Tara Olivo, Associate Editor01.06.22

As new nonwoven-based end-use products are developed, new opportunities are opening up for ultrasonic technology.

Ultrasonic bonding uses high frequency sound to generate localized heat through vibration and causes thermoplastic fibers to bond together. Manufacturers are using ultrasonic technology to laminate, emboss and slit synthetic materials for products like diapers, feminine care pads, face masks, filter media and more. Among the benefits of this technology is that it offers a sustainable option for manufacturers by eliminating glue.

“Ultrasonic bonding creates soft products with high quality and throughput with a process that supports sustainability initiatives,” says Evan Schott, sales director, Nonwovens, Herrmann Ultrasonics. “One of the largest reasons for utilizing ultrasonics in the nonwovens industry is to eliminate consumables such as adhesives.”

The ultrasonic vibrational energy that creates the bonds between the materials replaces hot melt and heat calendar applications, Schott continues. “Manufacturers are often not aware of the fact that ultrasonic welding can join nonwoven materials, even materials of a different composition, and thus replace traditional heat and adhesive applications.”

Following is a look at the latest innovations from some of the key suppliers of ultrasonic technology in the nonwovens industry.

Chase Machine and Engineering

Chase Machine and Engineering designs and builds custom web handling equipment that manufactures machinery for both the personal protective equipment (PPE) and filtration markets. Equipment such as face mask machines, ultrasonic laminators, slitters and winding equipment are in high demand. In addition to its custom machinery, Chase also manufactures manual ultrasonic sealing machinery such as the FS-90 and FS-180 products which are tools not only for manufacturing on a small scale, but also for research and development.

Years ago, manufacturers of nonwoven materials struggled with consistency and uniformity in their products, however, that is no longer the case, according to Guy Gil, president, Chase Machine and Engineering. “Of all the technologies available for joining nonwoven materials, ultrasonics is one of the most material dependent,” he says. “As nonwoven suppliers realized converters were looking for alternative ways to make their product faster and more efficient, much effort was spent improving their product. With improvements to spunbond and meltblown processing lines, nonwovens suppliers can now offer more uniform product that provide manufacturers an ultrasonic lamination option.”

Over the years, Chase Machine has seen the use of ultrasonics for nonwoven lamination, slitting and splicing grow within the filtration, medical and hygiene industries. “As manufacturers of nonwovens continue to improve their product, companies find more applications and quite often select ultrasonics to assemble those materials,” Gil says.

Among its benefits, ultrasonics is a clean and efficient method of joining or slitting synthetic materials. While the initial investment is much higher, the long-term benefits more than pay for itself, Gil explains. “Thermal methods for lamination and slitting utilizing hot oil or electrically heated systems require an initial preheat cycle in order to bring the tooling to operating temperature. Then, while running, there is a significant amount of heat loss. Ultrasonic technology is instantaneous. The operator can start and stop the equipment without worrying about over melting the materials being processed. It is also a very clean method of laminating as there are no hoses or rotary unions that may leak over time reducing the need to clean and service.”

When using ultrasonics for slitting synthetic nonwoven materials, the heat created from the process not only slits the material but also leaves a clean, sealed edge that reduces the possibility of unraveling or fraying. This technology may also be used to create hermetic seals which may be useful in products such as medical gowns, filtration products or packaging items.

In the hygiene market, ultrasonic technology has become a wonderful method of combining nonwovens and elastic materials for use in baby diapers as well as other hygiene products, Gil says. This is primarily due to the fact ultrasonic welding often creates a bond that is superior to adhesive joining. “When using adhesives, factors such as breathability, delamination due to heat or fluid penetration, flexibility and softness (hand) must all be taken into account,” he says. “When bonding similar nonwoven materials with ultrasonics, these issues are of less concern. Ultrasonic bond patterns may be selected that provide not only adequate weld strength but the desired flexibility and breathability as well, creating a superior product.”

Chase’s facility, located in Rhode Island, has a dedicated lab for continuous ultrasonic testing. Customers can send product samples to Chase in order to collect invaluable data such as bond strength, embossing quality, slit quality, power requirements and processing line speed. Information that is crucial in determining quality, feasibility and ROI.

