Karen McIntyre, Editor03.09.17

The continuously growing aging population, a pending baby boom and the acceleration of urbanization have driven growth in the Chinese disposable hygiene product industry, allowing it to develop at an unprecedented pace. However, ever-demanding consumer requirements and the competition of imported high end products, pose great challenges for hygiene product manufacturers to improve quality and differentiate their product ranges. What can equipment manufacturers—as a critical part of the value chain—do, to grow with customers and achieve a win-win? Lin Yingzong, the GM of Guangzhou Xingshi Equipments Co., Ltd. may provide some valuable inputs.

Years of Hard Work Equals Success

Founded in 1999, as the first fully servo-motor driven sanitary napkin product line developer in China, Xinshi Equipment enjoys a strong reputation across China and in Southeast Asia with its brand name “Xinshi Equipment” in the hygiene manufacturing machinery industry. Remember the early startups, Lin says, “At first, we didn’t think too much. My previous working experience at Nordson, where I started in 1994, enabled me to have very good understanding of the hygiene product industry through sales, after-sales, installation, commissioning and service maintenance. ”

After leaving Nordson, for three years Lin ran a tooling business, which also has many connections within the hygiene product industry. In 1999, Mr. Lin got a very important opportunity.

“One of my clients wanted to upgrade an existing sanitary napkin production lines, which failed after using excessive time and energy. They came to me to see if I could help redesign and produce the machine according to their requirements. We came up with a fully servo-driven wing-protection sanitary napkin manufacturing line within 15 months. The customer was satisfied with the machine from every aspect—including production speed, precision, stability, production efficiency. Based on this successful case, we have new orders continuously come in.”

This customer was Johnson & Johnson.

At that time, there were only a few companies in the world that could provide a fully servo-driven sanitary napkin production lines. No suppliers in China or Asia offered this kind of machine by then. So, Lin tried.

Now that it had its momentum, Xingshi continues to focus on technology developments, introducing the first baby diaper production line, stack machine and a 2000 pieces-per-minute pad production line that incorporates fully servo-driven technology. This achieves high speed, high efficiency, high performance stability, safety and easy operation making it competitive with the world’s most advanced technologies. If we just compared the cost and the performance of the international and local machines at that time, local machines cost less than 20% of the international ones with a much lower performance. For example, local diaper machine speeds were about 300 pieces/minute. Therefore it is not difficult to understand the excitement the local industry experienced at the launching of the first fully servo-driven machine from Xingshi. The company therefore earned its reputation for innovation, dedication, high quality and reliability.

Lin says, “Our first sanitary napkin machine produced 800 pieces per minute, its competitive performance to its international competitors offered a high cost performance option for J&J.” Ever since then, Xingshi started cooperating with J&J, and today, Xingshi is a very important member of the J&J global supply chain. Especially in South East Asia, J&J and its ODM system is one of Xingshi’s major customer group with more than 20 machines are running in J&J facilities in India, including its first introduced production (exactly the first fully servo-driven line of Xingshi), which also runs soundly at 800pieces/minutes.

In addition to J&J, Xingshi has a long-term cooperation with Hengan (the biggest local hygiene producer in China) and Guangxi Jieling, which has also helped further establish its reputation in the hygiene market. In 2002, Hengan imported two production lines specifically for its “seven dimensional space” product line. However, the machines failed to deliver products with required accuracy. Then, Hengan ordered another four fully servo-driven sanitary napkin lines from Xingshi, marking the first time that Hengan used this technology, which proved to be a success. In 2003, Guangxi Jieling decided to market mix packed products so they needed pad production lines immediately. “We delivered satisfactory results for the two clients in a very short time with production speed and qualified rates that met their standards. The cooperation signified very important milestone for us,” Lin recalls.

Grow Together With Key Clients

Xingshi Equipment has kept its position by clearly, focusing on key clients instead of hurrying to expand its customer base. Lin explains, “We focus on key customers and help them expand business, then we try to get more orders from them as well. The cooperative cycle runs in good condition and every party wins.” For example, one Malaysian customer purchased a sanitary napkin production line in 2001. Since then Xingshi has provided more than five renovation services for this machine to help the customers meet its continued product upgrading needs.

