Karen McIntyre, Editor03.27.17

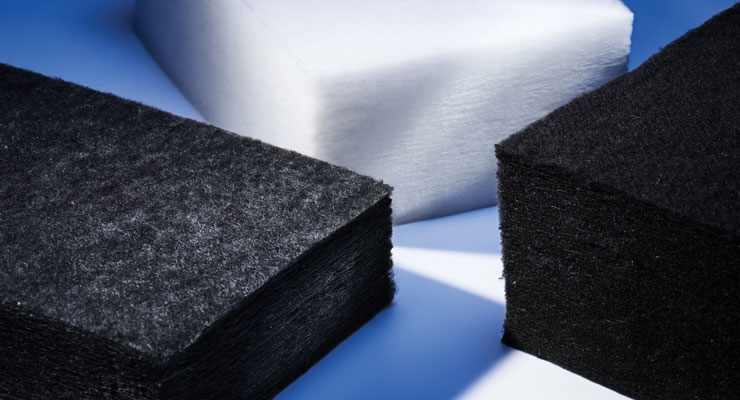

The ability of nonwovens to offer voluminous and soft materials that can handle a number of raw materials and fit nearly any shape continue to win them a role as acoustic materials. Whether the solutions are based on needlepunch, thermal bonded or some type of proprietary technology, nonwovens are meeting the needs in a range of applications and a number of companies are finding their role in the acoustics market grow.

Find Comfort With Sandler

Sandler Nonwovens’ fibercomfort acoustic nonwovens are made with a thermally bonded or hybrid thermal bonded/needlepunched process, depending on the end use application. Regardless the technology, the nonwovens used are voluminous and soft and used as acoustical room elements in partitions, acoustic wall decorations or even acoustic furniture.

“All fibercomfort products owe their high acoustic efficiency to their open-pore structure—fine fibers create a more or less flexible ‘fiber skeleton,’ featuring a large inner surface,” explains Gerhard Klier, sales director of technical products. “Sound is diffracted in numerous places, whereby sound waves are absorbed and dampened by the nonwoven. This structure also makes fibercomfort nonwovens ideal heat insulators.”

It is the structure of fibercomfort that makes these nonwovens highly efficient sound insulators. Product properties such as thickness and volumetric weight can be adjusted according to the requirements of the specific application. Particularly in construction, they also function as heat insulators. As such, they help lower the need for heating in the building and thereby contribute to reducing the energy consumption.

“fibercomfort nonwovens are made from polyester—the same fibers also used in clothing. They are light, easy to handle and manufactured without any chemical binders or additives,” Klier adds. “As such, these materials are gentle on the skin and odorless. They are also resistant to moisture and UV light and offer no breeding ground for germs or bacteria. Flame-resistant product variants are also available. All-in-all, the nonwovens fulfill the highest requirements of product safety, health and durability and provide an optimum alternative for people suffering from allergies.”

fibercomfort nonwovens can be printed or laminated with different kinds of fabric, thereby also supporting individual design concepts.

Sandler is primarily targeting the fibercomfort product range at materials for wall and roof insulation in construction as well as for technical insulation, for example pipe insulation or insulation of hot-water tanks where they efficiently insulate heat and dampen sound.

In the office, dimensionally stable, self-supporting product variants are used as acoustically efficient room elements in suspended ceilings, partition walls or in textile wall decoration.

“We work in close partnership with customers in all of these markets, designing new product solutions together and incorporating fibercomfort nonwovens into our partner’s acoustic products,” Klier says.

A relatively new field for nonwoven acoustics materials, the use of these materials in design and interior acoustics, has already won Sandler an INDEX award in 2014. Sandler is constantly working with its customers and partners to develop the product range further and expand into new areas.

