Tara Olivo, Associate Editor01.02.23

Ultrasonic technology is increasingly being used across various sectors of the nonwovens industry, including absorbent hygiene products, filtration, medical, geotextile applications and more. In general terms, ultrasonic bonding uses high frequency sound to generate localized heat through vibration and causes thermoplastic fibers to bond together. This technology is sometimes able to replace other bonding methods such as adhesive and thermal technologies in certain applications. Suppliers in the industry say the technology offers several advantages.

“Ultrasonics is a clean and efficient method of embossing, laminating, or slitting synthetic materials for use in the hygiene market. While the initial investment in equipment is more, the long-term benefits are easy to justify,” says Guy Gil, president of Chase Machine and Engineering.

Additional benefits of ultrasonic technology, according to Justin Lafferty, product manager Hygiene/Packaging, Dukane, are product discretion, improving product softness and product design flexibility. “Our ultrasonic welding modules use less material in hygienic products making them feel lighter, less noticeable, and gives users more confidence. This makes protective hygienic products feel like real underwear.”

Also, by removing adhesive, ultrasonic welding solutions eliminate the stiffening effect, as well as unwanted odor from petroleum-based adhesive, he adds.

Following is a look at what some of the key suppliers of ultrasonic technology have developed in the nonwovens industry.

Chase’s facility, located in Rhode Island, has a dedicated lab for continuous ultrasonic testing. The company is currently in the process of updating its equipment to include the latest ultrasonic technology from the world’s leading ultrasonic manufacturers.

According to Gil, the adult incontinence product market is poised for significant growth as the world continues to deal with an aging population. “Manufacturers are focusing on creating less bulky, better fitting, recyclable and biodegradable products that not only serve the need of the consumer but are also environmentally friendly,” he adds.

From Chase’s perspective, the elimination of adhesives addresses performance issues such as breathability, feel and performance. “Rather than having to source and test an appropriate adhesive that not only performs in the construction and use of the product but is also biodegradable and safe for the end user, engineers can turn to ultrasonic technology which uses the chemistry of the fibers to melt, creating a molecular bond that is superior to that of an adhesive,” Gil explains. “Manufacturers that design their products to satisfy the intended use as well as the added performance and environmental benefits will surely have an advantage.”

As manufactures continue to develop more green, sustainable and environmentally friendly consumer products, the practice of blending biodegradable synthetic fibers with natural fibers is becoming more common. If the nonwoven contains more than 70% synthetic material, ultrasonics may be a viable option for assembly without the need of adhesives or sewing, according to Gil.

Outside of the hygiene market, Chase has seen an increase in applications centered around personal protective equipment (PPE) and filtration products since Covid. Because nonwovens are primarily used in these types of consumable products, and ultrasonics is an effective and cost-efficient method of assembly, Gil expects that demand will continue to drive growth for the foreseeable future.

Customers can send product samples to Chase in order to collect invaluable data such as bond strength, embossing quality, slit quality, power requirements and processing line speed. Information that is crucial in determining quality, feasibility and ROI.

Dukane recently expanded its capabilities through the acquisition of Aurizon Rotary Ultrasonics in 2019, which gave the company a full product portfolio of vibration welding offerings (blade/rotary) to successfully compete in the hygiene market. The company is also bringing in additional hygiene industry personnel and changing/rebranding its Kimberly, WI, facility into a Center of Excellence (CoE) for hygiene.

Dukane’s CoE team comprised of industry veterans can deliver custom solutions beyond its comprehensive ultrasonic welding portfolio offerings. “Our CoE team has a plethora of industry experience, ranging from initial process ideation to launching new products in the marketplace,” Lafferty says.

Dukane’s current best seller is its patented and production proven elastic thread attachment modules and are scalable to fit any application (25mm-1200mm width).

