Karen McIntyre, Editor01.03.20

Manufacturers of ultrasonic technologies agree—as innovation continues in the nonwovens industry, new opportunities for ultrasonics grow—especially as manufacturers continue learn more about the value of the technology.

A clean and efficient way of joining or slitting synthetic materials, ultrasonic bonding uses high frequency sound to generate localized heat through vibration and causes thermoplastic fibers to bond together. Suppliers in the industry say the technology offers several advantages.

The creation of a mechanical bond, rather than a chemical bond, allows a product to hold up better in extreme heat conditions while also being friendlier to the environment.

Following is a look at the latest innovations from some of the key suppliers of ultrasonic technology in the nonwovens industry.

Chase Machine and Engineering

Chase Machine and Engineering designs and builds custom machinery with a primary focus on the integration of ultrasonic technology for continuous and intermittent web applications. Working with the industry’s leading suppliers of ultrasonic technology, Chase supplies ultrasonic laminators, embossers, slitters and splicing equipment to manufacturers of nonwoven materials and converters to produce a variety of products for the hygiene, filtration, textile, packaging and personal care industry.

Chase’s facility, located in Rhode Island, has a dedicated lab for continuous ultrasonic testing. Customers can send product samples to Chase in order to collect invaluable data such as bond strength, embossing quality, slit quality, power requirements and processing line speed. Information that is crucial in determining quality, feasibility and payback.

When designing and fabricating converting machinery, speed is always a major factor. One of the drawbacks when using conventional ultrasonic technology has to do with processing speed, but that is changing with rotary horn technology. Rotary horn manufacturers have found ways to bond at speeds up to 2000 feet per minute. Unfortunately, there are still limitations. For instance, in order to achieve high speeds, material selection is crucial. It must be lightweight with a low melting temperature. Another drawback is the actual weld width that may be bonded. Rotary horn width maxes out at approximately four inches while conventional ultrasonic horns can weld bond uniformly up to nine inches wide. Finally, there is expense. Rotary horns require a drive mechanism to rotate the horn and match line speed. This is much more expensive than utilizing a fixed ultrasonic actuator.

Years ago, manufacturers of nonwoven materials struggled with consistency and uniformity in the product, however, that is no longer the case, says Chase president Guy Gil. “Of all the technologies available for joining nonwoven materials, ultrasonics is one of the most material dependent,” he says. “As nonwoven suppliers realized converters were looking for alternative ways to make their product faster and more efficient, much effort was spent improving their product. With improvements to spunbond and meltblown processing lines, nonwovens suppliers can now offer a more uniform product that may provide end users an ultrasonic lamination option.”

Cost and quality are driving changes in the industry. From a cost standpoint, ultrasonics is a clean and efficient method of embossing, laminating or slitting synthetic materials. While the initial investment is greater, the long term benefits more than pay for itself. Thermal methods such as hot oil or electrically heated systems require an initial preheat cycle in order to bring the tooling to operating temperature. Then, while running, there is a significant amount of heat loss. Ultrasonics is instantaneous. The operator can start and stop the equipment without worrying about over melting the materials being processed. It is also a very clean method of laminating as hoses or rotary unions that may leak over time are no longer needed. From a quality standpoint, once the process is dialed in, the consistency of the bond or pattern is unparalleled.

The beauty of ultrasonic technology is that it eliminates the need for consumables such as needle and thread or adhesives, Gil adds. “Not only does it save the end user money in both materials and downtime, but also helps product designers as they specify the materials used in the construction of the product. For instance, the need to select an appropriate adhesive that not only performs in the construction of the product, but is also safe for the consumer, is no longer a concern. Ultrasonic technology uses the actual chemistry of the fibers themselves to melt thereby creating a bond that is superior to that

of adhesive.”

Another benefit to using ultrasonics is that the products that are manufactured with this technology can most likely be recycled more easily as they are made of similar materials.

