Tara Olivo, Associate Editor09.12.18

The 12th annual World of Wipes (WOW) International Conference, which took place June 5-8, successfully connected 440 participants in the wipes industry. Organized by INDA, the Association of the Nonwoven Fabrics Industry, the event was highlighted with an industry and committee majority vote announcing Diamond Wipes Internationals’ Hero Wipes as the recipient of this year’s World of Wipes Innovation Award. The innovative new wipe removes toxic, cancer-causing carcinogens from firefighters’ skin. Other finalists were Solugen, Inc.’s Ode to Clean Wipes made entirely from plant starch and National Wiper Alliance’s Rhino Wipe Tote System, a portable container for easy dispensing of heavy duty Rhino Wipes.

The annual award recognizes the product that most expands the use of nonwovens and demonstrates creativity, novelty, uniqueness, and technical sophistication within the entire nonwovens wipes value chain.

Held at the Sheraton Grand, Chicago, IL, the event attracted participants from 22 countries representing the entire wipes supply chain to examine issues and advances in the growing multi-billion dollar growing wipes sector.

Opening the conference was consumer psychologist Kit Yarrow, Ph.D., Professor Emeritus, Golden Gate University, presenting psychological insights and strategies for marketing to Gen Z. The program also included sessions centered on consumer trends and market data, sustainability, substrate innovation, challenges with preservatives, regulations, packaging, institutional wipe trends and progress on flushable wipes testing procedures.

Preceding the conference, INDA’s Wipes Academy was conducted by instructor Rob Johnson, PE, principal, Smith, Johnson & Associates. The academy is the first and only comprehensive wipes training for the entire wipes supply chain.

“This year’s program content hit the mark in addressing key issues facing wipes producers and marketers. WOW serves as the hub for international wipes professionals to convene and connect, and the buzz this year indicates this happened in abundance,” says Dave Rousse, INDA president.

WOW networking events included two evening receptions amid 52 tabletop displays, daily breakfasts, networking breaks, and the option to Dine with Industry Thought Leaders.

WOW 2019 will be held June 24-27, 2019, at the Atlanta Marriott Marquis in Atlanta, GA.

Sandler Showcases New Wipes Substrate

At World of Wipes, Sandler AG unveiled a new wipes substrate for different applications. Made with a special cellulosic fiber, the nonwoven is particularly soft and gentle on the skin, while also featuring high absorbency and opacity. The versatile product is also well suited for personal hygiene applications.

This nonwoven all-rounder additionally fosters environmental protection and sustainability. It is composed of viscose and cellulose acetate—a silky material naturally sourced from sustainably managed forests. The nonwoven is therefore both biodegradable and compostable.

Mogul Highlighted Recent Accomplishments

Mogul South Carolina Nonwovens was recently certified under ISO 9001:2015. ISO certification demonstrates Mogul’s commitment to serving markets that require the highest levels of quality assurance, according to the company. International Organization for Standardization (ISO) 9001:2015 is the most updated standard of its kind and focuses on quality management systems and performance. It provides guidelines for developing a management system that aligns quality with the company’s wider business strategy.

To support ongoing certification, Mogul invested in key staff members with external training to become certified internal auditors. This allows the company to simultaneously complete internal audits in each department throughout the year and prior to the annual recertification audit. The company selected BSI Group as the registrar, and through extensive preparation was certified with no major findings.

The company also recently earned the Forest Stewardship Council (FSC) Chain-of-Custody (CoC) certification [FSC-C137808] from the Rainforest Alliance. Mogul pursued the certification in alignment with its corporate sustainability objectives to participate in environmental stewardship through efficient use of energy, reduction of waste and emissions, and maintenance of the good health, safety and well-being of its employees.

Lonza Highlighted Solutions for Wipes

Lonza Consumer Product Ingredients showcased its preservation and disinfection solutions, as well as its regulatory expertise for the wet wipes industry at World of Wipes.

At its tabletop, Lonza Consumer Product Ingredients featured a range of new generation alternative preservation ingredients.

Additionally, during the conference, Hans Hummel, global marketing manager for the Hygiene business within Lonza Consumer Product Ingredients, presented “The FDA Issues New Rules for OTC Topical Antimicrobial Products: What’s Next for Wet Wipe Manufacturers?”

