Sebastian Basel, Roland Scholz, Kelheim11.11.15

Currently the product category of “flushable wipes” represents one of the most dominating topics in the world of paper and nonwoven production: wipes that can be flushed down the wastewater system without adversely impacting plumbing or wastewater infrastructure and operations. Due to their convenience, the request for such products is constantly growing at the consumer’s side and therefore increases the production demand at the manufacturer’s end. In the past broader market coverage of flushable wipes was prevented only by a contradiction that was hard to resolve: During the production process and during use, the web strength of the wipe has to be high enough so that the web stays intact. However, after use the wipe needs to disintegrate as quickly and as completely as possible as shown in picture 1.

Only a few products could manage this balancing act successfully using conventional spunlace-technology, based on carding and hydroentanglement. To clearly define the term of “flushability” for the end consumer, EDANA and INDA—the two leading trade associations for the nonwovens industry—published the third edition of their “Guidelines for Assessing the Flushability of Disposable Nonwoven Products” (EDANA III). These guidelines clearly define the testing methods that have to be completed and passed before a product can be labelled as flushable and avoid any problems with sewage clogging and further challenges during wastewater treatment. With the introduction of the new combined process of wetlaid and hydroentanglement into the market a breakthrough in the functionality of flushable products seems to have been achieved. In cooperation with Andritz, the supplier of Wetlace lines for the production of flushable wipes, Kelheim Fibres investigated the influence of two different viscose fiber types in combination with the flexibility of the Wetlace process and the manifold parameters that can be chosen. The following article describes the influence of such variations on the final wipe product.

On the process side, the conventional spunlacing—a carding process with subsequent hydroentanglement—can provide wipes with high tensile strength and softness. However, the necessary minimum fiber length of 20 mm creates entanglements of the fibers that are difficult to open up again when flushed. Even in case of an initial break-up of the wipe, the single web pieces entangle again or build up fiber ropes which prevent a sufficient dispersion into single fibers. More and more it became clear that a fiber length of considerably less than 20 mm is necessary to produce flushable wipes according to EDANA III. The challenge: The carding process does not work with such “short fibers.” This was the point where the wetlace process jumped in. In a wetlaid process a blend of pulp and cellulosic long fibers is dispersed in water and then drained on an inclined wire. The homogenously formed wet fiber is then bonded using hydroentanglement in the next step. Within this process the key to success is the perfect combination of all relevant parameters, namely the raw materials, the right fiber blend and specific process settings during wet laying and hydroentanglement. The questions regarding process technology have been addressed by machine suppliers like Andritz in recent years, which supply full turnkey lines to the market.

Influencing Wet Strength and Flushability Already on the Fiber Level

In the past, Kelheim Fibres GmbH investigated the influences of fiber properties such as length, dimensions, crosssection and surface on the flushability of nonwoven products to offer tailor -made solutions for these applications already on the fiber level. For the new wetlaid-hydroentanglement process the question arose how a viscose shortcut fiber could be modified to achieve both sufficient bonding to the pulp component of the fabric and the dispersion of the wipe in the wastewater system. Such a fiber would help to fulfil the requirements of initial web strength during production and use and break-up and dispersion after use. The current study investigated two different fiber cross-sections: Round (Danufil) and flat (Viloft) viscose fibers.

Danufil was chosen with a diameter of 1.7 dtex and a length of 12 mm, whereas Viloft was tested in three different types, varied in length of 10 and 12 mm and in diameter of 1,9 and 2,4 dtex.

In combination with 20% pulp each fiber was used in a Wetlace process for the production of flushable wipes with 65g/m² at Andritz.

Pressure sums of about 102 bar, 130 bar and 155 bar were applied at the hydroentanglement step and a special focus was put on the analysis of the wet strength and the flushability of the product, determined in the slosh-box test according to EDANA III guidelines.

Wet-strength

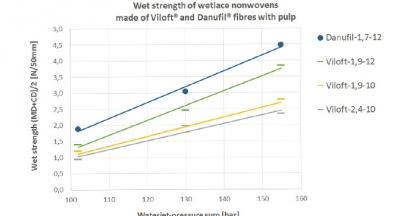

For the determination of the wet strength, samples of 50 mm width and a clamping length of 100 mm were soaked in water, dripped off and then measured immediately. The results are shown in graph 1:

As a first conclusion, it can be assumed that with all tested viscose fibers in a blend with 80% pulp, it is possible to achieve the wet-strength in the nonwoven that is required for later converting and the end use. In general all fibers show the typical correlation of an increasing nonwoven strength with increasing pressure applied for hydroentanglement. With the used process settings the rise of the curves was almost linear.

