Tara Olivo, Associate Editor12.03.21

The demand for nanofibers in the nonwovens industry is poised for growth. According to Allied Market Research, the global demand for nonwoven nanofibers in 2020 was more than 2500 kilotons. Looking ahead, the global demand for nonwoven nanofibers in 2030 is expected to be slightly more than 10,000 kilotons, growing with a lower double-digit CAGR throughout the forecast period.

Initially, fibers having diameter range less than 100 nanometer were considered as nanofibers, although in recent times the scope has been broadened with all fibers having diameter range less than 500 nanometer are considered as nanofibers, according to Prakhar Jain, analyst, Allied Market Research. Additionally, the diameters of nanofibers depend on the type of polymer used and the method of production, he says.

“Nanofibers are unique for their large surface area-to-volume ratio, high porosity, appreciable mechanical strength, and flexibility in functionalization as compared to their microfiber counterparts,” Jain says.

According to the market researcher, nanofibers can be composed of both natural polymers and synthetic polymers. Natural polymers include collagen, cellulose, silk fibroin, keratin, gelatin and polysaccharides such as chitosan and alginate. Synthetic polymers include polylactic acid (PLA), polycaprolactone (PCL), polyurethane (PU), poly (lactic-co-glycolic acid) (PLGA), poly (3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), and poly (ethylene-co- vinylacetate) (PEVA).

“Nanofibers have higher initial and ongoing efficiencies when compared to conventional fibers,” Jain says. “When clean, a network of nanofiber is able to capture dust and other harmful particles much better than clean filters that do not have a fine fiber layer. They are able to achieve these high levels of filtration using filtration methods such as interception, diffusion, and impaction.”

Another reason nanofiber is superior is owing to nanofiber layers lasting longer than other fibers. “Nanofiber traps these particles on the surface and helps to prevent them from clogging up the other layers of material in the fiber,” he explains. “Longer fiber life means that the end user will not have to buy fiber as often. So, even though many fine fibers have higher upfront costs, they can help save a considerable amount of money in the long run.”

In nanofiber nonwovens production, electrospinning has dominated the area, according to Phil Mango, associate consultant – Nonwovens, Smithers. “The electrospinning process has significant limitations due to high voltage requirements, a low production rate and a high dependency on polymer properties,” he says, adding that other methods of spinning micro and nanofibers include solution blowing or air-jet spinning, centrifugal spinning, phase inversion freeze drying and template synthesis.

“Solution blowing seems to be one of the most promising alternatives, without a requirement for high voltage, to replace electrospinning, because of its high production yield,” he explains. “Studies showed that solution-blown micro and nanofiber structures have almost the same morphology and structure as fibers obtained by electrospinning. However, solution blowing offers a production rate that is up to one order of magnitude higher, compared to electrospinning.”

Centrifugal spinning is considered an excellent candidate to replace electrospinning, he adds. “Similar to the solution blowing technique, centrifugal spinning has promise in industrial applications due to its high production capability.”

Some of the other non-electrospinning techniques, such as template synthesis, phase inversion, freeze-drying, and spinneret-based drawing techniques, are suitable for specific uses, such as electronic, optoelectronic, sensor and battery applications. “These alternative techniques have a lower production capacity compared to solution blowing and centrifugal spinning, but their ability to form three-dimensional structures make them promising candidates for biomedical applications, tissue engineering, reinforcing materials, smart textiles, actuators, or sensors,” Mango says. Meanwhile, meltblowing has recently emerged as a possible technology, though it reportedly can only produce fiber diameters near the thin end of the nanofiber range.

Hifyber Focuses on Filter Media

Hifyber of Denizli, Turkey, processes nanofibers that are 500 times thinner than a human hair. Due to its structure, the nanofiber layers show very unique properties such as high surface area-to-volume ratio, high porosity and small pore size.