The antimicrobial hand hygiene market in the U.S. is going through significant disruption due to the FDA’s proposed and final rulemakings for a range of over-the-counter (OTC) hand soaps, sanitizers, and sanitizing wipes. Hummel reviewed the monographs, discuss the implications of the FDA’s rulemaking for those that manufacture and market hand hygiene products including antimicrobial wipes, and outline how the industry is supporting theses product categories.

Barnhardt Presented its Range of Cotton

At World of Wipes, Barnhardt discussed its latest fiber products that can be used in wipes applications.

HighQ Ultra: Cotton in its purest form, HighQ Ultra is made from high-quality, USA grown, long staple cotton fiber and processed with Barnhardt’s proprietary fiber cleaning process resulting in a superior clean, pure cotton that is ideal for baby, medical and beauty wipes.

HighQ UltraSoft: Specially formulated to enhance the softness of cotton throughout the nonwoven production process, HighQ UltraSoft delivers exceptionally soft cotton consumers prefer in their wipes.

HyDri: An innovative cotton fiber that is specially formulated to be hydrophobic, HyDri allows nonwoven fabric producers to design fabrics that manage and control moisture while providing the comfort of cotton against the skin. Additionally, HyDri is oleophilic (oil-loving) making it an ideal fiber for dry wipes.

Organic HighQ UltraClean: Made from USA grown, certified organic, long staple cotton and purified with Barnhardt’s proprietary fiber cleaning process, Organic HighQ UltraClean provides superior purity for organic cotton wipes applications.

Teknoweb Discussed Converting Lines

Teknoweb Converting, which provides complete manufacturing solutions for the wet wipes industry, discussed its range of converting lines at WOW.

For flat folding wet wipes converting lines, Teknoweb offers new, high speed unwinders with tension control, a high speed stacker with 240 pack per minute capability, an improved log saw, and improved sanitary design.

Meanwhile, for crossfolding wet wipes converting lines, the company manufactures machines that are suitable for converting paper-based substrates and a servo-driven stacker for higher speed processing (up to 650 cuts per minute per lane).

Teknoweb also highlighted a new high-speed disposable glove converting line and a new multipack machine.

Meanwhile, Teknoweb’s new Connected Wipes platform, which the company launched in early 2017, was also discussed. It is a real MES (manufacturing execution system) embedded in the machine to keep track of all manufacturing information in real time. It receives up-to-the-minute data from the folder and all other connected machines that afterward can be used to assist line management. It automates data entry from the operators, keeps track of all data generated by the machine, collates and connects them to build smart reports for customers. Those are used to make quicker business decisions and more importantly is data based. The Connected Wipes can also be integrated with factory ERP (enterprise resource planning) systems on request.

OMNOVA Offers Nonwovens Technology Platform

OMNOVA has introduced an innovative technology platform for wipes consisting of a unique finishing treatment and compatible specialized binders. The platform helps create nonwoven performance advantages including thinner, softer, durable, more absorbent, lint-free wipes as well as the ability to substitute substrate components without impacting performance.

This special three-part platform includes special Sunbond and Acrygen binders and the innovative SoftWick SF20 surface treatment. It is ideal for use on polypropylene, polyester, PLA, and multi-fiber component substrates, and it enables the reduction of viscose in substrates without sacrificing softness or absorbency. With strong ionic compatibility between all the platform elements, the individual OMNOVA products can be used standalone or in tandem, based on performance requirements.

Lenzing Launches Veocel Brand

The Lenzing Group introduced Veocel, the company’s new nonwoven specialty brand. Positioned as a premium brand of nonwoven fibers for daily care rituals, Veocel provides the nonwovens industry with fibers that are certified clean and safe, biodegradable, from botanic origin and produced in an environmentally responsible production process. Offerings under the Veocel brand cover a broad range of applications for everyday use, from baby care, beauty and body care to intimate care and surface cleaning. Such applications are categorized under branded offers Veocel Beauty, Veocel Body, Veocel Intimate and Veocel Surface.

