Tara Olivo, Associate Editor11.12.20

In the nonwovens industry, ultrasonic technology is used to laminate, emboss and slit synthetic materials, and manufacturers and converters of nonwoven-based products are using the technology for a number of end-use products, from diapers and feminine care pads to filter media and oil containment booms. Additionally, the unprecedented demand for personal protective equipment (PPE) including face masks and medical gowns—which are made of nonwovens—is clearly being felt by suppliers of ultrasonic technology.

“The Covid-19 pandemic is really driving the growth for ultrasonics in the nonwovens industry, with a high demand for PPE and filtration products,” says Guy Gil, president, Chase Machine and Engineering. “Since nonwoven materials are primarily used in consumable products, and ultrasonics is the preferred method of assembly for these products, the demand will certainly continue to drive growth for the foreseeable future.”

Nonwovens Industry spoke to some of the key suppliers of ultrasonic technology to learn about their latest innovations as well as how the pandemic has impacted business.

Chase Machine and Engineering

Chase Machine and Engineering designs and builds custom machinery with a primary focus on the integration of ultrasonic technology for continuous and intermittent web converting applications. Working with the industry’s leading suppliers of ultrasonic technology, Chase supplies ultrasonic laminators, embossers, slitters and splicing equipment to manufacturers of nonwoven materials and converters to produce a variety of products for the hygiene, filtration, textile, packaging, medical and personal care industry.

“Chase’s reputation as one of the ‘go to companies’ for continuous ultrasonic machinery is a direct result of the creative solutions we have provided over the last 40 years working with this clean and efficient means of bonding,” says Gil.

Chase’s facility, located in Rhode Island, has a dedicated lab for continuous ultrasonic testing. Customers can send product samples to Chase in order to collect invaluable data such as bond strength, embossing quality, slit quality, power requirements and processing line speed. Information that is crucial in determining quality, feasibility and payback.

In new product news, Chase recently developed a new ultrasonic sewing machine used to sew around the perimeter of a tube or sleeve. It has a cantilevered anvil and ultrasonic welder that provides the operator the ability to weld contoured shapes. This type of manual ultrasonic sewing machine may be used to help make any type of contoured or hard to manipulate product.

Due to the pandemic, Chase, being a custom web handling machine builder familiar with ultrasonic integration, has been working alongside some of the world’s leading suppliers of PPE as well as smaller companies and entrepreneurs looking to help make a difference during such a troubling time, according to Gil. “We have helped companies by providing equipment to produce products such as gowns, N95 and surgical face masks, and a variety of filtration products,” he says. “Whether fully automated systems, or simple manually operated assembly machines, we have worked tirelessly to help our customers get their product to front line workers and fill the void for these most critical supplies.”

Many of these items start from rolls of nonwoven materials that must be converted in order to manufacture PPE, Gil adds. In filtration applications such as masks for example, a single layer of nonwoven material may not be sufficient to satisfy the filtration requirements for that particular use, but by using ultrasonic bonding technology, converters may take multiple layers of nonwoven materials, each with their own special characteristics and bond them together to produce a composite that has the unique filtration requirement necessary for their intended use.

“The Covid-19 pandemic has put an enormous amount of pressure on nonwoven suppliers to produce more material for PPE use,” Gil explains. “The issue is many of these nonwoven materials are used for applications other than PPE. Since the medical and filtration markets have placed such a high demand for nonwoven materials, other industries are seeing a shortage which is negatively effecting their business. For this reason, companies are getting creative by testing other types of materials that aren’t in as much demand.”

A suitable alternative, he says, may be as simple as ultrasonically bonding several nonwoven substrates together to provide a new composite with similar characteristics.

“The world’s most creative engineers and scientists are working diligently to create new products that protect our children, parents and frontline workers in this most difficult time,” Gil says. “Nonwoven materials play a major role in the construction of those products. For this reason, I’m sure ultrasonics will continue to be one of the dominant technologies used in the assembly of these vitally important and much needed products.”

