10.09.17

The 2017 Filtration International Conference & Exposition will be held at Chicago’s Navy Pier, October 10-12. INDA is expecting a strong turnout of about 1500 industry participants.

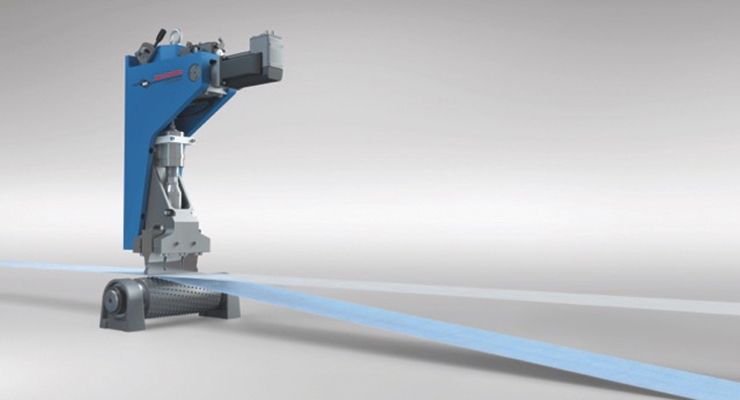

Among the innovations that will be launched in air and liquid filtration during the exposition are filter pockets that help lower energy consumption, multi-layer filters from new synthetic materials, filter assembly systems engineered for extreme duty performance and new intelligent equipment that makes pleats in heavy duty materials.

Filtration 2017 will also feature a powerful educational component to learn from world-renowned expert speakers. Sessions include the keynote lunch on recent growth activity in filtration by Phil Whitaker, president and CEO, AAF Flanders; a panel on the Industrial Internet of Things (IIoT) in Filtration; a panel discussion on the ISO 16890 standards; as well as sessions on air purification, media design and measuring air filter energy efficiency.

Filtration 2017 kicks off on Oct. 10 with the one-day Nonwoven Filter Media Training Course prior to the exposition on Oct. 11-12. The industry reception will be Oct. 11, from 5 to 6 p.m., on the show floor.

The following is a preview of what some exhibitors will be showing off in Chicago.

Ahlstrom-Munksjö

Booth 312

Ahlstrom-Munksjö is a global leader in fiber-based materials, supplying innovative and sustainable solutions to customers worldwide.

Ahlstrom-Munksjö has leading global positions in several segments with global reach and has expanded product and service offerings and improved service, design and R&D capabilities. The company was formed on April 1, 2017 through the merger of Ahlstrom Corporation and Munksjö Oyj.

Ahlstrom-Munksjö’s product offering for the filtration market is growing. It is expanding its filtration product portfolio with a major investment at its Madisonville plant in Kentucky. By enhancing its capabilities, it is creating even more solid long-term partnerships.

The filtration market continues to grow and the needs of especially industrial segments continue to evolve. Air quality standards are becoming closer to the real-life environments and the filter media performance must be adapted to perform in the highest levels.

As an example, Ahlstrom-Munksjö has expanded its gas turbine air intake product range and it covers both, pulse-jet and static media needs. Products have excellent performance even in extremely demanding filtration environments.

www.ahlstrom-munksjo.com

Albarrie Canada Limited

Booth 830

Albarrie is a leading producer of specialty fabrics. At the heart of the organization is its advanced needlefelt operation with multiple production lines including wide width, heavy weight and tubular needlefelt processing. These specialized processing lines can integrate fiber blends, layering/supporting materials to produce engineered fabrics from four to 120 oz/yd2.

The organization also boasts a wide array of finishing capabilities to customize fabrics and meet demanding performance specifications. Finishing capabilities include lamination, coating, impregnation, heat treating, singeing and calendering.

At Filtration 2017, Albarrie will be sharing two filtration fabrics that are exclusive to the company: Fabrics needled to Basalt fibers (P84, PPS, and Polyox), and fabrics that contain Polyoxadiazole fiber also known as Polyox. These combinations possess unique properties that no other filtration fabric on the market can match.

www.albarrie.com

American Truetzschler Inc.

Booth 115

Truetzschler Nonwovens’ equipment ranges from pilot or laboratory lines to complete spunlacing, needling, thermo- and chemical bonding lines.

Machinery for pilot lines—the MiniJet spunlacing unit: The MiniJet is a specially designed spunlacing unit serving the need of institutes and companies requiring research and development work or supplying niche markets. Due to proven features of the AquaJet—such as the jet head and the spunlacing drum—all manmade and natural fibers can be processed. The MiniJet allows for water pressures up to 400 bar. This feature, in combination with working width of 500, 1000 and 1300 mm and speeds up to 55 m/min, opens the door to the production of demanding end-products. The modular container design minimizes costs for erection and start-up.