“Chase has a great reputation for designing and building continuous ultrasonic machinery, which is a direct result of the creative solutions we have provided over the last 40 years working with this clean and efficient means of bonding,” Gil concludes.

Herrmann Ultrasonics

Herrmann Ultrasonics has held a dedicated focus on the welding of nonwoven materials since 1994 with the establishment of its Nonwovens business unit, of which specializes in utilizing ultrasonics for the bonding of materials in continuous manufacturing processes.

Specialized Herrmann Ultrasonics technology, such as the patented Microgap control system, utilizes a closed loop continuous feedback system that provides consistent, repeatable and high-quality production results. The Microgap system ensures the most effective use of the ultrasonic process parameters and the mechanical position of the ultrasonic welding components, automatically compensating for variations in material and the ambient environment, according to Schott. Meanwhile, a 10-inch tablet provides for a user-friendly interface for the visualization and operation of the bonding process, along with linking all assembly and safety functions. Web speeds of up to 800 m/min can be realized with a solution that is scalable to virtually any web width. The goal is an economical process by avoiding deficient products, reducing down times and raising Overall Equipment Effectiveness (OEE).

Herrmann’s patented Microbond system improves machine efficiency, allowing for multiple advantages such as low reject rates, fast set-up time, increased up time and significantly reduced energy consumption.

“Ultrasonics has been an instrumental technology in the manufacturing of medical devices including PPE products, cosmetic products, personal care, wound care, filter, and of course hygiene as well,” says Schott.

Describing the benefits of the technology, Schott says ultrasonic welding of nonwovens is an extremely fast and stable process that is easily repeatable and directly available without the need for pre-heating or reoccurring costs of purchasing consumables such as adhesives. Also, ultrasonic components can significantly reduce maintenance costs and improve uptime compared to thermal or adhesive systems. “Our exclusive ultrasonic technology uses a closed loop feedback process that reduces tool wear and eliminates the regular maintenance associated with adhesive nozzles,” he adds.

Ultrasonic technology can also be up to 75% more efficient than thermal or hot melt systems.

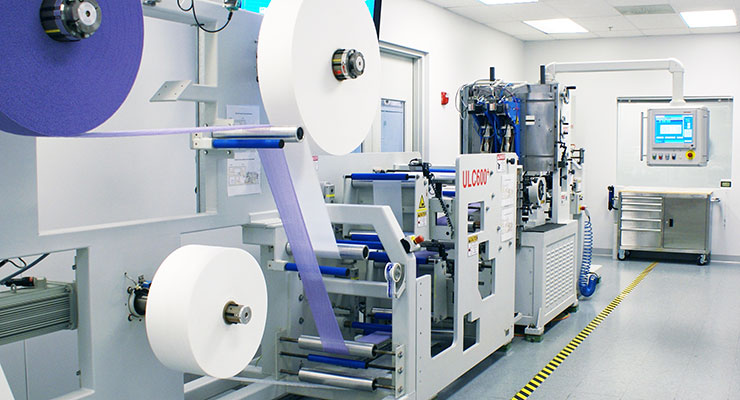

Over the last year, significant investment has been made into expanding Herrmann’s Nonwovens laboratory and upgrading the most modern and fastest lab calendar. In its Bartlett, IL, headquarters, Herrmann’s Ultrasonic Laboratory Calendar (ULC), the ULC600+ (>2000 ft/min), utilizes the company’s new closed-loop Microgap G4 platform that now includes the capability to process and demonstrate its new elastic anchoring technology.

“With our brand new quick exchange system for the ultrasonic stations we can experiment with different ultrasonic technologies – static or rotating – in one single day. Consequently, our customers will save time and money,” stresses Uwe Peregi, president of Herrmann Ultrasonics. “In addition, new documentation and analysis tools are available, such as the OPCUA interface that can provide all relevant data specific to the application and process.”

MS Ultrasonic Technology Group

For MS Ultrasonic Technology Group, the nonwovens industry is a new area of focus for the company.

In the past, MS has established a market-leading position in the field of ultrasonic special machines with a focus on the automotive industry, and this expertise has laid the foundation for many other pillars, according to Konrad Beretitsch, sales director systems and components, MS Ultrasonic Technology Group. “Many existing customers have literally been waiting for us to enter the nonwovens segment with our innovative ultrasonic technology,” he says.