Sonobond Ultrasonics

Sonobond’s ultrasonic machinery is used for many applications in the nonwovens industry, since its equipment can provide bonding, seaming, slitting, cutting and trimming. Depending upon the actual machine, more than one function can be performed on the unit, usually in just one step. For instance, with appropriate tooling, Sonobond’s SeamMaster Ultrasonic Sewing Machine can bond, seam and trim at the same time.

Sonobond’s equipment is used to assemble medical nonwoven items, including face masks; surgical and hospital gowns; disposable pillow and mattress covers; sterilization and storage pouches for medical instruments; and lint-free wound dressings; as well as hygiene items such as bedwetting protection panties. Meanwhile, filtration assembly applications include pleated, HVAC and HEPA filters; air, liquid and gas filters used in the automotive, transportation, and aerospace industries, along with acoustic and insulation panels used in these same markets; heavy-duty filter bags for food, chemical, pharma and household uses; and oil containment booms and spill clean-up cloths.

Janet Devine, president of Sonobond Ultrasonics, reports that the pandemic has greatly increased demand for the company’s SeamMaster Ultrasonic Sewing Machine. “This is the most popular ultrasonic machine on the market to assemble nonwoven medical and filtration items,” she says. “However, our adherence to CDC safety guidelines for our staff and our community has caused production delays. Thankfully, our customers have been patient and understanding of this situation.”

Recently, Sonobond has fine-tuned instructions for assembling face masks using its equipment so manufacturers can now produce them in approximately one minute, without thread or glue. “This is helping them increase their output while reducing their production costs,” Devine says.

The company has also produced a “how-to” video on this process, which can be accessed on its website and on YouTube.

According to Devine, ultrasonics is the preferred method for quickly creating strong, sealed edges and secure barrier seams that meet regulatory requirements. High-frequency sound waves cause heating and plasticization of the nonwoven material, creating high-quality bonds at pressure points without stitch holes, glue gaps, fraying or unraveling.

“Since ultrasonic assembly technology requires no thread or other consumables, manufacturers can realize lower production costs,” she says. “In addition, ultrasonic assembly is faster and easier to use than other technologies, providing greater production output without sacrificing quality.”

Herrmann Ultrasonics

In June, Herrmann Ultrasonics completed an expansion at its U.S. headquarters in Bartlett, IL, adding 10,000 square feet.

A newly designed office space has transitioned to an open office floor plan offering better communication and team collaboration. Increased customer support and application testing can now take place in division specific engineering and application labs, as well as an all-new buying center. Further, more machines have been added to the manufacturing floor for increased production of ultrasonic tooling.

“The growth over the last few years has supported Herrmann’s investment into a 50% extension of the North American headquarters, doubling the in-house tool manufacturing,” says Uwe Peregi, president of Herrmann Ultrasonics.

One of the most advanced ultrasonic laboratory calenders resides in its headquarters in Bartlett, Peregi adds. This calender, which can operate at >2,000 ft. / min, allows for high-level customer feasibility testing. Herrmann is further increasing the capabilities of this system by upgrading the ultrasonic solution to the latest Microbond G4 system and the control system to an Allen Bradley platform.

“Ultrasonic welding of nonwovens is an extremely fast and stable process that is easily repeatable and directly available without the need for pre-heating,” Peregi says. “The technology allows for simultaneous embossing, laminating and cutting. Bonding patterns can vary in size, shape and pattern, essentially designed for the requirements of the application independent of narrow or wide web widths. Our new Microbond G4 solution, the most innovative ultrasonic solution in the industry, offers the most advanced control and function in continuous ultrasonic bonding.”

Ultrasonics has been an instrumental technology in the manufacturing of medical testing devices and face mask manufacturing, Peregi adds. “The demand has increased worldwide due to the pandemic. Nine different mask types have been identified, ranging from simple face masks to complex three-dimensional deep-drawn masks with breathing valves. The technological solutions range from simple intermittent manual welding to complex high-speed systems. Herrmann offers products from standard machines and components to complex rotary ultrasonic welding modules to serve the different solutions.”

