11.08.18

Freudenberg Performance Materials will be presenting MDI-based PU foams and laminates with superabsorbent nonwovens, foams with directly applied silicone adhesives, as well as activated carbon filters for stoma applications at Compamed 2018, Nov. 12-15, 2018, in Düsseldorf, Germany. The company is a globally active developer and manufacturer of multi-layer material constructions made from hydrophilic PU foams and hydroactive nonwovens and will be exhibiting in Hall 8b / H01.

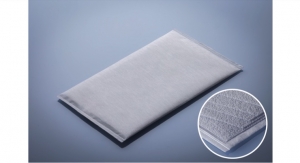

Freudenberg offers customers laminates made of hydrophilic PU foams and hydroactive nonwovens, which the company produces in series under ISO 13485 conditions. In this process, Freudenberg combines the foam and nonwoven components, which significantly improves the absorption and retention properties of the wound dressings. When specifying the components, customers can choose between MDI- and TDI-based foams.

Freudenberg foams with a direct coating of silicone adhesives are significantly more efficient than the commonly used foams with a transfer coating. Wound dressings with a direct coating of silicone adhesives are much more flexible, adapt better to the wound bed and enable antibacterial preparations to perform their function more effectively. In addition, the reduction of production process steps and complexity saves energy, avoids waste and simplifies the supply chain.

As a pioneer in MDI-based PU foams, Freudenberg offers a superior alternative to traditional TDI-based PU foams. When used as components of wound dressings for chronic venous leg ulcers, Freudenberg’s innovative MDI-based PU foams absorb wound fluids much faster, have a far higher retention capacity and significantly increased strength.

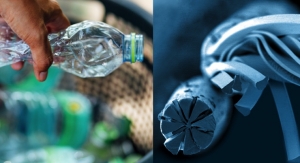

As an integrated part of ostomy bags, Freudenberg’s high-performance activated carbon filters reliably bind unpleasant odors and thus improve the quality of life for ostomy patients. The company offers numerous variants, both in roll form and as finished products. These meet the special requirements of illostomy or colostomy products, for example. On request, Freudenberg can also manufacture the filters according to individual customer specifications.

Freudenberg offers customers laminates made of hydrophilic PU foams and hydroactive nonwovens, which the company produces in series under ISO 13485 conditions. In this process, Freudenberg combines the foam and nonwoven components, which significantly improves the absorption and retention properties of the wound dressings. When specifying the components, customers can choose between MDI- and TDI-based foams.

Freudenberg foams with a direct coating of silicone adhesives are significantly more efficient than the commonly used foams with a transfer coating. Wound dressings with a direct coating of silicone adhesives are much more flexible, adapt better to the wound bed and enable antibacterial preparations to perform their function more effectively. In addition, the reduction of production process steps and complexity saves energy, avoids waste and simplifies the supply chain.

As a pioneer in MDI-based PU foams, Freudenberg offers a superior alternative to traditional TDI-based PU foams. When used as components of wound dressings for chronic venous leg ulcers, Freudenberg’s innovative MDI-based PU foams absorb wound fluids much faster, have a far higher retention capacity and significantly increased strength.

As an integrated part of ostomy bags, Freudenberg’s high-performance activated carbon filters reliably bind unpleasant odors and thus improve the quality of life for ostomy patients. The company offers numerous variants, both in roll form and as finished products. These meet the special requirements of illostomy or colostomy products, for example. On request, Freudenberg can also manufacture the filters according to individual customer specifications.