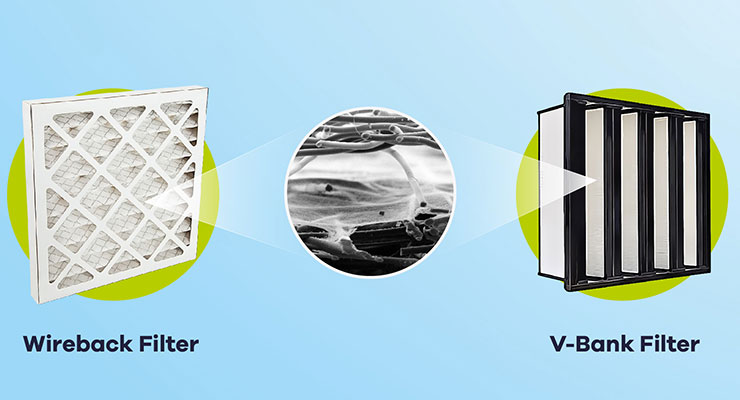

The small pore size of the nanofiber layer allows the mechanical filtration of very small size dust and biological impurities, and high porosity ensures high airflow (lower pressure drop) translates to reduced costs and energy savings. “These unique properties of the nanofibers, combined with the functionality of the materials themselves, have resulted in developing new diverse real-world applications,” says Mehmet Gonullu, sales manager, Hifyber.

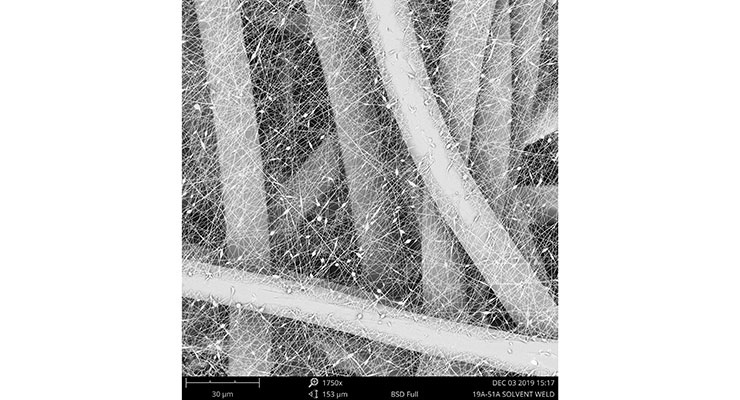

The polymer-based Hifyber nanolayer consists of a dense web of nanofibers with an average fiber thickness of 100-300 nm. To manufacture advanced and robust materials, Hifyber uses the groundbreaking electrospinning technology.

Hifyber recently developed a nanofiber-coated antibacterial-antiviral HVAC filter media to prevent microbial growth in air filters. This filter media is very effective against the growth of bacteria and viruses by disrupting the vital functions of bacterial cells and viruses. Hifyber offers high efficiency antibacterial-antiviral HVAC filter media that meets the air filtration test standards including ASHRAE 52.2, EN 779:2012, ISO 16890 and EN1822.

Hifyber has also developed a biodegradable nanofiber filter media with the aim of generating environmental benefits and to leave future generations a green, healthy and more livable world. Also, Hifyber nanofiber-based filter media, which meets the need for fresh and clean air in living spaces by providing high filtration efficiency in HVAC systems, also ensures safe working conditions with its flame-retardant properties.

“Thanks to its unique structure and material composition, Hifyber nanofiber media can be used for a longer period of time, unlike traditional electrostatically enhanced meltblowns,” says Gonullu. “Electrospinning technology produces very thin continuous fibers and this technology plays a key role in increasing filter efficiency. Hifyber filtration media rely only on mechanical filtration and provides continuous filtration efficiency throughout the life of the filter.”

Hifyber nanofiber media is manufactured by using fully synthetic eco-friendly materials, and this technology eliminates the concern of fiber shedding unlike glass fiber filter media, he adds. “Scientific studies showed that inhaling the fiber debris in the air provided by the filters made with glass fiber causes irritation in the throat and lungs of the people who are exposed, [and] it also causes permanent diseases in long-term continuous exposure.”

