03.09.17

EDANA, the leading global association serving the nonwovens and related industries, will sponsor INDEX, the global exhibition showcasing the nonwovens and related industries at PalExpo in Geneva, Switzerland, April 4-7. The show will feature more than 650 exhibitors and 12,500 visitors, providing an opportunity for suppliers and clients from more than 100 countries to convene in the same place.

In addition to the exhibition, the event will feature a rich four-day program featuring, amongst other things, a seminar highlighting segments for application of nonwovens including transportation, medical, healthcare and filtration. Each of the four sector-specific sessions will be opened by keynote speeches, which will be accessible to all INDEX 17 visitors. These will discuss the “big picture” environment and key challenges that will shape the future of each particular field.

“This innovative way of offering INDEX participants the opportunity to hear expert speakers deliver key learnings on the challenges within their nonwoven sector of choice is intended to add even more value to their experience in visiting what can already be announced as the largest ever nonwovens exhibition in the world. We hope that the compact format of the sector seminars will help attendees combine these with their busy schedule of business meetings and stand visits,” says Pierre Wiertz, general manager of EDANA.

Here is a look at what some exhibitors plan to showcase at INDEX.

Amotek

Amotek

Booth 2679

A packaging machine that packages various nonwoven products in film bags—the Amotek R 168 is suitable for feminine hygiene products, diapers, cotton pads and other products—and even for multipacks depending on the size. The packages can be supplied with holes, reinforcements, handle areas, zippers and other features. Different bag shapes can also be managed. The machine produces, on its own, the bags from a folded film and offers an option to produce the bags from a foil roll. The machine is easy to operate. Its output reaches up to 50 packages per minute. For particularly large products, an Amotek R 168 XL version is available.

The Amotek IS 81 was developed specially for diaper packages. The servo-controlled system works with a patented Sierem stacker. The diapers are taken from the converters with an inline rate of up to 800 pieces per minute and packaged at a rate of up to 55 film bags per minute. The system can be enhanced through the addition of various modules. These include the ability to produce packages with small counts or to load diapers manually into the packaging process.

In addition, Amotek will also be providing information at INDEX about its wide range of packaging machines for paper hygiene products. The company has decades of experience and offers efficient and competent service all over the world. Amotek is part of the OPTIMA packaging group GmbH (Schwäbisch Hall).

www.amotek.com

Andritz

Booth 2114

International technology Group Andritz will be presenting advanced technologies for spunlace, thermal bonding, air-through bonding, wetlaid, needlepunch and spunjet. Andritz Nonwoven offers customized and unique solutions to requirements from individual customers.

Over the past three years, there has been a steep rise in the world’s nonwovens market, with a significant demand for higher production performance, higher capacities with integrated fabric diversification, and greater energy efficiency. As a major player, Andritz is compelled to continuously seek innovative technologies that fulfill customer demands. Andritz Nonwoven has manufacturing facilities worldwide that comply with international standards, thus providing high quality assurance and quality control practices.

Running complete lines calls for in-depth nonwoven expertise and excellent service. Andritz offers a full service portfolio and thus can ensure improved uptime, productivity and product quality. This includes on-site support, specific training, line audits and troubleshooting, upgrades and modernizations, genuine spare parts, and service as well as roll repair centers in Europe, North America, and China. Only recently, an additional service center was opened in response to local demands in Torrington.

Andritz offers comprehensive trials at its own or its partners’ advanced technical centers to support customers’ product developments. Take advantage of the bus trip to see the top-end, flexible neXline spunlace pilot line located in Montbonnot. A shuttle bus will run from the Palexpo exhibition center on April 5 and 7.

Currently, the spunlace industry is being spurred by wipes. By combining the state-of-the-art TT card web forming and JetlaceEssentiel hydroentanglement units, Andritz is forging ahead in responding to specific market demands by streamlining and adding value to integrated installations with high production speeds. The JetlaceEssentiel with the outstanding neXjet injector sets a benchmark and is equipped with a full range of patterning solutions to customize spunlace fabrics while simultaneously ensuring efficient water recirculation and filtration. Andritz Nonwoven has sold a significant number of neXline spunlace lines including TT cards since 2011, thus opening doors to the Chinese market. The Andritz passion for perfection raises the bar with a highly advanced energy-saving system, called neXecodry, securing a swifter ROI.

Andritz Nonwoven has also gained a significant share in the booming, flushable wipes market thanks to its Wetlace technology. The original Wetlace process spearheads the production of flushable wipes from 100% natural and/or renewable raw materials without chemical binders, thereby even far exceeding the EDANA/INDA flushability standards. The first industrial line has been in operation for over a year, with Dalian Ruigang, China, supplying the world market with its top-quality products. The second industrial line at Akinal, Turkey, is launching a new generation of flushable fabrics, named BioFlush, accessing new markets.

www.andritz.com

Autefa Solutions

Autefa Solutions

Booth 4035

Following the slogan for this year’s INDEX, “Connecting you with nonwoven solutions,” Autefa Solutions is ready to take up the challenge. Nowadays nonwovens producers are looking for new energy savings opportunities and advanced technologies especially in the field of disposables.

The Autefa Solutions V-Jet is a new hydroentanglement system which saves up to 30% of the hydraulic energy required for the spunlace process. The patented jet-strip design enables a pressure reduction while keeping the product quality constant in comparison to a standard jet-strip. The spunlace process is optimized with the Square Drum Dryer SQ-V, which has significantly better energy efficiency and drying performance than a common drum dryer—at the same footprint.

The Crosslapper Topliner CL 4004 SL is characterized by a high infeed speed of up to 130 m/min and a precise weight distribution. These advantages are very important especially for lightweight applications in spunlace lines. The lapping of the web layers is continuously monitored, which minimizes rejects and saves material.

For the production of flushable wipes Autefa Solutions and Campen Machinery have developed hydrolaced airlaid process lines. The concept hits the specific need for medium and small size airlaid production solutions.

There is also a growing interest in high speed through air thermal bonding lines for hygiene products such as acquisition and distribution layers (ADL). These materials are used in baby diapers, sanitary napkins and adult incontinence products. The key strengths of the Autefa Solutions belt dryers are uniform airflow, precisely adjustable temperature distribution and the ability to maintain loft or to create high densities.

André Imhof, CEO Autefa Solutions Austria, explains: “The customer today is more demanding and requires best possible Total Cost of Ownership (TCO). The high productivity, the flexibility for various nonwovens products with low maintenance costs will increase the demand for top quality machines from Autefa Solutions.”

For the needle nonwovens process, Autefa Solutions presents the Needle Loom Fehrer Stylus ONE, a machine for all needling applications. StylusONE covers the needs of the market for a reliable and economic machine. With a performance of max 1200 strokes/min the Needle Loom StylusONE distinguishes itself through productivity, guaranteed longevity and maintenance free gear boxes.

www.autefa.com

Bostik

Booth 2138

At INDEX, Bostik, a leading global adhesive specialist for industrial, construction and consumer markets, will use interactive display stations to showcase its Smart@work adhesive technology and expertise at INDEX.

Fit, absorption, softness and odor are key dynamics to manufacturers of disposable hygiene products. Bostik will demonstrate how adhesive products and process expertise can help disposable hygiene producers create better products more efficiently.

“We believe creating an interactive experience will engage our customers in discussions of how Bostik can help them achieve their goals. This is a clear focus of Bostik and an area where we believe our global knowledge and almost 50 years of disposable hygiene experience can really add value to our customers,” says Diane Toonen, global director of Strategic Marketing for Bostik’s Global Nonwoven Division.

Darius Deak, Global R&D director of the Global Nonwoven Division of Bostik, will also deliver a presentation on Brilliance, a world’s first in adhesive products during INDEX’s conference session, Wednesday, April 5, from 11:30 - 11:50 a.m.

www.bostik.com

Brückner

Brückner

Booth 1580

As one of the leading producers of finishing and thermal treatment lines for the nonwovens and textile industry, Brückner considers its participation in the INDEX trade fair in Geneva as absolutely obligatory.