Complete lines—flexible thermo and binder bonding line: Thermobonding nonwovens in a drum oven results in high-quality, bulky materials. A new development by Truetzschler Nonwovens is a line including a drum dryer/oven as well as a foulard, a can dryer and a hot flue unit. In the thermobonding process, the drum oven is used as a thermobonder while all other components are bypassed. When using a liquid agent, the drum dryer is used for drying the nonwoven before entering the hot flue. This line concept is especially suited for the production of light weights webs.

www.am-truetzschler.com

Bdtronic

Booth 814

Bdtronic’s new atmospheric pressure plasma device, for all standard and high-performance plasma applications, will work optimize the surface tension on a large variety of materials. The plasma technology in Bdtronic’s VP4 is perfect for all ultra-fine cleaning or activation processes prior to bonding, soldering, injection molding, gluing, printing, or any other process that requires a clean and optimal surface energy to create adhesion. Its repeatable and stable process is guaranteed by its continuous process control. This process control is made possible by its proprietary software that keeps control of and monitors each and every relevant parameter. All VP4 systems can be easily integrated into a production line, whether manual, lean or fully automated production line. In order to ensure an efficient energy transfer, with no voltage drop, Bdtronic has removed any voltage cable to supply the compact plasma head with power. Instead, it uses a high flex cable to power the plasma head. Additionally, the air supply to the head is adjusted automatically, according to the set power. That allows the VP4 to dynamically change the plasma power during production. Bdtronic’s VP4 offers a light weight and reliable plasma solution at the optimal price.

www.bdtronic.com

Bondex

Booth 624

Bondex is introducing Hydrolox, a new technology to the industrial filtration market, produced from unique process technology that delivers superior filtration performance versus incumbents. Today’s utilities and industrial users are demanding higher performance filtration; filters that deliver improved collection efficiency with lower operating costs. Historically, industrial filtration felt was produced through a traditional needle loom which has met some market needs with a specific balance of properties. Hydrolox filter media, available only from Bondex, combines the benefits of needle loom fiber entangling with revolutionary hydroentangling technology to deliver industry leading dust collection performance. The phenomena of entangling fibers with high pressure water jets creates a unique balance of lower pore size in a strong media. Hydrolox represents a new paradigm in filtration by delivering a product with dramatically improved filtration efficiency, an inherent ability to promote surface dust collection, lower pressure drop over time, and reduction in pulse cycle times. Additionally, Hydrolox HCE is available as a family of filtration media using fine fibers that deliver even higher collection efficiency performance, comparable to membrane laminated needlefelt. Hydrolox and Hydrolox HCE are available in PPS, PET, Aramid, PTFE, Polyimide, Acrylic and others, in weights up to 17 oz/yd2¬.

www.bondexinc.com

Chase Machine and Engineering

Booth 418

For over 60 years, Rhode Island-based Chase Machine and Engineering has designed and built custom web handling systems and process equipment for many of the largest and most progressive filter media and filter manufacturers in the world.

Chase’s talented team of mechanical, automation and electrical engineers, along with its experienced and diverse manufacturing technicians, provides its customers the best custom automated equipment solution to compete and win in today’s worldwide and growing filtration Industries.

For those interested in product development, the Chase Materials Applications Lab exists to help their engineering team take their ideas, create new or improved product and determine the optimum method for producing it. Lab capabilities include web handling systems with ultrasonic technology for laminating, embossing, welding, slitting as well as cutting-to-length.

www.chasemachine.com

Fibertex Nonwovens

Booth 908

Fibertex Nonwovens, a market-leading nonwovens manufacturer with sites in the U.S., Denmark, France, Czech Republic, Turkey and South Africa is highlighting its new unique range of 100% synthetic pleatable filter media Pleatex, which sets the new standard for pleated filter products.

These media are a unique building platform for all filter manufacturers within both air and liquid filtration. Customized weight, air permeability and surface treatments on demand.

Pleatex is a synthetic inherent pleatable filter media, which has pleating behavior similar to cellulose and glass fiber media, like no other synthetic media. Pleatex can be processed on all kinds of different pleaters such as rotary pleaters, knife and blade pleaters. Production runs show that Pleatex undertakes faster pleating compared to other synthetic media when pleated on a rotary pleater.

Embossed pleat packs are possible to ensure lower pressure drop and better dust distribution. Pleatex is stiff and rigid enough to maintain in shape also when pulsed.

Pleatex product range from MERV 8 and upwards.

Besides its new Pleatex product range, Fibertex Nonwovens also produces a full range of different air and liquid filter media based on needlepunch, spunlace, spunbond and highloft production technologies.

www.fibertex.com

Fil-Tec

Booth 230

Fil-Tec’s American made products for the filter bag industry will help customers improve their efficiencies and reduce cost. Fil-Tec manufactures an extensive line of sewing thread and bobbins made from fiberglass, Nomex, polyester, PTFE and Conex fibers designed to keep machines and tubers running. Fil-Tec’s line of snap band gasket material has become the industry standard, lowering sewing room costs by eliminating extra sewing steps. Fil-Tec’s cuff bead and static dissipation ground wire give customers the finishing touches to a superior filter bag. Fil-Tec’s solutions extend to the baghouse with its door seal products for customers’ baghouse access doors.

