Company Headquarters

Via Corradino D'Ascanio, 3

Alanno (Pescara), 65020

Italia

Company Description

Our Corporate Video

“Extra Value for Innovative Films” is the Equity of Texol Group, headquartered in the Pescara “diaper valley” area, Italy, since 2005. We produce perforated films, nonwovens and laminated substrates with environmentally friendly solutions consistent with the circular economy model, through our own technology solutions.

We support a solid international Intellectual Property strategy and sponsor a Social Responsibility business model, both as caring for people and designing technologies that meet Sustainability criteria, with the positive impact of reducing the greenhouse gas emission. We’re in compliance with the standard ISO 9001:2015, the Forest Steward Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC), together with Sustainability & Safety standards of the products, conform to “Ok Compost Industrial” and “Oeko-Tex” requirements.

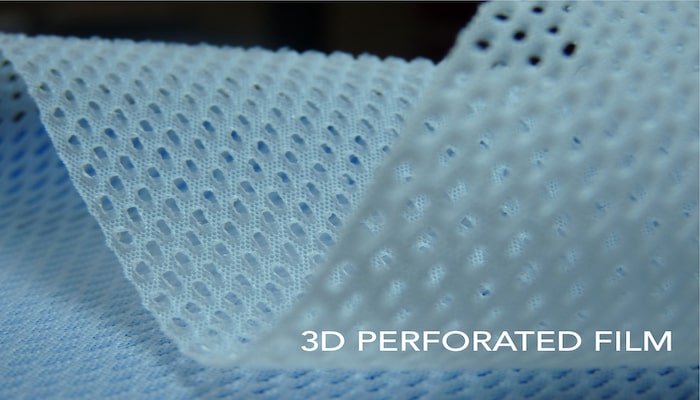

By means of our proprietary perforation technology for extrusion film, we have been able to deliver a material for topsheet application in Femcare with unique and unsurpassed dryness and softness consumer experience, allowing our customers to deliver product superiority. Our Key technological pillars are: 3D perforated poly and nonwoven with high tridimensional characteristics and technical laminated material for Femcare; breathable trilaminated elastic material for side panel, for baby diapers and for training pants; special nonwoven deep-embossed topsheet for Babycare, Adultcare and Light Inco products.

Our extreme flexibility allows us to satisfy different sectors, where there is the request of apertured films and laminates for filtration or as a support for other materials. To better serve all South & Central America markets we have also started the production in Chile, Via our Joint Venture with the company Winpack.

In 2017 Texol acquired the majority of hydroentanglement product manufacturer Orma Ormaitalia.com, an Italian company located in Pisticci Scalo - Matera, Italy, that offers spunlace nonwoven materials made of viscose bamboo, regular viscose, GOTS cotton hemp and other natural fibers, serving many fields such as: hygienic, automotive, ho.re.ca. (hotel, restaurant, catering), cleaning professional, wipes/babycare, medical/healthcare, industrial applications, specialties/laundry.

Our spunlace process is a unique nonwovens manufacturing system by means of high pressure water jets, that entangles staple fibers and with the capability to include cellulose fibers, providing fabric with high integrity without the use of any chemical binder and/or thermoplastic components. This is a very efficient solution to deliver absorbent structure for sanitary napkins under the “plastic free core” claim. The products are highly durable, absorbent, hypoallergenic and non-irritating. They can be perforated or embossed.

We have the capability to produce surface cleaning wipes and disposable tablecloth, using the “cross lapping technology”, whereby the fabric shows isotropic characteristics, meaning that the features in both machine direction & cross direction are almost the same.

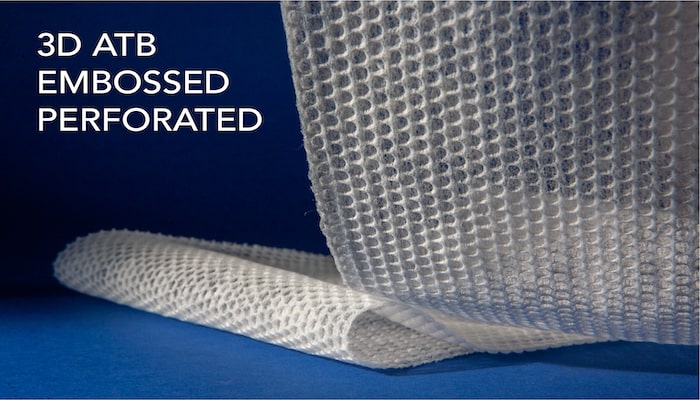

Our material technology portfolio includes “Air through bonding technology” too, a type of thermal bonding that involves the application of heated air to the surface of the nonwoven fabric. Nonwovens created by the ATB process have the characteristics of being uniform, soft, breathable and resilient. We use it to produce special nonwoven topsheet for baby/femcare, backsheet laminated and the “Hot Air Cotton”, perfectly suited to guarantee high loft wearing comfort of masks such as FFP2, preserving the efficiency of the filtering capacity.

Learn more here:

ormaitalia.com

texol.it

Buyers Guide Categories

Contract Services by Capability

Components

Have a password?

Content From Texol - Orma

-

Texol Group

Extra Value for innovative and sustainable films & nonwovensSponsored Content Released on 02.21.2023

-

“AIR THROUGH BONDING” FOR RESILIENT NONWOVENS BY TEXOL

The 3D online nonwoven technologySponsored Content Released on 06.29.2022

-

A solution for defense against infectious agents

Gowfense by Texol is the protective laminate for disposable gownsSponsored Content Released on 03.10.2021

Cookies help us to provide you with an excellent service. By using our website, you declare yourself in agreement with our use of cookies.

You can obtain detailed information about the use of cookies on our website by clicking on "More information”.

Copyright © 2024 Rodman Media. All rights reserved. Use of this constitutes acceptance of our privacy policy The material on this site may not be reproduced, distributed, transmitted, or otherwise used, except with the prior written permission of Rodman Media.