09.20.19

Until 2013 wet-laid/spunlaced materials, or WLS as Voith and Truetzschler call the process, were only a tiny niche product. This changed when joining this technology with a new application – true flushable wipes entered the scene. Meanwhile, these moist toilet tissues take up several meters of shelf space in the respective departments and drugstores.

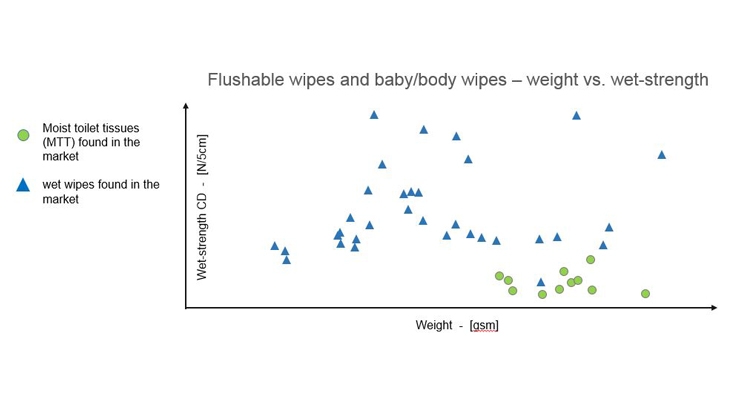

But the market for moist toilet wipes is limited – in contrast to the huge demand for single-use baby, personal care and household wipes. The trick of making flushable wipes is to lower the nonwoven’s wet strength so it disperses in agitated water. Picture 1 shows the different characteristics of both nonwoven-based flushable and wet wipes.

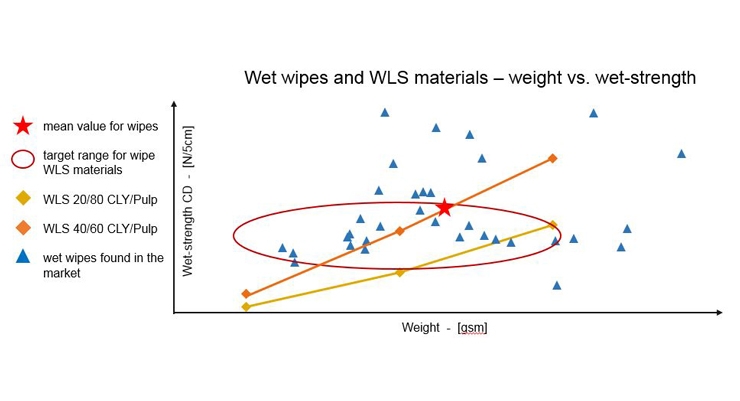

With the AquaJet, Truetzschler’s spunlacing unit, it’s easy to adapt the web bonding process to produce higher-strength, yet soft nonwovens too. So some two years ago Voith-Truetzschler started trials on making higher-strength wet-laid/spunlaced nonwovens which could compete with conventional baby and personal care wipes found in the market. The outcome are our “nextLevel wipes” which are similar to existing products – both in terms of wet strength and weight.

But besides being just another wet wipe they also are an approach to today’s wet wipes dilemma: single-use wipes are hygienic, convenient and affordable – who really wants to do without them? But doesn’t fit the mega-trend sustainability. Even more so because the majority of today’s products contain polyester or polypropylene fibers. Which disintegrate into tiny particles, so-called micro plastics, when the wipe is disposed of carelessly.

nextLevel wipes in contrast are made from only pulp and lyocell fibers. The material is fully biodegradable, no micro plastics and no chemical binders remain after use. The fibers come from renewable resources since both “wood” pulp and lyocell fibers are derived from fast growing, regenerative trees.

In other aspects, wet strength and softness for instance, the new wipes match commercially available products. There is no paper-like or flimsy feeling consumers could disapprove of. The pulp/lyocell fiber blend can be adapted to the requirements of the end product. A voluminous, top-quality wipe could have another fiber blend and weight as a nonwoven for a standard-quality product.

And there is another big advantage: “wood” pulp is significantly cheaper than man-made fibers. So cost-wise, a nextLevel wipe can compete with wet wipes available on the market today. The time is ripe to take wipes to a new level!

But the market for moist toilet wipes is limited – in contrast to the huge demand for single-use baby, personal care and household wipes. The trick of making flushable wipes is to lower the nonwoven’s wet strength so it disperses in agitated water. Picture 1 shows the different characteristics of both nonwoven-based flushable and wet wipes.

With the AquaJet, Truetzschler’s spunlacing unit, it’s easy to adapt the web bonding process to produce higher-strength, yet soft nonwovens too. So some two years ago Voith-Truetzschler started trials on making higher-strength wet-laid/spunlaced nonwovens which could compete with conventional baby and personal care wipes found in the market. The outcome are our “nextLevel wipes” which are similar to existing products – both in terms of wet strength and weight.

But besides being just another wet wipe they also are an approach to today’s wet wipes dilemma: single-use wipes are hygienic, convenient and affordable – who really wants to do without them? But doesn’t fit the mega-trend sustainability. Even more so because the majority of today’s products contain polyester or polypropylene fibers. Which disintegrate into tiny particles, so-called micro plastics, when the wipe is disposed of carelessly.

nextLevel wipes in contrast are made from only pulp and lyocell fibers. The material is fully biodegradable, no micro plastics and no chemical binders remain after use. The fibers come from renewable resources since both “wood” pulp and lyocell fibers are derived from fast growing, regenerative trees.

In other aspects, wet strength and softness for instance, the new wipes match commercially available products. There is no paper-like or flimsy feeling consumers could disapprove of. The pulp/lyocell fiber blend can be adapted to the requirements of the end product. A voluminous, top-quality wipe could have another fiber blend and weight as a nonwoven for a standard-quality product.

And there is another big advantage: “wood” pulp is significantly cheaper than man-made fibers. So cost-wise, a nextLevel wipe can compete with wet wipes available on the market today. The time is ripe to take wipes to a new level!