Tara Olivo, Associate Editor04.03.20

With its versatility and flexibility, needlepunch technology continues to grow in durable markets such as automotive, geotextiles, filtration, home furnishings and others.

“Today, needlepunch is the second-largest market segment in terms of capacity after the spunbond process segment. It is a continuously growing market,” says Jean-Philippe Dumon, sales director, Nonwoven, of machinery supplier Andritz Asselin-Thibeau.

The technology, which offers a lower start-up investment compared to other technologies, allows manufacturers to achieve several goals with just one line. Needlepunched nonwovens can be made in a wide range of weights and can be developed from an equally wide range of staple fibers, both natural and synthetic.

“Needlepunch technology is a very versatile technology,” says Freudenberg Performance Materials CTO John McNabb. “It’s relatively cost-effective, and it has really advanced in the past 15 years to make more uniform and lighter weight products. We can run different polymers, different types of fibers, so it’s very flexible.”

Freudenberg strengthened its needlepunch business late last year when it acquired Filc, a Slovenian manufacturer of needlepunch nonwovens and laminated materials. Headquartered in Škofja Loka, Slovenia, Filc also operates two production sites in Mengeš and Lendava, Slovenia, as well as a sales office in Dayton, OH.

“Geographically the acquisition of Filc was very important to us because it gave us a strong needlepunch presence in Europe,” McNabb comments. “Technology wise they’re well-known in the industry, whether it’s automotive or construction with the Dripstop product. They have new, very efficient lines, with good products, and they really filled this white spot that we had in Europe of needing more needlepunch technology.”

Freudenberg has been in the needlepunch business for a long time with its automotive headliners, which are needlepunched around the world. The company’s needlepunch technology is also used in the filtration market, as well as in construction, where it supplies staple fiber and spunbond products with glass reinforcement. In addition to the acquired Slovenian sites, Freudenberg Performance Materials’ needlepunch assets are in the U.S., China and Japan. The company’s partner Japan Vilene Company runs needlepunch lines in Mexico and South Korea.

Freudenberg expects to see growth for the technology, especially in the automotive and construction markets. “In automotive, the trend towards a lighter weight system, and moving away from heavier plastic parts to a lighter weight nonwoven, has happened and continues,” McNabb says.

More nonwovens will be used both in current vehicles with normal internal combustion engines to light weight the vehicles for better gas mileage, as well as in new mobility, such as electric vehicles or for fuel cell vehicles in the future. “Those will have a high requirement for sound absorbing materials and insulating products, and that’s where the needlepunch technology is quite effective,” he adds.

Meanwhile, in construction there’s a need for needlepunch because of its cost-effectiveness, it can run different types of staple fibers and it delivers strength in tensile and elongation properties that are needed, he says.

BontexGeo Debuts

Last year Low & Bonar sold its needlepunched nonwovens business (NPNW) to Nimbus, a Netherlands-based private equity fund. The disposal included the sale of the entire issued share capital of Low & Bonar NV and Low & Bonar Kft, which are based in Belgium and Hungary, respectively.

Low & Bonar said this move allowed it to reduce its net debt levels and invest in more profitable parts of its business. Previously, the company sold its Construction Fibres business, comprising the other part of its Civil Engineering division, to Adfil NV and Industria BV. NPNW’s management team and employees transferred with the business, and in October, it was renamed BontexGeo.

The last major expansion in capacity took place in 2016, according to Kenny De Wolf, product and marketing manager, BontexGeo. This allowed the division to explore new opportunities to fill this additional capacity. “Currently investments are being done in technical upgrades of our production facilities to make sure they are future-proof,” he adds. “Some new developments are in the pipeline and will be launched in due time.”

From BontexGeo’s point of view, the main driver of growth for needlepunched material is infrastructure projects ranging from rehabilitation of existing infrastructure to the establishment of new roads and railways. “For such projects, we see some variances in countries where there is dependence on EU support programs, but in general this is a stable market,” De Wolf says. “An important driver for the use of needlepunched nonwoven geotextile in infrastructure projects is the lowered environmental impact when designing with geotextiles compared to the ‘traditional’ design methods.”

While the market is stable, De Wolf says there is a threat of overcapacity in the market. “The will and need to anticipate likely future changes in climate and global population could have a positive impact on the market,” he says.