In the nonwovens sector the Brückner portfolio comprises all types of application systems, thermal treatment lines, dryers as well as cutting and batching units. On the occasion of this year’s INDEX trade fair in Geneva, Brückner wants to show its customers and prospective clients the new developments and improvements in the field of belt dryers, a type of dryer which gained compared to conventional drum dryers more and more acceptance in the last years.

The design of the high-performance dryer SUPRA-FLOW BH, which had been particularly developed for the air-through drying of light hydroentangled nonwovens, has been optimized. This type of dryer is characterized by its particularly high evaporation capacity, a high energy efficiency, the gentle material transport and an excellent drying homogeneity. It is thus clearly more than an alternative for the use of an air-through drum dryer and offers many benefits for the user.

Another new development is the Supra-Flow BE-ADL belt dryer developed for ADL products for thermo-fusion of card nonwovens. In the design of this dryer particular attention was paid to a gentle fabric transport, a high temperature accuracy and a precise air control. The air circulation in this dryer follows also the air-through principle.

Depending on the purposes, Brückner offers different dryers matching the customers’ individual needs and processes. Brückner’s portfolio comprises among other systems also flat dryers with one or several fabric passages, vertical dryer, cylinder dryers, drum dryers, airlaid dryers, infra-red radiation dryers, high temperature dryers and combinations thereof.

www.brueckner.com

Calemard/Spoolex

Calemard/Spoolex

Booth 2451

Offering the widest high speed spooling line for ADL in the world (with a mother roll width up to 1.5 meters) and a fully automated Pegase 3 Spooling Cell commissioned end of 2016, Spoolex Group confirms the world leading position of its Calemard machinery brand in providing customized spooling solutions for demanding productions with tension sensitive materials.

Even more so than in the past, the French company assists its customers to move in the “Smart Manufacturing” era. To help them to bring their production tools up-to-date and to improve safety and healthy working conditions, Spoolex’s integrated engineering department is always developing several automated solutions around its know-how, to propose a global offering with flexible machinery and smart automation.

Around the well-known Calemard Pegase 3, the new Complete Cell integrates new solutions for:

Big data is now crucially important for all industry and converters are also concerned. They are always looking for connected solutions to optimize their machinery production and overall plant efficiency. A few months ago, Spoolex dedicated a multi-service team to engineer a MES ready connection system.

As a result, Spoolex offers today multi-level DataSmart solutions for production performance analysis and production traceability. After collecting data directly from the line PLC (for reliability and speed), DataSmart is available as different packages adapted to each customer’s needs: from simple data collection to complete extraction, evaluations, indicators calculation and customized reporting.

With a single contact point and thanks to a systemized analysis needs approach, Spoolex Group is able to manage all in-house complete projects for simple problematic to complicated one. Working closely with Spoolex Group ensures efficiency, reliability, safety and serenity throughout the entire project, from first contact to equipment commissioning.

www.spoolex.com

Delta Converting

Booth 4040

Originating breakthrough ideas! This is the main motive that behind Delta’s success in the last five years.

Delta srl, an Italian company located in the North of Italy, designs and builds converting machines for the production of adult incontinence, feminine hygiene products and baby diapers. Delta has invested in research and development, introducing new innovation in the field of core forming on adult incontinence and feminine machines. Thinner, comfort, discreet, performing are the key words that have orientated Delta technology development. The market tendency and customers’ needs to produce high quality and performing product, saving raw materials, has brought Delta to design and build a revolutionary system to produce fluff less core for light and heavy incontinence products.

The Delta “fit-in-line” system prepares a fluffless core with superabsorbent polymer, with a technology that completely eliminates the traditional “core forming section” and give high quality products results in absorbency, softness and general savings of space, energy, raw materials and noise reduction. Delta engineers have also worked hard to design underpad machines with thinner cores using less fluff, which guarantees an even fluff distribution at low gsm at high speeds.

Feminine hygiene lines for the production of thin fluff core panty liners and sanitary napkins together with baby diaper with elastic ears complete the range of Delta machineries.

www.deltaconverting.com

Dilo

Booth 2010

Dilo’s new horizontal crosslayer DLSC 200 sets new standards in crosslapping technology with an electro-mechanical web infeed speed of 200 m/min depending on the fibers used. It is just one of several new developments that will be on display during INDEX 2017.

Dilo will also present a new needle module technique of DiloMachines that embeds 22 needles in a plastic support and is used in needle boards with very high needle density. These modules result in a fast and precise filling of needle boards. They are used in Variopunch needling technology where bad spots in stitch distribution are eliminated by variable needle arrangements thus creating a more homogeneous and higher surface quality.

This compact line is designed for the production of high quality needlefelts from special fibers such as carbon. It completes Dilo’s portfolio that includes not only small production lines for laboratories and large needling lines for paper machine felts but also machines for the production of needlefelts from staple fibers.

www.dilo.de

General Nonwovens

General Nonwovens

Booth 2241

General Nonwovens of Turkey is a member of Imam Kayali Holding which is active in different fields of trade and industry since 1928. The company has been making nonwoven fabrics already for more than a decade. During this period, the company expanded its operations to two factories in Turkey along with the expansion of offerings made to the nonwovens industry. Spunbond fabrics are made of polypropylene, polyester and PLA while SMS fabrics are made of polypropylene only. These fabrics are served at a large basis weight range of 10 to 200 gsm. General Nonwovens also uses staple fibers of mono and bi-component with various polymer compositions. These are bonded by means of heat, so lofty air through bonded fabrics are produced in a range of 18 to 80 gr/m2. General Nonwovens not only serves local markets but also the U.S. and European markets with a 50-50 split.

General Nonwovens’ HyGen brand products are widely used in the hygiene industry namely: topsheet, backsheet, ADL, leg cuffs, front ears and core-wrap. A very soft air through bond fabric is also served for those who are in search for soft-touch fabric for premium disposable product end uses. Apart from the HyGen brand, FilterGen brand is served for the filtration industry, TexGen for coated and laminated fabrics as well as home textiles, AutoGen for the automotive industry and IndiGen for industrial and technical textile applications.

www.generalnonwovens.com

H.B. Fuller

Booth 2461

As a leading adhesive supplier, innovation at H.B. Fuller encompasses more than the products we make. It touches the interactions we have with customers and the experiences they deliver to end-users. And, it shapes the future of industries across the globe. But don’t take our word for it. Why not take yourself on a multi-sensory experience. Touch, smell and see how our next generation hygiene solutions can make a difference to everyday disposable goods. Hear how our experts can help you make thinner, smarter, better fitting, more absorbent products a reality with our Full-Care line of high performance products. Feel for yourself how soft and stretchable they are with our new Conforma adhesive. See a fresh way to eliminate odor fast with our game-changing ODOGard technology. As a market leader, we’ve been challenging the limits of what’s possible for over 40 years to enable our hygiene customers to be the best at what they do.

www.hbfuller.com

Curt G. Joa

Curt G. Joa

Booth 4000

Curt G. Joa, Inc. will celebrate its 85th anniversary at INDEX. In 1930, founder and German immigrant, Curt G. Joa was given an opportunity to design an automated process to produce sanitary napkins. After demonstrating a working model of the process, he was commissioned to make the first machine in October 1931. In 1932, he received his first patent and established an engineering-consulting company bearing his name.

“The idea that an entrepreneur such as my grandfather could immigrate to the U.S. and start a successful business during the Great Depression is remarkable,” says Curt G. Joa, Inc. president Gene Kiela II. “As we enter into our 85th year, we still hold the values that he instilled – that good customer relationships lead to success.”

In addition to the first sanitary napkin machine, some of the company’s many pioneering accomplishments include the first JOA rotary mill, the flying splice, the vertical stacker, the Cut at Tape Speed (CATS) Unit, the web velocity modulator, the Single Transfer Insert Placement Process (STIPP) Unit and the No Scrap Ear (NoSE) Unit for baby diaper production.

