03.15.19

Vicki A. Barbur Ph.D., Senior Director, IP and Technology Commercialization, Battelle

Amy M. Heintz Ph.D., Technical Fellow, Materials Science, Battelle

Nonwoven materials are increasingly popular for both consumer and industrial applications, from hospital gowns to heavy-duty construction materials. How many of these nonwoven products could benefit from a lightweight, integrated heat source?

Carbon nanotube (CNT) coatings are lightweight, conductive and can be applied in a thin layer that does not interfere with the performance characteristics of nonwoven materials. A new heater coating system from Battelle brings the benefits of CNT technology to the nonwoven materials industry.

The Rise of Intelligent Nonwovens

“Smart” or “functional” nonwoven materials are gaining ground across several industries. These high-tech nonwovens incorporate smart coatings or interior layers that provide added functionality such as conductivity, sensor capabilities or antimicrobial characteristics.

Smart nonwovens combine the advantages of nonwoven materials with the functional characteristics of smart coatings and laminates. Nonwovens are an attractive alternative for many applications due to their high strength and durability and relatively low manufacturing costs compared to woven textiles. These characteristics have made nonwovens a popular choice for a wide variety of products, including materials used in the medical, personal care, transportation, home goods and construction sectors.

Nonwovens themselves can be made from a broad range of base materials, including both natural starches and synthetic or oil-based filaments, which are bonded using heat or resin to form polymeric meshes. Some may be created using a blend of base materials, which can include microfibers or nanofibers. Other nonwovens may be manufactured with both a core and a shell, each made using a different blend of base materials. Depending on the materials and manufacturing processes used, nonwovens can be created to deliver specific performance characteristics such as absorbency, liquid repellence, flame retardance, stretch, softness, insulation or filtration capabilities.

Adding a functional coating to a nonwoven material retains some or all of the initial performance characteristics of the nonwoven, while adding new functionality. Smart coatings can be created using resins, polymers and high-tech materials such as carbon nanotubes that can deliver unique functionality. The resulting coated nonwoven fabric will have combined properties that cannot be offered by either component individually. The base nonwoven fabric provides the tear and tensile strength, elongation and dimensional stability of the composite material and supports the layer of coating applied to it. The coating controls the chemical properties and features such as abrasion resistance and resistance to penetration by liquids and gases. By carefully selecting the combination of base fabric and functional coating, manufacturers can produce intelligent fabrics with many different possible combinations of desirable performance characteristics. In general, properties that can be altered using a coating include general fabric properties, appearance and aesthetics, and barrier properties. Smart coatings offer a broader range of performance characteristics, including conductivity, bacterial resistance or sensing capabilities.

Smart coated nonwoven materials are already creating new market opportunities in several markets. For example, antimicrobial properties could be added to disposable hospital gowns and other medical and personal care products. Moisture-sensing nonwoven materials have potential applications for construction and building materials as well as agricultural and environmental purposes. Heated nonwoven materials likewise have potential market opportunities in a variety of industries, including medical, transportation, construction, marine and military.

Creating Coated Nonwoven Fabrics

Coated fabrics are created by combining two or more layers into a composite material. The Textile Institute has two definitions of a coated fabric. The first is “a material composed of two or more layers, at least one of which is a textile fabric, and at least one of which is a substantially continuous polymeric layer. The layers are bonded closely together by means of an added adhesive or by the adhesive properties of one or more of the component-layers.” The second definition is “a textile fabric on which there has been formed in situ, on one or both surfaces, a layer or layers of adherent coating material.” They define a laminated fabric (or bonded fabric) as “a material composed of two or more layers, at least one of which is a textile fabric, bonded closely together by means of an added adhesive, or by the adhesive properties of one or more of the component layers.” While nonwovens are not considered textiles, they can be similarly coated or laminated to create composite materials.

Coated or laminated nonwoven fabrics can be created using a variety of methods, including knife coating, transfer, Zimmer coating, roll-to roll and spray coating. All of these processes share the same basic steps: feeding the textile material from rolls under tension to a coating zone where the coating is applied, heating the coated fabric to cure or gel the coating and volatize the solvents, cooling the coated fabric, and finally winding it into rolls.

For smart coated fabrics, the quality of the base fabric is critical. The purity and physical properties of materials used in the coating and the process sequence of the coating technology are also important factors to consider when creating a high-performance nonwoven coated fabric. The process used to deposit and bond the coating to the nonwoven must be carefully considered to ensure that the final product delivers the performance characteristics desired.

HeatCoat Technology: A Heated Coating for Flexible and Irregular Surfaces

Battelle has created a smart conductive coating that can be used on nonwoven fabrics and other flexible or irregular substrates. Battelle’s HeatCoat technology offers a unique blend of performance characteristics that can be used to create nonwoven fabrics that generate even, gentle warming without negatively impacting the properties of the fabric itself.

While there are many potential applications for heated or conductive fabrics, most conductive coatings are not ideal for use on soft, irregular or flexible substrates. Heater coatings are most commonly used on rigid substrates. Existing technologies do not allow for bending and flexing with a flexible substrate such as a nonwoven fabric, either losing conductivity during the bend, changing the surface properties to make the substrate more rigid, or both.

For this reason, most heated fabric technologies, including heating for nonwoven materials, rely on methods such as integrating wires between layers of fabric that generate heat when electricity is applied. Wires add weight and bulk, impact the drape of the material and are vulnerable to breakage. They also result in hot spots and uneven warming.

Gentler and more even warming can be achieved by pumping heated air in between layers of fabric, a method sometimes used for patient warming during surgery. This solves the hot spot problem and provides consistent warmth, but adds bulk and reduces the flexibility and drapability of the fabric. Forced air systems also require considerable power and must be hooked up to a fan, which limits the environments in which their use is practical.

