Tara Olivo, Associate Editor06.05.19

Needlepunch continues to make gains in the nonwovens industry. The technology, which offers a lower start-up investment compared to other technologies, is known for its flexibility—allowing manufacturers to achieve several goals with just one line.

Gale Shipley, automotive sales manager of Conover, NC-based Dalco Nonwovens believes versatility and cost effectiveness is what’s driving the growth in needlepunch. “Needlepunch products can be customized for strength/stretch in both the machine direction and cross machine direction while having fiber mechanical locking in the ‘Z’ direction (thickness direction) for endurance,” she explains.

As an example, she says, current day products use needlepunch nonwovens on visible surfaces due to enhanced needle morphology/manufacturing processes/raw materials providing comparable abrasion resistance and visible aesthetics to other technologies. “The ‘shaggy dog’ needlepunch product is a thing of the past,” she assures.

Dalco’s needlepunched products can provide enhanced physical characteristics over spunbonds used in geotextiles and some automotive applications as a result of mechanical locking of the fibers verses heat fusion. “Most spunbonds have good strength in one direction only; however, Dalco’s needlepunch has strength in all directions,” Shipley says. “Contrary to technologies such as spunbond and spunlace that have restrictive weight limits, Dalco can manufacture products up to 2000 gsm opening the doors for many other opportunities in industries such as automotive and furniture.”

Another advantage of needlepunch is that it can be easily merged with other technologies, including spunbond, woven products, and film. At Dalco, some of these can be introduced in line, Shipley adds.

Jean-Philippe Dumon, sales director, Nonwoven, of machinery supplier Andritz Asselin-Thibeau says needlepunch products offer the advantage of utmost flexibility in responding to its customers’ requests, as they can have a wide range of weights—from 50 to 3000 g/m²—and can be created from an equally wide range of staple fibers including natural, synthetic, cellulose and technical.

INDA, the association of the nonwoven fabrics industry, reports that needlepunch producers are enjoying continuous growth in the market. In the last two years, 19 needlepunch lines have started up in North America. These are not all carded lines, but also include a few airformed lines and a spunbond line, according to Brad Kalil, director of Market Research & Statistics, INDA, adding that at least 13 of those lines are making some material for the transportation end-use category.

According to INDA’s North American Nonwovens Supply Report, 2018, needlepunch/stitchbond accounted for 23% of capacity in North America. The majority (70%) of the drylaid needlepunch production in 2018 was in the transportation, home & office furnishings and geosynthetic end-use categories. And, in the last five years (2013-2018) needlepunch capacity has expanded at a 4.4% annual rate, compared to the total market growth rate of 2.7%.

The result of this growth has been new investment as well as continued machinery advancements and new product development.

In North America, Thrace-Linq completed the installation of a new Andritz needlepunch line in Summerville, SC. The line, totaling $9 million, is designed to produce fabrics for geosynthetics, automotive and floor covering markets. An in-line tenter oven and calender, along with finished width capability beyond 20-feet are just a few of the features this equipment offers.

Meanwhile in Georgia, TenCate Geosynthetics Americas completed an expansion of nonwoven production at its Jefferson facility as a result of increased demand for high-quality nonwoven geotextiles. The production line has advanced fiber distribution capabilities to create a uniquely consistent product in appearance and finished roll dimension. It also has the largest card/cross lapper in the staple fiber geosynthetics industry to produce both polypropylene and polyester geotextiles, the company claims.

For its part, Foss Performance Materials is investing in a new Dilo needlepunch line that will significantly increase its production capacity at its Hampton, NH, location. Acquired by AstenJohnson in 2017, Foss has a long history of innovation within the automotive, technical, fiber and felt markets. Steve Polston, president – Nonwovens for AstenJohnson, says that the investment will further its mandate for growth and its ability to leverage the strengths of Foss with its AstenJohnson Nonwovens business. Commissioning of the line is expected in early 2020.

Auto-Tuned

The growing demand for electric vehicles has been a boon to the needlepunch market.

Andritz’s Dumon says the automotive industry is one of the most dynamic markets for the technology, “where there is an increasing need for lightweight and heavyweight applications to insulate against external noise, which has become more noticeable with the trend towards electrically powered vehicles.”

In response to this market need, Andritz is offering its Random Velours needleloom (SDV), which is based on a patented, angled brush alignment to prevent fabric defects. “The automotive industry also uses economical PET fibers, and inline velouring is becoming more popular so that the fibers can be processed with minimum breakage. In this way, the fibers have less time to dry before completing the full needling process,” he adds.