In its third generation of family ownership, Curt G. Joa, Inc. now includes the JOA and Bikoma brands, with operations in the U.S., Germany and India.

www.joa.com

Kansan

Booth 4309

The industry leading wet wipe machinery manufacturer Kansan is planning to dominate INDEX once again. Kansan is ready to demonstrate four different machines and prepare a production environment for the convenience of visitors. Kansan’s booth will feature a fully automatic production line consisting of a flat pack converting machine, a flow pack machine and a lid applicator robot. In addition, the new generation cross fold machine of Kansan also will be exhibited there.

Kansan’s flat pack converting machine Quickstack series can vary from six to 25 lanes with a capacity of 800 cuts per minute with single or jumbo reel automatic splice unwind stations. These units are capable of running different substrates along with a variety of folding types and length and width options. Overall this platform presents itself as highly productive, easily operable, hygienic, safe and upgradable for future needs.

The full automatic flow pack machine from Acurapack series is a newly developed model flow wrap machine specially designed for wet wipes with a capacity of 150 packs per minute design speed thanks to advanced engineering in stroke mechanism. It is suitable for both flat packs and cross fold packs.

Probably the fastest, strongest and most flexible lid applicator machine the visitors will see at INDEX will also have the Kansan logo on it. This robust machine called LidmasterPRO is equipped with a camera system to visually check the position of a label on the packages. Even if there are incorrect alignments or off-center inflow of product, the advanced robotic system is able to place the lid on the pack in perfect position thanks to four-axis movement ability.

Flexiwork with two unit station will make its debut for the first time on floor ground this year. This machine was the most selling unit of 2016 and there are already more than 15 firm orders for 2017. Thanks to its compact design and enhanced performance, the actual working speed of the machine can go as high as 700 wipes per minute on single line. With one to four lines, converters can increase their production capacity with maximum output of 2400 wipes/minute. Unlike others, Flexiwork has mechanical folding with no vacuum. And very flexible to process different type of substrates with different folding types and dimensions.

www.kansanmak.com

Martin Automatic

Booth 2181

Martin Automatic will demonstrate its advanced Airnertia and MDR roller technologies at INDEX. Offering lowest roller inertia and essentially friction-free rotation, these technologies are among the solutions Martin Automatic offers for non-stop roll change and transport of web materials.

Martin Automatic continues to experience strong equipment sales to nonwovens converters and material manufacturers including unwinds using a variety of splicing methods for web speeds to 915 meters per minute. Martin systems can be integrated into new lines and retrofitted to existing processes for greater speed, tension control and productivity.

www.martinautomatic.com

Montalvo

Booth 4466

Montalvo International, specialists in web tension control, will be showcasing a range of new and innovative tension control technologies at INDEX 17 including load cells, controllers and complete new control systems.

For the first time ever in an open loop control system, users get a precise, reliable tension reference that operators can use to ensure consistent, high quality production runs. The TSC is a total tension control solution that delivers performance, convenience, and productivity. Simple, compact and easy to install and operate, the TSC is the latest innovation in open loop tension control. Patent pending technology allows easy integration into existing machines as well as new machine builds.

Improved quality, performance, and convenience, combined with lower pricing and shorter lead times, N Series Cantilever Load Cells are designed for single side machine frames such as label, film, foil, and other narrow webs. N Series Load Cells feature an anti-deflection design, semiconductor strain gauge technology and eliminate web steering for greater consistency and quality in your process.

TSR Tension Sensing Rollers are an all-in-one, drop-in tension measurement solution combining performance and convenience. Re-designed for shorter lead times, lower pricing, and improved performance, the TSR is available in standard sizes, and finishes or completely customizable, the TSR is one of the most versatile, performance driven machine components in the industry for both OEM’s and end-users.

Montalvo’s most advanced, fully featured tension control is now available with ODVA Certified Ethernet/IP. The new Ethernet/IP Communication allows customers to easily interface with an existing HMI on the operator panel of the machine, allow management to record and store information about the condition of the machine, and reduce, or eliminate the need for running cables/wires for installation.

At INDEX, Montalvo will launch its newest Range Expander, the P4. As originators of tension control range expansion, the P4, Montalvo’s elite Automatic Range Expander, expands the capabilities of existing machines, allowing them to be more effective at: running multiple types of materials with differing tension levels, gaining greater control at lower torque ranges, running high mass rolls at lighter tensions, and running low torque and tension applications that require high torque to stop.

Its newest line of cartridge style dead-shaft idler load cells have been developed to be dimensional drop-in, direct replacement load cells for a variety of other load cell manufacturers. This line provides all the dimensional and functional requirements you may be accustomed to, while often having equal or better lead times and pricing. And like all of our products, DR-Series Load Cells are back by our highest levels of support, quality, and performance.

www.montalvo.com

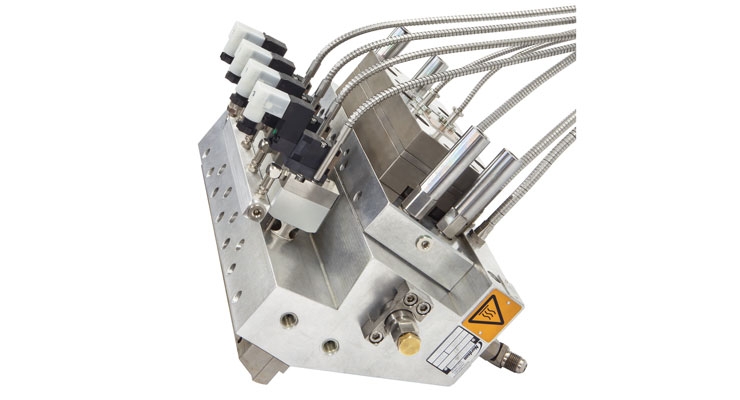

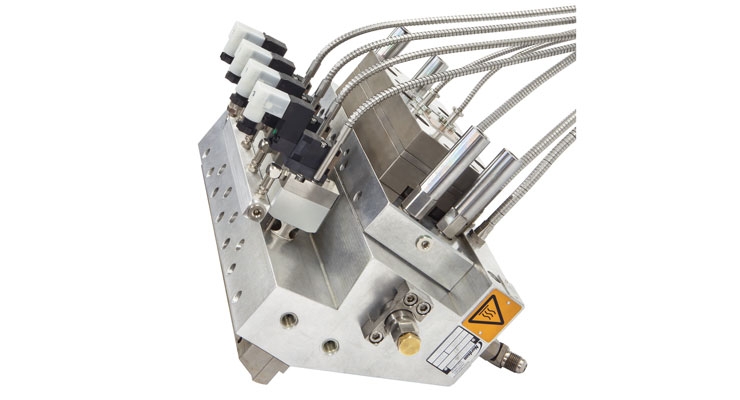

Nordson

Nordson

Booth 2161

Nordson will be featuring a broad line of applicators at INDEX.

Choices of spray, slot and metering applicators can apply hot melt adhesives, perfumes and lotions, among other materials, to the numerous components that comprise disposable hygiene products. The various applicators can be used across a wide range of dispensed materials, line speeds and material types and can be set up to produce customized patterns for continuous or intermittent applications. Designed with customer needs in mind, Nordson applicators are easily incorporated into OEM equipment and most applicators offer quick, easy change components such as nozzles and modules.

Nordson applicators’ innovative technologies represent Nordson’s commitment to delivering the highest quality products, enabling customers to apply the right amount of adhesive in the right place at the right time on their products.

www.nordson.com

Optima Nonwovens

Optima Nonwovens

Booth 2581

Optima’s “Project ZERO”technology is being billed as the future of production flexibility. This machine perfectly adapts to the requirements with optimized format change time, a new stacker for feminine care products and a platform with a completely modular design. The operator specifies designs and data, the machine handles the rest. The different packages are produced “inline.” Furthermore, new sensor technology leads to process stability that is once again significantly increased.

In addition to this new development, the Optima Nonwovens booth will give visitors the chance to experience the future of HMI (Human Machine Interface). Thanks to smartphones and tablets, today's users are accustomed to intuitive and clearly arranged interfaces for operating devices. New HMIs take up these developments, but are adapted to the industrial environment and expanded with essential features.