According to Dukane, conventional elastic thread adhesive systems limit changing the number of elastic threads and thread spacing because the adhesive applicators must match the product design. “They are expensive, difficult to properly setup, and not easily changed,” Lafferty says. “Adhesive free elastic attachment modules unlock so much potential to improve product designs because we have simple product change capability designed in our modules. Essentially, product designers can create fit offerings for all body shapes and sizes. Elastic thread spacing and counts can be changed within minutes allowing design teams to grow their product portfolio offerings.”

In the hygiene market, two trends that are driving the need for ultrasonic equipment are inflation and sustainable innovation, according to Lafferty.

As a result of inflation, Dukane is seeing capital investment from customers on projects that reduce consumption costs. “There is no need for introducing adhesive material to combine layers when using our ultrasonic welding solutions,” he says. “Typically, changing machinery to ultrasonic welding solutions instead of conventional adhesive combining systems can save millions of dollars yearly per asset.”

On the sustainability side, although natural and plant-based material development is still in its infancy, Dukane is committed to working with material manufacturers to grow its extensive range of application uses to include more sustainable hygienic materials. “We are working diligently to eliminate petroleum-based adhesive in hygienic products. Additionally, as the market attempts to transition to natural fiber material blends, we must develop ultrasonic solutions for said materials. The reintroduction / regression back to petroleum-based adhesive for combining natural fiber material blends would be unfavorable for hygiene market sustainability,” Lafferty says.

Herrmann’s patented Microgap control system, designed for the high-speed continuous bonding of nonwoven materials, utilizes a closed loop continuous feedback system that provides for high quality production results without manual adjustments or intervention. This exclusive Microgap solution ensures a consistent and repeatable bonding result, independent of variations in the materials or the manufacturing environment, that yields a high-quality product day after day, year after year. The system includes a 10-inch tablet that acts as the HMI (Human-Machine Interface) and accompanies the Microbond solution. This HMI offers a user-friendly interface that allows for the visualization and operation of the bonding process, along with the ability to link additional assembly and safety functions. This exclusive Microbond ultrasonic bonding solution is applicable to the continuous processing of webs up to 800m/minute, is scalable to virtually any web width and significantly contributes to increasing the OEE while reducing defective products and unscheduled down times.

Ultrasonics is Herrmann’s sole focus, and the company is constantly developing the next generation of its solutions based on direct feedback from its customers and the industries. Two examples of this include its Ultraspin RSD 20-85 and its exclusive Elastic Thread Anchoring (ETA) solution. The Ultraspin RSD 20-85 is a rotary ultrasonic system that was developed based on an industry need—a wide format (85mm) rotary ultrasonic bonding system for femcare, baby and adult applications. Meanwhile, the ETA solution, for the ultrasonic anchoring of elastic threads in panel and cuff applications, allows for the elimination of glue and the associated maintenance, consumables and downtime that goes along with a glue process. “The use of our ETA solution clearly has a very positive impact on sustainability initiatives while improving product quality, softness and the overall customer experience,” says Uwe Peregi, president, Herrmann Ultrasonics.

Sustainability is a mega trend influencing the hygiene market and is an important part of all the solutions at Herrmann. “Ultrasonic technology requires very little energy compared to thermal or gluing processes and works in such a precise way that rejects are reduced as much as possible. Easy on resources and efficient,” says Peregi. “Even today, we are already working on processing the recyclable, biodegradable and sustainable materials of tomorrow, because ultrasonic welding is the technology of the future.”

Free from additives, he says the material remains soft, smooth, and retains an undamaged surface. “Firm shape, supple edges and maximum layer adhesion can be achieved for premium quality products. This ensures high comfort and a pleasant feel on the skin.”

Herrmann regularly invests in its applications labs to ensure that it has the latest technology available for customer feasibility trials, proof of concepts and demonstrations. Its state-of-the-art lab calendar at its North American headquarters has been upgraded with its next generation G4 Microbond solution, the ability to process Elastic Thread Anchoring applications and its overall continuous processing capabilities now exceed 600m/minute, Peregi says. “Having these solutions readily available is one thing, but we apply the same focus and drive in the continuous development of our technical teams as well.”

