05.03.19

With its trend theme, ‘Urban Living – City of the Future’, the international trade fair Techtextil taking place May 14-17 in Frankfurt, Germany, is taking a look ahead to see how technical textiles will shape urban life in the future.

“Every two years, Techtextil mirrors the range of applications for textile materials. Leading international experts from the most diverse industries – be they from architecture, the automotive industry, medicine, the fashion industry or personal protection – come together at Techtextil in search of lightweight, durable and sustainable materials,” says Olaf Schmidt, vice president Textiles and Textile Technologies, Messe Frankfurt.

The suppliers at Techtextil represent the complete spectrum of technical textiles and nonwovens. There is a significant increase in the number of suppliers in the fields of technology, as well as fibers and yarns. Suppliers of woven fabrics, coated textiles and functional apparel textiles are also strongly represented. All areas of application for textile materials are covered. In particular, representatives from industry, architecture and construction, the fashion and clothing industry, the automotive sector, aerospace, medicine, sport, and hazard protection will find a more comprehensive range of products than before.

In collaboration with ‘Creative Holland’, the Dutch creative industries, Techtextil is dedicating an exhibition space to life in the city of the future with the ‘Urban Living – City of the Future’ special event. According to the United Nations, nearly 70% of all people are expected to be living in metropolises and megacities by 2050. This poses new challenges for living and mobility concepts, as well as food supplies and health services provision. Functional apparel, with smart functions for example, could also play an even more important role in people’s everyday lives in the future. The Techtextil and Texprocess exhibition area will be presenting examples of textile applications. In addition, an accompanying complementary program will offer insights into the industry.

On all four days, the trade fair will offer a new format of lectures, discussions and interactive sessions with the Techtextil Forum. The forum, which replaces the Techtextil Symposium, will take place directly in exhibition Hall 4.1 and all Techtextil participants will be able to access it free of charge. Trade visitors can look forward to contributions in the following thematic areas: sustainability, digital transformation, smart textiles, urban textiles, composites, and technical textiles in medical technology. In addition, both the Dornbirn Global Fiber Congress (GFC) and the textiles competence center at the General Association of the German Textile and Fashion Industry (Gesamtverband der deutschen Textil- und Modeindustrie e. V.) are organizing a thematic block.

For the 15th time now, Techtextil will be giving the Techtextil Innovation Award for outstanding new and further developments in the field of technical textiles, nonwovens and functional apparel fabrics. Both exhibitors and non-exhibitors at Techtextil can take part in the competition.

Sustainability is one of the central themes of the upcoming Techtextil and Texprocess. For the first time, the two fairs will be showcasing their exhibitors’ efforts towards sustainability. The Techtextil and Texprocess Innovation Awards give prizes for sustainable textile innovations and processing approaches. In addition, the Texprocess Forum will offer a thematic block exclusively around the theme of sustainability in the textile and fashion industry, with an offshoot of Fashionsustain, Messe Frankfurt’s conference about sustainable textile innovations.

In May 2019, Techtextil and the parallel Texprocess will be sharing an exhibition hall for the first time. In Hall 4.1, Techtextil will be showcasing some of the suppliers of woven, laid web, braided and knitted fabrics, coated textiles, and nonwovens, as well as selected suppliers of textile machines. Suppliers of functional apparel textiles and the ‘Digital Textile Micro Factory’ mark the transition to Texprocess, which will be showcasing different production lines for clothing, shoes, and the processing of technical textiles. In addition to these, exhibitors for product preparation, finishing, textile logistics, internal material flow and textile refinement, as well as providers of sewing solutions, will be there. In the shared hall, visitors will get an insight into the entire production process, from raw material to finished product.

In the next few pages, Nonwovens Industry will provide a glimpse of what some exhibitors plan to bring to Techtextil. And, we will be reporting live on key developments from Techtextil. Look for our breaking news e-mail blasts during the show.

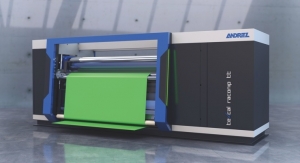

Andritz

Hall 3.0, B15

International technology Group Andritz will be presenting its innovative nonwovens production and textile solutions at Techtextil 2019. Andritz supports its customers in every aspect of nonwovens and textile processes and services with its most advanced expertise and complete technology solutions.

The long tradition of excellent calender technology for the textile industry is now continued with the teXcal Raconip TT calender. The teXcal Raconip TT mainly targets customers experienced in the manufacture of technical textiles with highest quality standards, for example, sports and work wear, sailcloth, parachute fabrics, or packaging materials.

The teXcal Raconip TT offers the operator a number of features that are useful during operation. For example, user-friendly access to all relevant areas of the calender, excellent data management for the calender process and product quality in real time, and extended maintenance intervals.

Overall, Andritz has focused on versatility and flexibility in development of the new textile calender – properties that should make this equipment more competitive. In addition, the calender contains an innovative, deflection-controlled roll, the Raconip TT. It offers highest flexibility by providing unrestricted profiling over the entire fabric width by means of hydrostatic pistons. This ensures top quality, such as absolute flatness and spot-on air permeability. The new calender has been developed in cooperation with Rolf Ramisch, a well-known specialist in textile calender technology.

Andritz will introduce visitors to the processing of glass fibers with wetlaid technology. Nonwoven end products based on glass fibers can be found almost everywhere: in ceiling tiles, cushion vinyl flooring, insulation, wallpaper and surfaces, geotextiles, batteries, roofing materials, as well as other applications. Glass fiber as a basic component is an excellent composite material and offers numerous advantages that lend the resulting products unique properties. And because of its wide range of applications, products made of glass fiber material have a strong, growing market.

The manufacture of products based on glass fibers requires particularly gentle treatment in the stock preparation and laying processes. Andritz meets these requirements perfectly. At Techtextil, Andritz Wetlaid experts will present details of this new configuration to interested visitors for the first time.

Another focus of Andritz at Techtextil 2019 is its needlepunch technology, which the company has been supplying successfully for many years to a variety of industries such as geotextiles, roofing materials, filtration, technical felts, carpeting, and many more.

One of Andritz’s main areas of needlepunch excellence is the needlelooming process, which gives the material the decisive properties for consistently high quality. Andritz needlelooms include pre-needling units as well as standard needlelooms and, above all, specialized needlelooms that can be fully adapted to the customers’ needs.