Three years ago at INDEX this was still just a vision, but today it is already a firmly entrenched part of the service Optima offers.

With TCAM from Optima, a digital tool is available that uses sensors to analyze the condition of packaging systems and provide advanced notice of the need for maintenance while also accelerating the flow of information.

www.optima-packaging.com

Radici Group

Booth 2629

Tessiture Pietro Radici—part of the Radici Group’s extrusion yard business area—specializes in the production of dylar spunbond nonwoven fabrics, designed – as well as for use in sanitation – especially for industrial application sectors, such as building insulation, the automotive industry, agriculture, furnishings and disposable products. These nonwoven fabrics are available in different weights and colors to meet the varying market demands and the range of choice is set to increase with the new production line currently under development.

Radici Yarn and Radici Chemie of the comfort fibres business area is a leader in the production of nylon staple fibers for technical and traditional clothing and for high quality carpets and rugs, expanding their production to include products for the abrasives sector (both household and industrial), the multi-application nonwoven fabrics sector and the felt sector for manufacturing and filtration. These products form part of the well-known family of Radilon polyamide 6 staple fiber products, to which is added the brand new range of dorix tech polyamide 66-based products, produced in the very latest lines specifically designed to guarantee maximum performance and the very highest standard of quality available today.

Radilon Staple Fibres and dorix teck are available in both raw and solution-dyed versions, with a choice of various colors and a guarantee of optimum performance in any specific application.

www.radicigroup.com

Sandler

Booth 2431

At INDEX, Sandler will present several innovations for the wipes market. sawatex classy silk and sawatex lace-o-paque add a certain something to cosmetics applications and baby care applications while sawatex classy silk features excellent cleaning efficiency and above all an extraordinarily silky touch, rendering every use into a wellness-treatment. sawatex lace-o-paque offers softness and high bulk, offering gentle care for little explorers. The new embossing design “square” captures the attention of another market segment: Small squares render the substrate bulkier and increase its surface—for even better results in cleaning applications. With a “double action“ substrate for cleaning wipes, Sandler gets to grips with stubborn dirt. The multi-layer nonwoven features a coarser side for efficient cleaning and a smooth side for gentle polishing and grooming the cleaned surface.

All of these nonwoven substrates receive their particular properties from the special fiber blends used. Selected raw materials bring about not only excellent functionality, but also enable a reduction of the basis weights—for less raw material usage. Embossed motifs for visual individualization of wipes are also more detailed.

Sandler’s range of nonwovens for disinfection wipes now encompasses an additional highlight: Colored product variants in various pastel shades enable a visual differentiation of various application areas.

“Stretch your limits“—is the motto with Sandler’s collection for elastic applications. Manufacturers are provided with an assembly kit of materials featuring different degrees of elongation to choose the ideal nonwoven for their respective use. From “basic stretch“ to “premium stretch plus“ it holds the right product for everyone. These nonwovens support an optimum fit, thus increasing wearing comfort.

Comfort is also the watchword when it comes to innovations for topsheets: A new design for these materials visually provides a sense of lightness in daily hygiene: Subtle butterflies make this product a veritable eye-catcher.

A new “canyon” structure for topsheet materials combines visual differentiation and optimized functionality: This special surface renders the topsheet bulkier and even softer; increases stability, and simultaneously supports fluid handling.

Sandler’s new nonwovens for intake layers take this function one step further. They quickly transport fluid away from the body and efficiently distribute it onto the entire surface, for optimal utilization of the core’s storage capacity. The nonwovens also function as an interim storage layer, preventing rewet and protecting the skin. Sandler designs these nonwovens in line with one’s product requirements: Softness and flexibility can be individually adjusted; embossing designs provide visual highlights.

www.sandler.de

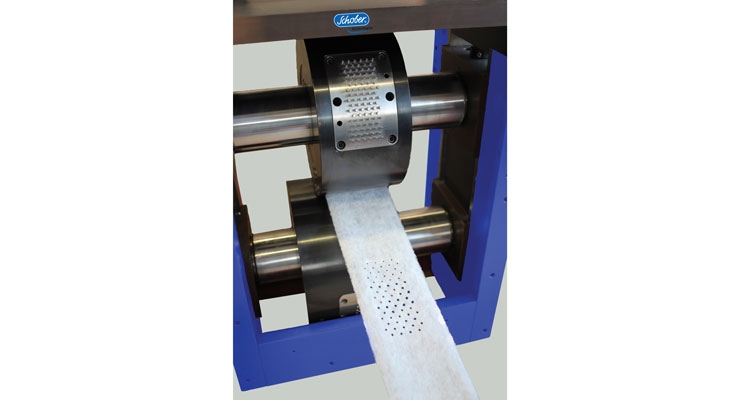

Schobertechnologies

Booth 4013

Schobertechnologies GmbH develops, designs and manufactures rotary tooling, modules, and complete specialty machines widely used in film-, foil-, packaging-, nonwovens and paper converting industries in more than 100 countries globally.

Schober’s high capacity die cutting modules all feature a mechanical preset and calibrated pressure load system, high-precision bearing assemblies and housings for low temperature running, vibration-free design and a pneumatically activated eccentric lifting device for a quick disengagement of the die cutting/anvil cylinder in order to ease web threading and consequently shorten set-up. The technically mature module concept complemented by the sophisticated tool design, provides productivity increase and outstanding high tool life performance.

The performance of these high precision units have a range for processing speeds of up to 1000 meters/per minute and tool diameters of up to 600 mm, with a working width of up to two meters.

With production speeds rising and higher quality requirements from end users, Schobertechnologies engineers have kept up with these demands by implementing further developments on their rotary punching tools and modules. All tooling is manufactured using the latest CNC technology.

Products developed by Schobertechnologies have found application in all sectors of rotary processing. In addition to the traditional sectors of paper, film and foil processing industries, new application fields could be acquired in the medical, automotive, security, electronical and pharmaceutical industries.

www.schobertechnologies.de

Suominen

Booth 1522

Suominen will showcase its broadest range of products for wipes, hygiene products and medical applications. These innovations have been developed thanks to the company’s recent investments in production technology and development and include innovations for household, workplace, flushable wipes as well as new freshness for the baby care segment.

Suominen booth visitors will also have a chance to discover the company’s approach to sustainability and how it continues to be pioneers in terms of environmental and social responsibility.

www.suominen.fi

Technoplants

Booth 4310

Technoplants, once known for its pioneering automatic end of line, from cutting to winding, stacking and packaging, is today specialized in making complete air lay lines. Its revolutionary air lay card machine MULTIline FPC is able to produce mats with any fiber in a range from 0.9-400 denier and any length from 4-100 mm. The combination of the three machines (former, precard and card) gives the maximum flexibility to the line and allows customers to produce fabrics with different characteristics, at the same time with a machine setting time of only a few minutes to change from one production to the other.

This has led to a wide range of weight, from 50-5000 gsm, which increase the products portfolio and then the market share.

Technoplant’s thermobonding MULTIoven operates from high-speed ADL to shoddy recycled fiber mats, with a constant thin air distribution for all the configurations.

www.techno-plants.com

Tietex

Booth 4361

Tietex International is featuring Optima Loop Closure and Proton Hygienic Microfiber.

Optima is the diaper industry’s softest, lightest and most consistent Landing Zone product; Proton Microfiber Towels, Mops and Wipes primarily serve Healthcare, Food Service & Production, JanSan and Textile Rental markets. These and other patented developments are the result of technology that brings together disparate materials to answer a growing need for high performance, technically engineered components – none more promising than products aimed at diaper, hygiene and cleaning markets.

Family owned and vertically integrated, Tietex has two factory locations and over 600 employees on two continents. The company’s core technology serves a variety of key markets, including athletic footwear, hook & loop fastening, mattress fabrics, roofing fabrics, automotive and wipes. In addition, Tietex continues to develop unique performance fabrics for many diverse custom applications.

www.tietex.com

Trützschler Nonwovens

Trützschler Nonwovens

Booth 2331

Trützschler Nonwovens will focus on high-quality webs and low conversion costs at INDEX. A major point of the company’s booth will be carding concepts for creating perfect webs for hygiene and other applications. Many end products require distinctive web characteristics, therefore Trützschler Nonwovens continuously extends its range of fiber treatment, carding and web forming machinery.

