Tara Olivo, Associate Editor04.23.20

Natural fibers are all the rage in nonwovens, but did you ever think you’d see wool in a disposable baby diaper or menstrual pad? A mother-daughter duo in New Zealand is making it happen.

Ten years ago Angela Potroz, a farmer from the Taranaki region of New Zealand, was grappling with the decline of crossbred wool prices. Her daughter, Derelee Potroz-Smith, a new mother, was shocked about the alarming amount of non-biodegradable, petroleum-derived plastics and potentially toxic chemical used in baby diapers and feminine hygiene products. That’s when they reached an ah-ha moment that these two problems could solve each other.

Woolchemy, founded in 2010, works with scientists to transform an underutilized traditional natural fiber—crossbred wool—into truly innovative, multi-use products. Today the company manufactures and supplies absorbent wool-based nonwovens to global brands that share its vision to deliver sustainable, high-performing products without compromising environmental and social responsibilities.

“New Zealand is the third largest producer of wool, contributing 9% of the world’s production,” says Derelee Potroz-Smith, CEO and founder of Woolchemy. “A majority of New Zealand’s wool output is strong/coarse wool which is an underutilized, natural, renewable resource. Woolchemy is challenging the traditional thinking of how wool can be used and creating truly innovative, multi-use textile technologies.”

Launched in 2015, Woolchemy’s first product was neweZorb, a world’s first absorbent wet treatment process. neweZorb relaxes the fiber structure, breaking down and reforming the wool’s molecular bonds to make the wool surfaces permanently super-hydrophilic and superabsorbent, according to Potroz-Smith. “In fact, it is said to be up to 25 times more absorbent than regular wool and retains all the natural qualities of wool,” she adds.

neweZorb is biodegradable and compostable, renewable and sustainable, washable and disposable, and contains no chemical residues. The treatment can be applied to any wool micron and any full or blended wool substrate including yarn, fiber, nonwovens, wovens and knits. neweZorb is capable of absorbing any moisture including blood, urine, water, chemicals and sweat, and can be used for washable and reusable products such as menstrual underwear, cleaning products and athleisure clothing.