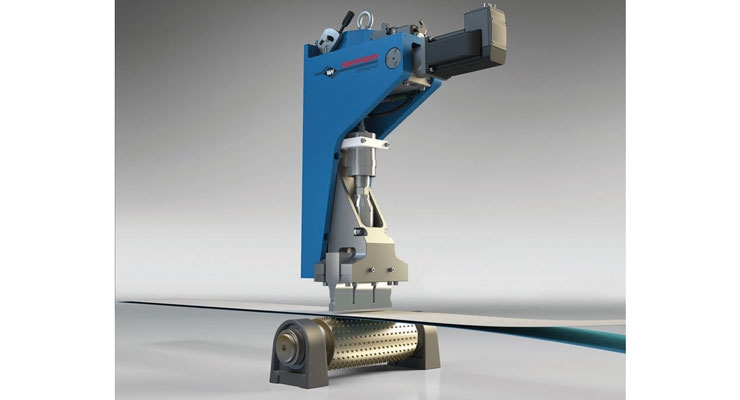

Herrmann Ultrasonics

Herrmann Ultrasonics has been developing interface protocols to support Industry 4.0, with the introduction of its new Microbond control system. It provides real time (1µs) detection of material and environmental variations and then compensates for deviations, resulting in consistent and repeatable bond quality.

“Process parameters can be viewed and analyzed in real time, for multiple bonding actuators, through the intuitive handheld touch display, which also allows for control of multiple actuators at the same time,” Dave Weiler, sales manager, Hygiene, says. “Listening to our customers’ needs and wants has led Herrmann to focus on transparency of

weld process.”

End users and OEM’s who are seeking to eliminate adhesives and improve machine efficiencies can rely on the Microbond system developed and patented by Herrmann Ultrasonics, which combines the advantages of low reject rates, fast set-up, no contamination, no consumables and reduced energy costs.

Nonwovens industries such as filter, textile, medical and consumer are turning to ultrasonics for welding, laminating, embossing, perforating and cutting. Ultrasonics allows for an efficient, continuous and closed loop process with increased productivity, making consumables such as adhesives, unnecessary.

Hygiene applications have an increased interest in ultrasonic technology, as they look to manufacturers for odorless, softer and quieter products. The four different global headquarters of Herrmann continue to develop and test new applications like ears, elastic laminations and constructions, ADL, core, TXBS and many more.

Sustainability is at the forefront of the industry and continues to be a driving force in product development, Weiler says. Ultrasonic welding technology is considered an environmentally friendly technology, using up to 75% less electric energy than other bonding methods. Bonding of various materials with ultrasonics does not require any consumables, making glue-free diapers a realistic and attainable achievement.

“Consumers are keeping an eye on what is used, not only to produce products but what impact disposed of goods have on our environment,” he adds. “When ultrasonic systems are used for bonding of materials, process efficiency increases while power consumption decreases, having the added benefits of being easily recyclable, as no additives

are needed.”

Ultrasonics brings added value to the customers with sustainable products and materials by removing hot melt adhesives from hygiene. This leads to less energy consumption and lower consumable and maintenance costs.

Sonobond Ultrasonics

Sonobond’s SeamMaster Ultrasonic Sewing Machines use a patented rotary process that is similar in operation to a traditional sewing machine, and its Ultrasonic PlungeBonders that seal the ends of thick and multi-layer materials, are the machines most often used to assemble hygiene products made of nonwovens including bedwetting protection and incontinence panties, surgical gowns and medical garments, face masks, wound dressings, mattress covers and similar medical disposable items, pouches used for sterilizing and storing medical and dental instruments, and lint-free cleaning wipes.

Sonobond’s ultrasonic assembly machines continue to keep pace with the hygiene industry,” says president Janet Devine. “We have been able to adapt our machinery to accommodate the latest nonwoven materials and assemble the new disposable and reusable products that are being designed for this market.”

Demand for disposable and reusable hygiene products is increasing, driven by aging baby boomers as well as stricter regulations on medical garments. Amidst this growth, the need for more eco-friendly products continues to rise.

“Ultrasonic technology is probably the most eco-friendly way to assemble hygiene and disposable products,” Devine says. “Our machines utilize high-frequency vibratory waves to soften and fuse synthetic and nonwoven fibers together, creating a strong molecular bond without stitch holes, glue gaps, fraying or unraveling. Since Sonobond’s machines seam and fuse the edges of the material, there is only a minimal amount of material that needs disposal. Traditional sewing or gluing leaves excess material that must often be cut off and discarded.”