Meanwhile, in the bonding process often a different type of challenge arises when productivity and efficiency become an issue. Take for instance chemical bonded webs: with the new Trützschler High-Speed Foulard for the application of liquid binding agents, Trützschler addresses line speed. Various optimizations on rolls (patent pending) and sub-components allow for increasing the production speed of lightweight webs by up to 50%.

Hydroentangling and drying are a third focus point at INDEX because these processes are always worth a detailed discussion. For decades both the AquaJet and the multi-drum dryer have been on top of Trützschler Nonwovens’ R&D agenda.

www.treutzschler.com

Ultra System

Booth 1268

Ultra System’s exhibition will include products from its two divisions. The display from the Rotary Cutting Dies Division will include tools for the manufacture of personal hygiene products (sanitary pads, nappies for babies and adults, light inco pads, plasters and advanced dressings) and the household paper industry (dry and wet wipes) in bonded steel, in sintered steel and also in Tungsten Carbide bonding cylinders for heat sealing, bonding cylinders for ultrasound sealing, complete cutting and embossing groups. A resharpening service for any cutter is available.

Meanwhile, the Moulds Division for the motor and motorbike industry, will feature moulds for heat forming (food, pharmaceutical, chemical industries), moulds for polyurethane foam (furniture, pharmaceutical industries etc), prototypes and assemblages.

www.ultrasystem.com

In addition to the exhibition, the event will feature a rich four-day program featuring, amongst other things, a seminar highlighting segments for application of nonwovens including transportation, medical, healthcare and filtration. Each of the four sector-specific sessions will be opened by keynote speeches, which will be accessible to all INDEX 17 visitors. These will discuss the “big picture” environment and key challenges that will shape the future of each particular field.

“This innovative way of offering INDEX participants the opportunity to hear expert speakers deliver key learnings on the challenges within their nonwoven sector of choice is intended to add even more value to their experience in visiting what can already be announced as the largest ever nonwovens exhibition in the world. We hope that the compact format of the sector seminars will help attendees combine these with their busy schedule of business meetings and stand visits,” says Pierre Wiertz, general manager of EDANA.

Here is a look at what some exhibitors plan to showcase at INDEX.

Booth 2679

A packaging machine that packages various nonwoven products in film bags—the Amotek R 168 is suitable for feminine hygiene products, diapers, cotton pads and other products—and even for multipacks depending on the size. The packages can be supplied with holes, reinforcements, handle areas, zippers and other features. Different bag shapes can also be managed. The machine produces, on its own, the bags from a folded film and offers an option to produce the bags from a foil roll. The machine is easy to operate. Its output reaches up to 50 packages per minute. For particularly large products, an Amotek R 168 XL version is available.

The Amotek IS 81 was developed specially for diaper packages. The servo-controlled system works with a patented Sierem stacker. The diapers are taken from the converters with an inline rate of up to 800 pieces per minute and packaged at a rate of up to 55 film bags per minute. The system can be enhanced through the addition of various modules. These include the ability to produce packages with small counts or to load diapers manually into the packaging process.

In addition, Amotek will also be providing information at INDEX about its wide range of packaging machines for paper hygiene products. The company has decades of experience and offers efficient and competent service all over the world. Amotek is part of the OPTIMA packaging group GmbH (Schwäbisch Hall).

www.amotek.com

Andritz

Booth 2114

International technology Group Andritz will be presenting advanced technologies for spunlace, thermal bonding, air-through bonding, wetlaid, needlepunch and spunjet. Andritz Nonwoven offers customized and unique solutions to requirements from individual customers.

Over the past three years, there has been a steep rise in the world’s nonwovens market, with a significant demand for higher production performance, higher capacities with integrated fabric diversification, and greater energy efficiency. As a major player, Andritz is compelled to continuously seek innovative technologies that fulfill customer demands. Andritz Nonwoven has manufacturing facilities worldwide that comply with international standards, thus providing high quality assurance and quality control practices.

Running complete lines calls for in-depth nonwoven expertise and excellent service. Andritz offers a full service portfolio and thus can ensure improved uptime, productivity and product quality. This includes on-site support, specific training, line audits and troubleshooting, upgrades and modernizations, genuine spare parts, and service as well as roll repair centers in Europe, North America, and China. Only recently, an additional service center was opened in response to local demands in Torrington.

Andritz offers comprehensive trials at its own or its partners’ advanced technical centers to support customers’ product developments. Take advantage of the bus trip to see the top-end, flexible neXline spunlace pilot line located in Montbonnot. A shuttle bus will run from the Palexpo exhibition center on April 5 and 7.

Currently, the spunlace industry is being spurred by wipes. By combining the state-of-the-art TT card web forming and JetlaceEssentiel hydroentanglement units, Andritz is forging ahead in responding to specific market demands by streamlining and adding value to integrated installations with high production speeds. The JetlaceEssentiel with the outstanding neXjet injector sets a benchmark and is equipped with a full range of patterning solutions to customize spunlace fabrics while simultaneously ensuring efficient water recirculation and filtration. Andritz Nonwoven has sold a significant number of neXline spunlace lines including TT cards since 2011, thus opening doors to the Chinese market. The Andritz passion for perfection raises the bar with a highly advanced energy-saving system, called neXecodry, securing a swifter ROI.

Andritz Nonwoven has also gained a significant share in the booming, flushable wipes market thanks to its Wetlace technology. The original Wetlace process spearheads the production of flushable wipes from 100% natural and/or renewable raw materials without chemical binders, thereby even far exceeding the EDANA/INDA flushability standards. The first industrial line has been in operation for over a year, with Dalian Ruigang, China, supplying the world market with its top-quality products. The second industrial line at Akinal, Turkey, is launching a new generation of flushable fabrics, named BioFlush, accessing new markets.

www.andritz.com

Booth 4035

Following the slogan for this year’s INDEX, “Connecting you with nonwoven solutions,” Autefa Solutions is ready to take up the challenge. Nowadays nonwovens producers are looking for new energy savings opportunities and advanced technologies especially in the field of disposables.

The Autefa Solutions V-Jet is a new hydroentanglement system which saves up to 30% of the hydraulic energy required for the spunlace process. The patented jet-strip design enables a pressure reduction while keeping the product quality constant in comparison to a standard jet-strip. The spunlace process is optimized with the Square Drum Dryer SQ-V, which has significantly better energy efficiency and drying performance than a common drum dryer—at the same footprint.

The Crosslapper Topliner CL 4004 SL is characterized by a high infeed speed of up to 130 m/min and a precise weight distribution. These advantages are very important especially for lightweight applications in spunlace lines. The lapping of the web layers is continuously monitored, which minimizes rejects and saves material.

For the production of flushable wipes Autefa Solutions and Campen Machinery have developed hydrolaced airlaid process lines. The concept hits the specific need for medium and small size airlaid production solutions.

There is also a growing interest in high speed through air thermal bonding lines for hygiene products such as acquisition and distribution layers (ADL). These materials are used in baby diapers, sanitary napkins and adult incontinence products. The key strengths of the Autefa Solutions belt dryers are uniform airflow, precisely adjustable temperature distribution and the ability to maintain loft or to create high densities.

André Imhof, CEO Autefa Solutions Austria, explains: “The customer today is more demanding and requires best possible Total Cost of Ownership (TCO). The high productivity, the flexibility for various nonwovens products with low maintenance costs will increase the demand for top quality machines from Autefa Solutions.”

For the needle nonwovens process, Autefa Solutions presents the Needle Loom Fehrer Stylus ONE, a machine for all needling applications. StylusONE covers the needs of the market for a reliable and economic machine. With a performance of max 1200 strokes/min the Needle Loom StylusONE distinguishes itself through productivity, guaranteed longevity and maintenance free gear boxes.

www.autefa.com

Bostik

Booth 2138

At INDEX, Bostik, a leading global adhesive specialist for industrial, construction and consumer markets, will use interactive display stations to showcase its Smart@work adhesive technology and expertise at INDEX.