The introduction of Veocel is a key milestone of Lenzing’s new brand strategy to transform from a business-to-business (B2B) fiber producer to a business-to-business-to-consumer (B2B2C) brand. Coupled with ongoing co-branding, joint marketing and brand education initiatives conducted with customers and brands globally, Veocel will enable Lenzing to shift its focus beyond fiber types to product application and build a relatable and emotional connection with consumers.

“Guided by our sCore TEN strategy, the launch of the Veocel brand will accelerate our migration into a specialty fiber business with a strong focus on innovation, quality and sustainability. Through ongoing proactive communication, the Veocel brand will also promote a holistic understanding about the benefits of botanic fibers in nonwoven products across the industry value chain and among consumers. This will not only help to maximize the marketing efforts of our customers and partners, but also drive dialogue about sustainability across the nonwoven industry. Through the Veocel brand, we hope to address the growing demand for transparency and sustainability across the value chain and provide consumers with greener product options,” says Robert van de Kerkhof, chief commercial officer of Lenzing Group.

Veocel fiber portfolio includes Veocel Lyocell and Veocel Specialty Viscose fibers, which are derived from renewable or sustainable wood sources from certified and controlled forests and plantations. The botanic origin of the fibers offers functional benefits such as improved moisture absorbency and management, contribution to breathability, good hand feel, blending versatility, and all Veocel fibers are certified biodegradable in soil, landfill, compost and seawater. With a strong commitment to ensure fiber cleanliness, these fibers are manufactured using a stringently monitored production process in accordance with Lenzing’s high quality, environmental and safety standards.

The latest addition to the Veocel Surface brand – the Veocel Lyocell Fiber with “Quat” Release technology, is a premium and specialty wood-based cellulose fiber that is used in hard surface cleaning and disinfectant wet wipes. Veocel Lyocell fibers with Lenzing’s Quat Release technology allow quaternary ammonium compounds, also known as “Quat”, to be released from wet wipes onto the surface for effective cleaning and disinfecting in household and industrial environments.

While the nonwovens industry has acknowledged the benefits of Lenzing’s cellulosic fibers, such as their sustainable nature, botanic origin and ability to improve cleaning experience, the majority of single-use cleaning and disinfectant wet wipes mainly consists of synthetic fibers such as polyester and polypropylene. This binding interaction substantially decreases the release of “Quat” and can negatively impact the efficacy of the disinfectant product. However, with Lenzing’s “Quat” Release technology, the binding of Quat to the surface of Veocel Lyocell Fibers is significantly reduced, resulting in improved effectiveness of surface cleaning and the disinfection process. Wet wipes containing Veocel Lyocell Fiber with “Quat” Release technology demonstrate significantly improved release of Quat from the wet wipe to the surface, resulting in improved product stability and performance. In addition, Veocel Lyocell fibers also promote good absorbency, homogenous distribution of liquid in wet wipes and good hand feel.

Edgewater Fullscope Helps Wipes Manufacturers Use Microsoft Technology

Edgewater Fullscope, a leading provider of Microsoft Dynamics 365 (formerly Dynamics AX and CRM), Business Intelligence and Microsoft’s modern technology platform, exhibited at the 2018 World of Wipes International Conference. At its tabletop, visitors learned how wipe manufacturers can utilize Microsoft Solutions, implemented by Edgewater Fullscope to get ahead of the competition. Fullscope has helped over 200 companies use Microsoft technology – Dynamics 365/ERP, CRM and Business Intelligence – to help solve their toughest business systems issues.

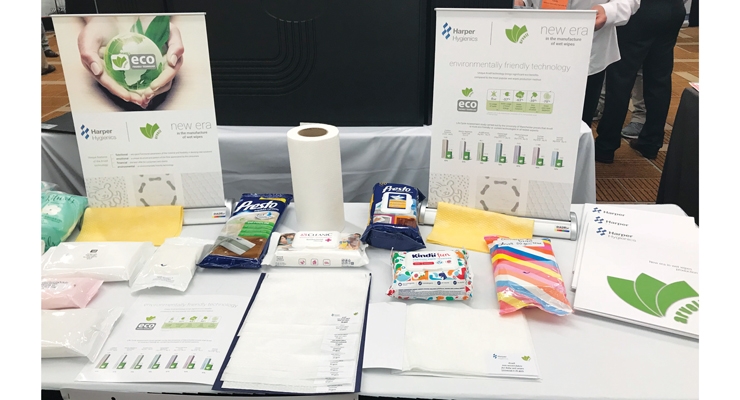

Harper Hygienics Showcased Arvell Substrates

Polish wipes maker Harper Hygienics showed off a variety of wipes manufactured using Arvell technology supplied by wipes converting line specialist Teknoweb Materials.