Due to the versatile specifications and processing quality of its needleloom systems combined with robustness for a sustainable product life cycle, Andritz presents its solutions for further innovative end uses wherever this form of mechanical bonding is required.

With a 3D-print model of the SDV needleloom at the booth in conjunction with Augmented Reality, the visitor can gain a unique insight into the Andritz smart service solutions marketed under the Metris technology brand name. This includes the new Metris spare part catalog as well as digitally based technical documentation.

www.andritz.com

Autefa Solutions

Hall 3.0, H31

During Techtextil, visitors will experience future-proof solutions for improving quality and productivity while visiting Autefa Solutions in Hall 3.0, H31. The company presents its portfolio as a full-line supplier for carded- crosslapped needlepunch lines, aerodynamic web forming technology, spunlace and thermobonding lines.

Autefa Solutions lines cover the needs of the highly-competitive nonwovens market. An improved and even surface quality has been set as key target by the customers. Therefore, Autefa Solutions offers the service of a customized needle board pattern. The i-Point needling simulation tool increases the capacity and the quality of needlepunched fabrics. The development of new needle patterns and the evaluation of surface quality is much more effective and economic with the i-Point software technology. It creates a layout of stripper and bed plate including the elliptic needling (Variliptic). This customized design of needle pattern, which takes also draft and shrinkage into consideration, reduces the process optimization time on customer site. Autefa Solutions needlepunch lines produce an even and homogenous fabric with outstanding technical performance in terms of tensile strength and evenness (MD/CD ratio).

www.autefa.com

Brückner

Hall 3.0, F29

Particularly in the field of hygiene nonwovens, the trend goes towards products of a better quality with a smoother handle, more volume and of more uniform texture. Nonwovens producers worldwide are supported by the new Brückner Supra-Flow BA belt oven, which gives them the technology to produce such high quality end products.

The new Supra-Flow BA guarantees a particularly gentle transport of the unbonded web. This is achieved by a sophisticated air circulation design. It is also characterized by minimum heat consumption, high flow uniformity and constant temperature distribution over the entire working width. The good accessibility of the oven chamber leads to a high maintenance friendliness. The dryer is available in working widths up to 4600 mm. It is designed for production speeds of up to 250 m/min and thus offers potential for line optimization.

Typical end products, which are bonded on the Brückner Supra-Flow BA high-end thermofusion oven according to the air-through principle, are nonwovens for diapers (ADL, topsheet, backsheet), nonwovens for feminine care and incontinence products but also filter nonwovens and special nonwovens.

One year ago Brückner presented the revised double belt oven for thermofusion of high-loft nonwovens to the expert public. The aim was to reduce the use of primary energy with a view to resource-conserving nonwovens production and thus to reduce production costs. With the double belt furnace Supra-Flow BX, established in the market, Brückner’s’s engineers have succeeded in achieving not only this increase in efficiency, but also the re-construction of the air circulation with fewer individual parts in the sense of the guiding principle “a good design is simple”. Furthermore there were many small detail improvements, which led to the fact that in 2018 so many Supra-Flow BX were sold in different configurations, as never before.

The oven is suitable for the production of high-loft nonwovens, medium as well as highly compressed fiber boards made of natural, synthetic and/or recycled fibres. It is a convective oven system which works according to the air-through principle. In each compartment the flow direction can be individually adjusted according to the product requirement. In most cases the basic material beside the matrix fibers are binding fibers melting at low temperatures such as bi-component fibers (PES/CoPES, PP/PR) and PP. Thermoplastic or duroplastic powders can be used also as binders.

The Supra-Flow BX is particularly suitable for products with a higher weight, thickness and/or density and relatively high pressure losses during the flow through the product. The following processes can be implemented on the system: Thermofusion (for bonding PP, PET/CoPET, PP/PE), heat-setting and drying. The Supra-Flow BX is of particular interest to manufacturers of mattresses, duvets, inserts, insulation, furniture (upholstery, cushions), cleaning (dry and wet wipes, painter’s cover foils), automotive components (headliners, thermal insulation, noise insulation, seat covers), thermal and acoustic insulation in the construction industry and carrier materials (floor coverings, technical coatings).

This type of oven is particularly suitable for the gentle drying of binder-bonded lightweight nonwovens. For such lines Brückner can supply the belt dryer type Supra-Flow BE as well as the foam padder, the cylinder dryer group and a smoothing calender downstream of the dryer. The Brückner Supra-Flow BE is successfully in operation and produces high-quality nonwovens for the medical sector.

Brückner has again improved and further developed its minimum application unit. The customer has the following advantages over a padder: Low-Add-On technology (fabric moisture < 60 g/m²), low water consumption, high energy savings in the subsequent drying processes, low residual liquor (2.5 l per m working width) and thus fewer chemicals which have to be disposed of during a batch change.

The Eco-Coat unit enables impregnation and precise one-sided Kiss Roll coating on the upper or lower side of the fabric web as well as functionalization such as hydrophobization or softener application by means of engraving roller pre-dosing. In addition, one-sided ink jet preparation is possible. Single-sided functionalizations with a wide variety of finishing chemicals can be realized, especially for fashion and technical applications. Brückner offers at any time the possibility to carry out tests on the laboratory plant in Leonberg with the advice of technologists.

www.brueckner-textile.com

DiloGroup

Hall 3.0, H33

Techtextil is one of the most important exhibitions in the field of nonwovens and Dilo has participated since its inception in 1986. During a history of more than 100 years Dilo has always set new standards with technologies like Hyperpunch and Di-Lour needling. These developments have opened new markets for nonwovens and raised the bar regarding quality and efficiency.

The development cycles in machine building cannot be measured in months. Therefore we are pleased that one of our latest developments in horizontal crosslappers, the “Hyperlayer” is now being installed in several spunlace production lines. This crosslapper can realize infeed speeds up to 200 m/min due to its special design and is ideal for a low number of layers of lightweight webs.

Our Dilo-“Hypertex” installation, consisting of a yarn laydown unit from Messrs. Ontec and subsequent needling, provides highly efficient inline production of reinforced needlefelts. With this system, scrim structures and preneedled weblayers can be needled together at speeds up to 20 m/min.

The new needle arrangement “8000 X” ensures homogeneous distribution of needle penetrations in the felt over a wide range of advance/stroke. The results are considered a breakthrough for improved surface qualities, particularly for car interiors.