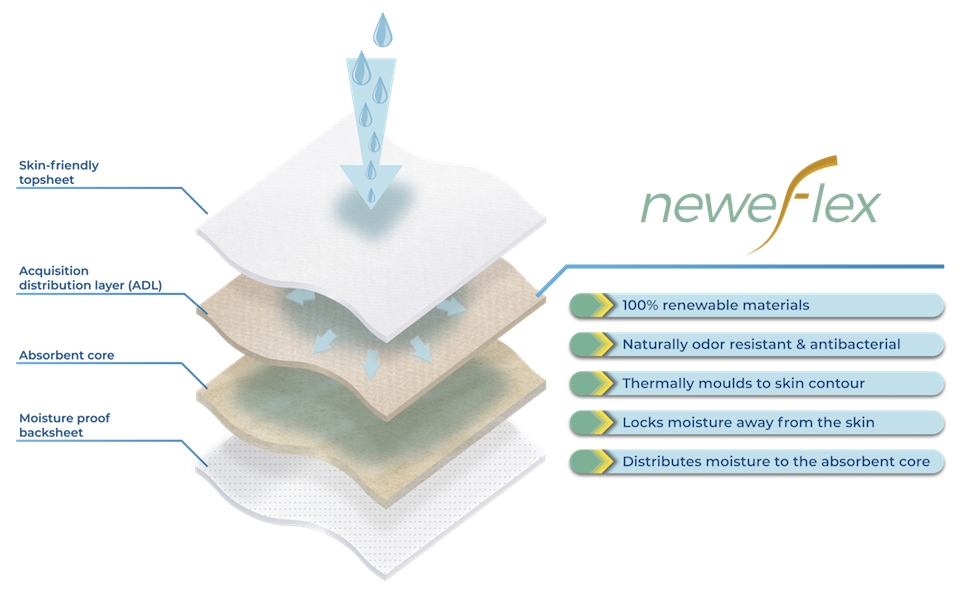

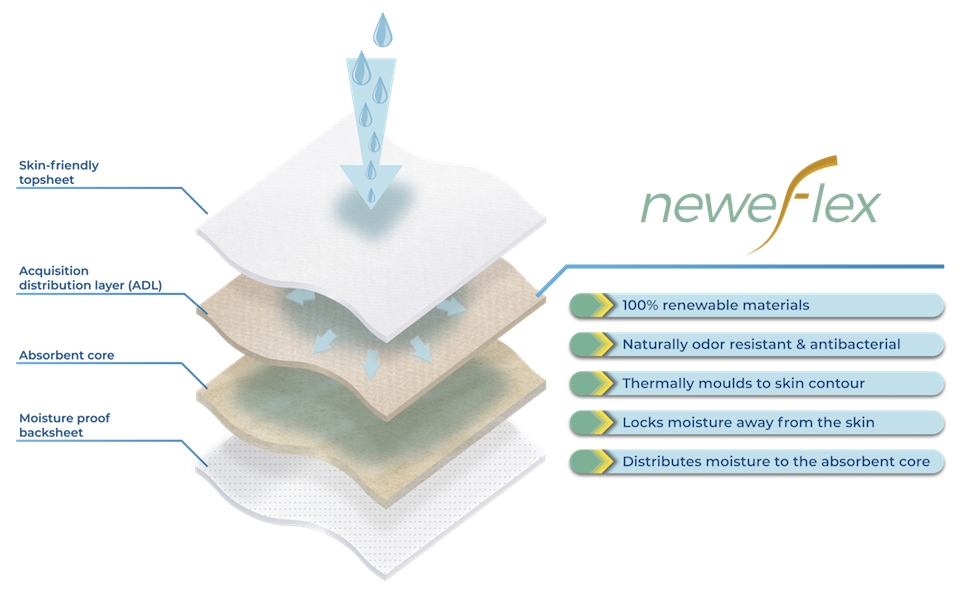

Now Woolchemy is directing its efforts toward disposable hygiene products with the launch of its latest development neweFlex, a bio-composite acquisition distribution layer (ADL) for single-use diapers and sanitary pads.

“The structure of wool fibers is very complex, allowing it to be moisture repelling on the outside but moisture loving on the inside,” Potroz-Smith explains.

In developing the product, Woolchemy’s first challenge was how to make wool instantly absorbent to handle a deluge of urine in one hit. The second challenge was how to do this in an eco-friendly way, which she says is uncommon amongst most textile processes. “Several years of research and development have now led to two patent-pending wool absorbency technologies called neweZorb and neweFlex.”

neweFlex is engineered to be both moisture-loving and moisture-repelling. “This is called a one-way-moisture-transfer-layer which keeps the skin dry and redistributes fluids to the absorbent core,” she explains. “Woolchemy have successfully been able to match and in some cases exceed performance of petroleum-derived equivalent textiles used today in disposable personal hygiene products as well as add extra benefits that only wool provides such as natural temperature regulation and odor control.”

neweFlex is engineered to be both moisture-loving and moisture-repelling. “This is called a one-way-moisture-transfer-layer which keeps the skin dry and redistributes fluids to the absorbent core,” she explains. “Woolchemy have successfully been able to match and in some cases exceed performance of petroleum-derived equivalent textiles used today in disposable personal hygiene products as well as add extra benefits that only wool provides such as natural temperature regulation and odor control.”

Woolchemy is working with outside manufacturers that have significant expertise in nonwovens manufacturing, and they’ve found that spunlace technology offers the best performance results for neweFlex. Today the company is working closely with a handful of pharmaceutical and FMCG companies in the hygiene sector on commercializing products with neweFlex technology.

Wool-based components can be a boon for hygiene manufacturers looking to add eco-friendly fibers to their products, as the wool fiber offers innate benefits like temperature regulation, odor control, durability, softness, breathability and comfort.

On the ecological side, Potroz-Smith says that wool requires little processing. “We shear the sheep (and the wool regrows again), we give the fleece a light clean and it’s ready to be formed into a carded web, the first step of the nonwoven process.”