Herrmann’s Microbond CSI system with different sonotrodes and engraved anvils is used for high-speed continuous lines. Welding takes place in multiple ultrasonic stations. The patented MicrogapControl technology ensures continuous, reproducible bonding quality and enables a production rate of 1000+ masks per minute.

For small quantities, a quick-change system of individual components can be used instead of the Microbond CSI system. It is also possible to use a HiQ Dialog welding machine integrated in a line or as a workstation for intermittent welding.

According to Peregi, ultrasonic bonding creates soft products in a sustainable process. “One of the largest reasons for utilizing ultrasonics in the nonwovens industry is to eliminate adhesives,” he says. “The patented MicrogapControl system improves machine efficiency, allowing for multiple advantages such as low reject rates, fast set-up times, no contamination, no consumables and reduced energy cost.”

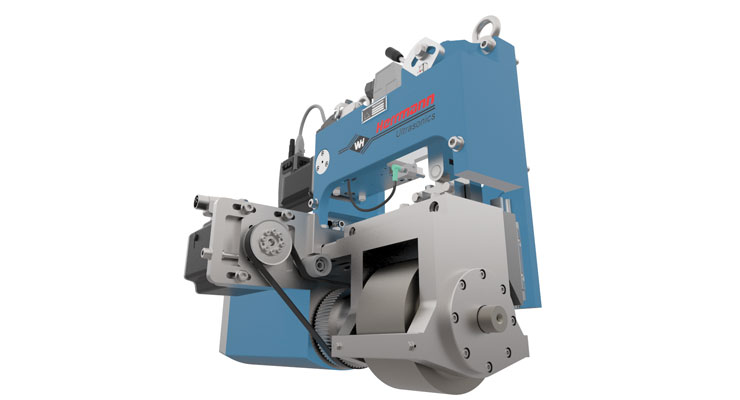

Another innovation from Herrmann is its modern computer based FEA (Finite Element Analysis) system, which has successfully calculated and simulated the widest rotary ultrasonic solution in the industry. Herrmann Ultrasonics rotary solutions offer continuous ultrasonic bonding, with low material friction resistance and high continuous process speeds exceeding 2,000 ft/min (600m/min). “With the addition of the newly designed Ultraspin RSD 20-85, coupled with the closed loop Microbond Control System, it becomes an unbeatable rotary solution in bonding width,” Peregi says.

Applications in hygiene products, such as femcare, baby and adult diapers, will benefit from the implementation of the 3.3” (85mm) wide rotary ultrasonic solution. The wide format solution can also improve machine efficiency, especially where multiple installations are needed to cover the width of this single 85mm solution. There are currently two systems in the field for beta site testing.

“The Covid-19 pandemic is really driving the growth for ultrasonics in the nonwovens industry, with a high demand for PPE and filtration products,” says Guy Gil, president, Chase Machine and Engineering. “Since nonwoven materials are primarily used in consumable products, and ultrasonics is the preferred method of assembly for these products, the demand will certainly continue to drive growth for the foreseeable future.”

Nonwovens Industry spoke to some of the key suppliers of ultrasonic technology to learn about their latest innovations as well as how the pandemic has impacted business.

Chase Machine and Engineering

Chase Machine and Engineering designs and builds custom machinery with a primary focus on the integration of ultrasonic technology for continuous and intermittent web converting applications. Working with the industry’s leading suppliers of ultrasonic technology, Chase supplies ultrasonic laminators, embossers, slitters and splicing equipment to manufacturers of nonwoven materials and converters to produce a variety of products for the hygiene, filtration, textile, packaging, medical and personal care industry.

“Chase’s reputation as one of the ‘go to companies’ for continuous ultrasonic machinery is a direct result of the creative solutions we have provided over the last 40 years working with this clean and efficient means of bonding,” says Gil.

