Tara Olivo, Associate Editor10.08.18

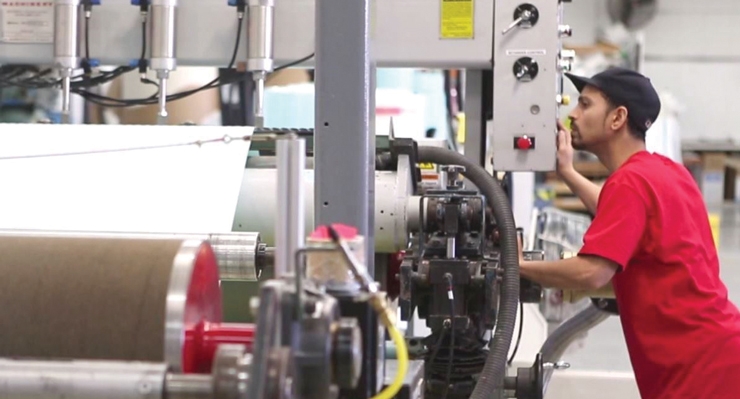

Converting companies are an integral part of the nonwovens supply chain. For all of the advantages the industry’s products provide, a lot has to happen prior to their end use. Nonwovens need to be cut into a variety of shapes and sizes, scaled down to become a single-use product, as well as printed, packaged and more. Sometimes the process is simple, and sometimes more complex, with converting companies using the latest technology to add value to products and make them easier to use. The following is a compilation of capabilities and services of some the nonwovens industry’s leading converters.

Athea Laboratories

Athea Laboratories continues capital investment in new machinery to further bolster its manufacturing capabilities. The addition of a new high speed perforator machine and 5000 gallon mixing tank will help to improve efficiency and speed of manufacturing with a number of products. These additions also help emphasize Athea’s capabilities as a full turnkey wet wipes and liquid product manufacturer with the ability to handle all manufacturing in house.

With over 50 years of experience, Athea Laboratories is the leader in specialty wipes, liquid, and powder contract manufacturing and packaging. Its expertise and experience gives customers an extensive variety of product formats to serve numerous end-user markets with their private labeled product. As an EPA and FDA facility, Athea’s manufacturing capabilities include custom wipe converting, custom formula development, blending services, on-site chemists, formula-substrate compatibility testing, graphics, and technical and regulatory support. Athea can offer customers a turnkey solution to their packaging needs at low minimums.

www.athea.com

Beckmann Converting

Beckmann Converting continues to upgrade its high tech, ultrasonic laminating equipment, both in bonding capability and in web handling, to create wide web, multilayer and multifunction composites. Upgrades have allowed the company to process more efficiently and to process more types of raw materials. Beckmann Converting operates as a contract or toll laminator and is able to create from two-layer composites to six-layer composites. It can create them as wide as 120 inches and slit in line, to any width a customer or its next step converter requires. These composites can be combinations of nonwovens, films, knits, wovens or meshes.

Ultrasonic laminating has a unique place in the creation of multi-layer composites because nothing other than the original materials are used in that process. This makes it a true “green” process. As long as there is sufficient thermoplastic content in the layers to be laminated, the ultrasonic energy melts the materials at the bonding points, making it the bonding link of the individual layers, unlike adhesive bonding, which introduces foreign substances into the composites. Because ultrasonic lamination is a “point bonding process,” all of the properties of the raw material layers, in between the bond points, are the same as before lamination, which include properties such as strength, loft, breathability, filtration and chemical resistance. Beckmann Converting has successfully produced multi-layer composites for applications such as filtration, environmental, protective apparel, protective covers, healthcare products, cleanroom wipes and many more.

www.beckmannconverting.com

Berk International

Boyertown, PA-based Berk International manufactures nonwoven wipes, toilet tissue and paper towels. The company is an expert in converting an assortment of materials including DRC, spunlace, airlaid, hydroentangled nonwovens, meltblown, needlepunch, TAD, tissue and towel. The Berk family has been in the wipes converting business since 1975 and has established a reputation of producing high quality products at reasonable prices. CEO Larry Berk and his brother Jeff Berk, who is president and head of sales, started Berk Wiper in 2000 and have grown the business every year since.