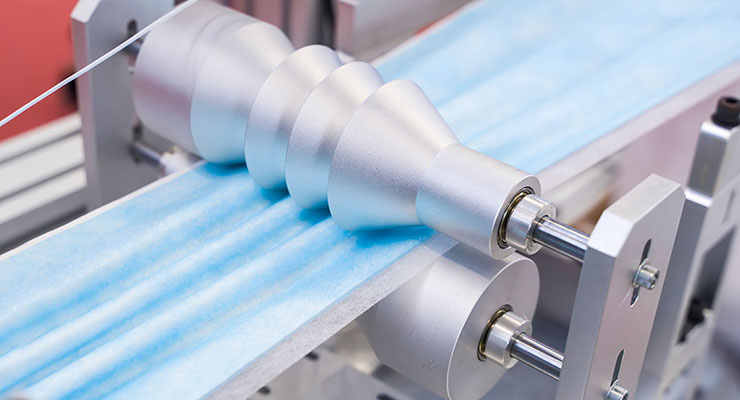

Hifyber nanofiber filter media rolls can be processed on both standard blade and rotary pleaters without performance loss. And, thanks to the long life of the filters, it helps to reduce the energy consumption of the users and to reduce their carbon footprint. Hifyber products meet international test standards and its commercially available MERV grades go up to MERV 16.

Matregenix Expands

In June, Matregenix Inc., a California-based technology company, announced the expansion into a new manufacturing facility in Irvine, CA, where the company installed a new nanofiber line.

“Recently, we decided to add another nanofiber production line because we felt it is necessary to increase the capacity to match the growing demand from our customers for our nanofiber technology,” says Dr. Sherif Soliman, founder and CEO of Matregenix.

Currently, Matregenix is operating one roll-to-roll assembly line and two “big machines.” The assembly line was the most recent addition and it more than doubled the company’s production capability, with the ability to run three times as fast as one big machine.

The company is targeting several applications between both the biomedical and filtration markets. On the biomedical side, the primary focus is within wound healing and tissue engineering scaffolds. On the filtration side, the two main focuses thus far have been with mask filter media along with developing filter media for HVAC filters.

“The mask filter media is where we are making the largest headway,” says Dr. Soliman. “Likewise, the filter media (nonwoven) sector is filled with nanofiber products already, but they are not based in the U.S. and recently a large supply chain issue developed creating a surge in demand for these same media types to be produced within the U.S.”

Matregenix has been investing in R&D to develop nanofiber-based products to address many unmet medical needs. The company is focused on product development and actively seeking strategic partners to co-develop these products and take them the rest of the way to commercialization. For filtration, Matregenix has recently developed a new antiviral and antimicrobial filter technology which eliminates 99% of airborne viruses, including human coronavirus. “Significantly, the active components responsible for the antiviral activity is not a metal oxide based, but a natural herbal extract that is non-toxic,” says Dr. Soliman. “Third party test labs show over 99% efficacy against viruses and reduction of bacteria growth.”

According to Dr. Soliman, the main factor driving growth for nanotechnology in the nonwovens industry is due to the value proposition of the technology itself. “In the filtration application, for example, the low pressure drop while maintaining high filtration efficiency rates cannot be compared with any other current nonwoven material,” he explains. “Its unique properties allow for a complete disruption across the industry where these two factors are highly desirable but with other nonwovens, they are typically unachievable.”

The low pressure drop while also maintaining high filtration efficiency rates allows for better breathability in a mask or the ability to have thinner filters at higher ratings in HVAC systems. Regarding masks, breathability is extremely important for specific jobs in the workforce such as doctors or teachers who are wearing masks all day for five days a week at least, he adds. “Another significant advantage of nanofiber filter media is that, unlike classic meltblown filter media, nanofibers’ filtration mechanism is independent of static charge and fully dependent on pore diameter, pore distribution, and morphology of nanofibers. This mechanical filtration mechanism allows for unlimited shelf-life at a time most governments are looking to stockpile on masks in case another pandemic hits.”