Fil-Tec Inc. is introducing a new 9 lb. put up of fiberglass sewing thread for tubers designed to increase tuber efficiency, its new Conex easy sew thread for Nomex and other high temp bags, and its new line of high temp snap band gaskets.

www.fil-tec.com

Herrmann Ultrasonics

Booth 881

Continuous welding of filtration material requires the highest level of precision. The Herrmann Ultrasonics Microbond CSI system, consisting of the VE Actuator, Microgap controller and high-performance Ultrabond generator guarantees consistent weld quality. Integrated in all Microbond systems is the patented Microgap control process, which ensures constant production quality via closed loop processing by monitoring the gap between the sonotrode and the anvil drum.

The Microbond CSI technology energy is only directed to the weld bond points and does not further restrict the filter laminate, nor change the fiber content; with typical thermal bonding heat radiates outside the bond zone.

Small bond points safeguard against restricted airflow, a common problem when using adhesives.

Multi-laminate structures with/without mesh reinforcement can simultaneously be incorporated.

Pinholes are eliminated using the Microbond CSI technology.

Loss of performance due to bonding errors is reduced to 0.5-4%.

Herrmann Ultrasonics has become the technology leader in ultrasonic welding by developing the most advanced products, providing ultrasonics engineering expertise and total solution offerings. The ultrasonic process can be used in the final assembly of the filtration product. Herrmann Ultrasonics is focused on providing ultrasonic welding technology for various markets such as the consumer, medical, food, hygiene and automotive industries.

www.herrmannultrasonics.com

Hollingsworth & Vose

Booth 402

Hollingsworth & Vose is a leading global manufacturer of advanced materials for filtration, battery separator and industrial applications operating manufacturing sites and research centers in the Americas, Asia, Europe, and India.

At Filtration 2017, H&V will be showing off its filter media for:

Math2Market

Booth 623

The innovative simulation software GeoDict from Math2Market GmbH is the most complete solution for the digital design of filters and filter media. GeoDict is the answer to broaden the boundaries of existing filters and to find new specialized solutions for filtration applications.

Starting from three-dimensional scans (µCT, FIB/SEM) of filter media, CAD models, or user-defined parameters it is straightforward to: model filter elements, pleats, and media, such as nonwoven, woven, glass- and steel-fiber, metal and plastic meshes, ceramics, foams, cellulose, membranes, diesel and gasoline particulate filters; simulate gas and liquid filtration processes: air, water, oil, fuel; analyze porosity, pore size distribution, bubble point, fluid flow, particle movement and deposition, MPPS, depth filtration, cake formation, dust holding capacity; design filter media and pleats to fit specifications and improve pressure drop, filter efficiency, filter selectivity, and filter lifetime.

The GeoDict solution incorporates personalized support, consultation, assistance and trainings in using simulation to create and vary filter media designs, to optimize processes, and to resolve complex filtration questions quickly and cost-effectively. The final goal is to cut prototyping and R&D costs and gain a competitive edge by accelerating design and production.

www.math2market.com

Midwest Filtration

Booth 611

Many customers call Midwest Filtration LLC the drug store of nonwovens. At its booth, visitors will find many types of nonwovens in one place. These are stocked at its Cincinnati warehouse in mill rolls and are ready to be converted by one of 12 re-rolling and slitting machines in rolls ranging in width from one to 150 inches in a short turn time. In addition, die-cutting machines can cut them into many shapes and sizes. Midwest Filtration’s highly experienced seamers can sew and heat-seal them into tubes, bags and sleeves.

At its booth this year, Midwest Filtration is featuring a new nonwoven filter media called Unipoly PSB. It is a new point-bonded, spunmelt polyester available in basis weights ranging from 17-140 gsm. Its distinctive low denier fibers create excellent uniformity. The unique manufacturing process creates greater strength properties (Tensile and Mullen) than similar spunmelt polyesters. As a result, many applications can consider using lower basis weights to achieve the same or better results.

www.midwestfiltration.com

Möller

Booth 514

Möller in Meschede/Germany is a leading European manufacturer of extruded plastic frames and accessories for the air filter industry. Möller distributes all of its products in more than 40 countries globally.

Möller produces frames and accessories for ¾ and 1-inch bag filters as well as for 2”, 3”, 4”, 6” and 11.5” panel box filters with and without header frame.

Moreover, Möller will display its new 4-V compact filter frame.

This new 4-V compact filter frame has several special features like carrying handles, self-contained mounting devices for the filter packs and the 4-V can be easily and safely stacked.