Technical Absorbents Expands SAF Needlepunch

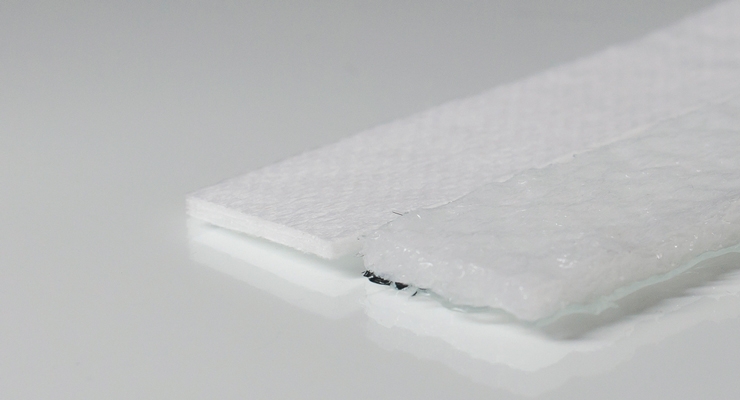

Technical Absorbents, inventor of Super Absorbent Fibre (SAF), develops superabsorbent needlepunch fabrics containing up to 100% SAF that can be produced in a variety of thicknesses and weights, typically from 150 to 1,000 gsm. SAF needlepunch is capable of absorbing many times their own weight in water or saline.

“They offer greater strength and integrity due to the nature of mechanical bonding (needling) and thermal bonding used during manufacture and they are generally less dense than other SAF fabrics – but still offer the same great levels of absorption,” says Dr. Mark Paterson, product development director, Technical Absorbents.

SAF long staple fiber grades – usually 52mm fibers – are typically blended with other synthetic fibers to manufacture superabsorbent SAF needlepunch fabrics. Due to the fact that SAF is a fiber, it can be mixed and fully integrated with other fibers, Dr. Paterson explains. This results in highly homogeneous fabrics that provide consistent levels of absorption throughout – with minimal dusting or SAF loss. It is also possible to laminate SAF needlepunch fabrics with other materials to build in additional functionality to meet the applications requirements.

SAF needlepunch fabrics are appropriate for a range of applications including filtration, medical, hygiene, transportation and packaging.

In new product news, last year Technical Absorbents launched a range of washable SAF needlefelt fabrics. Dr. Paterson says the new range has been received extremely positively in a number of applications that require reusability and durability. The washable feminine hygiene sector is one example.

SAF washable fabrics provide the same high levels of absorbency as SAF disposable fabrics but can be washed and re-used. Such fabrics are ideal for a wide range of moisture management applications, including intimate apparel and bed mats. The fabrics can also be used for evaporative cooling and even some medical cooling applications such as medicine storage.

To withstand laundering, the SAF washable fabric must be positioned between two outer layers, thus creating a three-layer fabric. Once in a final fabric construction, studies have indicated minimal absorbency loss of 20% after 40 wash cycles. If constructed correctly, end garments/products made using these fabrics can be tumble dried.

Technical Absorbents also launched a range of fabrics that include a High Gel Strength (HGS) SAF. Such fabrics provide a higher tensile gel strength when wetted and are ideal for applications that require an even more robust superabsorbent fabric. All SAF needlepunch fabrics can now be manufactured with HGS SAF if required.

“With regards SAF needlepunch fabrics, the washable fabrics are receiving phenomenal interest,” Dr. Paterson says. “The ongoing conversations around the use of single use plastics has resulted in many hygiene companies looking to develop more sustainable feminine hygiene and incontinence products. Absorption performance is still a required function and hence SAF fabrics are ideal for such applications.”

There are also a number of ongoing developments with the HGS fabrics in some existing and new application areas, according to Technical Absorbents. SAF needlepunch fabrics also continue to be used within the medical market in advanced wound care products and for filtration applications where there is a need to remove water from oils and fuels.

Lydall Develops Needlepunch Business

Over the course of the last five years, Lydall has been developing its global nonwoven footprint and capabilities to be able to offer innovative solutions answering specific customer needs in a wide field of applications. In relation to its needlepunch business, Lydall’s Technical Nonwovens segment has benefited from the Texel and Gutsche businesses, which were acquired in 2016.

As a specialist in needlepunched nonwoven technologies, Lydall is constantly looking at new opportunities for nonwovens applications in all sorts of industries, the company says.