This expansion has been facilitated by room design trends in both home and work spaces that are increasingly relying on open plan floor layouts. At home, residents want to relax and wind down after a hard day’s work and not hear the sounds of traffic, and while in the office, workers want to be able concentrate on their work, no matter how busy a day it is for the colleagues around us. This has made acoustic room elements vital in ensuring a quiet, pleasant atmosphere despite the hustle and bustle of everyday life. In light of these trends, partitions, acoustically efficient wall decoration and acoustic furniture are increasingly asked for. The market is growing and fibercomfort nonwovens commend themselves to these applications.

In addition to highly efficient sound insulation, fibercomfort also answers the call for easy-to-handle materials, that—ideally—take sustainability into account.

“Being made of 100% polyester, fibercomfort nonwovens are not only easy-to-handle and pose no health risks, they are also fully recyclable even after years of use. In addition, the materials are partially made from recycled fibers themselves, contributing to the conservation of resources,” Klier adds.

Texel Teams Up

Texel is offering differentiated technology for acoustical performance. This builds on Lydall’s leading capabilities in its Thermal Acoustical Fibers segment where the companies provide material in the automotives sector, such as headliners membrane, wheel arch liners, flooring and trunk liners. “We currently see a tendency in the building industry,” marketing coordinator Myriam Symard says. “We have a lot of inquiries for acoustical applications such as underfloor substrate and wall acoustical membranes. That same tendency is also presenting in the office furniture market. Major office furniture companies are looking for acoustical solutions to reduce airborne noises in the work environment.”

In response, Texel and its parent company Lydall have been developing a range of products that is addressing these issues, whether to absorb the airborne noises or to reduce the sound transmission.

LEED certification has brought many advantages for energy efficiency and environmental design. The use of glass technology has increased, in order to maximize more natural lighting in the building space. The use of glass and other hard surfaces such as engineered wood and ceramics instead of carpets and traditional fabrics, has brought some acoustical concerns, and Symard says acoustic nonwovens are meeting the demand for quieter environments, which is driving more demand for sound absorbers whether in construction material or in the office furniture material.

Meanwhile, in North America growing demand for acoustics is being driven by more densification of the population, less urban sprawl and an increase in multidwelling units, which brings more demand for acoustical solutions.

Texel’s ability to create multilayers allow it to not only combine several layers of different nonwovens but also to combine through needling other technologies such as foam, fabrics and other type of nonwovens. “In addition, with our extrusions line we can add films on our concept,” Symard says. “We offer infinite options to our partners to create the right product in the right environment. Making the nonwoven is one, but understanding the science of sound is two. Throughout our development process we are always characterizing our material with absorption curves (NRC) and sound transmission (STC), which allows the end user to choose the right acoustical solution.”

Texel executives report needlepunch felt has been successful in sound attenuation, vibration isolation and shock absorption thanks to a structural fibrous matrix of various densities. “Compared to other materials such as foam and rubber, the needlepunch technology is durable and stable. The products are very lightweight and the resiliency of this type of nonwoven is nearly permanent,” Symard says. “When you select the proper blend of fibers and density you can maximize the properties of vibration-energy absorption and isolation characteristics.”

Lydall has developed these capabilities and is a leading producer of these products through Texel as well as its sister companies in Lydall Technical Nonwovens and Lydall Thermal/Acoustical Fibers. With these abilities to change, the needlepunch technology can easily adjust itself to different environments.

Needlepunch nonwovens’ main competition in the acoustical field is primarily foam, cork and recycled rubber. In certain cases, all of the competing products can achieve acceptable performance but foam may dry within time and lose its resiliency properties, which lead to lesser performance in sound absorption. While cork can be a good solution, it is expensive due to it being a somewhat limited natural resource. Recycled rubber hardens with time, and in some cases the smell of rubber may add some discomfort. Nonwovens offer a great performance and a permanent solution, and will not lose any properties in time.