Arvell technology has been designed to enable intimate blending of the two types of fibers, which are then assembled into a web by thermocalendering technology. The result is a web that shows unsurpassed performance in terms of absorption through a process that gives manufacturers unlimited options when it comes to raw materials.

A completely dry process, Arvell does not require the use of hydroentanglement for bonding and the absence of water, giving it a better sustainability profile.

The annual award recognizes the product that most expands the use of nonwovens and demonstrates creativity, novelty, uniqueness, and technical sophistication within the entire nonwovens wipes value chain.

Held at the Sheraton Grand, Chicago, IL, the event attracted participants from 22 countries representing the entire wipes supply chain to examine issues and advances in the growing multi-billion dollar growing wipes sector.

Opening the conference was consumer psychologist Kit Yarrow, Ph.D., Professor Emeritus, Golden Gate University, presenting psychological insights and strategies for marketing to Gen Z. The program also included sessions centered on consumer trends and market data, sustainability, substrate innovation, challenges with preservatives, regulations, packaging, institutional wipe trends and progress on flushable wipes testing procedures.

Preceding the conference, INDA’s Wipes Academy was conducted by instructor Rob Johnson, PE, principal, Smith, Johnson & Associates. The academy is the first and only comprehensive wipes training for the entire wipes supply chain.

“This year’s program content hit the mark in addressing key issues facing wipes producers and marketers. WOW serves as the hub for international wipes professionals to convene and connect, and the buzz this year indicates this happened in abundance,” says Dave Rousse, INDA president.

WOW networking events included two evening receptions amid 52 tabletop displays, daily breakfasts, networking breaks, and the option to Dine with Industry Thought Leaders.

WOW 2019 will be held June 24-27, 2019, at the Atlanta Marriott Marquis in Atlanta, GA.

Sandler Showcases New Wipes Substrate

At World of Wipes, Sandler AG unveiled a new wipes substrate for different applications. Made with a special cellulosic fiber, the nonwoven is particularly soft and gentle on the skin, while also featuring high absorbency and opacity. The versatile product is also well suited for personal hygiene applications.

This nonwoven all-rounder additionally fosters environmental protection and sustainability. It is composed of viscose and cellulose acetate—a silky material naturally sourced from sustainably managed forests. The nonwoven is therefore both biodegradable and compostable.

Mogul Highlighted Recent Accomplishments

Mogul South Carolina Nonwovens was recently certified under ISO 9001:2015. ISO certification demonstrates Mogul’s commitment to serving markets that require the highest levels of quality assurance, according to the company. International Organization for Standardization (ISO) 9001:2015 is the most updated standard of its kind and focuses on quality management systems and performance. It provides guidelines for developing a management system that aligns quality with the company’s wider business strategy.

To support ongoing certification, Mogul invested in key staff members with external training to become certified internal auditors. This allows the company to simultaneously complete internal audits in each department throughout the year and prior to the annual recertification audit. The company selected BSI Group as the registrar, and through extensive preparation was certified with no major findings.

The company also recently earned the Forest Stewardship Council (FSC) Chain-of-Custody (CoC) certification [FSC-C137808] from the Rainforest Alliance. Mogul pursued the certification in alignment with its corporate sustainability objectives to participate in environmental stewardship through efficient use of energy, reduction of waste and emissions, and maintenance of the good health, safety and well-being of its employees.

Lonza Highlighted Solutions for Wipes

Lonza Consumer Product Ingredients showcased its preservation and disinfection solutions, as well as its regulatory expertise for the wet wipes industry at World of Wipes.

At its tabletop, Lonza Consumer Product Ingredients featured a range of new generation alternative preservation ingredients.