With 17 production lines running 24 hours a day in its 275,000 square foot facility, no job is too big or too small. From private labeling to contract converting to their own brands, Berk has it all. The company converts wipes for every market including Jan-San, food service, healthcare, automotive and industrial. Its capabilities include flat sheeting, interfolding, 1/2, 1/4, 1/6 and 1/8 folding, perforating, printing, rewinding, laminating and slitting.

www.berkwiper.com

BMP America

BMP America Inc. is part of a global manufacturing group specializing in the manufacture and conversion of technical nonwoven textiles, engineered polyurethane elastomers, mechanical components and sub-assemblies used in a diverse range of industrial applications. BMP America is a tier one supplier of components to major OEM companies in the appliance, construction, printing, automotive, filtration and renewable energy market sectors.

BMP America, Inc.’s headquarters and manufacturing facility is located in Western New York along with a subsidiary manufacturing facility located in Juarez, Mexico. The company also has technical sales offices in Oregon, Connecticut, Iowa and Maine.

The Western New York and Mexican facilities primarily manufacture engineered nonwoven products and assemblies for OEM accounts in North America,. Meanwhile, sister companies, BMP Europe, which is located in England, manufactures similar products as well as engineered polyurethane elastomers for accounts primarily in Europe, and BMP Asia manufactures similar products for accounts located primarily in the Asia-Pacific region and is a contract manufacturer for BMP America and BMP Europe.

In general the manufacturing process is short run and job shop in nature with many processing, converting and assembly operations. Both the U.S., European and Asian manufacturing facilities have similar capabilities and equipment enabling the transfer of business between its sister companies with minimal disruption if conditions warrant.

BMP is a wholly owned subsidiary of Andrew Industries Ltd., a privately owned company whose core technology is in the manufacture of industrial textiles, specifically, needle felts and thermal bonded nonwoven for various applications including filtration, insulation, laundry and business machine applications.

www.bmpworldwide.com

Converted Products

In 1993, Converted Products, Incorporated (CPI) opened for business with the simple idea of providing quality contract converting services in slitting and die cutting. Twenty-four years later, CPI has kept that same simple premise but has expanded its contract services to include wider width, high speed slitting, hot melt laminating, traverse (spool) winding, rotary and flat bed die cutting, warehousing/logistics and product/process development. Operating in an ISO9001 process, Converted Products’ 160,000 square foot facility is located on the northwest side of Milwaukee, WI.

CPI’s slitting capabilities include score, shear, razor, single knife and rotary, in widths ranging from 1/8 to 136 inches along with experience in a wide variety of flexible materials.

In 2017, CPI upgraded its high speed, wide-width equipment by installing a new winder with a drive assist unwind. President and founder of CPI Chris Gorenc says, “We had the opportunity to keep our equipment on the leading edge by installing a high speed, wide width surface winder with a drive assist unwind. There aren’t many contract converters who have the drive assist technology. It gives us an opportunity to work with low tensile materials that need a driven unwind to ensure a quality wound roll.”

But CPI’s work on efficiency didn’t end with just a machine. They went to work on eliminating as much waste in their process as well by implementing and adopting their own version of Overall Equipment Effectiveness (OEE). “We started by using whiteboard’s and worked into a more sophisticated database. Regardless of the method, we had to reduce our downtime as much as possible. It is a never-ending process to drive out wasted time and make sure our customers get the best price we can offer,” Gorenc adds.