Additionally, significant investments continue to be made in technology and information exchanges with its global headquarters in Germany.

“Our company is one of the largest suppliers worldwide in the field of power ultrasound, and our nonwovens division is still very young and very hungry and innovative, although it is largely made up of experienced people from the industry,” says Konrad Beretitsch, sales manager Systems and Components. “This team of young guns and old hands is taking us down some completely new paths and applications for our technology. We see ourselves as quite willing and able to break new ground and tackle topics that no one had previously seen in the ultrasound pipeline, for which there will be very interesting information in the coming years.”

After the company raised the curtain at INDEX 2021 and was able to show a rotary and an upright unit at the presentation of its brand-new units, MS Ultrasonic has now completed its portfolio. The company can now offer the market the units for different installation situations, depending on how it seems best for the plant.

Recently, the company has further improved the visualization and a very intuitive operation of its plant. There has been further investment in the manufacturing capabilities of its rolls so that the customer gets a complete solution from a single source. “This level of complexity cannot be offered by any other company in the world,” Beretitsch says.

In recent years, ultrasonic technology has strongly established itself as the safest, most efficient, environmentally friendly and sustainable joining method in the hygiene industry, according to Beretitsch. “A higher initial investment is quickly amortized through the total costs of ownership. In the hygiene sector, in addition to the material properties to be maintained, such as absorbency, surface softness and tear resistance, the most sterile possible processing is also of high importance.”

The world’s population is growing and average life expectancy is increasing. In the hygiene sector, this is leading to noticeably greater demand for hygiene and healthcare solutions in the market and offers enormous growth opportunities in this sector, according to the company.

In addition to demographic changes, MS Ultrasonic also sees an improvement in hygiene awareness as a result of the pandemic, and thus an increased demand for products that it can manufacture with its technology.

“We can see the latest swing towards ultrasonic technology since the beginning of the current energy crisis,” Beretitsch says. “Previously, it was partly a matter of being able to show a nice CO2 balance or doing something good for the ecological conscience, but today energy is an increasingly important cost factor that has become a primary issue.”

Beyond the hygiene sector, the company sees a clear growth potential in the areas of household products and medical technology, and also in areas such as automotive, construction and the packaging sector, where it sees more and more new application fields for its technology.

A modular version of this system consisting of the ultrasonic system and power supply plus pattern wheel assembly provides a cost-effective way for OEMs to incorporate ultrasonic seaming, slitting, cross cutting and trimming capabilities for the textile and nonwoven web handling systems. SeamMaster Modules can use a variety of stitch patterns to fuse and seal seams. The module can include the motor drive for rotating the sonics and the pattern wheel. Single or multiple modules can be used in special purpose machines or production lines.

Suitable materials for use with the SeamMaster or the Modular version include synthetics or blends with a 60% to 100% synthetic content including polyester, nylon, acrylics, vinyl, polypropylene, lycra spandex, tricot, and thermoplastic urethanes, constructed as woven, nonwoven, knit, laminate or coatings.

Applications include medical apparel, safety products, filters, draperies, blankets, oil absorbent pads, banners, and flags among others.

Sonobond also provides cylinder arm machines in two versions, similar to the operation of off-the-arm and around-the-arm sewing machines. The arm slips into cylinder shaped fabrics like a sleeve and seams the fabric using an ultrasonic bonding head mounted at the end of the arm. Whether the arm is for an off-the-arm sleeve or pant leg for instance or an-around-the arm for attaching a cuff depends on the orientation of the wheel. The drive speed is controlled by a foot pedal leaving the operator free to control the fabric placement.

The advantages of the ultrasonic process are that it requires no additional materials such as adhesive or thread, does not damage or transform the fabric and can operate even at high speed for a range of applications. These are all characteristics that continue to drive its growth as seen by its use in the ubiquitous face mask and other PPE in the current Covid crisis.

“Ultrasonics is a clean and efficient method of embossing, laminating, or slitting synthetic materials for use in the hygiene market. While the initial investment in equipment is more, the long-term benefits are easy to justify,” says Guy Gil, president of Chase Machine and Engineering.