The concepts above are only part of our continuous development and refinement work for needling and spunlacing lines.

www.dilo.de

Freudenberg Performance Materials

Hall 3.1, F37

Under the heading “Meet your experts,” Freudenberg Performance Materials will be presenting innovative technical textiles for the automotive, medical and apparel markets from May 14 to 17, 2019, at Techtextil.

Alongside personal discussions, the leading supplier of innovative technical textiles will be hosting a series of expert interviews at its booth. Freudenberg works with the broadest technology platform on the market. This enables the leading manufacturer of performance materials to equip technical textiles with an unparalleled variety of properties. The innovations Freudenberg will be presenting at Techtextil are excellent examples of this ability. Via the expert interviews, Freudenberg will also be giving trade fair visitors the opportunity to gain a good insight into these solutions, even if they do not wish to make an individual appointment. The interviews will be conducted several times a day at times that will be clearly communicated at the company’s booth.

Good acoustics in vehicles increase driving comfort. This factor is also very important for electric cars, as the alternative drives are quieter than combustion engines and other noises of different frequencies are more strongly perceived. Freudenberg will be presenting innovative Acoustic Pads that feature exceptionally high noise absorption in the vehicle interior. The lightweight pads are a very cost-effective solution and also help customers to reduce the weight of vehicles. Freudenberg Acoustic Pads are ideally suited for use in various automotive applications such as door panels, headliners, trunk linings, wheel arches and more.

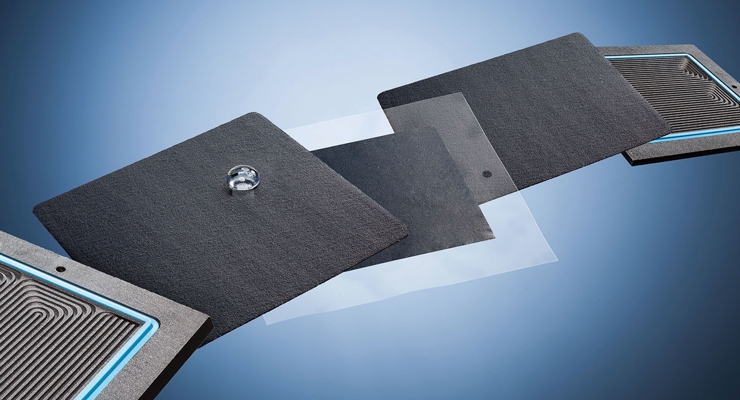

The fuel cell is already being used successfully in a number of applications and is regarded as a decisive energy source of the future. Freudenberg’s series-produced gas diffusion layers (GDL) contribute to making this technology more economical. Their pronounced thickness uniformity and material homogeneity increase electrical and thermal conductivity and improve the transport of gases and liquids within the fuel cell. The outstanding properties have been demonstrated in a broad range of very different customer applications. At the same time, Freudenberg’s GDL can be processed better than other products and exhibit superior mechanical properties.

Wound pads are a component of medical wound dressings. Freudenberg wound pads made from hydrophilic PU foams with a direct coating of silicone adhesives are significantly more effective than the commonly used foams with transfer coatings. They are much more flexible, adapt better to the wound bed, and enable antibacterial treatments to better develop their effectiveness. Moreover, the reduction of process steps and complexity during manufacture saves energy, avoids waste and simplifies the supply chain.

With comfortemp fiberball padding eco, Freudenberg will be presenting the world’s first padding made from continuous fiber balls, which functions as a perfect substitute for down in clothing. This novel insulation material is made from 100% recycled polyester fiber balls and combines the advantages of both padding and down. It is the ideal solution for the sports and outdoor sector, but is also suitable for use in fashion garments. It is manufactured without the use of chemicals, offers optimum breathability and is super-soft and fluffy.

www.freudenberg-pm.com

Groz-Beckert

Hall 3.0, F03

At Techtextil, Groz-Beckert, a leading supplier of industrial machine needles, will exhibit its comprehensive product and service portfolio in the knitting, weaving, felting, carding and sewing product areas.

The Felting area presents an absolute novelty with Groz-Beckert customized product: Thanks to the customizable customer label, Groz-Beckert customers not only benefit from enhanced know-how protection, but also from more security and safety when handling needles in production.

Another highlight of the stand is the 3D print model of the staple fiber needling line (SVL). The SVL has been available to Groz-Beckert customers and partners for the last two years at the company’s Albstadt headquarters, in the Technology and Development Center (TEZ), in Germany.

Within the traditional nonwovens industry, Groz-Beckert’s Gebecon felting needle offers the best possible fracture/bending properties and thus optimized needling parameters, as well as an improved surface quality of the final product. Groz-Beckert will be presenting details of the patented shape of working part of this needle at the trade fair stand using a man-sized needle exhibit. Groz-Beckert also has such an exhibit ready for spunlace customers: In addition to its improved handling properties, the innovative HyTec P jet strip also has a significantly higher hardness, which has a positive effect on all mechanical properties such as scratch resistance, flexural rigidity and service life.

The Carding area completes Groz-Beckert’s product range for the nonwovens industry. At Techtextil visitors can directly compare different tooth geometries. The worker and user sets SiroLock and EvoStep, for example, ensure improved fiber control in the fleece. SiroLock also impresses with performance enhancements in carding, while the EvoStep set emphasizes on saving raw material.

www.groz-beckert.com

Jowat

Hall 3.0, H89

Jowat will be putting the spotlight on innovative PUR hot melt adhesives for the automotive and textile industries at the Techtextil trade fair. The latest highlight in the adhesives manufacturer’s product range is a PUR “all-rounder” especially suited for laminating automotive interior parts, which is not subject to classified chemical labelling under GHS. Jowat is thus responding to the growing demand in the automotive industry for all-purpose adhesives that can be used in the manufacture of laminated interior parts and that do not have to be declared a hazardous material. The product once more demonstrates the company’s leading expertise in PUR technology.

The latest adhesive from the Jowatherm-Reaktant MR series, which comprises a comprehensive portfolio of monomer-reduced PUR hot melts, also impresses due to benefits like a high green strength, low creep tendency, and advantageous VOC and FOG values. The adhesive can be applied by all established methods, especially by spraying.