The new surface winder features the following capabilities: total width: 130”; slit widths: 3” to 130”; unwind OD max: 100”; rewind OD max: 72”; drive assist technology; unwind ID’s: 3”, 6”, 6-3/4”, 8”, 10”, 10-5/8”, 12” (others available upon request); rewind ID’s: 3”, 6”, 6-3/4”, 10” (others available upon request); and speeds in excess of 4000 ft per min.

www.convertedproducts.com

E&T Converters

E&T Converters was founded in 1972, with the goal to provide the best possible converting services at the most competitive price. Because it has so many years of experience in the converting business, its staff is able to offer a wide variety of slitting capabilities. This enables the company to provide contract converting for virtually any market. In 1989, E&T built a new 230,000 sq. foot state-of-the-art building with a rail site so that it could effectively manage the many needs of its customers. E&T is family owned and takes pride in its quality, service and value offered to all of its customers.

www.eandtconverters.com

Micrex Corporation

Micrex is the developer and manufacturer of the Micrex/Microcreper family of compressive treatment machinery for nonwovens, paper, films, composites and textiles. Companies worldwide use Micrex technology to add softness, bulk, drape, absorbency, extensibility, and stretch to a wide range of products.

Contract Microcreping is at the core of our business. Running a wide range of materials improves its grasp of market needs and informs its R&D. As the company has no product except its technology, it will never be a competitor to its contract converting customers.

Micrex performs product development through the Micrex Innovation Lab. This integrates with contract Microcreping services for those firms whose current needs do not yet require the purchase of a dedicated Micrex/Microcreper system. Micrex is prepared to support projects from initial development through large scale production. All configurations of Micrex/Microcreper are available for contract production.

No-cost lab scale screening trials are available to qualified customers. For information about this program please see: http://micrex.com/screening-trials/.

www.micrex.com

National Wiper Alliance

National Wiper Alliance (NWA) is North America’s premier contract converter for dry wipes. NWA operates out of its 500,000 square foot state-of-the-art facility located just outside Asheville, NC. NWA capabilities include slitting, inner folding, folding, sheeting, perforating and printing. Additional services offered include turn key & toll converting, private labeling, product development, sample runs, product testing, warehousing as well as supply chain management. Most recently, NWA has completed a major renovation of an additional 152,000 square foot warehouse ensuring space to meet the continued growth and needs of customers. Products converted by NWA can be found in the retail, aerospace, automotive, industrial, food service, hospitality, medical, government, military and janitorial markets. National Wiper Alliance is registered to ISO 9001:2015.

National Wiper Alliance and its owner have received numerous awards over the past year. These awards include: SBA-North Carolina 2015 Small Business Person of the Year – Jeff Slosman; NC Chamber of Commerce – 2015 Manufacturer of the Year – Honorable Mention; Business NC Magazine – 2015 NC Small Business of the Year and Wake Forest Family Business Center; 2016 NC Family Business of the Year, and INDA - 2018 WOW Innovation Award Finalist.

www.nationalwiper.com

Nonwovens of America

Nonwovens of America, Inc. (NOA) is located in Swannanoa, NC, operating a 5.4-meter air-lay needlepunch line and running colors in a weight range of 3.5 ounces per square yard to 34 ounces per square yard. In addition to the needlepunch line, NOA provides custom converting services which include a 10-color, 99” wide rotary screen print line, blanket lines, an inline calendar, and slitting and re-rolling. NOA offers toll converting services on the needlepunch line as well as all other converting services. The main areas of focus are automotive, retail, geotextile, industrial and disaster and emergency blankets. NOA provides in-house customer service, product development, warehousing, logistics and distribution support.

www.nonwovensofamerica.com

Royal Carolina

Royal Carolina offers printing on its rotary screen & flexographic lines up to 90” on woven and nonwoven fabric. Additionally, the company provides coating, a wide range of finishes, and capabilities for slitting.

Royal Carolina is a “Made in America” and geographically located in North Carolina. Its goal is to work collaboratively with customers to develop customized solutions.

Royal Carolina works with many industries including medical, bedding, furniture, automotive, industrial, filtration and construction.

Its rotary screen printing can provide 12 colors at 72” wide and eight colors at 90” wide. Its standard inks are water-based pigments. The company is adept with specialty products such as, PCM, conductive ink, color changing ink, anti-skid, adhesives and more.