Wool is also made of 50% carbon which means it plays an important role in the circular economy. “Wool stores carbon from the earth and returns it back to the soil at end of its life,” she explains.

For now, the company is excited to get its product on supermarket shelves this year, and it has a long list of innovation ideas in the pipeline. “The Covid-19 crisis has presented many opportunities to use our versatile sustainable materials in many different ways that can help both human health and the health of our planet without costing the earth,” Potroz-Smith concludes.

Ten years ago Angela Potroz, a farmer from the Taranaki region of New Zealand, was grappling with the decline of crossbred wool prices. Her daughter, Derelee Potroz-Smith, a new mother, was shocked about the alarming amount of non-biodegradable, petroleum-derived plastics and potentially toxic chemical used in baby diapers and feminine hygiene products. That’s when they reached an ah-ha moment that these two problems could solve each other.

Woolchemy, founded in 2010, works with scientists to transform an underutilized traditional natural fiber—crossbred wool—into truly innovative, multi-use products. Today the company manufactures and supplies absorbent wool-based nonwovens to global brands that share its vision to deliver sustainable, high-performing products without compromising environmental and social responsibilities.

“New Zealand is the third largest producer of wool, contributing 9% of the world’s production,” says Derelee Potroz-Smith, CEO and founder of Woolchemy. “A majority of New Zealand’s wool output is strong/coarse wool which is an underutilized, natural, renewable resource. Woolchemy is challenging the traditional thinking of how wool can be used and creating truly innovative, multi-use textile technologies.”

Launched in 2015, Woolchemy’s first product was neweZorb, a world’s first absorbent wet treatment process. neweZorb relaxes the fiber structure, breaking down and reforming the wool’s molecular bonds to make the wool surfaces permanently super-hydrophilic and superabsorbent, according to Potroz-Smith. “In fact, it is said to be up to 25 times more absorbent than regular wool and retains all the natural qualities of wool,” she adds.

neweZorb is biodegradable and compostable, renewable and sustainable, washable and disposable, and contains no chemical residues. The treatment can be applied to any wool micron and any full or blended wool substrate including yarn, fiber, nonwovens, wovens and knits. neweZorb is capable of absorbing any moisture including blood, urine, water, chemicals and sweat, and can be used for washable and reusable products such as menstrual underwear, cleaning products and athleisure clothing.

Now Woolchemy is directing its efforts toward disposable hygiene products with the launch of its latest development neweFlex, a bio-composite acquisition distribution layer (ADL) for single-use diapers and sanitary pads.

“The structure of wool fibers is very complex, allowing it to be moisture repelling on the outside but moisture loving on the inside,” Potroz-Smith explains.

In developing the product, Woolchemy’s first challenge was how to make wool instantly absorbent to handle a deluge of urine in one hit. The second challenge was how to do this in an eco-friendly way, which she says is uncommon amongst most textile processes. “Several years of research and development have now led to two patent-pending wool absorbency technologies called neweZorb and neweFlex.”

Woolchemy is working with outside manufacturers that have significant expertise in nonwovens manufacturing, and they’ve found that spunlace technology offers the best performance results for neweFlex. Today the company is working closely with a handful of pharmaceutical and FMCG companies in the hygiene sector on commercializing products with neweFlex technology.

Wool-based components can be a boon for hygiene manufacturers looking to add eco-friendly fibers to their products, as the wool fiber offers innate benefits like temperature regulation, odor control, durability, softness, breathability and comfort.

On the ecological side, Potroz-Smith says that wool requires little processing. “We shear the sheep (and the wool regrows again), we give the fleece a light clean and it’s ready to be formed into a carded web, the first step of the nonwoven process.”

Wool is also made of 50% carbon which means it plays an important role in the circular economy. “Wool stores carbon from the earth and returns it back to the soil at end of its life,” she explains.

For now, the company is excited to get its product on supermarket shelves this year, and it has a long list of innovation ideas in the pipeline. “The Covid-19 crisis has presented many opportunities to use our versatile sustainable materials in many different ways that can help both human health and the health of our planet without costing the earth,” Potroz-Smith concludes.