Later this spring, Texel will launch a new line of acoustical panels dedicated for the office furniture and architectural market. Know as Feltkütur, this product line will be exclusively done in polyester. The products will meet the building standards requirements. “Feltkütur was built to combine functionality and design together,” Symard says. “To start, we will offer four items. Our rigid PET panels Ünitex and Düotex, our 3D panel Tekboard and finally we’ll soon offer our collection of decorative color felt Yürtex. Our products can be used in wall applications, acoustical tiles and for the contract market. Our products will be available throughout our North American distributors network.”

Freudenberg Sounds Off

Freudenberg’s SoundTex acoustic nonwovens features a textile structure and light weight which offers significant advantages over other sound absorbing materials such as mineral wool. Unlike other acoustical products, Soundtex does not function as thermal insulation but is suitable for acoustic ceilings with integrated heating or cooling systems.

Sound absorption is a sound dissipation and can be achieved by means of very thin absorbers presenting an appropriate sound impedance. For sound absorption, the propagation of sounds is absorbed by converting sound energy into thermal energy. Materials with sound-absorbing properties are called sound-absorbing materials.

SoundTex is a porous sound-absorbing material. With porous sound-absorbing materials, sound energy is mainly converted into thermal energy by viscous friction between the oscillating particles of the sound-propagating medium (air) and the structure of the porous material.

Besides the high sound absorption values, there are additional benefits of SoundTex acoustic nonwovens including a low material thickness, the ability to be customized, high running lengths and cost efficient insulation.

Airport designers around the world have used Soundtex technology in aiding in their acoustical needs, favoring the effective sound absorption, improve intelligibility of announcements, easy installation, low bulk volume and environmental compatibility that Soundtex can offer. Freudenberg has already used SoundTex at four Indian airports in Hyderabad, Mumbai, Punjab and Bangalore.

In short, nonwovens based on SoundTex technology meet the acoustics requirements of modern building interiors and their highly reflective surfaces; they don’t release toxic fumes under fire; they support the trend of sustainable construction, they are suitable for cooled ceilings and they reduce transportation and storage costs.

Ziegler Nonwovens

A leading producer of thermal bonded nonwovens in Europe, Ziegler Nonwovens produces thermal bonded nonwovens in Europe in thicknesses up to 220 millimeters and weights up to 4400 gsm in Germany and Hungary.

According to Christian Kortevoß, industrial sales for Ziegler, these products are going into the building segments throughout Europe in roofs, walls, offices and oftentimes act as acoustic materials.

Roofs, walls and offices use Ziegler acoustic nonwovens to buffer sound.

Additionally, its Hacobonds and Hacolofts materials are used in loudspeakers and big acoustic halls on metal roofs and as an absorber.

Kortevoß says that the fiber cross section and diameter of microfiber nonwovens as well as the resulting thickness and uniformity of the web make them prime for acoustics.

Find Comfort With Sandler

Sandler Nonwovens’ fibercomfort acoustic nonwovens are made with a thermally bonded or hybrid thermal bonded/needlepunched process, depending on the end use application. Regardless the technology, the nonwovens used are voluminous and soft and used as acoustical room elements in partitions, acoustic wall decorations or even acoustic furniture.

“All fibercomfort products owe their high acoustic efficiency to their open-pore structure—fine fibers create a more or less flexible ‘fiber skeleton,’ featuring a large inner surface,” explains Gerhard Klier, sales director of technical products. “Sound is diffracted in numerous places, whereby sound waves are absorbed and dampened by the nonwoven. This structure also makes fibercomfort nonwovens ideal heat insulators.”

It is the structure of fibercomfort that makes these nonwovens highly efficient sound insulators. Product properties such as thickness and volumetric weight can be adjusted according to the requirements of the specific application. Particularly in construction, they also function as heat insulators. As such, they help lower the need for heating in the building and thereby contribute to reducing the energy consumption.