Royal Carolina’s flexographic press runs nonwoven materials up to 64” wide and prints up to four colors. This offers low cost printing for high volume needs.

Royal Carolina’s pad finishing capabilities include but are not limited to water repellants, fire retardants, antimicrobials, pad dyes, soil releases, odor elimination, insect repellant, and more. It has two ranges and can go up to 90” wide. It also offers coatings on material up to 72” wide.

www.royalcarolina.com

Southeast Nonwovens

Southeast Nonwovens, Inc. (SENW) has been in business for 21 years, serving the nonwovens industry as an independent facility for manufacturing, converting and research of staple based fiber nonwovens.

SENW offers contract manufacturing using the wet-lay, dry lay, and air lay processes.

SENW also offers contract research and product development services – supporting the wet, dry and air lay manufacturing processes. Its material science experts can understand a customer’s requirements, design a product using its laboratory & pilot scale equipment, then produce a customer’s custom product.

Southeast Nonwovens, Inc. has all the technology customers need to develop, prototype, and produce their next generation of nonwoven products…all in one facility.

www.southeastnonwovens.com

Web Industries

“Web Industries Inc. took giant steps in 2018 to strengthen its position as a preferred provider in the nonwovens sector,” says director of Sales, Personal and Home Care Adrienne Green. “This past May we completed an $8 million investment in two 8-color flexographic printing presses, and 60-inch OD web spooling and precision slitting lines.”

The new resources are housed at a single location, its Ft. Wayne, IN, plant. Web is the only precision formatter equipped to print, slit and spool flexible materials used in personal and home care products at a single location.

“Having our resources under the same roof gives our customers supply chain advantages, including product differentiation, faster throughput and a single point of accountability,” Green adds. “Web can print and spool specialized, colorful materials that customers can run at the highest level of efficiency. Large format spools can run more than 20 times longer than pad rolls.”

Web’s new eight-color printing capability is of particular interest to brands using vibrant graphics and logos to differentiate their products.

Green notes that Web can source materials from virtually any flexible materials supplier worldwide. “We are committed to open materials sourcing,” she says. “We believe that vertically integrated formatters have inherent restrictions to their material options. They are committed to using the materials they produce in house while offering smaller scale converting services. Web can source from anyone, anywhere on the planet, for speed, cost and proximity advantages. Web has unmatched scale which enables us to offer the best value to the market.”

Green continues: “Looking ahead, as Web Industries celebrates its 50-year anniversary next year, we will continue investing in ways that best serve our nonwovens customers and add to our status as the industry’s premier provider of flexible material formatting services.”

www.webindustries.com

Athea Laboratories

Athea Laboratories continues capital investment in new machinery to further bolster its manufacturing capabilities. The addition of a new high speed perforator machine and 5000 gallon mixing tank will help to improve efficiency and speed of manufacturing with a number of products. These additions also help emphasize Athea’s capabilities as a full turnkey wet wipes and liquid product manufacturer with the ability to handle all manufacturing in house.

With over 50 years of experience, Athea Laboratories is the leader in specialty wipes, liquid, and powder contract manufacturing and packaging. Its expertise and experience gives customers an extensive variety of product formats to serve numerous end-user markets with their private labeled product. As an EPA and FDA facility, Athea’s manufacturing capabilities include custom wipe converting, custom formula development, blending services, on-site chemists, formula-substrate compatibility testing, graphics, and technical and regulatory support. Athea can offer customers a turnkey solution to their packaging needs at low minimums.

www.athea.com

Beckmann Converting

Beckmann Converting continues to upgrade its high tech, ultrasonic laminating equipment, both in bonding capability and in web handling, to create wide web, multilayer and multifunction composites. Upgrades have allowed the company to process more efficiently and to process more types of raw materials. Beckmann Converting operates as a contract or toll laminator and is able to create from two-layer composites to six-layer composites. It can create them as wide as 120 inches and slit in line, to any width a customer or its next step converter requires. These composites can be combinations of nonwovens, films, knits, wovens or meshes.