Thanks to the simple snap-in method, the frames and corner pieces are easy and fast to assemble. All frame profiles and corners are made of HIPS and can be completely incinerated.

www.moeller-profilsysteme.de

Nanoscience Instruments

Booth 930

For 15 years, Nanoscience Instruments has partnered with its customers to deliver a wide variety of analytical solutions. It specializes in three-dimensional sample imaging, in-situ tensile testing, surface science and nanoscale microscopy instrumentation. Its line of products includes benchtop SEMs, electrospinning nanofiber manufacturing, and micro and nanomanipulation systems. Nanoscience Instruments sells a variety of scientific equipment and accessories while providing ongoing applications support. Its extensive line of equipment and technical expertise enables it to serve its customers to find simple and high quality solutions.

www.nanoscience.com

Phifer Incorporated

Booth 318

Phifer Incorporated will showcase its portfolio of filtration and performance meshes at Filtration 2017.

With more than 60 years of weaving excellence, Phifer is a one-stop shop for industrial meshes that add strength and support to virtually any type of medium, including cellulose, glass and synthetic. Meshes are available in woven aluminum, epoxy-coated low carbon steel, vinyl-coated fiberglass, and vinyl-coated polyester mesh performance fabrics. In addition to filtration, netting and reinforcement substrates, Phifer’s meshes are used in ventilation, wind screens, auto bug screens, pool skimmers and covers, and construction and agricultural netting.

Phifer is registered by Underwriters Laboratories, Inc., to the International Organization for Standardization (ISO), and all performance metals and fabrics undergo rigorous in-house inspections to ensure top quality.

www.phifer.com

Rando Machine

Booth 315

Rando Machine designs and manufactures quality airlaid machinery for a wide variety of major industries such as: automotive, abrasives, filtration, health and hygiene and furniture. Its machinery also has a strong history of making significant contributions in other specialty applications such as military, aerospace and agriculture. For nearly 70 years, Rando Machine Corporation has played a leading role in the evolution of the airlaid process in the nonwovens market and it continues to offer its customers opportunities to constantly improve their products.

As a recognized industry leader in the development and fabrication of nonwoven fiber processing systems, Rando Machine provides quality equipment for use in media filtration. These systems are designed to filter oil, gas, air, water, and agricultural products using a vast variety of fiber materials. Rando employs a range of equipment to fulfill its customers’ filtration needs, including feeders, webbers, opener/blenders and edge trim slitters, among others.

Rando equipment, in conjunction with that of its strategic partners, provide seamless, high quality turnkey solutions by offering machinery for fiber preparation, web formation, shredding/refiberizing (waste reclaiming), as well as ovens, winding/stacking, controls and other converting equipment.

www.randomachine.com

Sandler

Booth 608

At this year’s Filtration show, Sandler will present a wide range of synthetic filtration nonwovens. Efficient pocket filter media and pleatable nonwovens for ventilation and air conditioning maintain their efficiency even after discharge. Nonwovens for cabin air and engine air filters help improve the indoor air quality in vehicles. Fuel filter media protect the engine and contribute to efficient combustion. Synthetic vacuum cleaner bags reliably trap dirt particles and dust and foster a higher suction power.

In light of growing metropolitan areas, more and more vehicles on the roads and increasing air pollution, efficient filter media are in higher demand than ever to ensure optimum indoor air quality, particularly in public spaces. New norms and testing standards, above all the new ISO 16890, are shaping the industry. The norm bases filter classification on more realistic criteria and also takes into account the energy efficiency during operation of the filter unit.

Sandler’s new synthetic filter medium enAIRsave combines long-term performance and reduced energy usage. Multiple filter layers provide optimum dust separation across the entire width of the medium. The particles are primarily deposited in the coarse meltblown layer as well as the pre-filter layer. Air can still flow through the filter at a relatively low pressure and, consequently, at a reduced energy consumption.

www.sandler.de

Superior Felt & Filtration

Booth 120

With the completion of an additional environmentally controlled white room, Superior Felt & Filtration has expanded its medical filtration converting and fabrication capabilities to offer technology driven collating, control room slitting, offline needling, medical adhesive coating, heat sealing, ultrasonic’s, die cutting, printing and private label packaging. By incorporating various high efficiency filtration (electrostatic) media like Technostat, used in conjunction with spunbonds, mesh and other filtration substrates and composites, SFF continues to have an industry leading edge in respiratory, viral, bacterial, home care industry, HEPA, safety masks and respirators, cosmetic and wound care applications. Superior Felt & Filtration’s technical nonwovens and value added services reach into other industries like automotive, aerospace, appliance and cross platform industrial markets. With a world-class engineering and research and development department as well as a wealth of internal testing capabilities like Fractional Efficiency, CFM, MERV and NIOSH analysis, Superior has the unique ability to take a customer’s filtration application from concept to completion.

www.superiorfelt.com

Thrace Nonwovens & Geosynthetics

Booth 724

Thrace Nonwovens & Geosynthetics is going to exhibit its PP yarns used for filtration products. Thrace Group PP Multifilament Yarns are the ideal starting material for weaving, braiding and twisting. Their technical characteristics offer resistance to acids and alkalis. The wide range of Thrace’s PP Multifilament Yarns is supported by a rich color palette that includes natural, black and a large variety of colors, with tested color fastness. They all offer excellent technical parameters, with high tenacity, chemical resistance and flexibility. Precision winding is available for coarse yarns. High quality twisting ensures an excellent result in warping and weaving, especially for the filtration fabrics production.

www.thracegroup.com

Among the innovations that will be launched in air and liquid filtration during the exposition are filter pockets that help lower energy consumption, multi-layer filters from new synthetic materials, filter assembly systems engineered for extreme duty performance and new intelligent equipment that makes pleats in heavy duty materials.