“fibercomfort nonwovens are made from polyester—the same fibers also used in clothing. They are light, easy to handle and manufactured without any chemical binders or additives,” Klier adds. “As such, these materials are gentle on the skin and odorless. They are also resistant to moisture and UV light and offer no breeding ground for germs or bacteria. Flame-resistant product variants are also available. All-in-all, the nonwovens fulfill the highest requirements of product safety, health and durability and provide an optimum alternative for people suffering from allergies.”

fibercomfort nonwovens can be printed or laminated with different kinds of fabric, thereby also supporting individual design concepts.

Sandler is primarily targeting the fibercomfort product range at materials for wall and roof insulation in construction as well as for technical insulation, for example pipe insulation or insulation of hot-water tanks where they efficiently insulate heat and dampen sound.

In the office, dimensionally stable, self-supporting product variants are used as acoustically efficient room elements in suspended ceilings, partition walls or in textile wall decoration.

“We work in close partnership with customers in all of these markets, designing new product solutions together and incorporating fibercomfort nonwovens into our partner’s acoustic products,” Klier says.

A relatively new field for nonwoven acoustics materials, the use of these materials in design and interior acoustics, has already won Sandler an INDEX award in 2014. Sandler is constantly working with its customers and partners to develop the product range further and expand into new areas.

This expansion has been facilitated by room design trends in both home and work spaces that are increasingly relying on open plan floor layouts. At home, residents want to relax and wind down after a hard day’s work and not hear the sounds of traffic, and while in the office, workers want to be able concentrate on their work, no matter how busy a day it is for the colleagues around us. This has made acoustic room elements vital in ensuring a quiet, pleasant atmosphere despite the hustle and bustle of everyday life. In light of these trends, partitions, acoustically efficient wall decoration and acoustic furniture are increasingly asked for. The market is growing and fibercomfort nonwovens commend themselves to these applications.

In addition to highly efficient sound insulation, fibercomfort also answers the call for easy-to-handle materials, that—ideally—take sustainability into account.

“Being made of 100% polyester, fibercomfort nonwovens are not only easy-to-handle and pose no health risks, they are also fully recyclable even after years of use. In addition, the materials are partially made from recycled fibers themselves, contributing to the conservation of resources,” Klier adds.

Texel Teams Up

Texel is offering differentiated technology for acoustical performance. This builds on Lydall’s leading capabilities in its Thermal Acoustical Fibers segment where the companies provide material in the automotives sector, such as headliners membrane, wheel arch liners, flooring and trunk liners. “We currently see a tendency in the building industry,” marketing coordinator Myriam Symard says. “We have a lot of inquiries for acoustical applications such as underfloor substrate and wall acoustical membranes. That same tendency is also presenting in the office furniture market. Major office furniture companies are looking for acoustical solutions to reduce airborne noises in the work environment.”

In response, Texel and its parent company Lydall have been developing a range of products that is addressing these issues, whether to absorb the airborne noises or to reduce the sound transmission.

LEED certification has brought many advantages for energy efficiency and environmental design. The use of glass technology has increased, in order to maximize more natural lighting in the building space. The use of glass and other hard surfaces such as engineered wood and ceramics instead of carpets and traditional fabrics, has brought some acoustical concerns, and Symard says acoustic nonwovens are meeting the demand for quieter environments, which is driving more demand for sound absorbers whether in construction material or in the office furniture material.

Meanwhile, in North America growing demand for acoustics is being driven by more densification of the population, less urban sprawl and an increase in multidwelling units, which brings more demand for acoustical solutions.

Texel’s ability to create multilayers allow it to not only combine several layers of different nonwovens but also to combine through needling other technologies such as foam, fabrics and other type of nonwovens. “In addition, with our extrusions line we can add films on our concept,” Symard says. “We offer infinite options to our partners to create the right product in the right environment. Making the nonwoven is one, but understanding the science of sound is two. Throughout our development process we are always characterizing our material with absorption curves (NRC) and sound transmission (STC), which allows the end user to choose the right acoustical solution.”