Jowat supplies bonding technologies for all relevant lamination procedures in the automotive and textile industries. In addition, the enterprise prides itself in close customer contact and a strong dependability in the supply chain for maximum efficiency and process reliability, facilitated by the production of PUR-based adhesives in its own global manufacturing locations in America, Asia, and Europe.

www.jowat100.com

Monforts

Hall 3.0, F01

At Techtextil, A. Monforts Textilmaschinen GmbH & Co. KG will be highlighting all of the innovative features that have made the Montex stenter the undisputed leader in the field of technical fabric finishing.

“Techtextil is a very important show for us, because technical textiles are a key pillar of our production program and many of our existing customers will be exhibiting or attending, as well as those we have yet to meet,” says Jürgen Hanel, head of Technical Textiles at Monforts. “The show provides us with an opportunity to explain the diverse end-products that can be successfully finished on our stenters, as well as with our coating units.”

A number of successful recent Monforts Montex stenter installations in Europe, for example, are dedicated to the production of wide-width digital printing substrates, to high volume automotive fabrics and to heavy duty filter media, to name just three advanced technical materials.

The ability to thermally-set PTFE fabrics without oil greasing in the stenter chain and in the width adjustment is meanwhile particularly appreciated by manufacturers of filter media using Montex stenters.

“This protects workers and the environment from harmful oil vapors and keeps the filter material clean,” explains Hanel. “The guarantee of reaching 320°C with a very low temperature tolerance and with an excellent housing insulation is a major advantage, so that an outside temperature over 60°C is never reached at any point.”

Montex stenters in special executions are ideal for the preparation of filter materials for the drying and finishing of both wovens and nonwovens and characterized by high stretching devices in both length and width of up to 10,000N, with the ability to accommodate the higher operating temperatures required.

“The European-built Montex range of stenters has earned its leading position in the technical textiles market due to the overall robustness, reliability and economy of these machines,” Hanel concludes. “Whatever the intended end-product – and at each successive Techtextil we discover potentially new areas in which technical textiles can be utilized – we have the machine specification and know-how to turn your ideas into reality.”

www.monforts.de

Sandler

Hall 3.1, D54

At this year’s international trade fair for technical textiles and nonwovens, Sandler AG invites visitors to a world of nonwoven novelties at no. D54. High-tech materials for acoustic insulation in the home and the office or materials for transportation and for filtration—innovative nonwovens in a wide range of applications await the professional audience. Sandler acoustic nonwovens are versatile applicable and make the home more comfortable. Insulation materials are applied in the roof and in walls, providing for a pleasant temperature and at the same time helping to conserve energy. In partition walls sound-insulating nonwovens create optimum conversational acoustics. Additionally, these textile solutions also functioning as a design feature for individual room design.

Filter media provide clean air and contribute to an optimum indoor air quality at home as well as in industrial buildings. In addition to excellent filtration performance special pocket filter media contribute to energy conservation.

But Sandler nonwovens not only ensure comfort within buildings, they also help create a pleasant atmosphere on the go and minimize the noise level—in the automobile, in buses, trains or the working vehicles at the construction site. Efficient acoustical absorbers dampen engine and driving noise, while nonwovens for seat upholstery contribute to an optimum micro-climate of the seat. Hydro- and oleophobic nonwovens are especially suited to exterior applications in wheel house liners or underride guards. Soft and skin-friendly nonwovens for hygiene products and wipes complete the product range.

www.sandler.de

Technical Absorbents

Hall 4.2, B20

Techtextil is the next exhibition on the calendar for SAFM manufacturer Technical Absorbents (TAL).

The main focus for the company will be the promotion of its growing range of superabsorbent SAF fabrics – predominantly its innovative washable or high durability products which, since launch, have attracted a large amount of interest from a variety of market sectors. The material, when used as a core within protective outer materials, can be laundered and dried with minimal absorbency loss. Such a fabric has been developed as a solution for different industry sectors including hygiene and apparel.

“There has been an incredible amount of interest in our SAF washable fabrics,” explains product development director Dr. Mark Paterson. “The soft and conformable nature of the fabrics makes them ideal for everything from washable intimate wear to moisture management layers within apparel items.

“These fabrics are just one example of how we have taken our unique core SAFM fiber and, through creative product development, realized a unique fabric which can be integrated into a number of different products that require moisture containment/management.

“Innovation is at the heart of everything we do as a company. Events such as Techtextil not only allow us to promote the wide range of uses for all our SAF technologies – fibers, fabrics and yarns – but also discover new opportunities for its application within the industry of technical textiles.”

www.techabsorbents.com

Truetzschler

Hall 3.0, B03

Truetzschler Nonwovens will production lines for “green” nonwovens at Techtextil. Over the decades the machine supplier answered requirements on enhanced product quality, better line efficiency and higher productivity with new concepts and innovative processes. Now it sees a new dimension rising.

As a supplier of complete production lines Truetzschler Nonwovens offers machinery, service and know-how out of one hand – everything from implementing product ideas to enabling new businesses.

At booth B03 in hall 3.0 the focus is on solutions for processing eco-friendly materials. Cotton fibers – both virgin cotton and comber noils – make an excellent raw material for top-quality wipes. Truetzschler’s random and airlay cards are especially configured to cope with variable fiber lengths and a high short fiber content. The NCR and NCA cards reliably and efficiently form webs for the kind of soft cotton wipes sought after in premium markets worldwide.

Another focus point is fully biodegradable wetlaid and spunlaced (WLS) wipes. Voith and Truetzschler go one step beyond flushable wipes and show pulp and lyocell-based materials with sufficient strength to compete with conventional wipes from polyester/viscose blends. Proven machinery from both companies - such as Voith’s HydroFormer and Truetzschler’s AquaJet - add up to a versatile wet-laying and spunlacing line for future-fit end products.

www.truetzschler.de

TWE Group

Hall 3.1, F19

Sustainability is currently a big topic for many companies. The pressure of society is steadily growing and more and more understanding that the careful handling of resources, recycling of the produced materials or alternative uses of products is indispensable.

The TWE Group has been working in many areas for years with alternative raw materials or recycled fibers. At one of the 13 TWE locations, for example, almost only natural fiber nonwovens made from renewable raw materials have been produced for the last 15 years. These are used in pressed parts in the automobile sector, which not only have a good environmental balance through the use of bio fibers but also save weight and thus also reduce fuel consumption.

But also at all other locations use recycled fibers and the products in many cases also enable energy savings during production, lower storage and logistics costs through thinner material and less weigh or the option of 100% self-recycling later on.