Even though the nonwoven and specifically needlepunching technologies have evolved constantly in many ways during the last 30 years, the company believes that these technologies still have a lot more to offer in the coming years with new product developments pushed by the macro trends on ecology, low cost manufacturing initiatives and higher product performance requirements. The specific regional economic development will also impact the type of products and regional markets where nonwovens will see growth, Lydall says.

Dalco: Made in the USA

Dalco Nonwovens of Conover, NC, manufactures needlepunched materials for automotives, geotextiles, industrial/construction applications and more.

Growth in the needlepunch market, according to Dalco, is being driven by two items – acoustics and energy savings. “With the city’s infrastructure requiring multiple-family high-rises and the automotive world steering to EV’s, acoustics is the need,” says Gale Shipley, automotive sales manager, Dalco Nonwovens. “In construction, sound dampening and insulative properties, in flooring and walls, is essential. In EV’s, sound mitigation into the interior of the vehicle is essential for a pleasurable drive for the occupants. Energy-wise, most all vehicles are seeing the installation of underbody shields to eliminate air drag thus improving energy efficiencies whether EV or gasoline fueled.”

Shipley says needlepunch nonwovens are ideal for these market segments due to their ability to be readily adaptable for each application. “Changing fiber deniers or blends, changing weights, and many other manufacturing parameters can be modified quickly to provide resolution to any application.”

Supplier Point of View

Suppliers of needlepunch machinery are optimistic about growth in the market and continue to develop new technologies for customers all over the world.

According to Autefa Solutions, a major supplier of needlepunch lines, the major advantage of needlepunch technology versus other web forming technologies is the broad application base in which needlepunch technology can be used. Needlepunching lines distinguish themselves by easy operation, less energy consumptions/gms, excellent and reproducible product quality with reduced operation costs. The broad raw material base including natural fibers is in anticipation of increased raw material prices in the chemical fiber business an additional argument for using carding/needling technology. Adding to its attractiveness is the fact that needlepunch carries with it a relatively lower investment. This makes it easier to determine the risk in investing in the development of new products based on needlepunch technology in an era when manufacturers are more cost conservative, the company says. As a full line supplier, Autefa offers a wide product range for the nonwovens sector, including fiber preparation, carding, needling, thermobonding, hydroentanglement, drying and end-of-line equipment.

Needle looms from Autefa’s Stylus product family can process all fiber types. High-speed and an improved quality have been set as key targets by customers. The needle looms are designed to suit the required output and speed by adjusting the number of the drive modules. A dust extraction system is available and recommended when processing recycled and natural fibers, glass and short fibers, and carbon and mineral fibers.

According to the company, sustainability is a huge topic worldwide. Customers are using replacement fibers like recycled PET fibers, carbon fibers, reclaimed fibers as well as various natural fibers. In the construction and automotive market, recycled materials for efficient thermal and acoustic insulation are key factors that contribute to energy saving and to the reduction of natural resources consumption.

A key target for customers, according to Autefa, is an improved and even surface quality. Therefore, for needlepunched nonwovens products, Autefa offers the service of a customized needle board pattern. The i-Point needling simulation tool increases the capacity and the quality of needlepunched fabrics. The development of new needle patterns and the evaluation of surface quality is much more effective and economic with the i-Point software technology, the company claims. It creates a layout of stripper and bed plate including the elliptic needling (Variliptic). This customized design of needle pattern, which takes also draft and shrinkage into consideration, reduces the process optimization time on customer site.

“I like to point out that several new needle patterns were developed with i-Point and launched into the market,” says André Imhof, CEO of Autefa Solutions. “The latest development was designed for a high needle density for faster production speed with almost no needle marks on the felt surface.”

There is a general trend for light weight fabrics, reaching the same product properties with less material. “Our customers require machines and lines that are able to produce light weight fabrics without any compromises regarding material strength,” Imhof explains. “With the improved fine opener, the opening of the fibers is more flexible and suitable for any fibers that the market is proposing. Autefa Solutions opening line for low melt fibers allows customers to have the same mechanical and rigidness characteristics with less percentage of those kind of expensive fibers.”

For its part, Andritz Nonwoven covers all fields of needlepunch technology, supplying cost-efficient, flexible and reliable needlepunch production lines on a turnkey basis and state-of-the-art machinery. Its eXcelle, aXcess and hybrid ranges enable the supplier to meet all market needs.