Lin says, “Every production line we manufactured is customized according to client’s requirements. We invest heavily in research and development to meet their high demand on performance. For example, when we develop a functional model, we are not just modeling and simulating the product but manufacturing the practical machine and will put it into production only after it has passed all the necessary tests. ” Although the meticulous process may increase the costs, by doing so, we can better help our clients to realize the differentiation goal.”

It is fair to say, the growth of Xingshi is accompanied with the development of clients, and the support of Xingshi Equipment is also vital for the success of its clients. Most of the production lines of the “Seven Dimensional Space” from Hengan, which achieved significant marketshare in China’s sanitary napkin market, are produced by Xingshi machines. “So, we would like to say, the continuous upgrading of the ‘Seven Dimensional Space’ in all the past years is closely connected with the advancement of Xingshi Equipment,” Lin says.

“Hengan continued to propose new requirements each year, either for the production speed, the product precision or the complexity of the product’s structure. Theses force us to keep our technology improving. The whole process is also fruitful, as we never stop making new breakthroughs in equipment precision and technology advancement.”

Eager to Progress through Innovation and Upgrading

As Xingshi Equipment has established its reputation for high speeds, reliable and high cost-performance ratios in the industry. In recent years, the company has focused its product and performance development efforts on its customers’ practical needs. For example, the company combines different driving technologies such as servo, pneumatic, hydraulic and mechanical movement systematically as required to achieve highly automatic electromechanical integrated machines. “We have in-line material lamination and a consistent tension control system that is adaptive to different material applications, and we have incorporated technologies including 2D/3D cotton core module, automatic zero speed reduction roll change and vision inspection systems. If needed, we will develop new products with customers, to help them replace and upgrade equipment and products so their equipment can cope with the market trends at the lowest cost in the shortest time.” Mr. Lin says.

As a result, in 2015, Xingshi delivered a decent report. Their important cooperative project with Hengan-the napkin pants production line has been installed and put into operation successfully. The high speed cotton-core napkin machine developed by Xingshi for J&J has reached 1500 piece/minute with reliable performance, which have passed Johnson’s global system verification and will be the used as Johnson’s global demonstration machine. The high speed napkin equipment developed with Jieling integrates fully automatic stack and packaging machines that used Xingshi’s unique technologies, which provides an example for local peers. In addition, the high speed adult diaper manufacturing equipment, elastic ring-waist baby diaper machine and baby pull-up diaper production line developed with other well-known diaper manufactures also got positive feedback and repeat orders.

In 2015, Xingshi set up Guangzhou Xingshi Scientific Co. Ltd with an aim to establish an industrial 4.0 platform that combines automatic storage systems, internet capabilities, smart production and the ability to synergize the company’s experience and automation technology.

Ready for Expansion

Xingshi Equipment continues to maintain strong cooperation with old customers, while at the same time, its reputation attracts more and more new clients, which result a capacity shortage before 2015 for the company, a situation quite different from other peer players.

“Capacity is one of our bottlenecks that have contained our fast development to cope with the increasing orders. We have many orders that demand several lines at the same time, for example, we once had an order that need 12 same production lines. At that time, we were only installing one line at a time, and it’s very difficult to meet the demand either based on inventory or by new parts purchasing. ”

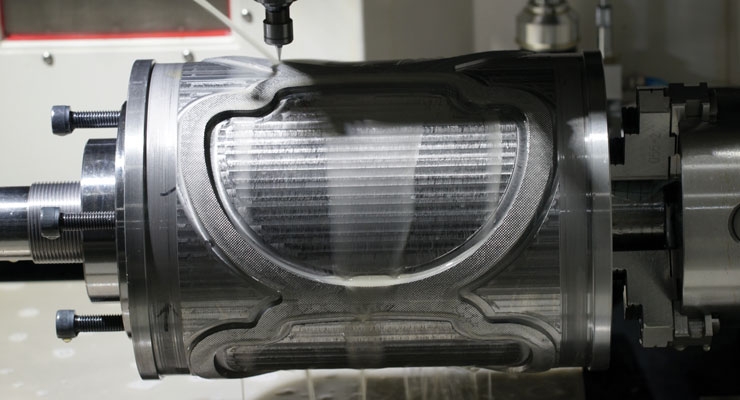

From 2010 to 2012, Xingshi invested more than RMB 60 million in machining facilities to enable precision machining in house. Then after about three years and repeated test and trials, the parts production capability is now comparable to international standards—thanks to a huge advancement in equipment accuracy and the appearance of the machines built.