Describing the technology, Beretitsch says that in continuous ultrasonic welding, mechanical vibrations are transmitted to nonwovens under pressure. Friction of the molecular and boundary surfaces generates heat, which causes the damping coefficient of the material to increase. The nonwoven material begins to melt at certain points. When processing continuous web materials, the main focus is on reproducibility and welding quality. Continuous welding in continuous mode also enables continuous welds without interruption, he adds.

“Ultrasonic technology is a very good alternative to other joining and cutting processes with high efficiency and further future-oriented possibilities,” Beretitsch says. “In contrast to other processes, the ultrasonic process - whether cutting, sealing, welding, cut-off welding, punching, riveting - does not cause any damage to the product itself, no heat is introduced from outside and no adhesive is required.”

MS’s ultrasonic calender for web speeds up to 850 m/min, servo-electrically driven ultrasonic units and industry-related modules for typical applications will be available for a wide range of tests. This will also allow the company to provide solutions for a very wide range of applications.

MS is seeing a high and an increasing demand for ultrasonic technology in the nonwovens industry. “Masks were of course a topic for all ultrasonic producers but this business was more a temporary one,” he says. “Hygiene products are growing such as adult diapers but also other products in the hygienic and medical world. More and more we are getting projects in with the use of nonwoven material from other sectors such as automotive, agriculture, food and drink, household, geotextiles, construction and others.”

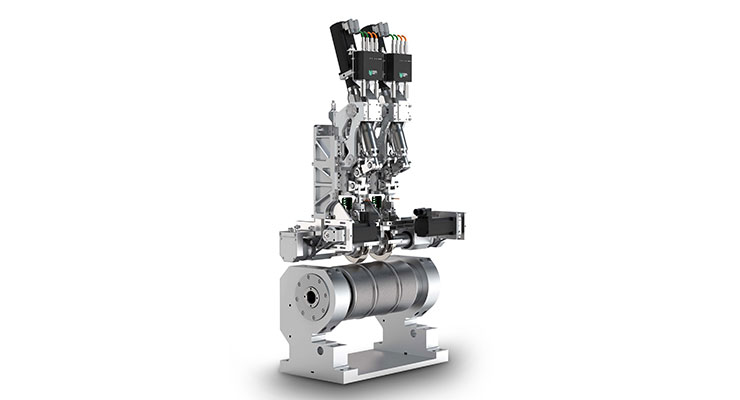

MS doesn’t just offer the ultrasonic technology itself but now offers a complete portfolio with anvil drums in highest precision. The company can supply the units together with the anvil drums, anvil drums without ultrasonic equipment and also supply them with bearings, frames as complete systems for an integration into machines.

Sonobond Ultrasonics

Sonobond’s ultrasonic machinery can provide bonding, seaming, slitting, cutting and trimming for a wide variety of applications in the nonwovens industry. More than one function can be performed on its most popular machine, the SeamMaster Ultrasonic Sewing Machine, usually in just one step to optimize production. With appropriate tooling, the SeamMaster can bond, seam and trim, all at the same time.

Typically, Sonobond’s equipment is used to assemble medical nonwoven items, including face masks, surgical and hospital gowns, disposable pillow and mattress covers, sterilization and storage pouches for medical instruments, and lint-free wound dressings, to name a few.

Its machines are commonly used for hygiene items as well, including diapers and bedwetting protection panties. “Personal hygiene products call for strong, fully sealed barrier seams to eliminate leaking issues that can be caused by stitch holes, glue gaps, fraying or unraveling,” says Janet Devine, president of Sonobond Ultrasonics. “The SeamMaster produces those results, which is why it is the top ultrasonic choice for manufacturers of personal hygiene items. In addition to this, the SeamMaster’s rotary operation channels the ultrasonic vibrations to soften and fuse synthetic materials, creating soft-to-the-touch seams that are sealed, secure and reliable.”

Also, pleated, HVAC and HEPA filters for commercial and residential use; and air, liquid and gas filters used in the automotive, transportation and aerospace industries are among Sonobond’s filtration assembly applications. Sonobond’s equipment has also been successfully used for nonwoven acoustic and insulation panels in these same markets; heavy-duty filter bags for food, chemical, pharma and household uses; as well as oil containment booms and spill clean-up cloths.