Fit, absorption, softness and odor are key dynamics to manufacturers of disposable hygiene products. Bostik will demonstrate how adhesive products and process expertise can help disposable hygiene producers create better products more efficiently.

“We believe creating an interactive experience will engage our customers in discussions of how Bostik can help them achieve their goals. This is a clear focus of Bostik and an area where we believe our global knowledge and almost 50 years of disposable hygiene experience can really add value to our customers,” says Diane Toonen, global director of Strategic Marketing for Bostik’s Global Nonwoven Division.

Darius Deak, Global R&D director of the Global Nonwoven Division of Bostik, will also deliver a presentation on Brilliance, a world’s first in adhesive products during INDEX’s conference session, Wednesday, April 5, from 11:30 - 11:50 a.m.

www.bostik.com

Booth 1580

As one of the leading producers of finishing and thermal treatment lines for the nonwovens and textile industry, Brückner considers its participation in the INDEX trade fair in Geneva as absolutely obligatory.

In the nonwovens sector the Brückner portfolio comprises all types of application systems, thermal treatment lines, dryers as well as cutting and batching units. On the occasion of this year’s INDEX trade fair in Geneva, Brückner wants to show its customers and prospective clients the new developments and improvements in the field of belt dryers, a type of dryer which gained compared to conventional drum dryers more and more acceptance in the last years.

The design of the high-performance dryer SUPRA-FLOW BH, which had been particularly developed for the air-through drying of light hydroentangled nonwovens, has been optimized. This type of dryer is characterized by its particularly high evaporation capacity, a high energy efficiency, the gentle material transport and an excellent drying homogeneity. It is thus clearly more than an alternative for the use of an air-through drum dryer and offers many benefits for the user.

Another new development is the Supra-Flow BE-ADL belt dryer developed for ADL products for thermo-fusion of card nonwovens. In the design of this dryer particular attention was paid to a gentle fabric transport, a high temperature accuracy and a precise air control. The air circulation in this dryer follows also the air-through principle.

Depending on the purposes, Brückner offers different dryers matching the customers’ individual needs and processes. Brückner’s portfolio comprises among other systems also flat dryers with one or several fabric passages, vertical dryer, cylinder dryers, drum dryers, airlaid dryers, infra-red radiation dryers, high temperature dryers and combinations thereof.

www.brueckner.com

Booth 2451

Offering the widest high speed spooling line for ADL in the world (with a mother roll width up to 1.5 meters) and a fully automated Pegase 3 Spooling Cell commissioned end of 2016, Spoolex Group confirms the world leading position of its Calemard machinery brand in providing customized spooling solutions for demanding productions with tension sensitive materials.

Even more so than in the past, the French company assists its customers to move in the “Smart Manufacturing” era. To help them to bring their production tools up-to-date and to improve safety and healthy working conditions, Spoolex’s integrated engineering department is always developing several automated solutions around its know-how, to propose a global offering with flexible machinery and smart automation.

Around the well-known Calemard Pegase 3, the new Complete Cell integrates new solutions for:

- Automatic mother roll loading with conveyor and automatic loader for mother rolls up to Ø 2m - 500kg.

- Automatic ultrasonic butt-to-butt splicing module with a line stoppage time down to 20 seconds and a faster and more ergonomic manual web positioning.

- A three step automatic jumbo spool unloading solution with automatic strip cutting, spool unloading, reclaiming and transfer to the packing cell.

- Complete packing cell for individual spool weighing, wrapping and labeling.

Big data is now crucially important for all industry and converters are also concerned. They are always looking for connected solutions to optimize their machinery production and overall plant efficiency. A few months ago, Spoolex dedicated a multi-service team to engineer a MES ready connection system.

As a result, Spoolex offers today multi-level DataSmart solutions for production performance analysis and production traceability. After collecting data directly from the line PLC (for reliability and speed), DataSmart is available as different packages adapted to each customer’s needs: from simple data collection to complete extraction, evaluations, indicators calculation and customized reporting.

With a single contact point and thanks to a systemized analysis needs approach, Spoolex Group is able to manage all in-house complete projects for simple problematic to complicated one. Working closely with Spoolex Group ensures efficiency, reliability, safety and serenity throughout the entire project, from first contact to equipment commissioning.

www.spoolex.com

Delta Converting

Booth 4040

Originating breakthrough ideas! This is the main motive that behind Delta’s success in the last five years.

Delta srl, an Italian company located in the North of Italy, designs and builds converting machines for the production of adult incontinence, feminine hygiene products and baby diapers. Delta has invested in research and development, introducing new innovation in the field of core forming on adult incontinence and feminine machines. Thinner, comfort, discreet, performing are the key words that have orientated Delta technology development. The market tendency and customers’ needs to produce high quality and performing product, saving raw materials, has brought Delta to design and build a revolutionary system to produce fluff less core for light and heavy incontinence products.

The Delta “fit-in-line” system prepares a fluffless core with superabsorbent polymer, with a technology that completely eliminates the traditional “core forming section” and give high quality products results in absorbency, softness and general savings of space, energy, raw materials and noise reduction. Delta engineers have also worked hard to design underpad machines with thinner cores using less fluff, which guarantees an even fluff distribution at low gsm at high speeds.

Feminine hygiene lines for the production of thin fluff core panty liners and sanitary napkins together with baby diaper with elastic ears complete the range of Delta machineries.

www.deltaconverting.com

Dilo

Booth 2010

Dilo’s new horizontal crosslayer DLSC 200 sets new standards in crosslapping technology with an electro-mechanical web infeed speed of 200 m/min depending on the fibers used. It is just one of several new developments that will be on display during INDEX 2017.

Dilo will also present a new needle module technique of DiloMachines that embeds 22 needles in a plastic support and is used in needle boards with very high needle density. These modules result in a fast and precise filling of needle boards. They are used in Variopunch needling technology where bad spots in stitch distribution are eliminated by variable needle arrangements thus creating a more homogeneous and higher surface quality.

This compact line is designed for the production of high quality needlefelts from special fibers such as carbon. It completes Dilo’s portfolio that includes not only small production lines for laboratories and large needling lines for paper machine felts but also machines for the production of needlefelts from staple fibers.

www.dilo.de

Booth 2241

General Nonwovens of Turkey is a member of Imam Kayali Holding which is active in different fields of trade and industry since 1928. The company has been making nonwoven fabrics already for more than a decade. During this period, the company expanded its operations to two factories in Turkey along with the expansion of offerings made to the nonwovens industry. Spunbond fabrics are made of polypropylene, polyester and PLA while SMS fabrics are made of polypropylene only. These fabrics are served at a large basis weight range of 10 to 200 gsm. General Nonwovens also uses staple fibers of mono and bi-component with various polymer compositions. These are bonded by means of heat, so lofty air through bonded fabrics are produced in a range of 18 to 80 gr/m2. General Nonwovens not only serves local markets but also the U.S. and European markets with a 50-50 split.

General Nonwovens’ HyGen brand products are widely used in the hygiene industry namely: topsheet, backsheet, ADL, leg cuffs, front ears and core-wrap. A very soft air through bond fabric is also served for those who are in search for soft-touch fabric for premium disposable product end uses. Apart from the HyGen brand, FilterGen brand is served for the filtration industry, TexGen for coated and laminated fabrics as well as home textiles, AutoGen for the automotive industry and IndiGen for industrial and technical textile applications.

www.generalnonwovens.com

H.B. Fuller

Booth 2461

As a leading adhesive supplier, innovation at H.B. Fuller encompasses more than the products we make. It touches the interactions we have with customers and the experiences they deliver to end-users. And, it shapes the future of industries across the globe. But don’t take our word for it. Why not take yourself on a multi-sensory experience. Touch, smell and see how our next generation hygiene solutions can make a difference to everyday disposable goods. Hear how our experts can help you make thinner, smarter, better fitting, more absorbent products a reality with our Full-Care line of high performance products. Feel for yourself how soft and stretchable they are with our new Conforma adhesive. See a fresh way to eliminate odor fast with our game-changing ODOGard technology. As a market leader, we’ve been challenging the limits of what’s possible for over 40 years to enable our hygiene customers to be the best at what they do.

www.hbfuller.com

Booth 4000

Curt G. Joa, Inc. will celebrate its 85th anniversary at INDEX. In 1930, founder and German immigrant, Curt G. Joa was given an opportunity to design an automated process to produce sanitary napkins. After demonstrating a working model of the process, he was commissioned to make the first machine in October 1931. In 1932, he received his first patent and established an engineering-consulting company bearing his name.