But it is not only the use of organic or recycled fibers that is important to TWE within the production of nonwovens. TWE nonwovens can do a lot more. As acoustic or thermal insulation, for example, they contribute to a higher quality of life in many areas. Sustainability means at TWE that its products have the ability to improve entire lives in many ways.

From warming nonwovens in clothing, to filter nonwovens for clean air and pure liquids, to noise-reducing acoustic nonwovens - there are no limits for the use of nonwovens.

At this year’s Techtextil, visitors can experience at TWE Group’s stand many applications for nonwovens made from recycled or bio fibers. In addition to existing products, the TWE Group’s R&D teams are working on many other exciting projects and uses of recycled or natural fibers.

www.twe-group.com

“Every two years, Techtextil mirrors the range of applications for textile materials. Leading international experts from the most diverse industries – be they from architecture, the automotive industry, medicine, the fashion industry or personal protection – come together at Techtextil in search of lightweight, durable and sustainable materials,” says Olaf Schmidt, vice president Textiles and Textile Technologies, Messe Frankfurt.

The suppliers at Techtextil represent the complete spectrum of technical textiles and nonwovens. There is a significant increase in the number of suppliers in the fields of technology, as well as fibers and yarns. Suppliers of woven fabrics, coated textiles and functional apparel textiles are also strongly represented. All areas of application for textile materials are covered. In particular, representatives from industry, architecture and construction, the fashion and clothing industry, the automotive sector, aerospace, medicine, sport, and hazard protection will find a more comprehensive range of products than before.

In collaboration with ‘Creative Holland’, the Dutch creative industries, Techtextil is dedicating an exhibition space to life in the city of the future with the ‘Urban Living – City of the Future’ special event. According to the United Nations, nearly 70% of all people are expected to be living in metropolises and megacities by 2050. This poses new challenges for living and mobility concepts, as well as food supplies and health services provision. Functional apparel, with smart functions for example, could also play an even more important role in people’s everyday lives in the future. The Techtextil and Texprocess exhibition area will be presenting examples of textile applications. In addition, an accompanying complementary program will offer insights into the industry.

On all four days, the trade fair will offer a new format of lectures, discussions and interactive sessions with the Techtextil Forum. The forum, which replaces the Techtextil Symposium, will take place directly in exhibition Hall 4.1 and all Techtextil participants will be able to access it free of charge. Trade visitors can look forward to contributions in the following thematic areas: sustainability, digital transformation, smart textiles, urban textiles, composites, and technical textiles in medical technology. In addition, both the Dornbirn Global Fiber Congress (GFC) and the textiles competence center at the General Association of the German Textile and Fashion Industry (Gesamtverband der deutschen Textil- und Modeindustrie e. V.) are organizing a thematic block.

For the 15th time now, Techtextil will be giving the Techtextil Innovation Award for outstanding new and further developments in the field of technical textiles, nonwovens and functional apparel fabrics. Both exhibitors and non-exhibitors at Techtextil can take part in the competition.

Sustainability is one of the central themes of the upcoming Techtextil and Texprocess. For the first time, the two fairs will be showcasing their exhibitors’ efforts towards sustainability. The Techtextil and Texprocess Innovation Awards give prizes for sustainable textile innovations and processing approaches. In addition, the Texprocess Forum will offer a thematic block exclusively around the theme of sustainability in the textile and fashion industry, with an offshoot of Fashionsustain, Messe Frankfurt’s conference about sustainable textile innovations.

In May 2019, Techtextil and the parallel Texprocess will be sharing an exhibition hall for the first time. In Hall 4.1, Techtextil will be showcasing some of the suppliers of woven, laid web, braided and knitted fabrics, coated textiles, and nonwovens, as well as selected suppliers of textile machines. Suppliers of functional apparel textiles and the ‘Digital Textile Micro Factory’ mark the transition to Texprocess, which will be showcasing different production lines for clothing, shoes, and the processing of technical textiles. In addition to these, exhibitors for product preparation, finishing, textile logistics, internal material flow and textile refinement, as well as providers of sewing solutions, will be there. In the shared hall, visitors will get an insight into the entire production process, from raw material to finished product.

In the next few pages, Nonwovens Industry will provide a glimpse of what some exhibitors plan to bring to Techtextil. And, we will be reporting live on key developments from Techtextil. Look for our breaking news e-mail blasts during the show.

Andritz

Hall 3.0, B15

International technology Group Andritz will be presenting its innovative nonwovens production and textile solutions at Techtextil 2019. Andritz supports its customers in every aspect of nonwovens and textile processes and services with its most advanced expertise and complete technology solutions.

The long tradition of excellent calender technology for the textile industry is now continued with the teXcal Raconip TT calender. The teXcal Raconip TT mainly targets customers experienced in the manufacture of technical textiles with highest quality standards, for example, sports and work wear, sailcloth, parachute fabrics, or packaging materials.

The teXcal Raconip TT offers the operator a number of features that are useful during operation. For example, user-friendly access to all relevant areas of the calender, excellent data management for the calender process and product quality in real time, and extended maintenance intervals.

Overall, Andritz has focused on versatility and flexibility in development of the new textile calender – properties that should make this equipment more competitive. In addition, the calender contains an innovative, deflection-controlled roll, the Raconip TT. It offers highest flexibility by providing unrestricted profiling over the entire fabric width by means of hydrostatic pistons. This ensures top quality, such as absolute flatness and spot-on air permeability. The new calender has been developed in cooperation with Rolf Ramisch, a well-known specialist in textile calender technology.

Andritz will introduce visitors to the processing of glass fibers with wetlaid technology. Nonwoven end products based on glass fibers can be found almost everywhere: in ceiling tiles, cushion vinyl flooring, insulation, wallpaper and surfaces, geotextiles, batteries, roofing materials, as well as other applications. Glass fiber as a basic component is an excellent composite material and offers numerous advantages that lend the resulting products unique properties. And because of its wide range of applications, products made of glass fiber material have a strong, growing market.

The manufacture of products based on glass fibers requires particularly gentle treatment in the stock preparation and laying processes. Andritz meets these requirements perfectly. At Techtextil, Andritz Wetlaid experts will present details of this new configuration to interested visitors for the first time.

Another focus of Andritz at Techtextil 2019 is its needlepunch technology, which the company has been supplying successfully for many years to a variety of industries such as geotextiles, roofing materials, filtration, technical felts, carpeting, and many more.