In addition to eliminating the use of costly consumables such as thread or adhesives, ultrasonic assembly methods can increase production output, since it is up to four times faster than sewing and up to 10 times faster than gluing. Although the initial cost of a machine is considered a capital equipment expense, there are substantial Section 179 tax breaks for which a customer may qualify.

“We constantly improve the capabilities of our existing machinery through tooling developments to accommodate new nonwoven materials as they are developed, as well as meet and often exceed regulatory requirements developed to ensure new products meet the needs of the user and the environment,” Devine says.

A clean and efficient way of joining or slitting synthetic materials, ultrasonic bonding uses high frequency sound to generate localized heat through vibration and causes thermoplastic fibers to bond together. Suppliers in the industry say the technology offers several advantages.

The creation of a mechanical bond, rather than a chemical bond, allows a product to hold up better in extreme heat conditions while also being friendlier to the environment.

Following is a look at the latest innovations from some of the key suppliers of ultrasonic technology in the nonwovens industry.

Chase Machine and Engineering

Chase Machine and Engineering designs and builds custom machinery with a primary focus on the integration of ultrasonic technology for continuous and intermittent web applications. Working with the industry’s leading suppliers of ultrasonic technology, Chase supplies ultrasonic laminators, embossers, slitters and splicing equipment to manufacturers of nonwoven materials and converters to produce a variety of products for the hygiene, filtration, textile, packaging and personal care industry.

Chase’s facility, located in Rhode Island, has a dedicated lab for continuous ultrasonic testing. Customers can send product samples to Chase in order to collect invaluable data such as bond strength, embossing quality, slit quality, power requirements and processing line speed. Information that is crucial in determining quality, feasibility and payback.

When designing and fabricating converting machinery, speed is always a major factor. One of the drawbacks when using conventional ultrasonic technology has to do with processing speed, but that is changing with rotary horn technology. Rotary horn manufacturers have found ways to bond at speeds up to 2000 feet per minute. Unfortunately, there are still limitations. For instance, in order to achieve high speeds, material selection is crucial. It must be lightweight with a low melting temperature. Another drawback is the actual weld width that may be bonded. Rotary horn width maxes out at approximately four inches while conventional ultrasonic horns can weld bond uniformly up to nine inches wide. Finally, there is expense. Rotary horns require a drive mechanism to rotate the horn and match line speed. This is much more expensive than utilizing a fixed ultrasonic actuator.

Years ago, manufacturers of nonwoven materials struggled with consistency and uniformity in the product, however, that is no longer the case, says Chase president Guy Gil. “Of all the technologies available for joining nonwoven materials, ultrasonics is one of the most material dependent,” he says. “As nonwoven suppliers realized converters were looking for alternative ways to make their product faster and more efficient, much effort was spent improving their product. With improvements to spunbond and meltblown processing lines, nonwovens suppliers can now offer a more uniform product that may provide end users an ultrasonic lamination option.”

Cost and quality are driving changes in the industry. From a cost standpoint, ultrasonics is a clean and efficient method of embossing, laminating or slitting synthetic materials. While the initial investment is greater, the long term benefits more than pay for itself. Thermal methods such as hot oil or electrically heated systems require an initial preheat cycle in order to bring the tooling to operating temperature. Then, while running, there is a significant amount of heat loss. Ultrasonics is instantaneous. The operator can start and stop the equipment without worrying about over melting the materials being processed. It is also a very clean method of laminating as hoses or rotary unions that may leak over time are no longer needed. From a quality standpoint, once the process is dialed in, the consistency of the bond or pattern is unparalleled.

The beauty of ultrasonic technology is that it eliminates the need for consumables such as needle and thread or adhesives, Gil adds. “Not only does it save the end user money in both materials and downtime, but also helps product designers as they specify the materials used in the construction of the product. For instance, the need to select an appropriate adhesive that not only performs in the construction of the product, but is also safe for the consumer, is no longer a concern. Ultrasonic technology uses the actual chemistry of the fibers themselves to melt thereby creating a bond that is superior to that

of adhesive.”