“The idea that an entrepreneur such as my grandfather could immigrate to the U.S. and start a successful business during the Great Depression is remarkable,” says Curt G. Joa, Inc. president Gene Kiela II. “As we enter into our 85th year, we still hold the values that he instilled – that good customer relationships lead to success.”

In addition to the first sanitary napkin machine, some of the company’s many pioneering accomplishments include the first JOA rotary mill, the flying splice, the vertical stacker, the Cut at Tape Speed (CATS) Unit, the web velocity modulator, the Single Transfer Insert Placement Process (STIPP) Unit and the No Scrap Ear (NoSE) Unit for baby diaper production.

In its third generation of family ownership, Curt G. Joa, Inc. now includes the JOA and Bikoma brands, with operations in the U.S., Germany and India.

www.joa.com

Kansan

Booth 4309

The industry leading wet wipe machinery manufacturer Kansan is planning to dominate INDEX once again. Kansan is ready to demonstrate four different machines and prepare a production environment for the convenience of visitors. Kansan’s booth will feature a fully automatic production line consisting of a flat pack converting machine, a flow pack machine and a lid applicator robot. In addition, the new generation cross fold machine of Kansan also will be exhibited there.

Kansan’s flat pack converting machine Quickstack series can vary from six to 25 lanes with a capacity of 800 cuts per minute with single or jumbo reel automatic splice unwind stations. These units are capable of running different substrates along with a variety of folding types and length and width options. Overall this platform presents itself as highly productive, easily operable, hygienic, safe and upgradable for future needs.

The full automatic flow pack machine from Acurapack series is a newly developed model flow wrap machine specially designed for wet wipes with a capacity of 150 packs per minute design speed thanks to advanced engineering in stroke mechanism. It is suitable for both flat packs and cross fold packs.

Probably the fastest, strongest and most flexible lid applicator machine the visitors will see at INDEX will also have the Kansan logo on it. This robust machine called LidmasterPRO is equipped with a camera system to visually check the position of a label on the packages. Even if there are incorrect alignments or off-center inflow of product, the advanced robotic system is able to place the lid on the pack in perfect position thanks to four-axis movement ability.

Flexiwork with two unit station will make its debut for the first time on floor ground this year. This machine was the most selling unit of 2016 and there are already more than 15 firm orders for 2017. Thanks to its compact design and enhanced performance, the actual working speed of the machine can go as high as 700 wipes per minute on single line. With one to four lines, converters can increase their production capacity with maximum output of 2400 wipes/minute. Unlike others, Flexiwork has mechanical folding with no vacuum. And very flexible to process different type of substrates with different folding types and dimensions.

www.kansanmak.com

Martin Automatic

Booth 2181

Martin Automatic will demonstrate its advanced Airnertia and MDR roller technologies at INDEX. Offering lowest roller inertia and essentially friction-free rotation, these technologies are among the solutions Martin Automatic offers for non-stop roll change and transport of web materials.

Martin Automatic continues to experience strong equipment sales to nonwovens converters and material manufacturers including unwinds using a variety of splicing methods for web speeds to 915 meters per minute. Martin systems can be integrated into new lines and retrofitted to existing processes for greater speed, tension control and productivity.

www.martinautomatic.com

Montalvo

Booth 4466

Montalvo International, specialists in web tension control, will be showcasing a range of new and innovative tension control technologies at INDEX 17 including load cells, controllers and complete new control systems.

For the first time ever in an open loop control system, users get a precise, reliable tension reference that operators can use to ensure consistent, high quality production runs. The TSC is a total tension control solution that delivers performance, convenience, and productivity. Simple, compact and easy to install and operate, the TSC is the latest innovation in open loop tension control. Patent pending technology allows easy integration into existing machines as well as new machine builds.

Improved quality, performance, and convenience, combined with lower pricing and shorter lead times, N Series Cantilever Load Cells are designed for single side machine frames such as label, film, foil, and other narrow webs. N Series Load Cells feature an anti-deflection design, semiconductor strain gauge technology and eliminate web steering for greater consistency and quality in your process.

TSR Tension Sensing Rollers are an all-in-one, drop-in tension measurement solution combining performance and convenience. Re-designed for shorter lead times, lower pricing, and improved performance, the TSR is available in standard sizes, and finishes or completely customizable, the TSR is one of the most versatile, performance driven machine components in the industry for both OEM’s and end-users.

Montalvo’s most advanced, fully featured tension control is now available with ODVA Certified Ethernet/IP. The new Ethernet/IP Communication allows customers to easily interface with an existing HMI on the operator panel of the machine, allow management to record and store information about the condition of the machine, and reduce, or eliminate the need for running cables/wires for installation.

At INDEX, Montalvo will launch its newest Range Expander, the P4. As originators of tension control range expansion, the P4, Montalvo’s elite Automatic Range Expander, expands the capabilities of existing machines, allowing them to be more effective at: running multiple types of materials with differing tension levels, gaining greater control at lower torque ranges, running high mass rolls at lighter tensions, and running low torque and tension applications that require high torque to stop.

Its newest line of cartridge style dead-shaft idler load cells have been developed to be dimensional drop-in, direct replacement load cells for a variety of other load cell manufacturers. This line provides all the dimensional and functional requirements you may be accustomed to, while often having equal or better lead times and pricing. And like all of our products, DR-Series Load Cells are back by our highest levels of support, quality, and performance.

www.montalvo.com

Booth 2161

Nordson will be featuring a broad line of applicators at INDEX.

Choices of spray, slot and metering applicators can apply hot melt adhesives, perfumes and lotions, among other materials, to the numerous components that comprise disposable hygiene products. The various applicators can be used across a wide range of dispensed materials, line speeds and material types and can be set up to produce customized patterns for continuous or intermittent applications. Designed with customer needs in mind, Nordson applicators are easily incorporated into OEM equipment and most applicators offer quick, easy change components such as nozzles and modules.

Nordson applicators’ innovative technologies represent Nordson’s commitment to delivering the highest quality products, enabling customers to apply the right amount of adhesive in the right place at the right time on their products.

www.nordson.com

Booth 2581

Optima’s “Project ZERO”technology is being billed as the future of production flexibility. This machine perfectly adapts to the requirements with optimized format change time, a new stacker for feminine care products and a platform with a completely modular design. The operator specifies designs and data, the machine handles the rest. The different packages are produced “inline.” Furthermore, new sensor technology leads to process stability that is once again significantly increased.

In addition to this new development, the Optima Nonwovens booth will give visitors the chance to experience the future of HMI (Human Machine Interface). Thanks to smartphones and tablets, today's users are accustomed to intuitive and clearly arranged interfaces for operating devices. New HMIs take up these developments, but are adapted to the industrial environment and expanded with essential features.

Three years ago at INDEX this was still just a vision, but today it is already a firmly entrenched part of the service Optima offers.

With TCAM from Optima, a digital tool is available that uses sensors to analyze the condition of packaging systems and provide advanced notice of the need for maintenance while also accelerating the flow of information.

www.optima-packaging.com

Radici Group

Booth 2629

Tessiture Pietro Radici—part of the Radici Group’s extrusion yard business area—specializes in the production of dylar spunbond nonwoven fabrics, designed – as well as for use in sanitation – especially for industrial application sectors, such as building insulation, the automotive industry, agriculture, furnishings and disposable products. These nonwoven fabrics are available in different weights and colors to meet the varying market demands and the range of choice is set to increase with the new production line currently under development.