The level of wet strength depends also considerably on the type of viscose fiber employed. Danufil with its round-shaped cross section offers the highest wet strength at lower pressure levels. However, Viloft with a flat cross section delivered a considerable range of strength depending on rather small variations of fiber length and diameter. The smallest fiber diameter of 1.9 dtex and the largest fiber length of 12 mm delivered the highest wet strength of the Wetlace nonwoven made of Viloft. The curves above also indicate a general trend of higher fiber length leading to higher wet strength in the nonwoven.

The results show that with both Viloft and Danufil a broad range of web strength can be achieved, taking advantage of the flexibility of the Wetlace process.

Flushability

For the application of flushable wipes like moist toilet paper (MTP), the flushability of the products is of paramount importance. Not only since the public discussion started to focus on wet wipes clogging drainage pipes, wastewater systems and pumps, it is a clear requirement for all products that are labelled flushable to comply with EDANA III guidelines. In particular, the slosh-box test defines the criteria for such a product. According to EDANA III, “a single article (e.g. individual hygienic wipe) is incubated for 3 hours” in “an oscillating box containing 2.0 liters of tap water. Subsequently, the contents of the box are transferred to and then rinsed through a 12.5 mm perforated plate sieve. The materials retained on the sieve are recovered and analyzed gravimetrically.” After three hours, more than 25% of an article’s initial dry mass must pass through the sieve.

All samples made of Danufil and Viloft fulfil the above mentioned criteria already after 10 minutes of incubation in the slosh box. This qualifies viscose short cut in general – in

combination with pulp – as an ideal raw material for dispersible products. To differentiate between the particular samples, graph two shows the results of the slosh box test after five minutes incubation time.

In general, the Viloft samples show a higher flushability performance than the Danufil nonwovens. At the lowest waterjet-pressure sum of 102 bar, the level of dispersion still is comparable for both fiber types; however, at a waterjet-pressure sum of 130 bar the Viloft samples with 10 mm fiber length can be flushed through the sieve at a higher extent than the Danufil sample. At 155 bar even all Viloft samples show better flushability.

It seems that the flat cross section of Viloft with a thickness-to-width ratio of about 1:5 clearly acts in favor of a quicker dispersion. This might be even more important against the background of tightened requirements for future editions of the guidelines and therefore for the slosh box test.

Conclusion

At a blend ratio of 20%, viscose short cut fibers in combination with pulp offer enough wet strength for the production and the use of flushable wipes. Round shaped Danufil delivers higher strength at lower waterjet pressures, but thanks to the flexibility of the Wetlace process, nonwovens made of Viloft can reach sufficient levels at higher pressure. In terms of flushability, Viloft clearly offers the advantage of very quick dispersion at all levels of entanglement. In combination with the versatile process of wetlaid and hydroentanglement like Andritz’s Wetlace technology, Kelheim Fibres offers the right raw material to trigger strength and flushability, without the need of any additional binder. The final product consists of 100% cellulosic material and is fully biodegradable.

Acknowledgements:

We thank Andritz for the processing and supply of the Wetlace materials discussed in this article. Wetlace is a registered trademark of Andritz Küsters GmbH.

Only a few products could manage this balancing act successfully using conventional spunlace-technology, based on carding and hydroentanglement. To clearly define the term of “flushability” for the end consumer, EDANA and INDA—the two leading trade associations for the nonwovens industry—published the third edition of their “Guidelines for Assessing the Flushability of Disposable Nonwoven Products” (EDANA III). These guidelines clearly define the testing methods that have to be completed and passed before a product can be labelled as flushable and avoid any problems with sewage clogging and further challenges during wastewater treatment. With the introduction of the new combined process of wetlaid and hydroentanglement into the market a breakthrough in the functionality of flushable products seems to have been achieved. In cooperation with Andritz, the supplier of Wetlace lines for the production of flushable wipes, Kelheim Fibres investigated the influence of two different viscose fiber types in combination with the flexibility of the Wetlace process and the manifold parameters that can be chosen. The following article describes the influence of such variations on the final wipe product.