Filtration 2017 will also feature a powerful educational component to learn from world-renowned expert speakers. Sessions include the keynote lunch on recent growth activity in filtration by Phil Whitaker, president and CEO, AAF Flanders; a panel on the Industrial Internet of Things (IIoT) in Filtration; a panel discussion on the ISO 16890 standards; as well as sessions on air purification, media design and measuring air filter energy efficiency.

Filtration 2017 kicks off on Oct. 10 with the one-day Nonwoven Filter Media Training Course prior to the exposition on Oct. 11-12. The industry reception will be Oct. 11, from 5 to 6 p.m., on the show floor.

The following is a preview of what some exhibitors will be showing off in Chicago.

Ahlstrom-Munksjö

Booth 312

Ahlstrom-Munksjö is a global leader in fiber-based materials, supplying innovative and sustainable solutions to customers worldwide.

Ahlstrom-Munksjö has leading global positions in several segments with global reach and has expanded product and service offerings and improved service, design and R&D capabilities. The company was formed on April 1, 2017 through the merger of Ahlstrom Corporation and Munksjö Oyj.

Ahlstrom-Munksjö’s product offering for the filtration market is growing. It is expanding its filtration product portfolio with a major investment at its Madisonville plant in Kentucky. By enhancing its capabilities, it is creating even more solid long-term partnerships.

The filtration market continues to grow and the needs of especially industrial segments continue to evolve. Air quality standards are becoming closer to the real-life environments and the filter media performance must be adapted to perform in the highest levels.

As an example, Ahlstrom-Munksjö has expanded its gas turbine air intake product range and it covers both, pulse-jet and static media needs. Products have excellent performance even in extremely demanding filtration environments.

www.ahlstrom-munksjo.com

Albarrie Canada Limited

Booth 830

Albarrie is a leading producer of specialty fabrics. At the heart of the organization is its advanced needlefelt operation with multiple production lines including wide width, heavy weight and tubular needlefelt processing. These specialized processing lines can integrate fiber blends, layering/supporting materials to produce engineered fabrics from four to 120 oz/yd2.

The organization also boasts a wide array of finishing capabilities to customize fabrics and meet demanding performance specifications. Finishing capabilities include lamination, coating, impregnation, heat treating, singeing and calendering.

At Filtration 2017, Albarrie will be sharing two filtration fabrics that are exclusive to the company: Fabrics needled to Basalt fibers (P84, PPS, and Polyox), and fabrics that contain Polyoxadiazole fiber also known as Polyox. These combinations possess unique properties that no other filtration fabric on the market can match.

www.albarrie.com

American Truetzschler Inc.

Booth 115

Truetzschler Nonwovens’ equipment ranges from pilot or laboratory lines to complete spunlacing, needling, thermo- and chemical bonding lines.

Machinery for pilot lines—the MiniJet spunlacing unit: The MiniJet is a specially designed spunlacing unit serving the need of institutes and companies requiring research and development work or supplying niche markets. Due to proven features of the AquaJet—such as the jet head and the spunlacing drum—all manmade and natural fibers can be processed. The MiniJet allows for water pressures up to 400 bar. This feature, in combination with working width of 500, 1000 and 1300 mm and speeds up to 55 m/min, opens the door to the production of demanding end-products. The modular container design minimizes costs for erection and start-up.

Complete lines—flexible thermo and binder bonding line: Thermobonding nonwovens in a drum oven results in high-quality, bulky materials. A new development by Truetzschler Nonwovens is a line including a drum dryer/oven as well as a foulard, a can dryer and a hot flue unit. In the thermobonding process, the drum oven is used as a thermobonder while all other components are bypassed. When using a liquid agent, the drum dryer is used for drying the nonwoven before entering the hot flue. This line concept is especially suited for the production of light weights webs.

www.am-truetzschler.com

Bdtronic

Booth 814

Bdtronic’s new atmospheric pressure plasma device, for all standard and high-performance plasma applications, will work optimize the surface tension on a large variety of materials. The plasma technology in Bdtronic’s VP4 is perfect for all ultra-fine cleaning or activation processes prior to bonding, soldering, injection molding, gluing, printing, or any other process that requires a clean and optimal surface energy to create adhesion. Its repeatable and stable process is guaranteed by its continuous process control. This process control is made possible by its proprietary software that keeps control of and monitors each and every relevant parameter. All VP4 systems can be easily integrated into a production line, whether manual, lean or fully automated production line. In order to ensure an efficient energy transfer, with no voltage drop, Bdtronic has removed any voltage cable to supply the compact plasma head with power. Instead, it uses a high flex cable to power the plasma head. Additionally, the air supply to the head is adjusted automatically, according to the set power. That allows the VP4 to dynamically change the plasma power during production. Bdtronic’s VP4 offers a light weight and reliable plasma solution at the optimal price.