To help nonwovens producers make the right investment decision, the company has developed the neXmatrix simulation tool. Andritz uses this tool to compare different possible line set-ups and find the best possible solution to identify and meet the customer’s requirements. By using this approach, Andritz can compile a proposal that matches the customer’s business plan. “New, innovative and proven equipment can then be installed and also up and running in a short space of time, offering greater potential for high productivity right from the outset,” says Dumon. “This method ensures that Andritz provides the appropriate range of equipment with the innovations necessary to optimize the customer’s investment by producing the most viable volume of a consistent, high-quality product in a cost-effective and efficient way.”

In terms of new technologies, Andritz’s new PA3000 pre-needleloom responds to customer demands for lighter-weight fabrics with perfect surface evenness. This new design is faster and wider than existing cylinder pre-needlers to match the carding production capacity and hence secure a good return on investment for the entire production line. There is no draft during pre-needling and absolutely no friction between the fiber mat and the cylinders.

The supplier’s new ProWin system further improves profile weight correction. It combines Andritz’s well-known technologies ProWid and ProDyn, enabling even better performance at higher production speeds. With this combination, customers have an even more homogeneous web and can reduce the input of raw materials. ProWin minimizes the level of instantaneous acceleration as well as the maximum internal speeds. As a result, the same machine can run faster with less mechanical stress.

Recent ProDyn installations can be upgraded with ProWin.

Meanwhile, smart IIoT solutions developed in-house by Andritz are available under the Metris brand. Metris features are tailored to the producers’ needs and help them to achieve their goals in terms of productivity and sustainability. “One of the main pillars of Metris is predictive maintenance. It allows needlepunch producers to substantially improve the uptime of their Andritz line,” Dumon says.

In the needlepunch market, Andritz is seeing increasing use of low-melt fibers, replacing the chemical binders that make the products difficult to recycle. Dumon says these fibers are being used more and more in filtration, automotive and building industry applications.

“One of the most dynamic markets for needlepunch technology is the automotive industry, where there is an increasing need for both lightweight and heavier products to insulate against external noise, which has become more noticeable with the trend towards electrically powered vehicles,” he adds.

To respond to this market need, Andritz is offering its innovative Random Velours needleloom (SDV), which is based on a patented, angled brush alignment to prevent fabric defects. “The inline velouring process is becoming more and more popular, delivering savings on raw materials and handling costs as well as increasing efficiency.

Complete lines are then designed to make optimum use of each machine’s production capacity,” he continues.

There is also a growing market demand for the production of light needlefelts at high linear speed. The solution comes from the global process approach by Andritz. “To be highly competitive in this world, dedicated production lines are a must,” he concludes.

“Today, needlepunch is the second-largest market segment in terms of capacity after the spunbond process segment. It is a continuously growing market,” says Jean-Philippe Dumon, sales director, Nonwoven, of machinery supplier Andritz Asselin-Thibeau.

The technology, which offers a lower start-up investment compared to other technologies, allows manufacturers to achieve several goals with just one line. Needlepunched nonwovens can be made in a wide range of weights and can be developed from an equally wide range of staple fibers, both natural and synthetic.

“Needlepunch technology is a very versatile technology,” says Freudenberg Performance Materials CTO John McNabb. “It’s relatively cost-effective, and it has really advanced in the past 15 years to make more uniform and lighter weight products. We can run different polymers, different types of fibers, so it’s very flexible.”

Freudenberg strengthened its needlepunch business late last year when it acquired Filc, a Slovenian manufacturer of needlepunch nonwovens and laminated materials. Headquartered in Škofja Loka, Slovenia, Filc also operates two production sites in Mengeš and Lendava, Slovenia, as well as a sales office in Dayton, OH.

“Geographically the acquisition of Filc was very important to us because it gave us a strong needlepunch presence in Europe,” McNabb comments. “Technology wise they’re well-known in the industry, whether it’s automotive or construction with the Dripstop product. They have new, very efficient lines, with good products, and they really filled this white spot that we had in Europe of needing more needlepunch technology.”

