDPEX 2018. Visitors will find Bostik (Shanghai) Management Company Limited in Booth #4H02 in the Disposable Hygiene Products Pavilion of this event.

Attendees visiting the booth will gain inside perspective on Bostik’s Smart solutions to disposable hygiene challenges. Bostik’s full line of elastic attachment adhesives will be showcased in an interactive way, providing attendees with a memorable experience. Regional and global Bostik experts also will be available to help existing and potential customers understand how adhesives can help them to achieve their overall business objectives.

As a major global supplier of high stress adhesive products for disposable hygiene, Bostik has always been a leader in the innovation of smart adhesive technologies, and has consistently revolutionized and spurred development in the industry. Bostik offers an extensive line of adhesive products that are ideal for new disposable hygiene products including industry leading technology like ZeroCreep and, a world’s first, Brilliance.

www.bostik.com

Xiamen Gachn Technology

Xiamen Gachn Technology will present the GM-085N diaper counting stack at CIDPEX. The machine is applied in diaper counting and stacking with stabilized speed and high efficiency. It is capable of counting and stacking products in different specifications. It can count and stack 10-45 pieces per minute and is designed to run at 600-650 pieces per minute. Its full servo driving system ensures the accuracy of counting and stacking and simplifies the process of changing its configuration by stacking the products from overlapping and lying pieces.

Also on display will be the full servo baby diaper fabricated bag packaging machine which can adopt servo systems, and completes the production processes of pressing, opening, feeding, sealing automatically – which greatly reduces the labor cost.

Main technical parameters include:

ITW Dynatec

ITW Dynatec will be displaying three new technologies at CIDPEX this year.

The UltraLink applicator platform is the first high-speed modular applicator platform that provides increased pattern flexibility and decreases the total cost of ownership (spare parts inventory, maintenance time and product life span). A portion of the technology (Ultra Strand Coating System) was a finalist for the IDEA16 Achievement Awards. ITW’s Velocity metering platform is an innovative high-speed technology that greatly increases the accuracy of glue application and when used in conjunction with Ultra achieves even greater savings. Meanwhile, Simplicity: 2017 Innovation for Packaging applications is specially designed to be simple to install, use, and maintain.

www.itwdynatec.com

NDC Spray Coating System

NDC provides equipment for the nonwovens industry in personal care, medical and furniture applications under a wide range of complete systems - including coaters, hot melting systems as well as gluing solutions. The RISE Series Melter will be the key equipment to be presented at CIDPEX. RISE Series Melter provides full control and operation for hot melt machines by being equipped with a user-friendly Siemens PLC control system. Furthermore, the melting tank with cast in heating can substantially reduce carbonation. The melter is equipped with a large capacity and a high density filter, which help in the improvement of precision degree in filtration and prolongs its service life.

Finally, by facilitating a high power electrical connector, it greatly improves safety and the reliability of the connector and communication.

A variety of 4L, 10L, 18L, 25L, 50L, 100L, 200L, 400L tanks are optional based on clients’ request.

www.ndc.com

Optima Machinery

From entry level to high performance, Optima offers packaging machines for nonwoven products tailored to all kind of needs. At CIDPEX, Optima will present several machines on a three-dimensional screen. The Optima DS1 is the entry level to fully automatic packaging of baby diapers at a low investment cost. The three semi-automatic packaging stations can later be expanded to a fully automatic packaging system. With the PAKSIS D5, designed and manufactured in cooperation with Fameccanica Data S.p.A., it is possible to simultaneously operate a fully-automatic packaging machine and two semi-automatic packaging stations for more production flexibility.

Optima also presents an entry level option to the fully-automatic packaging of femcare products such as sanitary napkins and panty shields. The OPTIMA TB300 has a compact design, excellent accessibility and a bag maker for side-gusseted bags from the roll that provides a fast start-up for high quality packaging. Producing small packages at high output, the OPTIMA HS1 OS1 stands-out due to its reliability and wide variety of packaging format selections.

High performance packaging lines by Optima Nonwovens offer leading-edge technologies. They take the products over from the production machines in a synchronous manner and package them in plastic film. The flexible systems can accommodate everything from the smallest packages to jumbo packs. Inspection functions and secondary packaging capabilities are integrated to achieve automated complete lines.

www.optima-nonwovens.com

Peixin

Peixin’s full-servo elastic back ear baby diaper production line is highly automated, with a number of intelligent features to ensure smooth operation.

Inserted is a user-friendly PLC interface operation system that collects statistics for record. Services such as online testing, dimensional control systems, and video inspection system are equipped to ensure close surveillance during manufacturing, and avoid sudden breakdowns that interfere the production line.