Additional benefits of ultrasonic technology, according to Justin Lafferty, product manager Hygiene/Packaging, Dukane, are product discretion, improving product softness and product design flexibility. “Our ultrasonic welding modules use less material in hygienic products making them feel lighter, less noticeable, and gives users more confidence. This makes protective hygienic products feel like real underwear.”

Also, by removing adhesive, ultrasonic welding solutions eliminate the stiffening effect, as well as unwanted odor from petroleum-based adhesive, he adds.

Following is a look at what some of the key suppliers of ultrasonic technology have developed in the nonwovens industry.

Chase Machine and Engineering

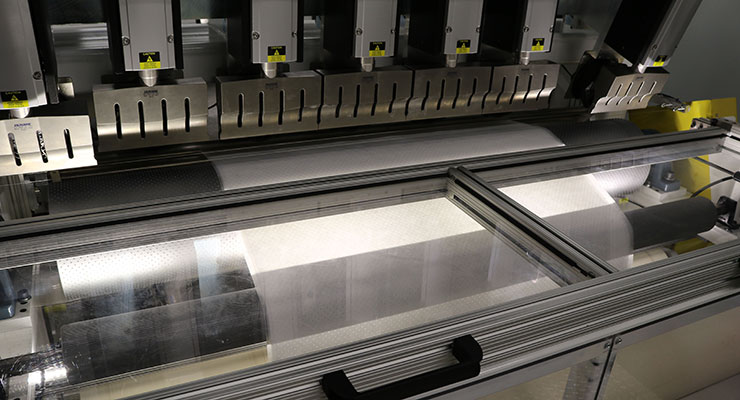

Chase Machine and Engineering designs and builds custom machinery with a primary focus on the integration of ultrasonic technology for continuous and intermittent web converting applications. Working with the industry’s leading suppliers of ultrasonic technology, Chase supplies ultrasonic laminators, embossers, slitters and splicing equipment to manufacturers of nonwoven materials and converters to produce a variety of products for the hygiene, filtration, textile, packaging, medical and personal care industry.Chase’s facility, located in Rhode Island, has a dedicated lab for continuous ultrasonic testing. The company is currently in the process of updating its equipment to include the latest ultrasonic technology from the world’s leading ultrasonic manufacturers.

According to Gil, the adult incontinence product market is poised for significant growth as the world continues to deal with an aging population. “Manufacturers are focusing on creating less bulky, better fitting, recyclable and biodegradable products that not only serve the need of the consumer but are also environmentally friendly,” he adds.

From Chase’s perspective, the elimination of adhesives addresses performance issues such as breathability, feel and performance. “Rather than having to source and test an appropriate adhesive that not only performs in the construction and use of the product but is also biodegradable and safe for the end user, engineers can turn to ultrasonic technology which uses the chemistry of the fibers to melt, creating a molecular bond that is superior to that of an adhesive,” Gil explains. “Manufacturers that design their products to satisfy the intended use as well as the added performance and environmental benefits will surely have an advantage.”

As manufactures continue to develop more green, sustainable and environmentally friendly consumer products, the practice of blending biodegradable synthetic fibers with natural fibers is becoming more common. If the nonwoven contains more than 70% synthetic material, ultrasonics may be a viable option for assembly without the need of adhesives or sewing, according to Gil.

Outside of the hygiene market, Chase has seen an increase in applications centered around personal protective equipment (PPE) and filtration products since Covid. Because nonwovens are primarily used in these types of consumable products, and ultrasonics is an effective and cost-efficient method of assembly, Gil expects that demand will continue to drive growth for the foreseeable future.

Customers can send product samples to Chase in order to collect invaluable data such as bond strength, embossing quality, slit quality, power requirements and processing line speed. Information that is crucial in determining quality, feasibility and ROI.