Freudenberg has been in the needlepunch business for a long time with its automotive headliners, which are needlepunched around the world. The company’s needlepunch technology is also used in the filtration market, as well as in construction, where it supplies staple fiber and spunbond products with glass reinforcement. In addition to the acquired Slovenian sites, Freudenberg Performance Materials’ needlepunch assets are in the U.S., China and Japan. The company’s partner Japan Vilene Company runs needlepunch lines in Mexico and South Korea.

Freudenberg expects to see growth for the technology, especially in the automotive and construction markets. “In automotive, the trend towards a lighter weight system, and moving away from heavier plastic parts to a lighter weight nonwoven, has happened and continues,” McNabb says.

More nonwovens will be used both in current vehicles with normal internal combustion engines to light weight the vehicles for better gas mileage, as well as in new mobility, such as electric vehicles or for fuel cell vehicles in the future. “Those will have a high requirement for sound absorbing materials and insulating products, and that’s where the needlepunch technology is quite effective,” he adds.

Meanwhile, in construction there’s a need for needlepunch because of its cost-effectiveness, it can run different types of staple fibers and it delivers strength in tensile and elongation properties that are needed, he says.

BontexGeo Debuts

Last year Low & Bonar sold its needlepunched nonwovens business (NPNW) to Nimbus, a Netherlands-based private equity fund. The disposal included the sale of the entire issued share capital of Low & Bonar NV and Low & Bonar Kft, which are based in Belgium and Hungary, respectively.

Low & Bonar said this move allowed it to reduce its net debt levels and invest in more profitable parts of its business. Previously, the company sold its Construction Fibres business, comprising the other part of its Civil Engineering division, to Adfil NV and Industria BV. NPNW’s management team and employees transferred with the business, and in October, it was renamed BontexGeo.

The last major expansion in capacity took place in 2016, according to Kenny De Wolf, product and marketing manager, BontexGeo. This allowed the division to explore new opportunities to fill this additional capacity. “Currently investments are being done in technical upgrades of our production facilities to make sure they are future-proof,” he adds. “Some new developments are in the pipeline and will be launched in due time.”

From BontexGeo’s point of view, the main driver of growth for needlepunched material is infrastructure projects ranging from rehabilitation of existing infrastructure to the establishment of new roads and railways. “For such projects, we see some variances in countries where there is dependence on EU support programs, but in general this is a stable market,” De Wolf says. “An important driver for the use of needlepunched nonwoven geotextile in infrastructure projects is the lowered environmental impact when designing with geotextiles compared to the ‘traditional’ design methods.”

While the market is stable, De Wolf says there is a threat of overcapacity in the market. “The will and need to anticipate likely future changes in climate and global population could have a positive impact on the market,” he says.

Technical Absorbents Expands SAF Needlepunch

Technical Absorbents, inventor of Super Absorbent Fibre (SAF), develops superabsorbent needlepunch fabrics containing up to 100% SAF that can be produced in a variety of thicknesses and weights, typically from 150 to 1,000 gsm. SAF needlepunch is capable of absorbing many times their own weight in water or saline.

“They offer greater strength and integrity due to the nature of mechanical bonding (needling) and thermal bonding used during manufacture and they are generally less dense than other SAF fabrics – but still offer the same great levels of absorption,” says Dr. Mark Paterson, product development director, Technical Absorbents.

SAF long staple fiber grades – usually 52mm fibers – are typically blended with other synthetic fibers to manufacture superabsorbent SAF needlepunch fabrics. Due to the fact that SAF is a fiber, it can be mixed and fully integrated with other fibers, Dr. Paterson explains. This results in highly homogeneous fabrics that provide consistent levels of absorption throughout – with minimal dusting or SAF loss. It is also possible to laminate SAF needlepunch fabrics with other materials to build in additional functionality to meet the applications requirements.

SAF needlepunch fabrics are appropriate for a range of applications including filtration, medical, hygiene, transportation and packaging.

In new product news, last year Technical Absorbents launched a range of washable SAF needlefelt fabrics. Dr. Paterson says the new range has been received extremely positively in a number of applications that require reusability and durability. The washable feminine hygiene sector is one example.

SAF washable fabrics provide the same high levels of absorbency as SAF disposable fabrics but can be washed and re-used. Such fabrics are ideal for a wide range of moisture management applications, including intimate apparel and bed mats. The fabrics can also be used for evaporative cooling and even some medical cooling applications such as medicine storage.