“The advantages that ultrasonic technology can provide to the nonwovens industry are certainly driving its growth,” says Devine.

Sonobond’s ultrasonic bonders can offer advantages like cleanly cutting and sealing edges of synthetics and nonwovens, and eliminating fraying, unraveling and material build-up. The machines require no needles, threads, adhesives, or other consumables.

Sonobond’s SeamMaster is four times faster than conventional sewing machines and 10 times faster than adhesive machines, according to Devine. “These are some of the time-saving and cost-cutting advantages that are driving growth for ultrasonics in the industry.”

Additionally, the unique circumstances that 2021 has presented have created an incredibly high demand for ultrasonics in the PPE and medical nonwoven markets.

“2021 has been a challenging year, with supply chain and production delays, as well as restrictions due to Covid-19,” Devine says. “We are happy to continue to provide equipment for all of our nonwoven customers, including PPE manufacturers who are keeping us safe with face masks and a wide variety of disposable medical products.”

Ultrasonic bonding uses high frequency sound to generate localized heat through vibration and causes thermoplastic fibers to bond together. Manufacturers are using ultrasonic technology to laminate, emboss and slit synthetic materials for products like diapers, feminine care pads, face masks, filter media and more. Among the benefits of this technology is that it offers a sustainable option for manufacturers by eliminating glue.

“Ultrasonic bonding creates soft products with high quality and throughput with a process that supports sustainability initiatives,” says Evan Schott, sales director, Nonwovens, Herrmann Ultrasonics. “One of the largest reasons for utilizing ultrasonics in the nonwovens industry is to eliminate consumables such as adhesives.”

The ultrasonic vibrational energy that creates the bonds between the materials replaces hot melt and heat calendar applications, Schott continues. “Manufacturers are often not aware of the fact that ultrasonic welding can join nonwoven materials, even materials of a different composition, and thus replace traditional heat and adhesive applications.”

Following is a look at the latest innovations from some of the key suppliers of ultrasonic technology in the nonwovens industry.

Chase Machine and Engineering

Chase Machine and Engineering designs and builds custom web handling equipment that manufactures machinery for both the personal protective equipment (PPE) and filtration markets. Equipment such as face mask machines, ultrasonic laminators, slitters and winding equipment are in high demand. In addition to its custom machinery, Chase also manufactures manual ultrasonic sealing machinery such as the FS-90 and FS-180 products which are tools not only for manufacturing on a small scale, but also for research and development.

Years ago, manufacturers of nonwoven materials struggled with consistency and uniformity in their products, however, that is no longer the case, according to Guy Gil, president, Chase Machine and Engineering. “Of all the technologies available for joining nonwoven materials, ultrasonics is one of the most material dependent,” he says. “As nonwoven suppliers realized converters were looking for alternative ways to make their product faster and more efficient, much effort was spent improving their product. With improvements to spunbond and meltblown processing lines, nonwovens suppliers can now offer more uniform product that provide manufacturers an ultrasonic lamination option.”

Over the years, Chase Machine has seen the use of ultrasonics for nonwoven lamination, slitting and splicing grow within the filtration, medical and hygiene industries. “As manufacturers of nonwovens continue to improve their product, companies find more applications and quite often select ultrasonics to assemble those materials,” Gil says.

Among its benefits, ultrasonics is a clean and efficient method of joining or slitting synthetic materials. While the initial investment is much higher, the long-term benefits more than pay for itself, Gil explains. “Thermal methods for lamination and slitting utilizing hot oil or electrically heated systems require an initial preheat cycle in order to bring the tooling to operating temperature. Then, while running, there is a significant amount of heat loss. Ultrasonic technology is instantaneous. The operator can start and stop the equipment without worrying about over melting the materials being processed. It is also a very clean method of laminating as there are no hoses or rotary unions that may leak over time reducing the need to clean and service.”

When using ultrasonics for slitting synthetic nonwoven materials, the heat created from the process not only slits the material but also leaves a clean, sealed edge that reduces the possibility of unraveling or fraying. This technology may also be used to create hermetic seals which may be useful in products such as medical gowns, filtration products or packaging items.