Chase’s facility, located in Rhode Island, has a dedicated lab for continuous ultrasonic testing. Customers can send product samples to Chase in order to collect invaluable data such as bond strength, embossing quality, slit quality, power requirements and processing line speed. Information that is crucial in determining quality, feasibility and payback.

In new product news, Chase recently developed a new ultrasonic sewing machine used to sew around the perimeter of a tube or sleeve. It has a cantilevered anvil and ultrasonic welder that provides the operator the ability to weld contoured shapes. This type of manual ultrasonic sewing machine may be used to help make any type of contoured or hard to manipulate product.

Due to the pandemic, Chase, being a custom web handling machine builder familiar with ultrasonic integration, has been working alongside some of the world’s leading suppliers of PPE as well as smaller companies and entrepreneurs looking to help make a difference during such a troubling time, according to Gil. “We have helped companies by providing equipment to produce products such as gowns, N95 and surgical face masks, and a variety of filtration products,” he says. “Whether fully automated systems, or simple manually operated assembly machines, we have worked tirelessly to help our customers get their product to front line workers and fill the void for these most critical supplies.”

Many of these items start from rolls of nonwoven materials that must be converted in order to manufacture PPE, Gil adds. In filtration applications such as masks for example, a single layer of nonwoven material may not be sufficient to satisfy the filtration requirements for that particular use, but by using ultrasonic bonding technology, converters may take multiple layers of nonwoven materials, each with their own special characteristics and bond them together to produce a composite that has the unique filtration requirement necessary for their intended use.

“The Covid-19 pandemic has put an enormous amount of pressure on nonwoven suppliers to produce more material for PPE use,” Gil explains. “The issue is many of these nonwoven materials are used for applications other than PPE. Since the medical and filtration markets have placed such a high demand for nonwoven materials, other industries are seeing a shortage which is negatively effecting their business. For this reason, companies are getting creative by testing other types of materials that aren’t in as much demand.”

A suitable alternative, he says, may be as simple as ultrasonically bonding several nonwoven substrates together to provide a new composite with similar characteristics.

“The world’s most creative engineers and scientists are working diligently to create new products that protect our children, parents and frontline workers in this most difficult time,” Gil says. “Nonwoven materials play a major role in the construction of those products. For this reason, I’m sure ultrasonics will continue to be one of the dominant technologies used in the assembly of these vitally important and much needed products.”

Sonobond Ultrasonics

Sonobond’s ultrasonic machinery is used for many applications in the nonwovens industry, since its equipment can provide bonding, seaming, slitting, cutting and trimming. Depending upon the actual machine, more than one function can be performed on the unit, usually in just one step. For instance, with appropriate tooling, Sonobond’s SeamMaster Ultrasonic Sewing Machine can bond, seam and trim at the same time.

Sonobond’s equipment is used to assemble medical nonwoven items, including face masks; surgical and hospital gowns; disposable pillow and mattress covers; sterilization and storage pouches for medical instruments; and lint-free wound dressings; as well as hygiene items such as bedwetting protection panties. Meanwhile, filtration assembly applications include pleated, HVAC and HEPA filters; air, liquid and gas filters used in the automotive, transportation, and aerospace industries, along with acoustic and insulation panels used in these same markets; heavy-duty filter bags for food, chemical, pharma and household uses; and oil containment booms and spill clean-up cloths.

Janet Devine, president of Sonobond Ultrasonics, reports that the pandemic has greatly increased demand for the company’s SeamMaster Ultrasonic Sewing Machine. “This is the most popular ultrasonic machine on the market to assemble nonwoven medical and filtration items,” she says. “However, our adherence to CDC safety guidelines for our staff and our community has caused production delays. Thankfully, our customers have been patient and understanding of this situation.”

Recently, Sonobond has fine-tuned instructions for assembling face masks using its equipment so manufacturers can now produce them in approximately one minute, without thread or glue. “This is helping them increase their output while reducing their production costs,” Devine says.

The company has also produced a “how-to” video on this process, which can be accessed on its website and on YouTube.