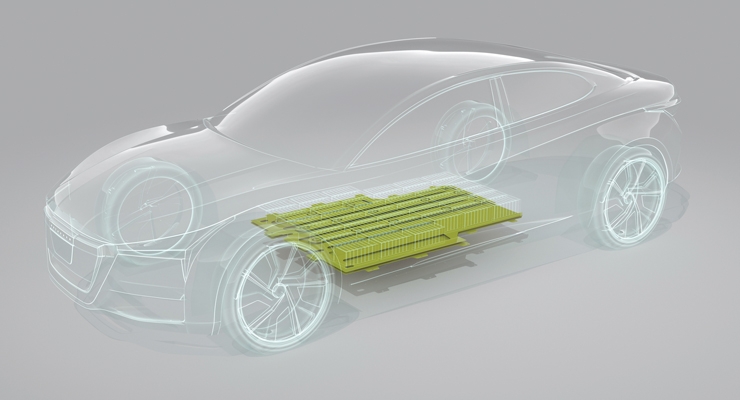

Autoneum, a specialist in acoustic and thermal management solutions, has focused its latest developments on the e-mobility market as sales of electric cars have grown worldwide. In order to support vehicle manufacturers in the production of lightweight and environmentally-friendly e-models, Autoneum has extended its product portfolio with textile battery undercovers made of Ultra-Silent that optimally meet the specific requirements for acoustic and thermal management of electric vehicles. Underbodies based on Ultra-Silent are made of molded nonwoven (needlepunched) PET.

The components act as insulators helping to lower sound that enters the passenger cabin, caused by tires, for instance, and also pass-by noise. Sound-reducing components are essential for electric models as well because external and internal sources such as fans, pumps and electronic drive components are more audible due to the lack of engine noise and accordingly influence driving comfort. The textile battery undercovers are also up to 50% lighter than corresponding components made of plastic and thus ensure a greater driving range.

Undercovers made of Ultra-Silent are installed underneath the battery casing, providing the battery cells with the best possible protection against significant cooling or heating and ensuring a constant temperature with a correspondingly optimized battery capacity. As a result, the components help to improve battery performance. They are also resistant to water, stone chipping and vibrations and thus help to protect the battery casing. In order to calibrate the temperature resistance and material stiffness of undercovers, Autoneum uses a broad range of internally developed simulation tools. They are deployed in both the development phase of new electric models as well as in the further development of those already on sale.

Lightweight components made of Ultra-Silent are mostly made from recycled PET fibers that can be fully reclaimed, and are produced in the company’s plants in Sevelen, Switzerland, Gundernhausen, Germany, Jeffersonville, IN, and Pinghu, China. They are already in use in models of European, U.S. and Chinese automobile manufacturers. From July 2020 onwards, the first battery undercovers will be produced in series at the Gundernhausen plant for the fully-electric model of a German premium manufacturer.

Another needlepunch-based innovation from Autoneum is its Tune-It product for carpets. Tune-It makes cars lighter, more comfortable and environmentally friendly, while also delivering ideal acoustic performance, the company says.

Tune-It is based on an innovative fiber combination in the carpet backing with which sound insulation and absorption can be tuned to the specific needs and geometry of the passenger cabin across the entire surface of the carpet. According to Autoneum, because of this technology, it is now possible to define the optimum insulation and absorption performance already during the development phase of new vehicle models by means of computer-aided simulations. As a result, needlepunch carpets based on Tune-It provide ideal noise protection in the passenger cabin. In addition, given a weight advantage of up to 25% compared to standard needlepunch carpets, components based on Tune-It also support reduced fuel consumption and less vehicle emissions.

The environmental footprint of this carpet technology that consists of 100% PET is also reflected in the fact that Tune-It based components are fully recyclable. Compared to conventional carpet molding, where non-recyclable production waste can reach a share of 30%, off-cuts produced during the manufacture of Tune-It can be processed into pellets and completely returned into the carpet manufacturing process in the form of fibers.

For its part, Freudenberg Performance Materials’ nonwovens based on Lutraflor technology for automotive carpets, insert mats and interior and trunk linings, can provide weight savings of up to 40% compared to conventional automotive carpets. Freudenberg utilizes recycled materials and a state-of-the-art velour needling process for a luxurious appearance and excellent wear characteristics. With balanced costs, reduced weights, improved performance and sustainability, the product is an advanced 100% PET sandwich construction with a velourized staple fiber surface and a spunlaid fabric base.

Meanwhile, Freudenberg & Vilene Nonwovens’ car headliners based on needlepunched technology continue to grow in the Asian market. In March, the joint venture between Freudenberg Performance Materials and Japan Vilene Company opened a new production line for car headliners at its Suzhou site in Eastern China. This enables the company to meet the increasing demand for high-quality car headliners in China and Southeast Asia. Freudenberg & Vilene Company first introduced printed headliners to the market in 2010.

With the new production line, Freudenberg will increase its annual production of technical textiles in Suzhou by around 8 million square meters. Customers will particularly benefit from higher quality of the next generation headliner products.