Dukane

Dukane offers a sustainable alternative to conventional petroleum-based adhesive typically used to combine materials in the hygiene industry. Its technologies are used to simplify machine processes, improve product designs, lower maintenance costs, and save manufacturers consumable material costs.Dukane recently expanded its capabilities through the acquisition of Aurizon Rotary Ultrasonics in 2019, which gave the company a full product portfolio of vibration welding offerings (blade/rotary) to successfully compete in the hygiene market. The company is also bringing in additional hygiene industry personnel and changing/rebranding its Kimberly, WI, facility into a Center of Excellence (CoE) for hygiene.

Dukane’s CoE team comprised of industry veterans can deliver custom solutions beyond its comprehensive ultrasonic welding portfolio offerings. “Our CoE team has a plethora of industry experience, ranging from initial process ideation to launching new products in the marketplace,” Lafferty says.

Dukane’s current best seller is its patented and production proven elastic thread attachment modules and are scalable to fit any application (25mm-1200mm width).

According to Dukane, conventional elastic thread adhesive systems limit changing the number of elastic threads and thread spacing because the adhesive applicators must match the product design. “They are expensive, difficult to properly setup, and not easily changed,” Lafferty says. “Adhesive free elastic attachment modules unlock so much potential to improve product designs because we have simple product change capability designed in our modules. Essentially, product designers can create fit offerings for all body shapes and sizes. Elastic thread spacing and counts can be changed within minutes allowing design teams to grow their product portfolio offerings.”

In the hygiene market, two trends that are driving the need for ultrasonic equipment are inflation and sustainable innovation, according to Lafferty.

As a result of inflation, Dukane is seeing capital investment from customers on projects that reduce consumption costs. “There is no need for introducing adhesive material to combine layers when using our ultrasonic welding solutions,” he says. “Typically, changing machinery to ultrasonic welding solutions instead of conventional adhesive combining systems can save millions of dollars yearly per asset.”

On the sustainability side, although natural and plant-based material development is still in its infancy, Dukane is committed to working with material manufacturers to grow its extensive range of application uses to include more sustainable hygienic materials. “We are working diligently to eliminate petroleum-based adhesive in hygienic products. Additionally, as the market attempts to transition to natural fiber material blends, we must develop ultrasonic solutions for said materials. The reintroduction / regression back to petroleum-based adhesive for combining natural fiber material blends would be unfavorable for hygiene market sustainability,” Lafferty says.

Herrmann Ultrasonics

Herrmann Ultrasonics has had a dedicated focus on the continuous ultrasonic bonding of nonwoven materials ever since its Nonwovens business unit was launched almost 30 years ago.Herrmann’s patented Microgap control system, designed for the high-speed continuous bonding of nonwoven materials, utilizes a closed loop continuous feedback system that provides for high quality production results without manual adjustments or intervention. This exclusive Microgap solution ensures a consistent and repeatable bonding result, independent of variations in the materials or the manufacturing environment, that yields a high-quality product day after day, year after year. The system includes a 10-inch tablet that acts as the HMI (Human-Machine Interface) and accompanies the Microbond solution. This HMI offers a user-friendly interface that allows for the visualization and operation of the bonding process, along with the ability to link additional assembly and safety functions. This exclusive Microbond ultrasonic bonding solution is applicable to the continuous processing of webs up to 800m/minute, is scalable to virtually any web width and significantly contributes to increasing the OEE while reducing defective products and unscheduled down times.