Despite these positives, Dr. Soliman says nanofibers have a bad reputation when it comes to product consistency and reproducibility. “The electrospinning process is delicate with a lot of variables to control, and it requires some deep scientific understanding of material science and chemistry to have good control over the process of electrospinning,” he says. “Moreover, electrospinning is not the kind of ‘plug and play’ process that can be quickly adapted as a manufacturing process, but it is a process that requires high customization for different products and that means long R&D commitments that most companies are not willing to invest in.”

What differentiates Matregenix is its “know-how” with its expert team of nanofiber scientists who have over 30 years of combined hands-on experience in nanofibers research and its applications. “Over the years, we have developed multiple proprietary formulations that cover a wide range of characteristics and that allow us to quickly re-purpose these formulations to establish standard operating procedures (SOPs) to develop different products,” he says. “What that really means is that we can turn a proof-of-concept into a product in a very short time. We also implemented a very rigid quality control system that ensures the products meet its target profile in terms of fiber morphology and microstructure characteristics.”

NXTNano Installs New Lines

Earlier this year NXTNano announced it was installing three additional HYPR-Spun Nanofiber production lines. The new lines take the Claremore, OK-based company’s total line count to six and—similar to existing production lines—the newest equipment facilitates high volume nanofiber manufacturing up to a maximum roll width of 2.15 meters.

“2020 was an incredible year for NXTNano. We saw rapid adoption of the technology into a number of new markets, and more importantly we have a social obligation to continue serving our mask, respirator and indoor air purification customers who have taken up the fight against Covid,” says Andrew McDowell, NXTNano, LLC’s director of sales. “In existing markets, we expected Covid to produce a pronounced slowdown but that never materialized. As a result of the growth and new projects moving to commercial sales, the time has arrived for us to add capacity.”

The company’s decision to install the extra lines is driven by demand for the products. According to McDowell, the company decided to make two extra lines with some internal modifications. The extra modifications demand more air-handling, but will allow the two lines to outproduce three without the changes. Meanwhile, NXTNano’s fourth line is up and running now, with line five being in-position, but waiting on some control components. One of its original lines, No. 3, received some upgrades which further boosted capacity. “Currently we are caught up and doing well on capacity and cell five will give us some much-needed slack to resume work on membranes for the apparel and venting industry,” McDowell says.

At its core, NXTNano is a high-volume producer of nanofiber materials and specializes in delivering these products, at commercial scale, to markets that have not been able to adopt them yet. Its production lines are developed in-house and use a process it calls HYPR spinning. HYPR spinning is a derivative of electrospinning, with some unique twists and additional forces allowing the company to produce at much greater rates and with a wider range of control than traditional electrospinning.

“The largest markets for nanofiber today in terms of yardage used is filtration; it’s also the most established and longest existing market for nano materials,” McDowell says. “Yet even in a market where nano has been used commercially for 30 years, the application is still in its infancy. The relatively easy and obvious uses like industrial air filtration, or automotive intake filtration, are well addressed, though perhaps not optimized. There is a lot of performance being left on the table in terms of reduced restriction by moving to synthetic materials or further improving carrier media permeability.”

NXTNano has also had great adoption of its nanofiber media into the indoor air quality markets, and expects to see this trend continue. “Never before have consumers been so concerned with the quality of the air they breathe, and nanofiber is there to deliver the high performance demanded,” he says.

Since the early days of Covid, the company has also dedicated capacity to make sure its partners using nanofiber for their N95 respirators always had availability. NXTNano even made the materials available to the general public so they could cut swatches and sew them into cloth masks for improved performance.

Other markets such as micro-venting and microfiltration, which require nanofiber membranes of greater basis weight, are areas where NXTNano has been putting focus, and where it doesn’t see other production technologies being capable of fabricating the membranes.

Initially, fibers having diameter range less than 100 nanometer were considered as nanofibers, although in recent times the scope has been broadened with all fibers having diameter range less than 500 nanometer are considered as nanofibers, according to Prakhar Jain, analyst, Allied Market Research. Additionally, the diameters of nanofibers depend on the type of polymer used and the method of production, he says.