Lin is satisfied with this investment. “We used to enjoy great advantage in electro control system, now our precision machining ability allows us to make even greater improvements in mechanical parts accuracy and product quality and the coordination of different units. These capabilities are enough to support our independent development and manufacturing. Today, we can deliver equipment with higher accuracy, reliability and speed. At the same time, we have shortened equipment commissioning time and increase the efficiency significantly. ”

The previous hurdle of the capacity that restrained Xingshi from serving clients and developing markets does not exist any longer after five years of working to upgrade its capacity. Mr. Lin summarized, “Started in 2015, we have and will put more emphasis and resources in market development in the coming three years, especially the overseas market development, to prepare us better for the challenges of entering a global market.”

Years of Hard Work Equals Success

Founded in 1999, as the first fully servo-motor driven sanitary napkin product line developer in China, Xinshi Equipment enjoys a strong reputation across China and in Southeast Asia with its brand name “Xinshi Equipment” in the hygiene manufacturing machinery industry. Remember the early startups, Lin says, “At first, we didn’t think too much. My previous working experience at Nordson, where I started in 1994, enabled me to have very good understanding of the hygiene product industry through sales, after-sales, installation, commissioning and service maintenance. ”

After leaving Nordson, for three years Lin ran a tooling business, which also has many connections within the hygiene product industry. In 1999, Mr. Lin got a very important opportunity.

“One of my clients wanted to upgrade an existing sanitary napkin production lines, which failed after using excessive time and energy. They came to me to see if I could help redesign and produce the machine according to their requirements. We came up with a fully servo-driven wing-protection sanitary napkin manufacturing line within 15 months. The customer was satisfied with the machine from every aspect—including production speed, precision, stability, production efficiency. Based on this successful case, we have new orders continuously come in.”

This customer was Johnson & Johnson.

At that time, there were only a few companies in the world that could provide a fully servo-driven sanitary napkin production lines. No suppliers in China or Asia offered this kind of machine by then. So, Lin tried.

Now that it had its momentum, Xingshi continues to focus on technology developments, introducing the first baby diaper production line, stack machine and a 2000 pieces-per-minute pad production line that incorporates fully servo-driven technology. This achieves high speed, high efficiency, high performance stability, safety and easy operation making it competitive with the world’s most advanced technologies. If we just compared the cost and the performance of the international and local machines at that time, local machines cost less than 20% of the international ones with a much lower performance. For example, local diaper machine speeds were about 300 pieces/minute. Therefore it is not difficult to understand the excitement the local industry experienced at the launching of the first fully servo-driven machine from Xingshi. The company therefore earned its reputation for innovation, dedication, high quality and reliability.

Lin says, “Our first sanitary napkin machine produced 800 pieces per minute, its competitive performance to its international competitors offered a high cost performance option for J&J.” Ever since then, Xingshi started cooperating with J&J, and today, Xingshi is a very important member of the J&J global supply chain. Especially in South East Asia, J&J and its ODM system is one of Xingshi’s major customer group with more than 20 machines are running in J&J facilities in India, including its first introduced production (exactly the first fully servo-driven line of Xingshi), which also runs soundly at 800pieces/minutes.

In addition to J&J, Xingshi has a long-term cooperation with Hengan (the biggest local hygiene producer in China) and Guangxi Jieling, which has also helped further establish its reputation in the hygiene market. In 2002, Hengan imported two production lines specifically for its “seven dimensional space” product line. However, the machines failed to deliver products with required accuracy. Then, Hengan ordered another four fully servo-driven sanitary napkin lines from Xingshi, marking the first time that Hengan used this technology, which proved to be a success. In 2003, Guangxi Jieling decided to market mix packed products so they needed pad production lines immediately. “We delivered satisfactory results for the two clients in a very short time with production speed and qualified rates that met their standards. The cooperation signified very important milestone for us,” Lin recalls.

Grow Together With Key Clients

Xingshi Equipment has kept its position by clearly, focusing on key clients instead of hurrying to expand its customer base. Lin explains, “We focus on key customers and help them expand business, then we try to get more orders from them as well. The cooperative cycle runs in good condition and every party wins.” For example, one Malaysian customer purchased a sanitary napkin production line in 2001. Since then Xingshi has provided more than five renovation services for this machine to help the customers meet its continued product upgrading needs.