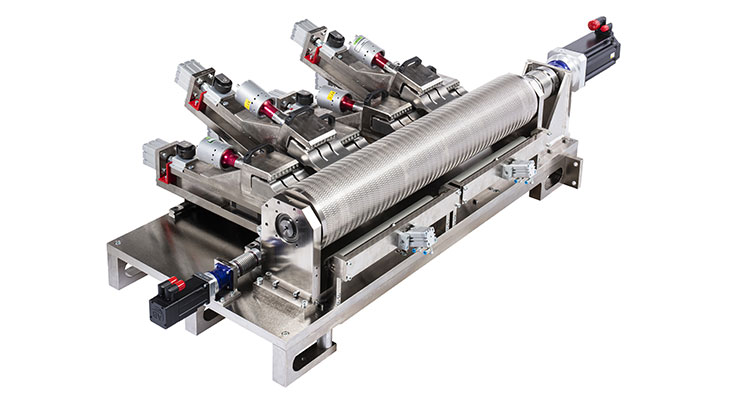

Ultrasonics is Herrmann’s sole focus, and the company is constantly developing the next generation of its solutions based on direct feedback from its customers and the industries. Two examples of this include its Ultraspin RSD 20-85 and its exclusive Elastic Thread Anchoring (ETA) solution. The Ultraspin RSD 20-85 is a rotary ultrasonic system that was developed based on an industry need—a wide format (85mm) rotary ultrasonic bonding system for femcare, baby and adult applications. Meanwhile, the ETA solution, for the ultrasonic anchoring of elastic threads in panel and cuff applications, allows for the elimination of glue and the associated maintenance, consumables and downtime that goes along with a glue process. “The use of our ETA solution clearly has a very positive impact on sustainability initiatives while improving product quality, softness and the overall customer experience,” says Uwe Peregi, president, Herrmann Ultrasonics.

Sustainability is a mega trend influencing the hygiene market and is an important part of all the solutions at Herrmann. “Ultrasonic technology requires very little energy compared to thermal or gluing processes and works in such a precise way that rejects are reduced as much as possible. Easy on resources and efficient,” says Peregi. “Even today, we are already working on processing the recyclable, biodegradable and sustainable materials of tomorrow, because ultrasonic welding is the technology of the future.”

Free from additives, he says the material remains soft, smooth, and retains an undamaged surface. “Firm shape, supple edges and maximum layer adhesion can be achieved for premium quality products. This ensures high comfort and a pleasant feel on the skin.”

Herrmann regularly invests in its applications labs to ensure that it has the latest technology available for customer feasibility trials, proof of concepts and demonstrations. Its state-of-the-art lab calendar at its North American headquarters has been upgraded with its next generation G4 Microbond solution, the ability to process Elastic Thread Anchoring applications and its overall continuous processing capabilities now exceed 600m/minute, Peregi says. “Having these solutions readily available is one thing, but we apply the same focus and drive in the continuous development of our technical teams as well.”

Additionally, significant investments continue to be made in technology and information exchanges with its global headquarters in Germany.

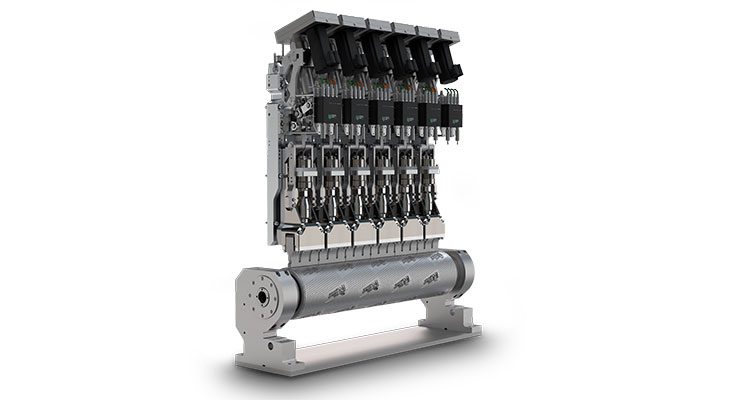

MS Ultrasonic Technology Group

The nonwovens industry is a new area of focus for MS Ultrasonic Technology Group.“Our company is one of the largest suppliers worldwide in the field of power ultrasound, and our nonwovens division is still very young and very hungry and innovative, although it is largely made up of experienced people from the industry,” says Konrad Beretitsch, sales manager Systems and Components. “This team of young guns and old hands is taking us down some completely new paths and applications for our technology. We see ourselves as quite willing and able to break new ground and tackle topics that no one had previously seen in the ultrasound pipeline, for which there will be very interesting information in the coming years.”