“Nanofibers are unique for their large surface area-to-volume ratio, high porosity, appreciable mechanical strength, and flexibility in functionalization as compared to their microfiber counterparts,” Jain says.

According to the market researcher, nanofibers can be composed of both natural polymers and synthetic polymers. Natural polymers include collagen, cellulose, silk fibroin, keratin, gelatin and polysaccharides such as chitosan and alginate. Synthetic polymers include polylactic acid (PLA), polycaprolactone (PCL), polyurethane (PU), poly (lactic-co-glycolic acid) (PLGA), poly (3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), and poly (ethylene-co- vinylacetate) (PEVA).

“Nanofibers have higher initial and ongoing efficiencies when compared to conventional fibers,” Jain says. “When clean, a network of nanofiber is able to capture dust and other harmful particles much better than clean filters that do not have a fine fiber layer. They are able to achieve these high levels of filtration using filtration methods such as interception, diffusion, and impaction.”

Another reason nanofiber is superior is owing to nanofiber layers lasting longer than other fibers. “Nanofiber traps these particles on the surface and helps to prevent them from clogging up the other layers of material in the fiber,” he explains. “Longer fiber life means that the end user will not have to buy fiber as often. So, even though many fine fibers have higher upfront costs, they can help save a considerable amount of money in the long run.”

In nanofiber nonwovens production, electrospinning has dominated the area, according to Phil Mango, associate consultant – Nonwovens, Smithers. “The electrospinning process has significant limitations due to high voltage requirements, a low production rate and a high dependency on polymer properties,” he says, adding that other methods of spinning micro and nanofibers include solution blowing or air-jet spinning, centrifugal spinning, phase inversion freeze drying and template synthesis.

“Solution blowing seems to be one of the most promising alternatives, without a requirement for high voltage, to replace electrospinning, because of its high production yield,” he explains. “Studies showed that solution-blown micro and nanofiber structures have almost the same morphology and structure as fibers obtained by electrospinning. However, solution blowing offers a production rate that is up to one order of magnitude higher, compared to electrospinning.”

Centrifugal spinning is considered an excellent candidate to replace electrospinning, he adds. “Similar to the solution blowing technique, centrifugal spinning has promise in industrial applications due to its high production capability.”

Some of the other non-electrospinning techniques, such as template synthesis, phase inversion, freeze-drying, and spinneret-based drawing techniques, are suitable for specific uses, such as electronic, optoelectronic, sensor and battery applications. “These alternative techniques have a lower production capacity compared to solution blowing and centrifugal spinning, but their ability to form three-dimensional structures make them promising candidates for biomedical applications, tissue engineering, reinforcing materials, smart textiles, actuators, or sensors,” Mango says. Meanwhile, meltblowing has recently emerged as a possible technology, though it reportedly can only produce fiber diameters near the thin end of the nanofiber range.

Hifyber Focuses on Filter Media

Hifyber of Denizli, Turkey, processes nanofibers that are 500 times thinner than a human hair. Due to its structure, the nanofiber layers show very unique properties such as high surface area-to-volume ratio, high porosity and small pore size.

The small pore size of the nanofiber layer allows the mechanical filtration of very small size dust and biological impurities, and high porosity ensures high airflow (lower pressure drop) translates to reduced costs and energy savings. “These unique properties of the nanofibers, combined with the functionality of the materials themselves, have resulted in developing new diverse real-world applications,” says Mehmet Gonullu, sales manager, Hifyber.

The polymer-based Hifyber nanolayer consists of a dense web of nanofibers with an average fiber thickness of 100-300 nm. To manufacture advanced and robust materials, Hifyber uses the groundbreaking electrospinning technology.

Hifyber recently developed a nanofiber-coated antibacterial-antiviral HVAC filter media to prevent microbial growth in air filters. This filter media is very effective against the growth of bacteria and viruses by disrupting the vital functions of bacterial cells and viruses. Hifyber offers high efficiency antibacterial-antiviral HVAC filter media that meets the air filtration test standards including ASHRAE 52.2, EN 779:2012, ISO 16890 and EN1822.