To withstand laundering, the SAF washable fabric must be positioned between two outer layers, thus creating a three-layer fabric. Once in a final fabric construction, studies have indicated minimal absorbency loss of 20% after 40 wash cycles. If constructed correctly, end garments/products made using these fabrics can be tumble dried.

Technical Absorbents also launched a range of fabrics that include a High Gel Strength (HGS) SAF. Such fabrics provide a higher tensile gel strength when wetted and are ideal for applications that require an even more robust superabsorbent fabric. All SAF needlepunch fabrics can now be manufactured with HGS SAF if required.

“With regards SAF needlepunch fabrics, the washable fabrics are receiving phenomenal interest,” Dr. Paterson says. “The ongoing conversations around the use of single use plastics has resulted in many hygiene companies looking to develop more sustainable feminine hygiene and incontinence products. Absorption performance is still a required function and hence SAF fabrics are ideal for such applications.”

There are also a number of ongoing developments with the HGS fabrics in some existing and new application areas, according to Technical Absorbents. SAF needlepunch fabrics also continue to be used within the medical market in advanced wound care products and for filtration applications where there is a need to remove water from oils and fuels.

Lydall Develops Needlepunch Business

Over the course of the last five years, Lydall has been developing its global nonwoven footprint and capabilities to be able to offer innovative solutions answering specific customer needs in a wide field of applications. In relation to its needlepunch business, Lydall’s Technical Nonwovens segment has benefited from the Texel and Gutsche businesses, which were acquired in 2016.

As a specialist in needlepunched nonwoven technologies, Lydall is constantly looking at new opportunities for nonwovens applications in all sorts of industries, the company says.

Even though the nonwoven and specifically needlepunching technologies have evolved constantly in many ways during the last 30 years, the company believes that these technologies still have a lot more to offer in the coming years with new product developments pushed by the macro trends on ecology, low cost manufacturing initiatives and higher product performance requirements. The specific regional economic development will also impact the type of products and regional markets where nonwovens will see growth, Lydall says.

Dalco: Made in the USA

Dalco Nonwovens of Conover, NC, manufactures needlepunched materials for automotives, geotextiles, industrial/construction applications and more.

Growth in the needlepunch market, according to Dalco, is being driven by two items – acoustics and energy savings. “With the city’s infrastructure requiring multiple-family high-rises and the automotive world steering to EV’s, acoustics is the need,” says Gale Shipley, automotive sales manager, Dalco Nonwovens. “In construction, sound dampening and insulative properties, in flooring and walls, is essential. In EV’s, sound mitigation into the interior of the vehicle is essential for a pleasurable drive for the occupants. Energy-wise, most all vehicles are seeing the installation of underbody shields to eliminate air drag thus improving energy efficiencies whether EV or gasoline fueled.”

Shipley says needlepunch nonwovens are ideal for these market segments due to their ability to be readily adaptable for each application. “Changing fiber deniers or blends, changing weights, and many other manufacturing parameters can be modified quickly to provide resolution to any application.”

Supplier Point of View

Suppliers of needlepunch machinery are optimistic about growth in the market and continue to develop new technologies for customers all over the world.

According to Autefa Solutions, a major supplier of needlepunch lines, the major advantage of needlepunch technology versus other web forming technologies is the broad application base in which needlepunch technology can be used. Needlepunching lines distinguish themselves by easy operation, less energy consumptions/gms, excellent and reproducible product quality with reduced operation costs. The broad raw material base including natural fibers is in anticipation of increased raw material prices in the chemical fiber business an additional argument for using carding/needling technology. Adding to its attractiveness is the fact that needlepunch carries with it a relatively lower investment. This makes it easier to determine the risk in investing in the development of new products based on needlepunch technology in an era when manufacturers are more cost conservative, the company says. As a full line supplier, Autefa offers a wide product range for the nonwovens sector, including fiber preparation, carding, needling, thermobonding, hydroentanglement, drying and end-of-line equipment.

Needle looms from Autefa’s Stylus product family can process all fiber types. High-speed and an improved quality have been set as key targets by customers. The needle looms are designed to suit the required output and speed by adjusting the number of the drive modules. A dust extraction system is available and recommended when processing recycled and natural fibers, glass and short fibers, and carbon and mineral fibers.