One of Andritz’s main areas of needlepunch excellence is the needlelooming process, which gives the material the decisive properties for consistently high quality. Andritz needlelooms include pre-needling units as well as standard needlelooms and, above all, specialized needlelooms that can be fully adapted to the customers’ needs.

Due to the versatile specifications and processing quality of its needleloom systems combined with robustness for a sustainable product life cycle, Andritz presents its solutions for further innovative end uses wherever this form of mechanical bonding is required.

With a 3D-print model of the SDV needleloom at the booth in conjunction with Augmented Reality, the visitor can gain a unique insight into the Andritz smart service solutions marketed under the Metris technology brand name. This includes the new Metris spare part catalog as well as digitally based technical documentation.

www.andritz.com

Autefa Solutions

Hall 3.0, H31

During Techtextil, visitors will experience future-proof solutions for improving quality and productivity while visiting Autefa Solutions in Hall 3.0, H31. The company presents its portfolio as a full-line supplier for carded- crosslapped needlepunch lines, aerodynamic web forming technology, spunlace and thermobonding lines.

Autefa Solutions lines cover the needs of the highly-competitive nonwovens market. An improved and even surface quality has been set as key target by the customers. Therefore, Autefa Solutions offers the service of a customized needle board pattern. The i-Point needling simulation tool increases the capacity and the quality of needlepunched fabrics. The development of new needle patterns and the evaluation of surface quality is much more effective and economic with the i-Point software technology. It creates a layout of stripper and bed plate including the elliptic needling (Variliptic). This customized design of needle pattern, which takes also draft and shrinkage into consideration, reduces the process optimization time on customer site. Autefa Solutions needlepunch lines produce an even and homogenous fabric with outstanding technical performance in terms of tensile strength and evenness (MD/CD ratio).

www.autefa.com

Brückner

Hall 3.0, F29

Particularly in the field of hygiene nonwovens, the trend goes towards products of a better quality with a smoother handle, more volume and of more uniform texture. Nonwovens producers worldwide are supported by the new Brückner Supra-Flow BA belt oven, which gives them the technology to produce such high quality end products.

The new Supra-Flow BA guarantees a particularly gentle transport of the unbonded web. This is achieved by a sophisticated air circulation design. It is also characterized by minimum heat consumption, high flow uniformity and constant temperature distribution over the entire working width. The good accessibility of the oven chamber leads to a high maintenance friendliness. The dryer is available in working widths up to 4600 mm. It is designed for production speeds of up to 250 m/min and thus offers potential for line optimization.

Typical end products, which are bonded on the Brückner Supra-Flow BA high-end thermofusion oven according to the air-through principle, are nonwovens for diapers (ADL, topsheet, backsheet), nonwovens for feminine care and incontinence products but also filter nonwovens and special nonwovens.

One year ago Brückner presented the revised double belt oven for thermofusion of high-loft nonwovens to the expert public. The aim was to reduce the use of primary energy with a view to resource-conserving nonwovens production and thus to reduce production costs. With the double belt furnace Supra-Flow BX, established in the market, Brückner’s’s engineers have succeeded in achieving not only this increase in efficiency, but also the re-construction of the air circulation with fewer individual parts in the sense of the guiding principle “a good design is simple”. Furthermore there were many small detail improvements, which led to the fact that in 2018 so many Supra-Flow BX were sold in different configurations, as never before.

The oven is suitable for the production of high-loft nonwovens, medium as well as highly compressed fiber boards made of natural, synthetic and/or recycled fibres. It is a convective oven system which works according to the air-through principle. In each compartment the flow direction can be individually adjusted according to the product requirement. In most cases the basic material beside the matrix fibers are binding fibers melting at low temperatures such as bi-component fibers (PES/CoPES, PP/PR) and PP. Thermoplastic or duroplastic powders can be used also as binders.

The Supra-Flow BX is particularly suitable for products with a higher weight, thickness and/or density and relatively high pressure losses during the flow through the product. The following processes can be implemented on the system: Thermofusion (for bonding PP, PET/CoPET, PP/PE), heat-setting and drying. The Supra-Flow BX is of particular interest to manufacturers of mattresses, duvets, inserts, insulation, furniture (upholstery, cushions), cleaning (dry and wet wipes, painter’s cover foils), automotive components (headliners, thermal insulation, noise insulation, seat covers), thermal and acoustic insulation in the construction industry and carrier materials (floor coverings, technical coatings).

This type of oven is particularly suitable for the gentle drying of binder-bonded lightweight nonwovens. For such lines Brückner can supply the belt dryer type Supra-Flow BE as well as the foam padder, the cylinder dryer group and a smoothing calender downstream of the dryer. The Brückner Supra-Flow BE is successfully in operation and produces high-quality nonwovens for the medical sector.

Brückner has again improved and further developed its minimum application unit. The customer has the following advantages over a padder: Low-Add-On technology (fabric moisture < 60 g/m²), low water consumption, high energy savings in the subsequent drying processes, low residual liquor (2.5 l per m working width) and thus fewer chemicals which have to be disposed of during a batch change.

The Eco-Coat unit enables impregnation and precise one-sided Kiss Roll coating on the upper or lower side of the fabric web as well as functionalization such as hydrophobization or softener application by means of engraving roller pre-dosing. In addition, one-sided ink jet preparation is possible. Single-sided functionalizations with a wide variety of finishing chemicals can be realized, especially for fashion and technical applications. Brückner offers at any time the possibility to carry out tests on the laboratory plant in Leonberg with the advice of technologists.

www.brueckner-textile.com

DiloGroup

Hall 3.0, H33

Techtextil is one of the most important exhibitions in the field of nonwovens and Dilo has participated since its inception in 1986. During a history of more than 100 years Dilo has always set new standards with technologies like Hyperpunch and Di-Lour needling. These developments have opened new markets for nonwovens and raised the bar regarding quality and efficiency.

The development cycles in machine building cannot be measured in months. Therefore we are pleased that one of our latest developments in horizontal crosslappers, the “Hyperlayer” is now being installed in several spunlace production lines. This crosslapper can realize infeed speeds up to 200 m/min due to its special design and is ideal for a low number of layers of lightweight webs.

Our Dilo-“Hypertex” installation, consisting of a yarn laydown unit from Messrs. Ontec and subsequent needling, provides highly efficient inline production of reinforced needlefelts. With this system, scrim structures and preneedled weblayers can be needled together at speeds up to 20 m/min.