Hifyber has also developed a biodegradable nanofiber filter media with the aim of generating environmental benefits and to leave future generations a green, healthy and more livable world. Also, Hifyber nanofiber-based filter media, which meets the need for fresh and clean air in living spaces by providing high filtration efficiency in HVAC systems, also ensures safe working conditions with its flame-retardant properties.

“Thanks to its unique structure and material composition, Hifyber nanofiber media can be used for a longer period of time, unlike traditional electrostatically enhanced meltblowns,” says Gonullu. “Electrospinning technology produces very thin continuous fibers and this technology plays a key role in increasing filter efficiency. Hifyber filtration media rely only on mechanical filtration and provides continuous filtration efficiency throughout the life of the filter.”

Hifyber nanofiber media is manufactured by using fully synthetic eco-friendly materials, and this technology eliminates the concern of fiber shedding unlike glass fiber filter media, he adds. “Scientific studies showed that inhaling the fiber debris in the air provided by the filters made with glass fiber causes irritation in the throat and lungs of the people who are exposed, [and] it also causes permanent diseases in long-term continuous exposure.”

Hifyber nanofiber filter media rolls can be processed on both standard blade and rotary pleaters without performance loss. And, thanks to the long life of the filters, it helps to reduce the energy consumption of the users and to reduce their carbon footprint. Hifyber products meet international test standards and its commercially available MERV grades go up to MERV 16.

Matregenix Expands

In June, Matregenix Inc., a California-based technology company, announced the expansion into a new manufacturing facility in Irvine, CA, where the company installed a new nanofiber line.

“Recently, we decided to add another nanofiber production line because we felt it is necessary to increase the capacity to match the growing demand from our customers for our nanofiber technology,” says Dr. Sherif Soliman, founder and CEO of Matregenix.

Currently, Matregenix is operating one roll-to-roll assembly line and two “big machines.” The assembly line was the most recent addition and it more than doubled the company’s production capability, with the ability to run three times as fast as one big machine.

The company is targeting several applications between both the biomedical and filtration markets. On the biomedical side, the primary focus is within wound healing and tissue engineering scaffolds. On the filtration side, the two main focuses thus far have been with mask filter media along with developing filter media for HVAC filters.

“The mask filter media is where we are making the largest headway,” says Dr. Soliman. “Likewise, the filter media (nonwoven) sector is filled with nanofiber products already, but they are not based in the U.S. and recently a large supply chain issue developed creating a surge in demand for these same media types to be produced within the U.S.”

Matregenix has been investing in R&D to develop nanofiber-based products to address many unmet medical needs. The company is focused on product development and actively seeking strategic partners to co-develop these products and take them the rest of the way to commercialization. For filtration, Matregenix has recently developed a new antiviral and antimicrobial filter technology which eliminates 99% of airborne viruses, including human coronavirus. “Significantly, the active components responsible for the antiviral activity is not a metal oxide based, but a natural herbal extract that is non-toxic,” says Dr. Soliman. “Third party test labs show over 99% efficacy against viruses and reduction of bacteria growth.”

According to Dr. Soliman, the main factor driving growth for nanotechnology in the nonwovens industry is due to the value proposition of the technology itself. “In the filtration application, for example, the low pressure drop while maintaining high filtration efficiency rates cannot be compared with any other current nonwoven material,” he explains. “Its unique properties allow for a complete disruption across the industry where these two factors are highly desirable but with other nonwovens, they are typically unachievable.”

The low pressure drop while also maintaining high filtration efficiency rates allows for better breathability in a mask or the ability to have thinner filters at higher ratings in HVAC systems. Regarding masks, breathability is extremely important for specific jobs in the workforce such as doctors or teachers who are wearing masks all day for five days a week at least, he adds. “Another significant advantage of nanofiber filter media is that, unlike classic meltblown filter media, nanofibers’ filtration mechanism is independent of static charge and fully dependent on pore diameter, pore distribution, and morphology of nanofibers. This mechanical filtration mechanism allows for unlimited shelf-life at a time most governments are looking to stockpile on masks in case another pandemic hits.”