“This investment underscores our long-term commitment to Asia. We want to continue to support our customers in the automotive market with innovative and sustainable solutions that will help them grow,” says \Frank Heislitz, CEO of Freudenberg Performance Materials.

Freudenberg & Vilene Company headliners are based on nonwovens and can be finished in various ways to provide additional functionality. Apart from excellent surface appearance with good abrasion resistance, outstanding acoustic properties and improved stain resistance, these products contribute to higher comfort in the car interior as well as marked reduction in vehicle weight when combined with other vehicle components. In addition, the company also uses a proportion of recycled products in the manufacture of its products. In this way, Freudenberg helps its customers to reduce their environmental footprint.

Gale Shipley, automotive sales manager of Conover, NC-based Dalco Nonwovens believes versatility and cost effectiveness is what’s driving the growth in needlepunch. “Needlepunch products can be customized for strength/stretch in both the machine direction and cross machine direction while having fiber mechanical locking in the ‘Z’ direction (thickness direction) for endurance,” she explains.

As an example, she says, current day products use needlepunch nonwovens on visible surfaces due to enhanced needle morphology/manufacturing processes/raw materials providing comparable abrasion resistance and visible aesthetics to other technologies. “The ‘shaggy dog’ needlepunch product is a thing of the past,” she assures.

Dalco’s needlepunched products can provide enhanced physical characteristics over spunbonds used in geotextiles and some automotive applications as a result of mechanical locking of the fibers verses heat fusion. “Most spunbonds have good strength in one direction only; however, Dalco’s needlepunch has strength in all directions,” Shipley says. “Contrary to technologies such as spunbond and spunlace that have restrictive weight limits, Dalco can manufacture products up to 2000 gsm opening the doors for many other opportunities in industries such as automotive and furniture.”

Another advantage of needlepunch is that it can be easily merged with other technologies, including spunbond, woven products, and film. At Dalco, some of these can be introduced in line, Shipley adds.

Jean-Philippe Dumon, sales director, Nonwoven, of machinery supplier Andritz Asselin-Thibeau says needlepunch products offer the advantage of utmost flexibility in responding to its customers’ requests, as they can have a wide range of weights—from 50 to 3000 g/m²—and can be created from an equally wide range of staple fibers including natural, synthetic, cellulose and technical.

INDA, the association of the nonwoven fabrics industry, reports that needlepunch producers are enjoying continuous growth in the market. In the last two years, 19 needlepunch lines have started up in North America. These are not all carded lines, but also include a few airformed lines and a spunbond line, according to Brad Kalil, director of Market Research & Statistics, INDA, adding that at least 13 of those lines are making some material for the transportation end-use category.

According to INDA’s North American Nonwovens Supply Report, 2018, needlepunch/stitchbond accounted for 23% of capacity in North America. The majority (70%) of the drylaid needlepunch production in 2018 was in the transportation, home & office furnishings and geosynthetic end-use categories. And, in the last five years (2013-2018) needlepunch capacity has expanded at a 4.4% annual rate, compared to the total market growth rate of 2.7%.

The result of this growth has been new investment as well as continued machinery advancements and new product development.

In North America, Thrace-Linq completed the installation of a new Andritz needlepunch line in Summerville, SC. The line, totaling $9 million, is designed to produce fabrics for geosynthetics, automotive and floor covering markets. An in-line tenter oven and calender, along with finished width capability beyond 20-feet are just a few of the features this equipment offers.

Meanwhile in Georgia, TenCate Geosynthetics Americas completed an expansion of nonwoven production at its Jefferson facility as a result of increased demand for high-quality nonwoven geotextiles. The production line has advanced fiber distribution capabilities to create a uniquely consistent product in appearance and finished roll dimension. It also has the largest card/cross lapper in the staple fiber geosynthetics industry to produce both polypropylene and polyester geotextiles, the company claims.

For its part, Foss Performance Materials is investing in a new Dilo needlepunch line that will significantly increase its production capacity at its Hampton, NH, location. Acquired by AstenJohnson in 2017, Foss has a long history of innovation within the automotive, technical, fiber and felt markets. Steve Polston, president – Nonwovens for AstenJohnson, says that the investment will further its mandate for growth and its ability to leverage the strengths of Foss with its AstenJohnson Nonwovens business. Commissioning of the line is expected in early 2020.

Auto-Tuned

The growing demand for electric vehicles has been a boon to the needlepunch market.

Andritz’s Dumon says the automotive industry is one of the most dynamic markets for the technology, “where there is an increasing need for lightweight and heavyweight applications to insulate against external noise, which has become more noticeable with the trend towards electrically powered vehicles.”

In response to this market need, Andritz is offering its Random Velours needleloom (SDV), which is based on a patented, angled brush alignment to prevent fabric defects. “The automotive industry also uses economical PET fibers, and inline velouring is becoming more popular so that the fibers can be processed with minimum breakage. In this way, the fibers have less time to dry before completing the full needling process,” he adds.