The new needle arrangement “8000 X” ensures homogeneous distribution of needle penetrations in the felt over a wide range of advance/stroke. The results are considered a breakthrough for improved surface qualities, particularly for car interiors.

The concepts above are only part of our continuous development and refinement work for needling and spunlacing lines.

www.dilo.de

Freudenberg Performance Materials

Hall 3.1, F37

Under the heading “Meet your experts,” Freudenberg Performance Materials will be presenting innovative technical textiles for the automotive, medical and apparel markets from May 14 to 17, 2019, at Techtextil.

Alongside personal discussions, the leading supplier of innovative technical textiles will be hosting a series of expert interviews at its booth. Freudenberg works with the broadest technology platform on the market. This enables the leading manufacturer of performance materials to equip technical textiles with an unparalleled variety of properties. The innovations Freudenberg will be presenting at Techtextil are excellent examples of this ability. Via the expert interviews, Freudenberg will also be giving trade fair visitors the opportunity to gain a good insight into these solutions, even if they do not wish to make an individual appointment. The interviews will be conducted several times a day at times that will be clearly communicated at the company’s booth.

Good acoustics in vehicles increase driving comfort. This factor is also very important for electric cars, as the alternative drives are quieter than combustion engines and other noises of different frequencies are more strongly perceived. Freudenberg will be presenting innovative Acoustic Pads that feature exceptionally high noise absorption in the vehicle interior. The lightweight pads are a very cost-effective solution and also help customers to reduce the weight of vehicles. Freudenberg Acoustic Pads are ideally suited for use in various automotive applications such as door panels, headliners, trunk linings, wheel arches and more.

The fuel cell is already being used successfully in a number of applications and is regarded as a decisive energy source of the future. Freudenberg’s series-produced gas diffusion layers (GDL) contribute to making this technology more economical. Their pronounced thickness uniformity and material homogeneity increase electrical and thermal conductivity and improve the transport of gases and liquids within the fuel cell. The outstanding properties have been demonstrated in a broad range of very different customer applications. At the same time, Freudenberg’s GDL can be processed better than other products and exhibit superior mechanical properties.

Wound pads are a component of medical wound dressings. Freudenberg wound pads made from hydrophilic PU foams with a direct coating of silicone adhesives are significantly more effective than the commonly used foams with transfer coatings. They are much more flexible, adapt better to the wound bed, and enable antibacterial treatments to better develop their effectiveness. Moreover, the reduction of process steps and complexity during manufacture saves energy, avoids waste and simplifies the supply chain.

With comfortemp fiberball padding eco, Freudenberg will be presenting the world’s first padding made from continuous fiber balls, which functions as a perfect substitute for down in clothing. This novel insulation material is made from 100% recycled polyester fiber balls and combines the advantages of both padding and down. It is the ideal solution for the sports and outdoor sector, but is also suitable for use in fashion garments. It is manufactured without the use of chemicals, offers optimum breathability and is super-soft and fluffy.

www.freudenberg-pm.com

Groz-Beckert

Hall 3.0, F03

At Techtextil, Groz-Beckert, a leading supplier of industrial machine needles, will exhibit its comprehensive product and service portfolio in the knitting, weaving, felting, carding and sewing product areas.

The Felting area presents an absolute novelty with Groz-Beckert customized product: Thanks to the customizable customer label, Groz-Beckert customers not only benefit from enhanced know-how protection, but also from more security and safety when handling needles in production.

Another highlight of the stand is the 3D print model of the staple fiber needling line (SVL). The SVL has been available to Groz-Beckert customers and partners for the last two years at the company’s Albstadt headquarters, in the Technology and Development Center (TEZ), in Germany.

Within the traditional nonwovens industry, Groz-Beckert’s Gebecon felting needle offers the best possible fracture/bending properties and thus optimized needling parameters, as well as an improved surface quality of the final product. Groz-Beckert will be presenting details of the patented shape of working part of this needle at the trade fair stand using a man-sized needle exhibit. Groz-Beckert also has such an exhibit ready for spunlace customers: In addition to its improved handling properties, the innovative HyTec P jet strip also has a significantly higher hardness, which has a positive effect on all mechanical properties such as scratch resistance, flexural rigidity and service life.

The Carding area completes Groz-Beckert’s product range for the nonwovens industry. At Techtextil visitors can directly compare different tooth geometries. The worker and user sets SiroLock and EvoStep, for example, ensure improved fiber control in the fleece. SiroLock also impresses with performance enhancements in carding, while the EvoStep set emphasizes on saving raw material.

www.groz-beckert.com

Jowat

Hall 3.0, H89

Jowat will be putting the spotlight on innovative PUR hot melt adhesives for the automotive and textile industries at the Techtextil trade fair. The latest highlight in the adhesives manufacturer’s product range is a PUR “all-rounder” especially suited for laminating automotive interior parts, which is not subject to classified chemical labelling under GHS. Jowat is thus responding to the growing demand in the automotive industry for all-purpose adhesives that can be used in the manufacture of laminated interior parts and that do not have to be declared a hazardous material. The product once more demonstrates the company’s leading expertise in PUR technology.

The latest adhesive from the Jowatherm-Reaktant MR series, which comprises a comprehensive portfolio of monomer-reduced PUR hot melts, also impresses due to benefits like a high green strength, low creep tendency, and advantageous VOC and FOG values. The adhesive can be applied by all established methods, especially by spraying.

Jowat supplies bonding technologies for all relevant lamination procedures in the automotive and textile industries. In addition, the enterprise prides itself in close customer contact and a strong dependability in the supply chain for maximum efficiency and process reliability, facilitated by the production of PUR-based adhesives in its own global manufacturing locations in America, Asia, and Europe.

www.jowat100.com

Monforts

Hall 3.0, F01

At Techtextil, A. Monforts Textilmaschinen GmbH & Co. KG will be highlighting all of the innovative features that have made the Montex stenter the undisputed leader in the field of technical fabric finishing.

“Techtextil is a very important show for us, because technical textiles are a key pillar of our production program and many of our existing customers will be exhibiting or attending, as well as those we have yet to meet,” says Jürgen Hanel, head of Technical Textiles at Monforts. “The show provides us with an opportunity to explain the diverse end-products that can be successfully finished on our stenters, as well as with our coating units.”