Radici Yarn and Radici Chemie of the comfort fibres business area is a leader in the production of nylon staple fibers for technical and traditional clothing and for high quality carpets and rugs, expanding their production to include products for the abrasives sector (both household and industrial), the multi-application nonwoven fabrics sector and the felt sector for manufacturing and filtration. These products form part of the well-known family of Radilon polyamide 6 staple fiber products, to which is added the brand new range of dorix tech polyamide 66-based products, produced in the very latest lines specifically designed to guarantee maximum performance and the very highest standard of quality available today.

Radilon Staple Fibres and dorix teck are available in both raw and solution-dyed versions, with a choice of various colors and a guarantee of optimum performance in any specific application.

www.radicigroup.com

Sandler

Booth 2431

At INDEX, Sandler will present several innovations for the wipes market. sawatex classy silk and sawatex lace-o-paque add a certain something to cosmetics applications and baby care applications while sawatex classy silk features excellent cleaning efficiency and above all an extraordinarily silky touch, rendering every use into a wellness-treatment. sawatex lace-o-paque offers softness and high bulk, offering gentle care for little explorers. The new embossing design “square” captures the attention of another market segment: Small squares render the substrate bulkier and increase its surface—for even better results in cleaning applications. With a “double action“ substrate for cleaning wipes, Sandler gets to grips with stubborn dirt. The multi-layer nonwoven features a coarser side for efficient cleaning and a smooth side for gentle polishing and grooming the cleaned surface.

All of these nonwoven substrates receive their particular properties from the special fiber blends used. Selected raw materials bring about not only excellent functionality, but also enable a reduction of the basis weights—for less raw material usage. Embossed motifs for visual individualization of wipes are also more detailed.

Sandler’s range of nonwovens for disinfection wipes now encompasses an additional highlight: Colored product variants in various pastel shades enable a visual differentiation of various application areas.

“Stretch your limits“—is the motto with Sandler’s collection for elastic applications. Manufacturers are provided with an assembly kit of materials featuring different degrees of elongation to choose the ideal nonwoven for their respective use. From “basic stretch“ to “premium stretch plus“ it holds the right product for everyone. These nonwovens support an optimum fit, thus increasing wearing comfort.

Comfort is also the watchword when it comes to innovations for topsheets: A new design for these materials visually provides a sense of lightness in daily hygiene: Subtle butterflies make this product a veritable eye-catcher.

A new “canyon” structure for topsheet materials combines visual differentiation and optimized functionality: This special surface renders the topsheet bulkier and even softer; increases stability, and simultaneously supports fluid handling.

Sandler’s new nonwovens for intake layers take this function one step further. They quickly transport fluid away from the body and efficiently distribute it onto the entire surface, for optimal utilization of the core’s storage capacity. The nonwovens also function as an interim storage layer, preventing rewet and protecting the skin. Sandler designs these nonwovens in line with one’s product requirements: Softness and flexibility can be individually adjusted; embossing designs provide visual highlights.

www.sandler.de

Schobertechnologies

Booth 4013

Schobertechnologies GmbH develops, designs and manufactures rotary tooling, modules, and complete specialty machines widely used in film-, foil-, packaging-, nonwovens and paper converting industries in more than 100 countries globally.

Schober’s high capacity die cutting modules all feature a mechanical preset and calibrated pressure load system, high-precision bearing assemblies and housings for low temperature running, vibration-free design and a pneumatically activated eccentric lifting device for a quick disengagement of the die cutting/anvil cylinder in order to ease web threading and consequently shorten set-up. The technically mature module concept complemented by the sophisticated tool design, provides productivity increase and outstanding high tool life performance.

The performance of these high precision units have a range for processing speeds of up to 1000 meters/per minute and tool diameters of up to 600 mm, with a working width of up to two meters.

With production speeds rising and higher quality requirements from end users, Schobertechnologies engineers have kept up with these demands by implementing further developments on their rotary punching tools and modules. All tooling is manufactured using the latest CNC technology.

Products developed by Schobertechnologies have found application in all sectors of rotary processing. In addition to the traditional sectors of paper, film and foil processing industries, new application fields could be acquired in the medical, automotive, security, electronical and pharmaceutical industries.

www.schobertechnologies.de

Suominen

Booth 1522

Suominen will showcase its broadest range of products for wipes, hygiene products and medical applications. These innovations have been developed thanks to the company’s recent investments in production technology and development and include innovations for household, workplace, flushable wipes as well as new freshness for the baby care segment.

Suominen booth visitors will also have a chance to discover the company’s approach to sustainability and how it continues to be pioneers in terms of environmental and social responsibility.

www.suominen.fi

Technoplants

Booth 4310

Technoplants, once known for its pioneering automatic end of line, from cutting to winding, stacking and packaging, is today specialized in making complete air lay lines. Its revolutionary air lay card machine MULTIline FPC is able to produce mats with any fiber in a range from 0.9-400 denier and any length from 4-100 mm. The combination of the three machines (former, precard and card) gives the maximum flexibility to the line and allows customers to produce fabrics with different characteristics, at the same time with a machine setting time of only a few minutes to change from one production to the other.

This has led to a wide range of weight, from 50-5000 gsm, which increase the products portfolio and then the market share.

Technoplant’s thermobonding MULTIoven operates from high-speed ADL to shoddy recycled fiber mats, with a constant thin air distribution for all the configurations.

www.techno-plants.com

Tietex

Booth 4361

Tietex International is featuring Optima Loop Closure and Proton Hygienic Microfiber.

Optima is the diaper industry’s softest, lightest and most consistent Landing Zone product; Proton Microfiber Towels, Mops and Wipes primarily serve Healthcare, Food Service & Production, JanSan and Textile Rental markets. These and other patented developments are the result of technology that brings together disparate materials to answer a growing need for high performance, technically engineered components – none more promising than products aimed at diaper, hygiene and cleaning markets.

Family owned and vertically integrated, Tietex has two factory locations and over 600 employees on two continents. The company’s core technology serves a variety of key markets, including athletic footwear, hook & loop fastening, mattress fabrics, roofing fabrics, automotive and wipes. In addition, Tietex continues to develop unique performance fabrics for many diverse custom applications.

www.tietex.com

Booth 2331

Trützschler Nonwovens will focus on high-quality webs and low conversion costs at INDEX. A major point of the company’s booth will be carding concepts for creating perfect webs for hygiene and other applications. Many end products require distinctive web characteristics, therefore Trützschler Nonwovens continuously extends its range of fiber treatment, carding and web forming machinery.

Meanwhile, in the bonding process often a different type of challenge arises when productivity and efficiency become an issue. Take for instance chemical bonded webs: with the new Trützschler High-Speed Foulard for the application of liquid binding agents, Trützschler addresses line speed. Various optimizations on rolls (patent pending) and sub-components allow for increasing the production speed of lightweight webs by up to 50%.

Hydroentangling and drying are a third focus point at INDEX because these processes are always worth a detailed discussion. For decades both the AquaJet and the multi-drum dryer have been on top of Trützschler Nonwovens’ R&D agenda.

www.treutzschler.com

Ultra System

Booth 1268

Ultra System’s exhibition will include products from its two divisions. The display from the Rotary Cutting Dies Division will include tools for the manufacture of personal hygiene products (sanitary pads, nappies for babies and adults, light inco pads, plasters and advanced dressings) and the household paper industry (dry and wet wipes) in bonded steel, in sintered steel and also in Tungsten Carbide bonding cylinders for heat sealing, bonding cylinders for ultrasound sealing, complete cutting and embossing groups. A resharpening service for any cutter is available.

Meanwhile, the Moulds Division for the motor and motorbike industry, will feature moulds for heat forming (food, pharmaceutical, chemical industries), moulds for polyurethane foam (furniture, pharmaceutical industries etc), prototypes and assemblages.

www.ultrasystem.com