In the hygiene market, ultrasonic technology has become a wonderful method of combining nonwovens and elastic materials for use in baby diapers as well as other hygiene products, Gil says. This is primarily due to the fact ultrasonic welding often creates a bond that is superior to adhesive joining. “When using adhesives, factors such as breathability, delamination due to heat or fluid penetration, flexibility and softness (hand) must all be taken into account,” he says. “When bonding similar nonwoven materials with ultrasonics, these issues are of less concern. Ultrasonic bond patterns may be selected that provide not only adequate weld strength but the desired flexibility and breathability as well, creating a superior product.”

Chase’s facility, located in Rhode Island, has a dedicated lab for continuous ultrasonic testing. Customers can send product samples to Chase in order to collect invaluable data such as bond strength, embossing quality, slit quality, power requirements and processing line speed. Information that is crucial in determining quality, feasibility and ROI.

“Chase has a great reputation for designing and building continuous ultrasonic machinery, which is a direct result of the creative solutions we have provided over the last 40 years working with this clean and efficient means of bonding,” Gil concludes.

Herrmann Ultrasonics

Herrmann Ultrasonics has held a dedicated focus on the welding of nonwoven materials since 1994 with the establishment of its Nonwovens business unit, of which specializes in utilizing ultrasonics for the bonding of materials in continuous manufacturing processes.

Specialized Herrmann Ultrasonics technology, such as the patented Microgap control system, utilizes a closed loop continuous feedback system that provides consistent, repeatable and high-quality production results. The Microgap system ensures the most effective use of the ultrasonic process parameters and the mechanical position of the ultrasonic welding components, automatically compensating for variations in material and the ambient environment, according to Schott. Meanwhile, a 10-inch tablet provides for a user-friendly interface for the visualization and operation of the bonding process, along with linking all assembly and safety functions. Web speeds of up to 800 m/min can be realized with a solution that is scalable to virtually any web width. The goal is an economical process by avoiding deficient products, reducing down times and raising Overall Equipment Effectiveness (OEE).

Herrmann’s patented Microbond system improves machine efficiency, allowing for multiple advantages such as low reject rates, fast set-up time, increased up time and significantly reduced energy consumption.

“Ultrasonics has been an instrumental technology in the manufacturing of medical devices including PPE products, cosmetic products, personal care, wound care, filter, and of course hygiene as well,” says Schott.

Describing the benefits of the technology, Schott says ultrasonic welding of nonwovens is an extremely fast and stable process that is easily repeatable and directly available without the need for pre-heating or reoccurring costs of purchasing consumables such as adhesives. Also, ultrasonic components can significantly reduce maintenance costs and improve uptime compared to thermal or adhesive systems. “Our exclusive ultrasonic technology uses a closed loop feedback process that reduces tool wear and eliminates the regular maintenance associated with adhesive nozzles,” he adds.

Ultrasonic technology can also be up to 75% more efficient than thermal or hot melt systems.

Over the last year, significant investment has been made into expanding Herrmann’s Nonwovens laboratory and upgrading the most modern and fastest lab calendar. In its Bartlett, IL, headquarters, Herrmann’s Ultrasonic Laboratory Calendar (ULC), the ULC600+ (>2000 ft/min), utilizes the company’s new closed-loop Microgap G4 platform that now includes the capability to process and demonstrate its new elastic anchoring technology.

“With our brand new quick exchange system for the ultrasonic stations we can experiment with different ultrasonic technologies – static or rotating – in one single day. Consequently, our customers will save time and money,” stresses Uwe Peregi, president of Herrmann Ultrasonics. “In addition, new documentation and analysis tools are available, such as the OPCUA interface that can provide all relevant data specific to the application and process.”

MS Ultrasonic Technology Group

For MS Ultrasonic Technology Group, the nonwovens industry is a new area of focus for the company.

In the past, MS has established a market-leading position in the field of ultrasonic special machines with a focus on the automotive industry, and this expertise has laid the foundation for many other pillars, according to Konrad Beretitsch, sales director systems and components, MS Ultrasonic Technology Group. “Many existing customers have literally been waiting for us to enter the nonwovens segment with our innovative ultrasonic technology,” he says.