According to Devine, ultrasonics is the preferred method for quickly creating strong, sealed edges and secure barrier seams that meet regulatory requirements. High-frequency sound waves cause heating and plasticization of the nonwoven material, creating high-quality bonds at pressure points without stitch holes, glue gaps, fraying or unraveling.

“Since ultrasonic assembly technology requires no thread or other consumables, manufacturers can realize lower production costs,” she says. “In addition, ultrasonic assembly is faster and easier to use than other technologies, providing greater production output without sacrificing quality.”

Herrmann Ultrasonics

In June, Herrmann Ultrasonics completed an expansion at its U.S. headquarters in Bartlett, IL, adding 10,000 square feet.

A newly designed office space has transitioned to an open office floor plan offering better communication and team collaboration. Increased customer support and application testing can now take place in division specific engineering and application labs, as well as an all-new buying center. Further, more machines have been added to the manufacturing floor for increased production of ultrasonic tooling.

“The growth over the last few years has supported Herrmann’s investment into a 50% extension of the North American headquarters, doubling the in-house tool manufacturing,” says Uwe Peregi, president of Herrmann Ultrasonics.

One of the most advanced ultrasonic laboratory calenders resides in its headquarters in Bartlett, Peregi adds. This calender, which can operate at >2,000 ft. / min, allows for high-level customer feasibility testing. Herrmann is further increasing the capabilities of this system by upgrading the ultrasonic solution to the latest Microbond G4 system and the control system to an Allen Bradley platform.

“Ultrasonic welding of nonwovens is an extremely fast and stable process that is easily repeatable and directly available without the need for pre-heating,” Peregi says. “The technology allows for simultaneous embossing, laminating and cutting. Bonding patterns can vary in size, shape and pattern, essentially designed for the requirements of the application independent of narrow or wide web widths. Our new Microbond G4 solution, the most innovative ultrasonic solution in the industry, offers the most advanced control and function in continuous ultrasonic bonding.”

Ultrasonics has been an instrumental technology in the manufacturing of medical testing devices and face mask manufacturing, Peregi adds. “The demand has increased worldwide due to the pandemic. Nine different mask types have been identified, ranging from simple face masks to complex three-dimensional deep-drawn masks with breathing valves. The technological solutions range from simple intermittent manual welding to complex high-speed systems. Herrmann offers products from standard machines and components to complex rotary ultrasonic welding modules to serve the different solutions.”

Herrmann’s Microbond CSI system with different sonotrodes and engraved anvils is used for high-speed continuous lines. Welding takes place in multiple ultrasonic stations. The patented MicrogapControl technology ensures continuous, reproducible bonding quality and enables a production rate of 1000+ masks per minute.

For small quantities, a quick-change system of individual components can be used instead of the Microbond CSI system. It is also possible to use a HiQ Dialog welding machine integrated in a line or as a workstation for intermittent welding.

According to Peregi, ultrasonic bonding creates soft products in a sustainable process. “One of the largest reasons for utilizing ultrasonics in the nonwovens industry is to eliminate adhesives,” he says. “The patented MicrogapControl system improves machine efficiency, allowing for multiple advantages such as low reject rates, fast set-up times, no contamination, no consumables and reduced energy cost.”

Another innovation from Herrmann is its modern computer based FEA (Finite Element Analysis) system, which has successfully calculated and simulated the widest rotary ultrasonic solution in the industry. Herrmann Ultrasonics rotary solutions offer continuous ultrasonic bonding, with low material friction resistance and high continuous process speeds exceeding 2,000 ft/min (600m/min). “With the addition of the newly designed Ultraspin RSD 20-85, coupled with the closed loop Microbond Control System, it becomes an unbeatable rotary solution in bonding width,” Peregi says.

Applications in hygiene products, such as femcare, baby and adult diapers, will benefit from the implementation of the 3.3” (85mm) wide rotary ultrasonic solution. The wide format solution can also improve machine efficiency, especially where multiple installations are needed to cover the width of this single 85mm solution. There are currently two systems in the field for beta site testing.