Another benefit to using ultrasonics is that the products that are manufactured with this technology can most likely be recycled more easily as they are made of similar materials.

Herrmann Ultrasonics

Herrmann Ultrasonics has been developing interface protocols to support Industry 4.0, with the introduction of its new Microbond control system. It provides real time (1µs) detection of material and environmental variations and then compensates for deviations, resulting in consistent and repeatable bond quality.

“Process parameters can be viewed and analyzed in real time, for multiple bonding actuators, through the intuitive handheld touch display, which also allows for control of multiple actuators at the same time,” Dave Weiler, sales manager, Hygiene, says. “Listening to our customers’ needs and wants has led Herrmann to focus on transparency of

weld process.”

End users and OEM’s who are seeking to eliminate adhesives and improve machine efficiencies can rely on the Microbond system developed and patented by Herrmann Ultrasonics, which combines the advantages of low reject rates, fast set-up, no contamination, no consumables and reduced energy costs.

Nonwovens industries such as filter, textile, medical and consumer are turning to ultrasonics for welding, laminating, embossing, perforating and cutting. Ultrasonics allows for an efficient, continuous and closed loop process with increased productivity, making consumables such as adhesives, unnecessary.

Hygiene applications have an increased interest in ultrasonic technology, as they look to manufacturers for odorless, softer and quieter products. The four different global headquarters of Herrmann continue to develop and test new applications like ears, elastic laminations and constructions, ADL, core, TXBS and many more.

Sustainability is at the forefront of the industry and continues to be a driving force in product development, Weiler says. Ultrasonic welding technology is considered an environmentally friendly technology, using up to 75% less electric energy than other bonding methods. Bonding of various materials with ultrasonics does not require any consumables, making glue-free diapers a realistic and attainable achievement.

“Consumers are keeping an eye on what is used, not only to produce products but what impact disposed of goods have on our environment,” he adds. “When ultrasonic systems are used for bonding of materials, process efficiency increases while power consumption decreases, having the added benefits of being easily recyclable, as no additives

are needed.”

Ultrasonics brings added value to the customers with sustainable products and materials by removing hot melt adhesives from hygiene. This leads to less energy consumption and lower consumable and maintenance costs.

Sonobond Ultrasonics

Sonobond’s SeamMaster Ultrasonic Sewing Machines use a patented rotary process that is similar in operation to a traditional sewing machine, and its Ultrasonic PlungeBonders that seal the ends of thick and multi-layer materials, are the machines most often used to assemble hygiene products made of nonwovens including bedwetting protection and incontinence panties, surgical gowns and medical garments, face masks, wound dressings, mattress covers and similar medical disposable items, pouches used for sterilizing and storing medical and dental instruments, and lint-free cleaning wipes.

Sonobond’s ultrasonic assembly machines continue to keep pace with the hygiene industry,” says president Janet Devine. “We have been able to adapt our machinery to accommodate the latest nonwoven materials and assemble the new disposable and reusable products that are being designed for this market.”

Demand for disposable and reusable hygiene products is increasing, driven by aging baby boomers as well as stricter regulations on medical garments. Amidst this growth, the need for more eco-friendly products continues to rise.

“Ultrasonic technology is probably the most eco-friendly way to assemble hygiene and disposable products,” Devine says. “Our machines utilize high-frequency vibratory waves to soften and fuse synthetic and nonwoven fibers together, creating a strong molecular bond without stitch holes, glue gaps, fraying or unraveling. Since Sonobond’s machines seam and fuse the edges of the material, there is only a minimal amount of material that needs disposal. Traditional sewing or gluing leaves excess material that must often be cut off and discarded.”

In addition to eliminating the use of costly consumables such as thread or adhesives, ultrasonic assembly methods can increase production output, since it is up to four times faster than sewing and up to 10 times faster than gluing. Although the initial cost of a machine is considered a capital equipment expense, there are substantial Section 179 tax breaks for which a customer may qualify.

“We constantly improve the capabilities of our existing machinery through tooling developments to accommodate new nonwoven materials as they are developed, as well as meet and often exceed regulatory requirements developed to ensure new products meet the needs of the user and the environment,” Devine says.