Lin says, “Every production line we manufactured is customized according to client’s requirements. We invest heavily in research and development to meet their high demand on performance. For example, when we develop a functional model, we are not just modeling and simulating the product but manufacturing the practical machine and will put it into production only after it has passed all the necessary tests. ” Although the meticulous process may increase the costs, by doing so, we can better help our clients to realize the differentiation goal.”

It is fair to say, the growth of Xingshi is accompanied with the development of clients, and the support of Xingshi Equipment is also vital for the success of its clients. Most of the production lines of the “Seven Dimensional Space” from Hengan, which achieved significant marketshare in China’s sanitary napkin market, are produced by Xingshi machines. “So, we would like to say, the continuous upgrading of the ‘Seven Dimensional Space’ in all the past years is closely connected with the advancement of Xingshi Equipment,” Lin says.

“Hengan continued to propose new requirements each year, either for the production speed, the product precision or the complexity of the product’s structure. Theses force us to keep our technology improving. The whole process is also fruitful, as we never stop making new breakthroughs in equipment precision and technology advancement.”

Eager to Progress through Innovation and Upgrading

As Xingshi Equipment has established its reputation for high speeds, reliable and high cost-performance ratios in the industry. In recent years, the company has focused its product and performance development efforts on its customers’ practical needs. For example, the company combines different driving technologies such as servo, pneumatic, hydraulic and mechanical movement systematically as required to achieve highly automatic electromechanical integrated machines. “We have in-line material lamination and a consistent tension control system that is adaptive to different material applications, and we have incorporated technologies including 2D/3D cotton core module, automatic zero speed reduction roll change and vision inspection systems. If needed, we will develop new products with customers, to help them replace and upgrade equipment and products so their equipment can cope with the market trends at the lowest cost in the shortest time.” Mr. Lin says.

As a result, in 2015, Xingshi delivered a decent report. Their important cooperative project with Hengan-the napkin pants production line has been installed and put into operation successfully. The high speed cotton-core napkin machine developed by Xingshi for J&J has reached 1500 piece/minute with reliable performance, which have passed Johnson’s global system verification and will be the used as Johnson’s global demonstration machine. The high speed napkin equipment developed with Jieling integrates fully automatic stack and packaging machines that used Xingshi’s unique technologies, which provides an example for local peers. In addition, the high speed adult diaper manufacturing equipment, elastic ring-waist baby diaper machine and baby pull-up diaper production line developed with other well-known diaper manufactures also got positive feedback and repeat orders.

In 2015, Xingshi set up Guangzhou Xingshi Scientific Co. Ltd with an aim to establish an industrial 4.0 platform that combines automatic storage systems, internet capabilities, smart production and the ability to synergize the company’s experience and automation technology.

Ready for Expansion

Xingshi Equipment continues to maintain strong cooperation with old customers, while at the same time, its reputation attracts more and more new clients, which result a capacity shortage before 2015 for the company, a situation quite different from other peer players.

“Capacity is one of our bottlenecks that have contained our fast development to cope with the increasing orders. We have many orders that demand several lines at the same time, for example, we once had an order that need 12 same production lines. At that time, we were only installing one line at a time, and it’s very difficult to meet the demand either based on inventory or by new parts purchasing. ”

From 2010 to 2012, Xingshi invested more than RMB 60 million in machining facilities to enable precision machining in house. Then after about three years and repeated test and trials, the parts production capability is now comparable to international standards—thanks to a huge advancement in equipment accuracy and the appearance of the machines built.

Lin is satisfied with this investment. “We used to enjoy great advantage in electro control system, now our precision machining ability allows us to make even greater improvements in mechanical parts accuracy and product quality and the coordination of different units. These capabilities are enough to support our independent development and manufacturing. Today, we can deliver equipment with higher accuracy, reliability and speed. At the same time, we have shortened equipment commissioning time and increase the efficiency significantly. ”

The previous hurdle of the capacity that restrained Xingshi from serving clients and developing markets does not exist any longer after five years of working to upgrade its capacity. Mr. Lin summarized, “Started in 2015, we have and will put more emphasis and resources in market development in the coming three years, especially the overseas market development, to prepare us better for the challenges of entering a global market.”