Autoneum, a specialist in acoustic and thermal management solutions, has focused its latest developments on the e-mobility market as sales of electric cars have grown worldwide. In order to support vehicle manufacturers in the production of lightweight and environmentally-friendly e-models, Autoneum has extended its product portfolio with textile battery undercovers made of Ultra-Silent that optimally meet the specific requirements for acoustic and thermal management of electric vehicles. Underbodies based on Ultra-Silent are made of molded nonwoven (needlepunched) PET.

The components act as insulators helping to lower sound that enters the passenger cabin, caused by tires, for instance, and also pass-by noise. Sound-reducing components are essential for electric models as well because external and internal sources such as fans, pumps and electronic drive components are more audible due to the lack of engine noise and accordingly influence driving comfort. The textile battery undercovers are also up to 50% lighter than corresponding components made of plastic and thus ensure a greater driving range.

Undercovers made of Ultra-Silent are installed underneath the battery casing, providing the battery cells with the best possible protection against significant cooling or heating and ensuring a constant temperature with a correspondingly optimized battery capacity. As a result, the components help to improve battery performance. They are also resistant to water, stone chipping and vibrations and thus help to protect the battery casing. In order to calibrate the temperature resistance and material stiffness of undercovers, Autoneum uses a broad range of internally developed simulation tools. They are deployed in both the development phase of new electric models as well as in the further development of those already on sale.

Lightweight components made of Ultra-Silent are mostly made from recycled PET fibers that can be fully reclaimed, and are produced in the company’s plants in Sevelen, Switzerland, Gundernhausen, Germany, Jeffersonville, IN, and Pinghu, China. They are already in use in models of European, U.S. and Chinese automobile manufacturers. From July 2020 onwards, the first battery undercovers will be produced in series at the Gundernhausen plant for the fully-electric model of a German premium manufacturer.

Another needlepunch-based innovation from Autoneum is its Tune-It product for carpets. Tune-It makes cars lighter, more comfortable and environmentally friendly, while also delivering ideal acoustic performance, the company says.

Tune-It is based on an innovative fiber combination in the carpet backing with which sound insulation and absorption can be tuned to the specific needs and geometry of the passenger cabin across the entire surface of the carpet. According to Autoneum, because of this technology, it is now possible to define the optimum insulation and absorption performance already during the development phase of new vehicle models by means of computer-aided simulations. As a result, needlepunch carpets based on Tune-It provide ideal noise protection in the passenger cabin. In addition, given a weight advantage of up to 25% compared to standard needlepunch carpets, components based on Tune-It also support reduced fuel consumption and less vehicle emissions.

The environmental footprint of this carpet technology that consists of 100% PET is also reflected in the fact that Tune-It based components are fully recyclable. Compared to conventional carpet molding, where non-recyclable production waste can reach a share of 30%, off-cuts produced during the manufacture of Tune-It can be processed into pellets and completely returned into the carpet manufacturing process in the form of fibers.

For its part, Freudenberg Performance Materials’ nonwovens based on Lutraflor technology for automotive carpets, insert mats and interior and trunk linings, can provide weight savings of up to 40% compared to conventional automotive carpets. Freudenberg utilizes recycled materials and a state-of-the-art velour needling process for a luxurious appearance and excellent wear characteristics. With balanced costs, reduced weights, improved performance and sustainability, the product is an advanced 100% PET sandwich construction with a velourized staple fiber surface and a spunlaid fabric base.

Meanwhile, Freudenberg & Vilene Nonwovens’ car headliners based on needlepunched technology continue to grow in the Asian market. In March, the joint venture between Freudenberg Performance Materials and Japan Vilene Company opened a new production line for car headliners at its Suzhou site in Eastern China. This enables the company to meet the increasing demand for high-quality car headliners in China and Southeast Asia. Freudenberg & Vilene Company first introduced printed headliners to the market in 2010.

With the new production line, Freudenberg will increase its annual production of technical textiles in Suzhou by around 8 million square meters. Customers will particularly benefit from higher quality of the next generation headliner products.

“This investment underscores our long-term commitment to Asia. We want to continue to support our customers in the automotive market with innovative and sustainable solutions that will help them grow,” says \Frank Heislitz, CEO of Freudenberg Performance Materials.

Freudenberg & Vilene Company headliners are based on nonwovens and can be finished in various ways to provide additional functionality. Apart from excellent surface appearance with good abrasion resistance, outstanding acoustic properties and improved stain resistance, these products contribute to higher comfort in the car interior as well as marked reduction in vehicle weight when combined with other vehicle components. In addition, the company also uses a proportion of recycled products in the manufacture of its products. In this way, Freudenberg helps its customers to reduce their environmental footprint.