Furthermore, Peixin’s equipment abides by the CE standard, with electric parts fulfilling CE and UL quality certification.

www.peixin.com

Sandvik Hyperion

The cutting unit is a critical component of a hygiene converting line. Its reliability and lifetime can heavily influence the total productivity output. Sandvik Hyperion can support customers to identify the main drivers to generate savings in their daily operations and continuously improve the overall equipment efficiency (OEE).

From the engineering development of the cutting solution, to the manufacturing, the internal tests, the start-up assistance, the operators’ training, the after-sales assistance and up to the carbide recycling program, Sandvik Hyperion works closely with customers to provide a high level of technical and manufacturing support throughout the whole cutting unit lifecycle. This translates directly into customer savings through excellent production efficiency, optimization of spare part quantities and a reduction of machine downtimes and maintenance needs.

Sandvik’s expertise is strengthened by an extended support team comprised of members from the engineering, production, sales, and customer service departments, who are continuously striving to provide our customers with assistance, advice and innovation that will surpass their expectations.

The most recent developments of Sandvik Hyperion are supporting this customer focused approach.

IQut, integrating “intelligence” to the cutting unit, through sensors which measure the main parameters influencing the cutting performance and thus anticipating and preventing possible machine downtimes.

A-Flex, allowing a quick change of the tools installed in the cutting frame, thus minimizing machine downtimes and maximizing productivity.

www.sandvik-hyperion.com

With the proportion of overseas exhibitors and visitors improving, internationalized services will be provided through the whole exhibition process. CNHPIA will provide English registration information, traffic guide and a visa invitation letter to help overseas visitors get to the exhibition venue more conveniently. An English show directory with general information and exhibitor profiles will be provided onsite. Another highlight of CIDPEX 2018 is the conference on April 17, one day before the exhibition. Insightful analysis and practical solutions will be provided on the latest hot topics in the industry. All speeches at the CIDPEX 2018 conference will be given in both Chinese and English with simultaneous interpretation.

This show preview will introduce the highlights and some important exhibitors of each pavilion. More information can be found on CNHPIA’s website, www.cnhpia.org.

Disposable Hygiene Products Pavilion

Many disposable hygiene products enterprises have added new and differentiated products to their offerings. Well-known brands such as Via, Daddybaby, Baby Energy and COCO will show-off high-quality products at the exhibition. Tampons appeared at CIDPEX for the first time in 2017, and will be an important part of this year’s event. Further, pure cotton continues to gain in popularity in China and is being used more in sanitary napkins, diapers, wet wipes, etc. The industry is also paying attention to pregnant women, and manufacturers have developed a series of products around this special group.

Raw Material Pavilion

Raw material providers will bring their new solutions to help make differentiated finished products with excellent performance. Visitors will find technology improvements in all kinds of raw materials, including hot melt adhesives, closing systems, packing materials, SAP, nonwovens and other raw materials. For example, Henkel (China) will launch its new product, the Technomelt Ultra Cool hot melt adhesive, which can be used at ultra low temperatures. Shandong Rongtai will bring its latest elastic and three-dimensional cotton nonwovens for sanitary napkins and diapers.

Machinery Pavilion

In the machinery pavilion, hundreds of machines will be demonstrated onsite and visitors will see the latest in new technologies and machinery improvements. Well-known machinery companies will be in attendance, including A.Celli, Andritz, Valmet, Toscotec, Kawanoe Zoki, Fabio Perini, Baosuo, Dechangyu, Soontrue, Fameccanica and Hengchang, among others.

Bostik Brings Adhesives

Bostik is a leading global adhesive specialist for construction, consumer and industrial markets and will be participating at CIDPEX 2018. Visitors will find Bostik (Shanghai) Management Company Limited in Booth #4H02 in the Disposable Hygiene Products Pavilion of this event.

Attendees visiting the booth will gain inside perspective on Bostik’s Smart solutions to disposable hygiene challenges. Bostik’s full line of elastic attachment adhesives will be showcased in an interactive way, providing attendees with a memorable experience. Regional and global Bostik experts also will be available to help existing and potential customers understand how adhesives can help them to achieve their overall business objectives.

As a major global supplier of high stress adhesive products for disposable hygiene, Bostik has always been a leader in the innovation of smart adhesive technologies, and has consistently revolutionized and spurred development in the industry. Bostik offers an extensive line of adhesive products that are ideal for new disposable hygiene products including industry leading technology like ZeroCreep and, a world’s first, Brilliance.

www.bostik.com

Xiamen Gachn Technology

Xiamen Gachn Technology will present the GM-085N diaper counting stack at CIDPEX. The machine is applied in diaper counting and stacking with stabilized speed and high efficiency. It is capable of counting and stacking products in different specifications. It can count and stack 10-45 pieces per minute and is designed to run at 600-650 pieces per minute. Its full servo driving system ensures the accuracy of counting and stacking and simplifies the process of changing its configuration by stacking the products from overlapping and lying pieces.