Despite these positives, Dr. Soliman says nanofibers have a bad reputation when it comes to product consistency and reproducibility. “The electrospinning process is delicate with a lot of variables to control, and it requires some deep scientific understanding of material science and chemistry to have good control over the process of electrospinning,” he says. “Moreover, electrospinning is not the kind of ‘plug and play’ process that can be quickly adapted as a manufacturing process, but it is a process that requires high customization for different products and that means long R&D commitments that most companies are not willing to invest in.”

What differentiates Matregenix is its “know-how” with its expert team of nanofiber scientists who have over 30 years of combined hands-on experience in nanofibers research and its applications. “Over the years, we have developed multiple proprietary formulations that cover a wide range of characteristics and that allow us to quickly re-purpose these formulations to establish standard operating procedures (SOPs) to develop different products,” he says. “What that really means is that we can turn a proof-of-concept into a product in a very short time. We also implemented a very rigid quality control system that ensures the products meet its target profile in terms of fiber morphology and microstructure characteristics.”

NXTNano Installs New Lines

Earlier this year NXTNano announced it was installing three additional HYPR-Spun Nanofiber production lines. The new lines take the Claremore, OK-based company’s total line count to six and—similar to existing production lines—the newest equipment facilitates high volume nanofiber manufacturing up to a maximum roll width of 2.15 meters.

“2020 was an incredible year for NXTNano. We saw rapid adoption of the technology into a number of new markets, and more importantly we have a social obligation to continue serving our mask, respirator and indoor air purification customers who have taken up the fight against Covid,” says Andrew McDowell, NXTNano, LLC’s director of sales. “In existing markets, we expected Covid to produce a pronounced slowdown but that never materialized. As a result of the growth and new projects moving to commercial sales, the time has arrived for us to add capacity.”

The company’s decision to install the extra lines is driven by demand for the products. According to McDowell, the company decided to make two extra lines with some internal modifications. The extra modifications demand more air-handling, but will allow the two lines to outproduce three without the changes. Meanwhile, NXTNano’s fourth line is up and running now, with line five being in-position, but waiting on some control components. One of its original lines, No. 3, received some upgrades which further boosted capacity. “Currently we are caught up and doing well on capacity and cell five will give us some much-needed slack to resume work on membranes for the apparel and venting industry,” McDowell says.

At its core, NXTNano is a high-volume producer of nanofiber materials and specializes in delivering these products, at commercial scale, to markets that have not been able to adopt them yet. Its production lines are developed in-house and use a process it calls HYPR spinning. HYPR spinning is a derivative of electrospinning, with some unique twists and additional forces allowing the company to produce at much greater rates and with a wider range of control than traditional electrospinning.

“The largest markets for nanofiber today in terms of yardage used is filtration; it’s also the most established and longest existing market for nano materials,” McDowell says. “Yet even in a market where nano has been used commercially for 30 years, the application is still in its infancy. The relatively easy and obvious uses like industrial air filtration, or automotive intake filtration, are well addressed, though perhaps not optimized. There is a lot of performance being left on the table in terms of reduced restriction by moving to synthetic materials or further improving carrier media permeability.”

NXTNano has also had great adoption of its nanofiber media into the indoor air quality markets, and expects to see this trend continue. “Never before have consumers been so concerned with the quality of the air they breathe, and nanofiber is there to deliver the high performance demanded,” he says.

Since the early days of Covid, the company has also dedicated capacity to make sure its partners using nanofiber for their N95 respirators always had availability. NXTNano even made the materials available to the general public so they could cut swatches and sew them into cloth masks for improved performance.

Other markets such as micro-venting and microfiltration, which require nanofiber membranes of greater basis weight, are areas where NXTNano has been putting focus, and where it doesn’t see other production technologies being capable of fabricating the membranes.