www.bdtronic.com

Bondex

Booth 624

Bondex is introducing Hydrolox, a new technology to the industrial filtration market, produced from unique process technology that delivers superior filtration performance versus incumbents. Today’s utilities and industrial users are demanding higher performance filtration; filters that deliver improved collection efficiency with lower operating costs. Historically, industrial filtration felt was produced through a traditional needle loom which has met some market needs with a specific balance of properties. Hydrolox filter media, available only from Bondex, combines the benefits of needle loom fiber entangling with revolutionary hydroentangling technology to deliver industry leading dust collection performance. The phenomena of entangling fibers with high pressure water jets creates a unique balance of lower pore size in a strong media. Hydrolox represents a new paradigm in filtration by delivering a product with dramatically improved filtration efficiency, an inherent ability to promote surface dust collection, lower pressure drop over time, and reduction in pulse cycle times. Additionally, Hydrolox HCE is available as a family of filtration media using fine fibers that deliver even higher collection efficiency performance, comparable to membrane laminated needlefelt. Hydrolox and Hydrolox HCE are available in PPS, PET, Aramid, PTFE, Polyimide, Acrylic and others, in weights up to 17 oz/yd2¬.

www.bondexinc.com

Chase Machine and Engineering

Booth 418

For over 60 years, Rhode Island-based Chase Machine and Engineering has designed and built custom web handling systems and process equipment for many of the largest and most progressive filter media and filter manufacturers in the world.

Chase’s talented team of mechanical, automation and electrical engineers, along with its experienced and diverse manufacturing technicians, provides its customers the best custom automated equipment solution to compete and win in today’s worldwide and growing filtration Industries.

For those interested in product development, the Chase Materials Applications Lab exists to help their engineering team take their ideas, create new or improved product and determine the optimum method for producing it. Lab capabilities include web handling systems with ultrasonic technology for laminating, embossing, welding, slitting as well as cutting-to-length.

www.chasemachine.com

Fibertex Nonwovens

Booth 908

Fibertex Nonwovens, a market-leading nonwovens manufacturer with sites in the U.S., Denmark, France, Czech Republic, Turkey and South Africa is highlighting its new unique range of 100% synthetic pleatable filter media Pleatex, which sets the new standard for pleated filter products.

These media are a unique building platform for all filter manufacturers within both air and liquid filtration. Customized weight, air permeability and surface treatments on demand.

Pleatex is a synthetic inherent pleatable filter media, which has pleating behavior similar to cellulose and glass fiber media, like no other synthetic media. Pleatex can be processed on all kinds of different pleaters such as rotary pleaters, knife and blade pleaters. Production runs show that Pleatex undertakes faster pleating compared to other synthetic media when pleated on a rotary pleater.

Embossed pleat packs are possible to ensure lower pressure drop and better dust distribution. Pleatex is stiff and rigid enough to maintain in shape also when pulsed.

Pleatex product range from MERV 8 and upwards.

Besides its new Pleatex product range, Fibertex Nonwovens also produces a full range of different air and liquid filter media based on needlepunch, spunlace, spunbond and highloft production technologies.

www.fibertex.com

Fil-Tec

Booth 230

Fil-Tec’s American made products for the filter bag industry will help customers improve their efficiencies and reduce cost. Fil-Tec manufactures an extensive line of sewing thread and bobbins made from fiberglass, Nomex, polyester, PTFE and Conex fibers designed to keep machines and tubers running. Fil-Tec’s line of snap band gasket material has become the industry standard, lowering sewing room costs by eliminating extra sewing steps. Fil-Tec’s cuff bead and static dissipation ground wire give customers the finishing touches to a superior filter bag. Fil-Tec’s solutions extend to the baghouse with its door seal products for customers’ baghouse access doors.

Fil-Tec Inc. is introducing a new 9 lb. put up of fiberglass sewing thread for tubers designed to increase tuber efficiency, its new Conex easy sew thread for Nomex and other high temp bags, and its new line of high temp snap band gaskets.

www.fil-tec.com

Herrmann Ultrasonics

Booth 881

Continuous welding of filtration material requires the highest level of precision. The Herrmann Ultrasonics Microbond CSI system, consisting of the VE Actuator, Microgap controller and high-performance Ultrabond generator guarantees consistent weld quality. Integrated in all Microbond systems is the patented Microgap control process, which ensures constant production quality via closed loop processing by monitoring the gap between the sonotrode and the anvil drum.

The Microbond CSI technology energy is only directed to the weld bond points and does not further restrict the filter laminate, nor change the fiber content; with typical thermal bonding heat radiates outside the bond zone.

Small bond points safeguard against restricted airflow, a common problem when using adhesives.

Multi-laminate structures with/without mesh reinforcement can simultaneously be incorporated.

Pinholes are eliminated using the Microbond CSI technology.