A number of successful recent Monforts Montex stenter installations in Europe, for example, are dedicated to the production of wide-width digital printing substrates, to high volume automotive fabrics and to heavy duty filter media, to name just three advanced technical materials.

The ability to thermally-set PTFE fabrics without oil greasing in the stenter chain and in the width adjustment is meanwhile particularly appreciated by manufacturers of filter media using Montex stenters.

“This protects workers and the environment from harmful oil vapors and keeps the filter material clean,” explains Hanel. “The guarantee of reaching 320°C with a very low temperature tolerance and with an excellent housing insulation is a major advantage, so that an outside temperature over 60°C is never reached at any point.”

Montex stenters in special executions are ideal for the preparation of filter materials for the drying and finishing of both wovens and nonwovens and characterized by high stretching devices in both length and width of up to 10,000N, with the ability to accommodate the higher operating temperatures required.

“The European-built Montex range of stenters has earned its leading position in the technical textiles market due to the overall robustness, reliability and economy of these machines,” Hanel concludes. “Whatever the intended end-product – and at each successive Techtextil we discover potentially new areas in which technical textiles can be utilized – we have the machine specification and know-how to turn your ideas into reality.”

www.monforts.de

Sandler

Hall 3.1, D54

At this year’s international trade fair for technical textiles and nonwovens, Sandler AG invites visitors to a world of nonwoven novelties at no. D54. High-tech materials for acoustic insulation in the home and the office or materials for transportation and for filtration—innovative nonwovens in a wide range of applications await the professional audience. Sandler acoustic nonwovens are versatile applicable and make the home more comfortable. Insulation materials are applied in the roof and in walls, providing for a pleasant temperature and at the same time helping to conserve energy. In partition walls sound-insulating nonwovens create optimum conversational acoustics. Additionally, these textile solutions also functioning as a design feature for individual room design.

Filter media provide clean air and contribute to an optimum indoor air quality at home as well as in industrial buildings. In addition to excellent filtration performance special pocket filter media contribute to energy conservation.

But Sandler nonwovens not only ensure comfort within buildings, they also help create a pleasant atmosphere on the go and minimize the noise level—in the automobile, in buses, trains or the working vehicles at the construction site. Efficient acoustical absorbers dampen engine and driving noise, while nonwovens for seat upholstery contribute to an optimum micro-climate of the seat. Hydro- and oleophobic nonwovens are especially suited to exterior applications in wheel house liners or underride guards. Soft and skin-friendly nonwovens for hygiene products and wipes complete the product range.

www.sandler.de

Technical Absorbents

Hall 4.2, B20

Techtextil is the next exhibition on the calendar for SAFM manufacturer Technical Absorbents (TAL).

The main focus for the company will be the promotion of its growing range of superabsorbent SAF fabrics – predominantly its innovative washable or high durability products which, since launch, have attracted a large amount of interest from a variety of market sectors. The material, when used as a core within protective outer materials, can be laundered and dried with minimal absorbency loss. Such a fabric has been developed as a solution for different industry sectors including hygiene and apparel.

“There has been an incredible amount of interest in our SAF washable fabrics,” explains product development director Dr. Mark Paterson. “The soft and conformable nature of the fabrics makes them ideal for everything from washable intimate wear to moisture management layers within apparel items.

“These fabrics are just one example of how we have taken our unique core SAFM fiber and, through creative product development, realized a unique fabric which can be integrated into a number of different products that require moisture containment/management.

“Innovation is at the heart of everything we do as a company. Events such as Techtextil not only allow us to promote the wide range of uses for all our SAF technologies – fibers, fabrics and yarns – but also discover new opportunities for its application within the industry of technical textiles.”

www.techabsorbents.com

Truetzschler

Hall 3.0, B03

Truetzschler Nonwovens will production lines for “green” nonwovens at Techtextil. Over the decades the machine supplier answered requirements on enhanced product quality, better line efficiency and higher productivity with new concepts and innovative processes. Now it sees a new dimension rising.

As a supplier of complete production lines Truetzschler Nonwovens offers machinery, service and know-how out of one hand – everything from implementing product ideas to enabling new businesses.

At booth B03 in hall 3.0 the focus is on solutions for processing eco-friendly materials. Cotton fibers – both virgin cotton and comber noils – make an excellent raw material for top-quality wipes. Truetzschler’s random and airlay cards are especially configured to cope with variable fiber lengths and a high short fiber content. The NCR and NCA cards reliably and efficiently form webs for the kind of soft cotton wipes sought after in premium markets worldwide.

Another focus point is fully biodegradable wetlaid and spunlaced (WLS) wipes. Voith and Truetzschler go one step beyond flushable wipes and show pulp and lyocell-based materials with sufficient strength to compete with conventional wipes from polyester/viscose blends. Proven machinery from both companies - such as Voith’s HydroFormer and Truetzschler’s AquaJet - add up to a versatile wet-laying and spunlacing line for future-fit end products.

www.truetzschler.de

TWE Group

Hall 3.1, F19

Sustainability is currently a big topic for many companies. The pressure of society is steadily growing and more and more understanding that the careful handling of resources, recycling of the produced materials or alternative uses of products is indispensable.

The TWE Group has been working in many areas for years with alternative raw materials or recycled fibers. At one of the 13 TWE locations, for example, almost only natural fiber nonwovens made from renewable raw materials have been produced for the last 15 years. These are used in pressed parts in the automobile sector, which not only have a good environmental balance through the use of bio fibers but also save weight and thus also reduce fuel consumption.

But also at all other locations use recycled fibers and the products in many cases also enable energy savings during production, lower storage and logistics costs through thinner material and less weigh or the option of 100% self-recycling later on.

But it is not only the use of organic or recycled fibers that is important to TWE within the production of nonwovens. TWE nonwovens can do a lot more. As acoustic or thermal insulation, for example, they contribute to a higher quality of life in many areas. Sustainability means at TWE that its products have the ability to improve entire lives in many ways.

From warming nonwovens in clothing, to filter nonwovens for clean air and pure liquids, to noise-reducing acoustic nonwovens - there are no limits for the use of nonwovens.

At this year’s Techtextil, visitors can experience at TWE Group’s stand many applications for nonwovens made from recycled or bio fibers. In addition to existing products, the TWE Group’s R&D teams are working on many other exciting projects and uses of recycled or natural fibers.

www.twe-group.com