After the company raised the curtain at INDEX 2021 and was able to show a rotary and an upright unit at the presentation of its brand-new units, MS Ultrasonic has now completed its portfolio. The company can now offer the market the units for different installation situations, depending on how it seems best for the plant.

Recently, the company has further improved the visualization and a very intuitive operation of its plant. There has been further investment in the manufacturing capabilities of its rolls so that the customer gets a complete solution from a single source. “This level of complexity cannot be offered by any other company in the world,” Beretitsch says.

In recent years, ultrasonic technology has strongly established itself as the safest, most efficient, environmentally friendly and sustainable joining method in the hygiene industry, according to Beretitsch. “A higher initial investment is quickly amortized through the total costs of ownership. In the hygiene sector, in addition to the material properties to be maintained, such as absorbency, surface softness and tear resistance, the most sterile possible processing is also of high importance.”

The world’s population is growing and average life expectancy is increasing. In the hygiene sector, this is leading to noticeably greater demand for hygiene and healthcare solutions in the market and offers enormous growth opportunities in this sector, according to the company.

In addition to demographic changes, MS Ultrasonic also sees an improvement in hygiene awareness as a result of the pandemic, and thus an increased demand for products that it can manufacture with its technology.

“We can see the latest swing towards ultrasonic technology since the beginning of the current energy crisis,” Beretitsch says. “Previously, it was partly a matter of being able to show a nice CO2 balance or doing something good for the ecological conscience, but today energy is an increasingly important cost factor that has become a primary issue.”

Beyond the hygiene sector, the company sees a clear growth potential in the areas of household products and medical technology, and also in areas such as automotive, construction and the packaging sector, where it sees more and more new application fields for its technology.

Sonobond Ultrasonics

Sonobond has been offering textile assembly equipment for over 30 years in a stand-alone format. The SeamMaster Ultrasonic Sewing machine was in great demand when disposable gowns without needle holes or glue gaps were mandated for surgical gowns in medical facilities, to prevent bodily fluids from infecting patients or medical personnel with HIV. Since then, newer versions of this machine still prove the most popular for assembly of nonwoven fabrics for medical and general use items including surgical and hospital gowns, disposable pillow and mattress covers, face masks and filters to name a few. The SeamMaster is a top choice for producing barrier seams that eliminate leaking issues, creating soft-to-the-touch seams that are secure and reliable.A modular version of this system consisting of the ultrasonic system and power supply plus pattern wheel assembly provides a cost-effective way for OEMs to incorporate ultrasonic seaming, slitting, cross cutting and trimming capabilities for the textile and nonwoven web handling systems. SeamMaster Modules can use a variety of stitch patterns to fuse and seal seams. The module can include the motor drive for rotating the sonics and the pattern wheel. Single or multiple modules can be used in special purpose machines or production lines.

Suitable materials for use with the SeamMaster or the Modular version include synthetics or blends with a 60% to 100% synthetic content including polyester, nylon, acrylics, vinyl, polypropylene, lycra spandex, tricot, and thermoplastic urethanes, constructed as woven, nonwoven, knit, laminate or coatings.

Applications include medical apparel, safety products, filters, draperies, blankets, oil absorbent pads, banners, and flags among others.

Sonobond also provides cylinder arm machines in two versions, similar to the operation of off-the-arm and around-the-arm sewing machines. The arm slips into cylinder shaped fabrics like a sleeve and seams the fabric using an ultrasonic bonding head mounted at the end of the arm. Whether the arm is for an off-the-arm sleeve or pant leg for instance or an-around-the arm for attaching a cuff depends on the orientation of the wheel. The drive speed is controlled by a foot pedal leaving the operator free to control the fabric placement.

The advantages of the ultrasonic process are that it requires no additional materials such as adhesive or thread, does not damage or transform the fabric and can operate even at high speed for a range of applications. These are all characteristics that continue to drive its growth as seen by its use in the ubiquitous face mask and other PPE in the current Covid crisis.