Loss of performance due to bonding errors is reduced to 0.5-4%.

Herrmann Ultrasonics has become the technology leader in ultrasonic welding by developing the most advanced products, providing ultrasonics engineering expertise and total solution offerings. The ultrasonic process can be used in the final assembly of the filtration product. Herrmann Ultrasonics is focused on providing ultrasonic welding technology for various markets such as the consumer, medical, food, hygiene and automotive industries.

www.herrmannultrasonics.com

Hollingsworth & Vose

Booth 402

Hollingsworth & Vose is a leading global manufacturer of advanced materials for filtration, battery separator and industrial applications operating manufacturing sites and research centers in the Americas, Asia, Europe, and India.

At Filtration 2017, H&V will be showing off its filter media for:

- Room Air Cleaner, Cabin Air, and Facemask - Introducing AlphaPERM - meltblown air filtration media offering 40% lower resistance compared to standard meltblown media.

- Cabin Air - Technostat and AlphaPERM particulate layers for high efficiency with low pressure drop solutions. Selection of high performance carbons to optimize gas and odor removal.

- Gas Turbine / Dust Collector - NANOWEB for advanced microfiltration composite media available in cellulose/synthetic blends, synthetic/glass wetlaid and 100% synthetic wetlaid options.

- Fuel — Efficiency >99.9% @ 4 micron and emulsified water separation from fuel is >95% in all-synthetic, nanofiber, microfiber glass, and cellulose-based fiber options.

- Lube - Efficiency > 99% @ 20 micron while offering excellent capacity and cold start performance, available in cellulose based, to cellulose/synthetic blends, to full synthetic.

- HVAC / Pocket and Rigid Filter — NanoWave synthetic media results in longest filter life through highest dust loading capacity

Math2Market

Booth 623

The innovative simulation software GeoDict from Math2Market GmbH is the most complete solution for the digital design of filters and filter media. GeoDict is the answer to broaden the boundaries of existing filters and to find new specialized solutions for filtration applications.

Starting from three-dimensional scans (µCT, FIB/SEM) of filter media, CAD models, or user-defined parameters it is straightforward to: model filter elements, pleats, and media, such as nonwoven, woven, glass- and steel-fiber, metal and plastic meshes, ceramics, foams, cellulose, membranes, diesel and gasoline particulate filters; simulate gas and liquid filtration processes: air, water, oil, fuel; analyze porosity, pore size distribution, bubble point, fluid flow, particle movement and deposition, MPPS, depth filtration, cake formation, dust holding capacity; design filter media and pleats to fit specifications and improve pressure drop, filter efficiency, filter selectivity, and filter lifetime.

The GeoDict solution incorporates personalized support, consultation, assistance and trainings in using simulation to create and vary filter media designs, to optimize processes, and to resolve complex filtration questions quickly and cost-effectively. The final goal is to cut prototyping and R&D costs and gain a competitive edge by accelerating design and production.

www.math2market.com

Midwest Filtration

Booth 611

Many customers call Midwest Filtration LLC the drug store of nonwovens. At its booth, visitors will find many types of nonwovens in one place. These are stocked at its Cincinnati warehouse in mill rolls and are ready to be converted by one of 12 re-rolling and slitting machines in rolls ranging in width from one to 150 inches in a short turn time. In addition, die-cutting machines can cut them into many shapes and sizes. Midwest Filtration’s highly experienced seamers can sew and heat-seal them into tubes, bags and sleeves.

At its booth this year, Midwest Filtration is featuring a new nonwoven filter media called Unipoly PSB. It is a new point-bonded, spunmelt polyester available in basis weights ranging from 17-140 gsm. Its distinctive low denier fibers create excellent uniformity. The unique manufacturing process creates greater strength properties (Tensile and Mullen) than similar spunmelt polyesters. As a result, many applications can consider using lower basis weights to achieve the same or better results.

www.midwestfiltration.com

Möller

Booth 514

Möller in Meschede/Germany is a leading European manufacturer of extruded plastic frames and accessories for the air filter industry. Möller distributes all of its products in more than 40 countries globally.

Möller produces frames and accessories for ¾ and 1-inch bag filters as well as for 2”, 3”, 4”, 6” and 11.5” panel box filters with and without header frame.

Moreover, Möller will display its new 4-V compact filter frame.

This new 4-V compact filter frame has several special features like carrying handles, self-contained mounting devices for the filter packs and the 4-V can be easily and safely stacked.

Thanks to the simple snap-in method, the frames and corner pieces are easy and fast to assemble. All frame profiles and corners are made of HIPS and can be completely incinerated.

www.moeller-profilsysteme.de

Nanoscience Instruments

Booth 930

For 15 years, Nanoscience Instruments has partnered with its customers to deliver a wide variety of analytical solutions. It specializes in three-dimensional sample imaging, in-situ tensile testing, surface science and nanoscale microscopy instrumentation. Its line of products includes benchtop SEMs, electrospinning nanofiber manufacturing, and micro and nanomanipulation systems. Nanoscience Instruments sells a variety of scientific equipment and accessories while providing ongoing applications support. Its extensive line of equipment and technical expertise enables it to serve its customers to find simple and high quality solutions.

www.nanoscience.com

Phifer Incorporated

Booth 318

Phifer Incorporated will showcase its portfolio of filtration and performance meshes at Filtration 2017.