Influencing Wet Strength and Flushability Already on the Fiber Level

In the past, Kelheim Fibres GmbH investigated the influences of fiber properties such as length, dimensions, crosssection and surface on the flushability of nonwoven products to offer tailor -made solutions for these applications already on the fiber level. For the new wetlaid-hydroentanglement process the question arose how a viscose shortcut fiber could be modified to achieve both sufficient bonding to the pulp component of the fabric and the dispersion of the wipe in the wastewater system. Such a fiber would help to fulfil the requirements of initial web strength during production and use and break-up and dispersion after use. The current study investigated two different fiber cross-sections: Round (Danufil) and flat (Viloft) viscose fibers.

Danufil was chosen with a diameter of 1.7 dtex and a length of 12 mm, whereas Viloft was tested in three different types, varied in length of 10 and 12 mm and in diameter of 1,9 and 2,4 dtex.

In combination with 20% pulp each fiber was used in a Wetlace process for the production of flushable wipes with 65g/m² at Andritz.

Pressure sums of about 102 bar, 130 bar and 155 bar were applied at the hydroentanglement step and a special focus was put on the analysis of the wet strength and the flushability of the product, determined in the slosh-box test according to EDANA III guidelines.

Wet-strength

For the determination of the wet strength, samples of 50 mm width and a clamping length of 100 mm were soaked in water, dripped off and then measured immediately. The results are shown in graph 1:

As a first conclusion, it can be assumed that with all tested viscose fibers in a blend with 80% pulp, it is possible to achieve the wet-strength in the nonwoven that is required for later converting and the end use. In general all fibers show the typical correlation of an increasing nonwoven strength with increasing pressure applied for hydroentanglement. With the used process settings the rise of the curves was almost linear.

The level of wet strength depends also considerably on the type of viscose fiber employed. Danufil with its round-shaped cross section offers the highest wet strength at lower pressure levels. However, Viloft with a flat cross section delivered a considerable range of strength depending on rather small variations of fiber length and diameter. The smallest fiber diameter of 1.9 dtex and the largest fiber length of 12 mm delivered the highest wet strength of the Wetlace nonwoven made of Viloft. The curves above also indicate a general trend of higher fiber length leading to higher wet strength in the nonwoven.

The results show that with both Viloft and Danufil a broad range of web strength can be achieved, taking advantage of the flexibility of the Wetlace process.

Flushability

For the application of flushable wipes like moist toilet paper (MTP), the flushability of the products is of paramount importance. Not only since the public discussion started to focus on wet wipes clogging drainage pipes, wastewater systems and pumps, it is a clear requirement for all products that are labelled flushable to comply with EDANA III guidelines. In particular, the slosh-box test defines the criteria for such a product. According to EDANA III, “a single article (e.g. individual hygienic wipe) is incubated for 3 hours” in “an oscillating box containing 2.0 liters of tap water. Subsequently, the contents of the box are transferred to and then rinsed through a 12.5 mm perforated plate sieve. The materials retained on the sieve are recovered and analyzed gravimetrically.” After three hours, more than 25% of an article’s initial dry mass must pass through the sieve.

All samples made of Danufil and Viloft fulfil the above mentioned criteria already after 10 minutes of incubation in the slosh box. This qualifies viscose short cut in general – in

In general, the Viloft samples show a higher flushability performance than the Danufil nonwovens. At the lowest waterjet-pressure sum of 102 bar, the level of dispersion still is comparable for both fiber types; however, at a waterjet-pressure sum of 130 bar the Viloft samples with 10 mm fiber length can be flushed through the sieve at a higher extent than the Danufil sample. At 155 bar even all Viloft samples show better flushability.

It seems that the flat cross section of Viloft with a thickness-to-width ratio of about 1:5 clearly acts in favor of a quicker dispersion. This might be even more important against the background of tightened requirements for future editions of the guidelines and therefore for the slosh box test.

Conclusion

At a blend ratio of 20%, viscose short cut fibers in combination with pulp offer enough wet strength for the production and the use of flushable wipes. Round shaped Danufil delivers higher strength at lower waterjet pressures, but thanks to the flexibility of the Wetlace process, nonwovens made of Viloft can reach sufficient levels at higher pressure. In terms of flushability, Viloft clearly offers the advantage of very quick dispersion at all levels of entanglement. In combination with the versatile process of wetlaid and hydroentanglement like Andritz’s Wetlace technology, Kelheim Fibres offers the right raw material to trigger strength and flushability, without the need of any additional binder. The final product consists of 100% cellulosic material and is fully biodegradable.

Acknowledgements:

We thank Andritz for the processing and supply of the Wetlace materials discussed in this article. Wetlace is a registered trademark of Andritz Küsters GmbH.