Ultrasonic laminating has a unique place in the creation of multi-layer composites because nothing other than the original materials are used in that process. This makes it a true “green” process. As long as there is sufficient thermoplastic content in the layers to be laminated, the ultrasonic energy melts the materials at the bonding points, making it the bonding link of the individual layers, unlike adhesive bonding, which introduces foreign substances into the composites. Because ultrasonic lamination is a “point bonding process,” all of the properties of the raw material layers, in between the bond points, are the same as before lamination, which include properties such as strength, loft, breathability, filtration and chemical resistance. Beckmann Converting has successfully produced multi-layer composites for applications such as filtration, environmental, protective apparel, protective covers, healthcare products, cleanroom wipes and many more.

www.beckmannconverting.com

Berk International

Boyertown, PA-based Berk International manufactures nonwoven wipes, toilet tissue and paper towels. The company is an expert in converting an assortment of materials including DRC, spunlace, airlaid, hydroentangled nonwovens, meltblown, needlepunch, TAD, tissue and towel. The Berk family has been in the wipes converting business since 1975 and has established a reputation of producing high quality products at reasonable prices. CEO Larry Berk and his brother Jeff Berk, who is president and head of sales, started Berk Wiper in 2000 and have grown the business every year since.

With 17 production lines running 24 hours a day in its 275,000 square foot facility, no job is too big or too small. From private labeling to contract converting to their own brands, Berk has it all. The company converts wipes for every market including Jan-San, food service, healthcare, automotive and industrial. Its capabilities include flat sheeting, interfolding, 1/2, 1/4, 1/6 and 1/8 folding, perforating, printing, rewinding, laminating and slitting.

www.berkwiper.com

BMP America

BMP America Inc. is part of a global manufacturing group specializing in the manufacture and conversion of technical nonwoven textiles, engineered polyurethane elastomers, mechanical components and sub-assemblies used in a diverse range of industrial applications. BMP America is a tier one supplier of components to major OEM companies in the appliance, construction, printing, automotive, filtration and renewable energy market sectors.

BMP America, Inc.’s headquarters and manufacturing facility is located in Western New York along with a subsidiary manufacturing facility located in Juarez, Mexico. The company also has technical sales offices in Oregon, Connecticut, Iowa and Maine.

The Western New York and Mexican facilities primarily manufacture engineered nonwoven products and assemblies for OEM accounts in North America,. Meanwhile, sister companies, BMP Europe, which is located in England, manufactures similar products as well as engineered polyurethane elastomers for accounts primarily in Europe, and BMP Asia manufactures similar products for accounts located primarily in the Asia-Pacific region and is a contract manufacturer for BMP America and BMP Europe.

In general the manufacturing process is short run and job shop in nature with many processing, converting and assembly operations. Both the U.S., European and Asian manufacturing facilities have similar capabilities and equipment enabling the transfer of business between its sister companies with minimal disruption if conditions warrant.

BMP is a wholly owned subsidiary of Andrew Industries Ltd., a privately owned company whose core technology is in the manufacture of industrial textiles, specifically, needle felts and thermal bonded nonwoven for various applications including filtration, insulation, laundry and business machine applications.

www.bmpworldwide.com

Converted Products

In 1993, Converted Products, Incorporated (CPI) opened for business with the simple idea of providing quality contract converting services in slitting and die cutting. Twenty-four years later, CPI has kept that same simple premise but has expanded its contract services to include wider width, high speed slitting, hot melt laminating, traverse (spool) winding, rotary and flat bed die cutting, warehousing/logistics and product/process development. Operating in an ISO9001 process, Converted Products’ 160,000 square foot facility is located on the northwest side of Milwaukee, WI.

CPI’s slitting capabilities include score, shear, razor, single knife and rotary, in widths ranging from 1/8 to 136 inches along with experience in a wide variety of flexible materials.