Describing the technology, Beretitsch says that in continuous ultrasonic welding, mechanical vibrations are transmitted to nonwovens under pressure. Friction of the molecular and boundary surfaces generates heat, which causes the damping coefficient of the material to increase. The nonwoven material begins to melt at certain points. When processing continuous web materials, the main focus is on reproducibility and welding quality. Continuous welding in continuous mode also enables continuous welds without interruption, he adds.

“Ultrasonic technology is a very good alternative to other joining and cutting processes with high efficiency and further future-oriented possibilities,” Beretitsch says. “In contrast to other processes, the ultrasonic process - whether cutting, sealing, welding, cut-off welding, punching, riveting - does not cause any damage to the product itself, no heat is introduced from outside and no adhesive is required.”

MS’s ultrasonic calender for web speeds up to 850 m/min, servo-electrically driven ultrasonic units and industry-related modules for typical applications will be available for a wide range of tests. This will also allow the company to provide solutions for a very wide range of applications.

MS is seeing a high and an increasing demand for ultrasonic technology in the nonwovens industry. “Masks were of course a topic for all ultrasonic producers but this business was more a temporary one,” he says. “Hygiene products are growing such as adult diapers but also other products in the hygienic and medical world. More and more we are getting projects in with the use of nonwoven material from other sectors such as automotive, agriculture, food and drink, household, geotextiles, construction and others.”

MS doesn’t just offer the ultrasonic technology itself but now offers a complete portfolio with anvil drums in highest precision. The company can supply the units together with the anvil drums, anvil drums without ultrasonic equipment and also supply them with bearings, frames as complete systems for an integration into machines.

Sonobond Ultrasonics

Sonobond’s ultrasonic machinery can provide bonding, seaming, slitting, cutting and trimming for a wide variety of applications in the nonwovens industry. More than one function can be performed on its most popular machine, the SeamMaster Ultrasonic Sewing Machine, usually in just one step to optimize production. With appropriate tooling, the SeamMaster can bond, seam and trim, all at the same time.

Typically, Sonobond’s equipment is used to assemble medical nonwoven items, including face masks, surgical and hospital gowns, disposable pillow and mattress covers, sterilization and storage pouches for medical instruments, and lint-free wound dressings, to name a few.

Its machines are commonly used for hygiene items as well, including diapers and bedwetting protection panties. “Personal hygiene products call for strong, fully sealed barrier seams to eliminate leaking issues that can be caused by stitch holes, glue gaps, fraying or unraveling,” says Janet Devine, president of Sonobond Ultrasonics. “The SeamMaster produces those results, which is why it is the top ultrasonic choice for manufacturers of personal hygiene items. In addition to this, the SeamMaster’s rotary operation channels the ultrasonic vibrations to soften and fuse synthetic materials, creating soft-to-the-touch seams that are sealed, secure and reliable.”

Also, pleated, HVAC and HEPA filters for commercial and residential use; and air, liquid and gas filters used in the automotive, transportation and aerospace industries are among Sonobond’s filtration assembly applications. Sonobond’s equipment has also been successfully used for nonwoven acoustic and insulation panels in these same markets; heavy-duty filter bags for food, chemical, pharma and household uses; as well as oil containment booms and spill clean-up cloths.

“The advantages that ultrasonic technology can provide to the nonwovens industry are certainly driving its growth,” says Devine.

Sonobond’s ultrasonic bonders can offer advantages like cleanly cutting and sealing edges of synthetics and nonwovens, and eliminating fraying, unraveling and material build-up. The machines require no needles, threads, adhesives, or other consumables.

Sonobond’s SeamMaster is four times faster than conventional sewing machines and 10 times faster than adhesive machines, according to Devine. “These are some of the time-saving and cost-cutting advantages that are driving growth for ultrasonics in the industry.”

Additionally, the unique circumstances that 2021 has presented have created an incredibly high demand for ultrasonics in the PPE and medical nonwoven markets.

“2021 has been a challenging year, with supply chain and production delays, as well as restrictions due to Covid-19,” Devine says. “We are happy to continue to provide equipment for all of our nonwoven customers, including PPE manufacturers who are keeping us safe with face masks and a wide variety of disposable medical products.”