With more than 60 years of weaving excellence, Phifer is a one-stop shop for industrial meshes that add strength and support to virtually any type of medium, including cellulose, glass and synthetic. Meshes are available in woven aluminum, epoxy-coated low carbon steel, vinyl-coated fiberglass, and vinyl-coated polyester mesh performance fabrics. In addition to filtration, netting and reinforcement substrates, Phifer’s meshes are used in ventilation, wind screens, auto bug screens, pool skimmers and covers, and construction and agricultural netting.

Phifer is registered by Underwriters Laboratories, Inc., to the International Organization for Standardization (ISO), and all performance metals and fabrics undergo rigorous in-house inspections to ensure top quality.

www.phifer.com

Rando Machine

Booth 315

Rando Machine designs and manufactures quality airlaid machinery for a wide variety of major industries such as: automotive, abrasives, filtration, health and hygiene and furniture. Its machinery also has a strong history of making significant contributions in other specialty applications such as military, aerospace and agriculture. For nearly 70 years, Rando Machine Corporation has played a leading role in the evolution of the airlaid process in the nonwovens market and it continues to offer its customers opportunities to constantly improve their products.

As a recognized industry leader in the development and fabrication of nonwoven fiber processing systems, Rando Machine provides quality equipment for use in media filtration. These systems are designed to filter oil, gas, air, water, and agricultural products using a vast variety of fiber materials. Rando employs a range of equipment to fulfill its customers’ filtration needs, including feeders, webbers, opener/blenders and edge trim slitters, among others.

Rando equipment, in conjunction with that of its strategic partners, provide seamless, high quality turnkey solutions by offering machinery for fiber preparation, web formation, shredding/refiberizing (waste reclaiming), as well as ovens, winding/stacking, controls and other converting equipment.

www.randomachine.com

Sandler

Booth 608

At this year’s Filtration show, Sandler will present a wide range of synthetic filtration nonwovens. Efficient pocket filter media and pleatable nonwovens for ventilation and air conditioning maintain their efficiency even after discharge. Nonwovens for cabin air and engine air filters help improve the indoor air quality in vehicles. Fuel filter media protect the engine and contribute to efficient combustion. Synthetic vacuum cleaner bags reliably trap dirt particles and dust and foster a higher suction power.

In light of growing metropolitan areas, more and more vehicles on the roads and increasing air pollution, efficient filter media are in higher demand than ever to ensure optimum indoor air quality, particularly in public spaces. New norms and testing standards, above all the new ISO 16890, are shaping the industry. The norm bases filter classification on more realistic criteria and also takes into account the energy efficiency during operation of the filter unit.

Sandler’s new synthetic filter medium enAIRsave combines long-term performance and reduced energy usage. Multiple filter layers provide optimum dust separation across the entire width of the medium. The particles are primarily deposited in the coarse meltblown layer as well as the pre-filter layer. Air can still flow through the filter at a relatively low pressure and, consequently, at a reduced energy consumption.

www.sandler.de

Superior Felt & Filtration

Booth 120

With the completion of an additional environmentally controlled white room, Superior Felt & Filtration has expanded its medical filtration converting and fabrication capabilities to offer technology driven collating, control room slitting, offline needling, medical adhesive coating, heat sealing, ultrasonic’s, die cutting, printing and private label packaging. By incorporating various high efficiency filtration (electrostatic) media like Technostat, used in conjunction with spunbonds, mesh and other filtration substrates and composites, SFF continues to have an industry leading edge in respiratory, viral, bacterial, home care industry, HEPA, safety masks and respirators, cosmetic and wound care applications. Superior Felt & Filtration’s technical nonwovens and value added services reach into other industries like automotive, aerospace, appliance and cross platform industrial markets. With a world-class engineering and research and development department as well as a wealth of internal testing capabilities like Fractional Efficiency, CFM, MERV and NIOSH analysis, Superior has the unique ability to take a customer’s filtration application from concept to completion.

www.superiorfelt.com

Thrace Nonwovens & Geosynthetics

Booth 724

Thrace Nonwovens & Geosynthetics is going to exhibit its PP yarns used for filtration products. Thrace Group PP Multifilament Yarns are the ideal starting material for weaving, braiding and twisting. Their technical characteristics offer resistance to acids and alkalis. The wide range of Thrace’s PP Multifilament Yarns is supported by a rich color palette that includes natural, black and a large variety of colors, with tested color fastness. They all offer excellent technical parameters, with high tenacity, chemical resistance and flexibility. Precision winding is available for coarse yarns. High quality twisting ensures an excellent result in warping and weaving, especially for the filtration fabrics production.

www.thracegroup.com