In 2017, CPI upgraded its high speed, wide-width equipment by installing a new winder with a drive assist unwind. President and founder of CPI Chris Gorenc says, “We had the opportunity to keep our equipment on the leading edge by installing a high speed, wide width surface winder with a drive assist unwind. There aren’t many contract converters who have the drive assist technology. It gives us an opportunity to work with low tensile materials that need a driven unwind to ensure a quality wound roll.”

But CPI’s work on efficiency didn’t end with just a machine. They went to work on eliminating as much waste in their process as well by implementing and adopting their own version of Overall Equipment Effectiveness (OEE). “We started by using whiteboard’s and worked into a more sophisticated database. Regardless of the method, we had to reduce our downtime as much as possible. It is a never-ending process to drive out wasted time and make sure our customers get the best price we can offer,” Gorenc adds.

The new surface winder features the following capabilities: total width: 130”; slit widths: 3” to 130”; unwind OD max: 100”; rewind OD max: 72”; drive assist technology; unwind ID’s: 3”, 6”, 6-3/4”, 8”, 10”, 10-5/8”, 12” (others available upon request); rewind ID’s: 3”, 6”, 6-3/4”, 10” (others available upon request); and speeds in excess of 4000 ft per min.

www.convertedproducts.com

E&T Converters

E&T Converters was founded in 1972, with the goal to provide the best possible converting services at the most competitive price. Because it has so many years of experience in the converting business, its staff is able to offer a wide variety of slitting capabilities. This enables the company to provide contract converting for virtually any market. In 1989, E&T built a new 230,000 sq. foot state-of-the-art building with a rail site so that it could effectively manage the many needs of its customers. E&T is family owned and takes pride in its quality, service and value offered to all of its customers.

www.eandtconverters.com

Micrex Corporation

Micrex is the developer and manufacturer of the Micrex/Microcreper family of compressive treatment machinery for nonwovens, paper, films, composites and textiles. Companies worldwide use Micrex technology to add softness, bulk, drape, absorbency, extensibility, and stretch to a wide range of products.

Contract Microcreping is at the core of our business. Running a wide range of materials improves its grasp of market needs and informs its R&D. As the company has no product except its technology, it will never be a competitor to its contract converting customers.

Micrex performs product development through the Micrex Innovation Lab. This integrates with contract Microcreping services for those firms whose current needs do not yet require the purchase of a dedicated Micrex/Microcreper system. Micrex is prepared to support projects from initial development through large scale production. All configurations of Micrex/Microcreper are available for contract production.

No-cost lab scale screening trials are available to qualified customers. For information about this program please see: http://micrex.com/screening-trials/.

www.micrex.com

National Wiper Alliance

National Wiper Alliance (NWA) is North America’s premier contract converter for dry wipes. NWA operates out of its 500,000 square foot state-of-the-art facility located just outside Asheville, NC. NWA capabilities include slitting, inner folding, folding, sheeting, perforating and printing. Additional services offered include turn key & toll converting, private labeling, product development, sample runs, product testing, warehousing as well as supply chain management. Most recently, NWA has completed a major renovation of an additional 152,000 square foot warehouse ensuring space to meet the continued growth and needs of customers. Products converted by NWA can be found in the retail, aerospace, automotive, industrial, food service, hospitality, medical, government, military and janitorial markets. National Wiper Alliance is registered to ISO 9001:2015.

