06.22.18

ExxonMobil has started production of hydrogenated hydrocarbon resin and halobutyl rubber at its integrated manufacturing complex in Singapore, the company’s largest integrated refining and petrochemical complex in the world.

“These new plants enhance the competitiveness and strategic importance of ExxonMobil’s integrated manufacturing facility in Singapore, and are part of the company’s long-term plan for advantaged investments around the world,” says John Verity, president of the ExxonMobil Chemical Company. “We remain committed to safe and environmentally-responsible operations as we manufacture products that support better living standards and economic progress for a fast-growing middle class population in Asia Pacific.”

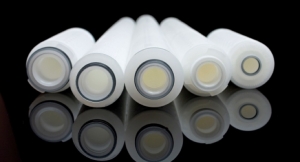

ExxonMobil’s new Escorez hydrogenated hydrocarbon resins plant will be the world’s largest with a capacity of 90,000 tons per year, and will meet long-term demand growth for hot-melt adhesives used in packaging or baby diapers. The new 140,000-tons-per-year butyl plant will produce premium halobutyl rubber used by manufacturers for tires that better maintain inflation to improve fuel economy.

Construction of the multi-billion dollar expansion project was completed safely and on schedule. The project employed more than 5500 contract workers at the peak of construction. The plants add 140 jobs to ExxonMobil’s existing workforce of more than 2500 at its Singapore manufacturing complex. ExxonMobil has more than 4000 employees in Singapore.

The startup of these two new plants follows ExxonMobil’s earlier acquisition of one of the world’s largest aromatics production facilities in Singapore last year.

“With these latest additions, we are well-positioned to serve customers in key Asian growth markets,” says Gan Seow Kee, chairman and managing director of ExxonMobil Asia Pacific Pte Ltd. “The expansion helps to further establish Singapore as a key producer of fuels and petrochemical products, particularly products that help our customers improve fuel economy and reduce emissions.”

The new plants expand on ExxonMobil’s flexible steam cracking capability in Singapore, which provides a range of feedstocks for upgraded specialty products to meet growing long-term demand in Asia Pacific. The Singapore complex also includes a new cogeneration unit at the refinery, bringing the total cogeneration capacity of the site to over 440 megawatts, which will help reduce emissions and support more efficient use of energy.

“These new plants enhance the competitiveness and strategic importance of ExxonMobil’s integrated manufacturing facility in Singapore, and are part of the company’s long-term plan for advantaged investments around the world,” says John Verity, president of the ExxonMobil Chemical Company. “We remain committed to safe and environmentally-responsible operations as we manufacture products that support better living standards and economic progress for a fast-growing middle class population in Asia Pacific.”

ExxonMobil’s new Escorez hydrogenated hydrocarbon resins plant will be the world’s largest with a capacity of 90,000 tons per year, and will meet long-term demand growth for hot-melt adhesives used in packaging or baby diapers. The new 140,000-tons-per-year butyl plant will produce premium halobutyl rubber used by manufacturers for tires that better maintain inflation to improve fuel economy.

Construction of the multi-billion dollar expansion project was completed safely and on schedule. The project employed more than 5500 contract workers at the peak of construction. The plants add 140 jobs to ExxonMobil’s existing workforce of more than 2500 at its Singapore manufacturing complex. ExxonMobil has more than 4000 employees in Singapore.

The startup of these two new plants follows ExxonMobil’s earlier acquisition of one of the world’s largest aromatics production facilities in Singapore last year.

“With these latest additions, we are well-positioned to serve customers in key Asian growth markets,” says Gan Seow Kee, chairman and managing director of ExxonMobil Asia Pacific Pte Ltd. “The expansion helps to further establish Singapore as a key producer of fuels and petrochemical products, particularly products that help our customers improve fuel economy and reduce emissions.”

The new plants expand on ExxonMobil’s flexible steam cracking capability in Singapore, which provides a range of feedstocks for upgraded specialty products to meet growing long-term demand in Asia Pacific. The Singapore complex also includes a new cogeneration unit at the refinery, bringing the total cogeneration capacity of the site to over 440 megawatts, which will help reduce emissions and support more efficient use of energy.