Additionally, during the conference, Hans Hummel, global marketing manager for the Hygiene business within Lonza Consumer Product Ingredients, presented “The FDA Issues New Rules for OTC Topical Antimicrobial Products: What’s Next for Wet Wipe Manufacturers?”

The antimicrobial hand hygiene market in the U.S. is going through significant disruption due to the FDA’s proposed and final rulemakings for a range of over-the-counter (OTC) hand soaps, sanitizers, and sanitizing wipes. Hummel reviewed the monographs, discuss the implications of the FDA’s rulemaking for those that manufacture and market hand hygiene products including antimicrobial wipes, and outline how the industry is supporting theses product categories.

Barnhardt Presented its Range of Cotton

At World of Wipes, Barnhardt discussed its latest fiber products that can be used in wipes applications.

HighQ Ultra: Cotton in its purest form, HighQ Ultra is made from high-quality, USA grown, long staple cotton fiber and processed with Barnhardt’s proprietary fiber cleaning process resulting in a superior clean, pure cotton that is ideal for baby, medical and beauty wipes.

HighQ UltraSoft: Specially formulated to enhance the softness of cotton throughout the nonwoven production process, HighQ UltraSoft delivers exceptionally soft cotton consumers prefer in their wipes.

HyDri: An innovative cotton fiber that is specially formulated to be hydrophobic, HyDri allows nonwoven fabric producers to design fabrics that manage and control moisture while providing the comfort of cotton against the skin. Additionally, HyDri is oleophilic (oil-loving) making it an ideal fiber for dry wipes.

Organic HighQ UltraClean: Made from USA grown, certified organic, long staple cotton and purified with Barnhardt’s proprietary fiber cleaning process, Organic HighQ UltraClean provides superior purity for organic cotton wipes applications.

Teknoweb Discussed Converting Lines

Teknoweb Converting, which provides complete manufacturing solutions for the wet wipes industry, discussed its range of converting lines at WOW.

For flat folding wet wipes converting lines, Teknoweb offers new, high speed unwinders with tension control, a high speed stacker with 240 pack per minute capability, an improved log saw, and improved sanitary design.

Meanwhile, for crossfolding wet wipes converting lines, the company manufactures machines that are suitable for converting paper-based substrates and a servo-driven stacker for higher speed processing (up to 650 cuts per minute per lane).

Teknoweb also highlighted a new high-speed disposable glove converting line and a new multipack machine.

Meanwhile, Teknoweb’s new Connected Wipes platform, which the company launched in early 2017, was also discussed. It is a real MES (manufacturing execution system) embedded in the machine to keep track of all manufacturing information in real time. It receives up-to-the-minute data from the folder and all other connected machines that afterward can be used to assist line management. It automates data entry from the operators, keeps track of all data generated by the machine, collates and connects them to build smart reports for customers. Those are used to make quicker business decisions and more importantly is data based. The Connected Wipes can also be integrated with factory ERP (enterprise resource planning) systems on request.

OMNOVA Offers Nonwovens Technology Platform

OMNOVA has introduced an innovative technology platform for wipes consisting of a unique finishing treatment and compatible specialized binders. The platform helps create nonwoven performance advantages including thinner, softer, durable, more absorbent, lint-free wipes as well as the ability to substitute substrate components without impacting performance.

This special three-part platform includes special Sunbond and Acrygen binders and the innovative SoftWick SF20 surface treatment. It is ideal for use on polypropylene, polyester, PLA, and multi-fiber component substrates, and it enables the reduction of viscose in substrates without sacrificing softness or absorbency. With strong ionic compatibility between all the platform elements, the individual OMNOVA products can be used standalone or in tandem, based on performance requirements.

Lenzing Launches Veocel Brand

The Lenzing Group introduced Veocel, the company’s new nonwoven specialty brand. Positioned as a premium brand of nonwoven fibers for daily care rituals, Veocel provides the nonwovens industry with fibers that are certified clean and safe, biodegradable, from botanic origin and produced in an environmentally responsible production process. Offerings under the Veocel brand cover a broad range of applications for everyday use, from baby care, beauty and body care to intimate care and surface cleaning. Such applications are categorized under branded offers Veocel Beauty, Veocel Body, Veocel Intimate and Veocel Surface.