National Wiper Alliance and its owner have received numerous awards over the past year. These awards include: SBA-North Carolina 2015 Small Business Person of the Year – Jeff Slosman; NC Chamber of Commerce – 2015 Manufacturer of the Year – Honorable Mention; Business NC Magazine – 2015 NC Small Business of the Year and Wake Forest Family Business Center; 2016 NC Family Business of the Year, and INDA - 2018 WOW Innovation Award Finalist.

www.nationalwiper.com

Nonwovens of America

Nonwovens of America, Inc. (NOA) is located in Swannanoa, NC, operating a 5.4-meter air-lay needlepunch line and running colors in a weight range of 3.5 ounces per square yard to 34 ounces per square yard. In addition to the needlepunch line, NOA provides custom converting services which include a 10-color, 99” wide rotary screen print line, blanket lines, an inline calendar, and slitting and re-rolling. NOA offers toll converting services on the needlepunch line as well as all other converting services. The main areas of focus are automotive, retail, geotextile, industrial and disaster and emergency blankets. NOA provides in-house customer service, product development, warehousing, logistics and distribution support.

www.nonwovensofamerica.com

Royal Carolina

Royal Carolina offers printing on its rotary screen & flexographic lines up to 90” on woven and nonwoven fabric. Additionally, the company provides coating, a wide range of finishes, and capabilities for slitting.

Royal Carolina is a “Made in America” and geographically located in North Carolina. Its goal is to work collaboratively with customers to develop customized solutions.

Royal Carolina works with many industries including medical, bedding, furniture, automotive, industrial, filtration and construction.

Its rotary screen printing can provide 12 colors at 72” wide and eight colors at 90” wide. Its standard inks are water-based pigments. The company is adept with specialty products such as, PCM, conductive ink, color changing ink, anti-skid, adhesives and more.

Royal Carolina’s flexographic press runs nonwoven materials up to 64” wide and prints up to four colors. This offers low cost printing for high volume needs.

Royal Carolina’s pad finishing capabilities include but are not limited to water repellants, fire retardants, antimicrobials, pad dyes, soil releases, odor elimination, insect repellant, and more. It has two ranges and can go up to 90” wide. It also offers coatings on material up to 72” wide.

www.royalcarolina.com

Southeast Nonwovens

Southeast Nonwovens, Inc. (SENW) has been in business for 21 years, serving the nonwovens industry as an independent facility for manufacturing, converting and research of staple based fiber nonwovens.

SENW offers contract manufacturing using the wet-lay, dry lay, and air lay processes.

- Wet lay lines - 32” and 63” wide

- Dry lay line - up to 90” wide

- Air lay line - 1 meter wide

SENW also offers contract research and product development services – supporting the wet, dry and air lay manufacturing processes. Its material science experts can understand a customer’s requirements, design a product using its laboratory & pilot scale equipment, then produce a customer’s custom product.

Southeast Nonwovens, Inc. has all the technology customers need to develop, prototype, and produce their next generation of nonwoven products…all in one facility.

www.southeastnonwovens.com

Web Industries

“Web Industries Inc. took giant steps in 2018 to strengthen its position as a preferred provider in the nonwovens sector,” says director of Sales, Personal and Home Care Adrienne Green. “This past May we completed an $8 million investment in two 8-color flexographic printing presses, and 60-inch OD web spooling and precision slitting lines.”

The new resources are housed at a single location, its Ft. Wayne, IN, plant. Web is the only precision formatter equipped to print, slit and spool flexible materials used in personal and home care products at a single location.

“Having our resources under the same roof gives our customers supply chain advantages, including product differentiation, faster throughput and a single point of accountability,” Green adds. “Web can print and spool specialized, colorful materials that customers can run at the highest level of efficiency. Large format spools can run more than 20 times longer than pad rolls.”

Web’s new eight-color printing capability is of particular interest to brands using vibrant graphics and logos to differentiate their products.

Green notes that Web can source materials from virtually any flexible materials supplier worldwide. “We are committed to open materials sourcing,” she says. “We believe that vertically integrated formatters have inherent restrictions to their material options. They are committed to using the materials they produce in house while offering smaller scale converting services. Web can source from anyone, anywhere on the planet, for speed, cost and proximity advantages. Web has unmatched scale which enables us to offer the best value to the market.”

Green continues: “Looking ahead, as Web Industries celebrates its 50-year anniversary next year, we will continue investing in ways that best serve our nonwovens customers and add to our status as the industry’s premier provider of flexible material formatting services.”

www.webindustries.com