The need of green technologies and of high performing material has strengthened Texol's commitment to developing solutions as “air through bonded” nonwovens.

“Air through bonding” technology is a process that involves the application of heated air to the surface of the nonwoven fabric, to achieve web integrity: it is the only thermal bonding process that allows the entire product to be exposed to a uniform temperature.

The working environment and a much safer production process are due to the fact that air through bonded nonwovens are processed without the use of chemical binders, which also means no binder preparation is required.

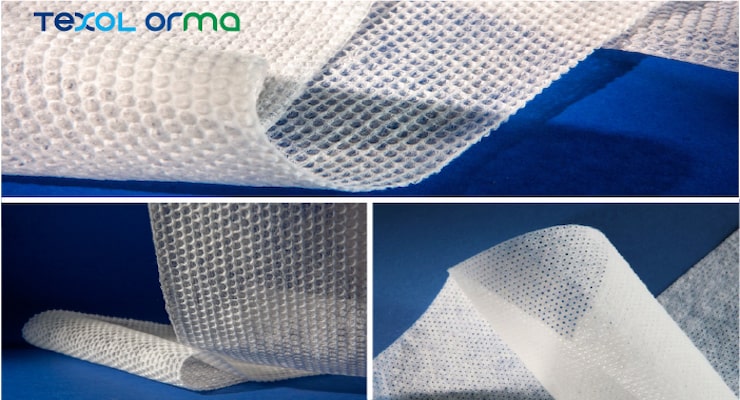

The nonwovens created by the ATB process have the characteristics of being resilient, soft, breathable, uniform and with lower basis weights.

ATB perforated and embossed nonwoven is used to produce topsheets and textile backsheets laminated for baby/femcare, in the range from 18 to 40 gsm.

Texol “Hot Air Cotton” is also the result of this technology, perfectly suited to guarantee high loft wearing comfort masks such as FFP2, preserving the efficiency of the filtering capacity.

Texol - Orma Group produces films, nonwovens and laminates with environmentally friendly solutions consistent with the circular economy through its own technologies, constantly investing in people, research and development.