Also on display will be the full servo baby diaper fabricated bag packaging machine which can adopt servo systems, and completes the production processes of pressing, opening, feeding, sealing automatically – which greatly reduces the labor cost.

Main technical parameters include:

- Packaging speed: max designed speed 50 bags/min, stable at 45bags/min

- Packaging dimension: 150~400mm

- Film material: PE and composite materials

- Packaging method: via Rolling film tape or prefabricated bags

ITW Dynatec

ITW Dynatec will be displaying three new technologies at CIDPEX this year.

The UltraLink applicator platform is the first high-speed modular applicator platform that provides increased pattern flexibility and decreases the total cost of ownership (spare parts inventory, maintenance time and product life span). A portion of the technology (Ultra Strand Coating System) was a finalist for the IDEA16 Achievement Awards. ITW’s Velocity metering platform is an innovative high-speed technology that greatly increases the accuracy of glue application and when used in conjunction with Ultra achieves even greater savings. Meanwhile, Simplicity: 2017 Innovation for Packaging applications is specially designed to be simple to install, use, and maintain.

www.itwdynatec.com

NDC Spray Coating System

NDC provides equipment for the nonwovens industry in personal care, medical and furniture applications under a wide range of complete systems - including coaters, hot melting systems as well as gluing solutions. The RISE Series Melter will be the key equipment to be presented at CIDPEX. RISE Series Melter provides full control and operation for hot melt machines by being equipped with a user-friendly Siemens PLC control system. Furthermore, the melting tank with cast in heating can substantially reduce carbonation. The melter is equipped with a large capacity and a high density filter, which help in the improvement of precision degree in filtration and prolongs its service life.

Finally, by facilitating a high power electrical connector, it greatly improves safety and the reliability of the connector and communication.

A variety of 4L, 10L, 18L, 25L, 50L, 100L, 200L, 400L tanks are optional based on clients’ request.

www.ndc.com

Optima Machinery

From entry level to high performance, Optima offers packaging machines for nonwoven products tailored to all kind of needs. At CIDPEX, Optima will present several machines on a three-dimensional screen. The Optima DS1 is the entry level to fully automatic packaging of baby diapers at a low investment cost. The three semi-automatic packaging stations can later be expanded to a fully automatic packaging system. With the PAKSIS D5, designed and manufactured in cooperation with Fameccanica Data S.p.A., it is possible to simultaneously operate a fully-automatic packaging machine and two semi-automatic packaging stations for more production flexibility.

Optima also presents an entry level option to the fully-automatic packaging of femcare products such as sanitary napkins and panty shields. The OPTIMA TB300 has a compact design, excellent accessibility and a bag maker for side-gusseted bags from the roll that provides a fast start-up for high quality packaging. Producing small packages at high output, the OPTIMA HS1 OS1 stands-out due to its reliability and wide variety of packaging format selections.

High performance packaging lines by Optima Nonwovens offer leading-edge technologies. They take the products over from the production machines in a synchronous manner and package them in plastic film. The flexible systems can accommodate everything from the smallest packages to jumbo packs. Inspection functions and secondary packaging capabilities are integrated to achieve automated complete lines.

www.optima-nonwovens.com

Peixin

Peixin’s full-servo elastic back ear baby diaper production line is highly automated, with a number of intelligent features to ensure smooth operation.

Inserted is a user-friendly PLC interface operation system that collects statistics for record. Services such as online testing, dimensional control systems, and video inspection system are equipped to ensure close surveillance during manufacturing, and avoid sudden breakdowns that interfere the production line.

Furthermore, Peixin’s equipment abides by the CE standard, with electric parts fulfilling CE and UL quality certification.

www.peixin.com

Sandvik Hyperion

The cutting unit is a critical component of a hygiene converting line. Its reliability and lifetime can heavily influence the total productivity output. Sandvik Hyperion can support customers to identify the main drivers to generate savings in their daily operations and continuously improve the overall equipment efficiency (OEE).

From the engineering development of the cutting solution, to the manufacturing, the internal tests, the start-up assistance, the operators’ training, the after-sales assistance and up to the carbide recycling program, Sandvik Hyperion works closely with customers to provide a high level of technical and manufacturing support throughout the whole cutting unit lifecycle. This translates directly into customer savings through excellent production efficiency, optimization of spare part quantities and a reduction of machine downtimes and maintenance needs.

Sandvik’s expertise is strengthened by an extended support team comprised of members from the engineering, production, sales, and customer service departments, who are continuously striving to provide our customers with assistance, advice and innovation that will surpass their expectations.

The most recent developments of Sandvik Hyperion are supporting this customer focused approach.

IQut, integrating “intelligence” to the cutting unit, through sensors which measure the main parameters influencing the cutting performance and thus anticipating and preventing possible machine downtimes.

A-Flex, allowing a quick change of the tools installed in the cutting frame, thus minimizing machine downtimes and maximizing productivity.

www.sandvik-hyperion.com