Texel executives report needlepunch felt has been successful in sound attenuation, vibration isolation and shock absorption thanks to a structural fibrous matrix of various densities. “Compared to other materials such as foam and rubber, the needlepunch technology is durable and stable. The products are very lightweight and the resiliency of this type of nonwoven is nearly permanent,” Symard says. “When you select the proper blend of fibers and density you can maximize the properties of vibration-energy absorption and isolation characteristics.”

Lydall has developed these capabilities and is a leading producer of these products through Texel as well as its sister companies in Lydall Technical Nonwovens and Lydall Thermal/Acoustical Fibers. With these abilities to change, the needlepunch technology can easily adjust itself to different environments.

Needlepunch nonwovens’ main competition in the acoustical field is primarily foam, cork and recycled rubber. In certain cases, all of the competing products can achieve acceptable performance but foam may dry within time and lose its resiliency properties, which lead to lesser performance in sound absorption. While cork can be a good solution, it is expensive due to it being a somewhat limited natural resource. Recycled rubber hardens with time, and in some cases the smell of rubber may add some discomfort. Nonwovens offer a great performance and a permanent solution, and will not lose any properties in time.

Later this spring, Texel will launch a new line of acoustical panels dedicated for the office furniture and architectural market. Know as Feltkütur, this product line will be exclusively done in polyester. The products will meet the building standards requirements. “Feltkütur was built to combine functionality and design together,” Symard says. “To start, we will offer four items. Our rigid PET panels Ünitex and Düotex, our 3D panel Tekboard and finally we’ll soon offer our collection of decorative color felt Yürtex. Our products can be used in wall applications, acoustical tiles and for the contract market. Our products will be available throughout our North American distributors network.”

Freudenberg Sounds Off

Freudenberg’s SoundTex acoustic nonwovens features a textile structure and light weight which offers significant advantages over other sound absorbing materials such as mineral wool. Unlike other acoustical products, Soundtex does not function as thermal insulation but is suitable for acoustic ceilings with integrated heating or cooling systems.

Sound absorption is a sound dissipation and can be achieved by means of very thin absorbers presenting an appropriate sound impedance. For sound absorption, the propagation of sounds is absorbed by converting sound energy into thermal energy. Materials with sound-absorbing properties are called sound-absorbing materials.

SoundTex is a porous sound-absorbing material. With porous sound-absorbing materials, sound energy is mainly converted into thermal energy by viscous friction between the oscillating particles of the sound-propagating medium (air) and the structure of the porous material.

Besides the high sound absorption values, there are additional benefits of SoundTex acoustic nonwovens including a low material thickness, the ability to be customized, high running lengths and cost efficient insulation.

Airport designers around the world have used Soundtex technology in aiding in their acoustical needs, favoring the effective sound absorption, improve intelligibility of announcements, easy installation, low bulk volume and environmental compatibility that Soundtex can offer. Freudenberg has already used SoundTex at four Indian airports in Hyderabad, Mumbai, Punjab and Bangalore.

In short, nonwovens based on SoundTex technology meet the acoustics requirements of modern building interiors and their highly reflective surfaces; they don’t release toxic fumes under fire; they support the trend of sustainable construction, they are suitable for cooled ceilings and they reduce transportation and storage costs.

Ziegler Nonwovens

A leading producer of thermal bonded nonwovens in Europe, Ziegler Nonwovens produces thermal bonded nonwovens in Europe in thicknesses up to 220 millimeters and weights up to 4400 gsm in Germany and Hungary.

According to Christian Kortevoß, industrial sales for Ziegler, these products are going into the building segments throughout Europe in roofs, walls, offices and oftentimes act as acoustic materials.

Roofs, walls and offices use Ziegler acoustic nonwovens to buffer sound.

Additionally, its Hacobonds and Hacolofts materials are used in loudspeakers and big acoustic halls on metal roofs and as an absorber.

Kortevoß says that the fiber cross section and diameter of microfiber nonwovens as well as the resulting thickness and uniformity of the web make them prime for acoustics.