According to the company, sustainability is a huge topic worldwide. Customers are using replacement fibers like recycled PET fibers, carbon fibers, reclaimed fibers as well as various natural fibers. In the construction and automotive market, recycled materials for efficient thermal and acoustic insulation are key factors that contribute to energy saving and to the reduction of natural resources consumption.

A key target for customers, according to Autefa, is an improved and even surface quality. Therefore, for needlepunched nonwovens products, Autefa offers the service of a customized needle board pattern. The i-Point needling simulation tool increases the capacity and the quality of needlepunched fabrics. The development of new needle patterns and the evaluation of surface quality is much more effective and economic with the i-Point software technology, the company claims. It creates a layout of stripper and bed plate including the elliptic needling (Variliptic). This customized design of needle pattern, which takes also draft and shrinkage into consideration, reduces the process optimization time on customer site.

“I like to point out that several new needle patterns were developed with i-Point and launched into the market,” says André Imhof, CEO of Autefa Solutions. “The latest development was designed for a high needle density for faster production speed with almost no needle marks on the felt surface.”

There is a general trend for light weight fabrics, reaching the same product properties with less material. “Our customers require machines and lines that are able to produce light weight fabrics without any compromises regarding material strength,” Imhof explains. “With the improved fine opener, the opening of the fibers is more flexible and suitable for any fibers that the market is proposing. Autefa Solutions opening line for low melt fibers allows customers to have the same mechanical and rigidness characteristics with less percentage of those kind of expensive fibers.”

For its part, Andritz Nonwoven covers all fields of needlepunch technology, supplying cost-efficient, flexible and reliable needlepunch production lines on a turnkey basis and state-of-the-art machinery. Its eXcelle, aXcess and hybrid ranges enable the supplier to meet all market needs.

To help nonwovens producers make the right investment decision, the company has developed the neXmatrix simulation tool. Andritz uses this tool to compare different possible line set-ups and find the best possible solution to identify and meet the customer’s requirements. By using this approach, Andritz can compile a proposal that matches the customer’s business plan. “New, innovative and proven equipment can then be installed and also up and running in a short space of time, offering greater potential for high productivity right from the outset,” says Dumon. “This method ensures that Andritz provides the appropriate range of equipment with the innovations necessary to optimize the customer’s investment by producing the most viable volume of a consistent, high-quality product in a cost-effective and efficient way.”

In terms of new technologies, Andritz’s new PA3000 pre-needleloom responds to customer demands for lighter-weight fabrics with perfect surface evenness. This new design is faster and wider than existing cylinder pre-needlers to match the carding production capacity and hence secure a good return on investment for the entire production line. There is no draft during pre-needling and absolutely no friction between the fiber mat and the cylinders.

The supplier’s new ProWin system further improves profile weight correction. It combines Andritz’s well-known technologies ProWid and ProDyn, enabling even better performance at higher production speeds. With this combination, customers have an even more homogeneous web and can reduce the input of raw materials. ProWin minimizes the level of instantaneous acceleration as well as the maximum internal speeds. As a result, the same machine can run faster with less mechanical stress.

Recent ProDyn installations can be upgraded with ProWin.

Meanwhile, smart IIoT solutions developed in-house by Andritz are available under the Metris brand. Metris features are tailored to the producers’ needs and help them to achieve their goals in terms of productivity and sustainability. “One of the main pillars of Metris is predictive maintenance. It allows needlepunch producers to substantially improve the uptime of their Andritz line,” Dumon says.

In the needlepunch market, Andritz is seeing increasing use of low-melt fibers, replacing the chemical binders that make the products difficult to recycle. Dumon says these fibers are being used more and more in filtration, automotive and building industry applications.

“One of the most dynamic markets for needlepunch technology is the automotive industry, where there is an increasing need for both lightweight and heavier products to insulate against external noise, which has become more noticeable with the trend towards electrically powered vehicles,” he adds.

To respond to this market need, Andritz is offering its innovative Random Velours needleloom (SDV), which is based on a patented, angled brush alignment to prevent fabric defects. “The inline velouring process is becoming more and more popular, delivering savings on raw materials and handling costs as well as increasing efficiency.

Complete lines are then designed to make optimum use of each machine’s production capacity,” he continues.

There is also a growing market demand for the production of light needlefelts at high linear speed. The solution comes from the global process approach by Andritz. “To be highly competitive in this world, dedicated production lines are a must,” he concludes.