The introduction of Veocel is a key milestone of Lenzing’s new brand strategy to transform from a business-to-business (B2B) fiber producer to a business-to-business-to-consumer (B2B2C) brand. Coupled with ongoing co-branding, joint marketing and brand education initiatives conducted with customers and brands globally, Veocel will enable Lenzing to shift its focus beyond fiber types to product application and build a relatable and emotional connection with consumers.

“Guided by our sCore TEN strategy, the launch of the Veocel brand will accelerate our migration into a specialty fiber business with a strong focus on innovation, quality and sustainability. Through ongoing proactive communication, the Veocel brand will also promote a holistic understanding about the benefits of botanic fibers in nonwoven products across the industry value chain and among consumers. This will not only help to maximize the marketing efforts of our customers and partners, but also drive dialogue about sustainability across the nonwoven industry. Through the Veocel brand, we hope to address the growing demand for transparency and sustainability across the value chain and provide consumers with greener product options,” says Robert van de Kerkhof, chief commercial officer of Lenzing Group.

Veocel fiber portfolio includes Veocel Lyocell and Veocel Specialty Viscose fibers, which are derived from renewable or sustainable wood sources from certified and controlled forests and plantations. The botanic origin of the fibers offers functional benefits such as improved moisture absorbency and management, contribution to breathability, good hand feel, blending versatility, and all Veocel fibers are certified biodegradable in soil, landfill, compost and seawater. With a strong commitment to ensure fiber cleanliness, these fibers are manufactured using a stringently monitored production process in accordance with Lenzing’s high quality, environmental and safety standards.

The latest addition to the Veocel Surface brand – the Veocel Lyocell Fiber with “Quat” Release technology, is a premium and specialty wood-based cellulose fiber that is used in hard surface cleaning and disinfectant wet wipes. Veocel Lyocell fibers with Lenzing’s Quat Release technology allow quaternary ammonium compounds, also known as “Quat”, to be released from wet wipes onto the surface for effective cleaning and disinfecting in household and industrial environments.

While the nonwovens industry has acknowledged the benefits of Lenzing’s cellulosic fibers, such as their sustainable nature, botanic origin and ability to improve cleaning experience, the majority of single-use cleaning and disinfectant wet wipes mainly consists of synthetic fibers such as polyester and polypropylene. This binding interaction substantially decreases the release of “Quat” and can negatively impact the efficacy of the disinfectant product. However, with Lenzing’s “Quat” Release technology, the binding of Quat to the surface of Veocel Lyocell Fibers is significantly reduced, resulting in improved effectiveness of surface cleaning and the disinfection process. Wet wipes containing Veocel Lyocell Fiber with “Quat” Release technology demonstrate significantly improved release of Quat from the wet wipe to the surface, resulting in improved product stability and performance. In addition, Veocel Lyocell fibers also promote good absorbency, homogenous distribution of liquid in wet wipes and good hand feel.

Edgewater Fullscope Helps Wipes Manufacturers Use Microsoft Technology

Edgewater Fullscope, a leading provider of Microsoft Dynamics 365 (formerly Dynamics AX and CRM), Business Intelligence and Microsoft’s modern technology platform, exhibited at the 2018 World of Wipes International Conference. At its tabletop, visitors learned how wipe manufacturers can utilize Microsoft Solutions, implemented by Edgewater Fullscope to get ahead of the competition. Fullscope has helped over 200 companies use Microsoft technology – Dynamics 365/ERP, CRM and Business Intelligence – to help solve their toughest business systems issues.

Harper Hygienics Showcased Arvell Substrates

Polish wipes maker Harper Hygienics showed off a variety of wipes manufactured using Arvell technology supplied by wipes converting line specialist Teknoweb Materials.

Arvell technology has been designed to enable intimate blending of the two types of fibers, which are then assembled into a web by thermocalendering technology. The result is a web that shows unsurpassed performance in terms of absorption through a process that gives manufacturers unlimited options when it comes to raw materials.

A completely dry process, Arvell does not require the use of hydroentanglement for bonding and the absence of water, giving it a better sustainability profile.