Other products, such as home health products or consumer goods, may use a layer of gel in between the fabric layers that can be heated in an oven or microwave. These products provide an even layer of heat, but are very heavy and bulky. The gel layer also cools down quickly, often becoming too hot when initially warmed but rapidly losing heat once the product is removed from the warming source. Some products use chemicals that react to produce heat when a barrier between them is broken. These products retain their heat longer but are single use only and have the same drawbacks in terms of weight and bulk, with additional consumer risks due to the chemicals involved.

Battelle’s HeatCoat technology uses an entirely different approach. The coating consists of a formulation of dispersed single walled carbon nanotubes. When applied to the nonwoven fabric, it forms a thin conductive layer that generates heat when power is applied. The CNT coating is applied in a very thin layer that does not change the flexibility or drape of the fabric it is applied to and does not add unwanted weight or bulk to the final product. The HeatCoat technology maintains conductivity even when bent and delivers uniform, predictable heat on soft, flexible and irregular substrates. It offers several advantages over traditional heater coating solutions (see Table 1).

Power Budget Limited? HeatCoat technology is applied directly to the substrate. Combined with a closed loop temperature control and low resistance electrical interfaces, HeatCoat technology delivers only the heat needed, minimizing the power required

Flexibility or Repeated Bending Needed? HeatCoat technology is flexible and maintains conductivity during bend. When applied to even the most flexible substrates like memory foam or fabric, it does not affect durometer and moves with the substrate.

Soft or irregular surface? HeatCoat technology can be applied to nonwovens using a variety of methods, including knife coating, transfer, Zimmer coating, roll-to roll and spray coating. Once applied, it provides good thermal contact even on flexible or irregular surfaces, which prevents hot spots.

Thermally Sensitive Substrate? HeatCoat technology delivers power to the surface, allowing precise control of the temperature profile and eliminating unintentional overheating of the substrate or underlying objects. This makes it safe for use in fabrics that will come in contact with people and in other temperature-sensitive applications.

Optical, NIR, or Radar Transparency Needed? HeatCoat technology can be formulated as a transparent conductor and has no effect on RF communications.

Battelle developed and optimized the coating over more than a decade of internally-funded research into CNT coatings. Through these efforts, Battelle has optimized the properties, stability, manufacturing, integration and sustainment of CNT coatings and their products. HeatCoat technology incorporates design elements that enhance thermal uniformity, reduce wasted power, and enable zonal-control of separate heaters by closed loop feedback. These design elements can be incorporated as needed to create a spectrum of products from low-cost, flexible heaters for consumer applications to sophisticated, purpose-engineered heaters for use in aviation or industrial applications.

HeatCoat technology has already been proven in the aviation industry for anti-icing and de-icing for aircraft and drones. Applying the technology to nonwovens opens up possibilities for many new applications for medical, consumer, industrial and military use. The technology has been demonstrated in several nonwoven applications, including a fabric warming system for thermoregulation therapy and a durable fiberglass mat suitable for wind turbine or proprotor anti-icing or de-icing.

How HeatCoat Technology Works

HeatCoat technology is an integrated heater coating system based on CNT coatings. A resistive heater is created by passing current through a conductor. At fixed voltage, the heat generated is determined by Joule’s law and depends on the square of the applied voltage and the inverse of the heater’s resistance; low resistance is a requirement for resistive heaters. The high conductivity/low resistivity of CNT coatings means that heat can be generated from extremely thin films, which can be flexible and even transparent.

The CNT coating can be sprayed, painted or roll-to-roll coated onto surfaces. The resulting coating is very thin and conformable, typically no more than 3 µm thick, resulting in a surface that adheres closely to the substrate’s surface characteristics. The coating can be readily spray-applied or printed onto any substrate, including thermally stable and/or sensitive substrates. It can also be patterned into heater zones or arrays, something that is difficult with a carbon veil or similar system.

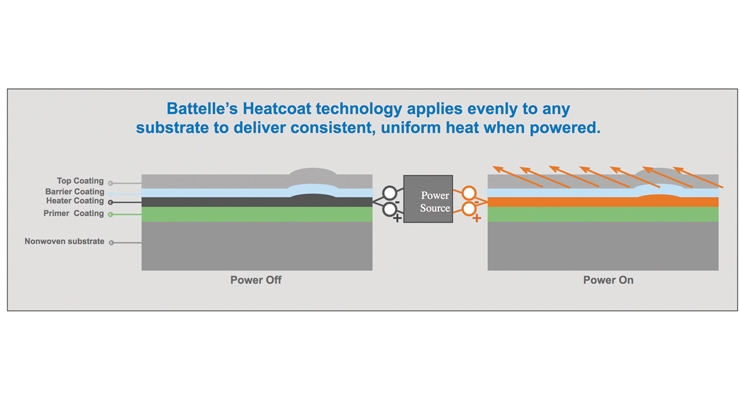

A minimal configuration for the HeatCoat technology systems includes (see Figure 2):

Market Opportunities for Conductive Nonwoven Materials: Heating and Beyond

Nonwoven fabric heaters created using CNT coating technology could be used in a broad range of commercial and industrial applications. These heaters are lighter, thinner and more flexible than existing fabric heater technologies on the market, offering significant advantages for current applications and opening up new possibilities in areas where weight, thickness or conformability requirements have made heating difficult.

Possible applications for HeatCoat technology include:

In Summary

Battelle has been awarded several patents for the technologies used in our HeatCoat technology. Now, the system is ready for the next phase of development. It is highly customizable for a variety of potential nonwoven applications requiring different thermal or conductive properties and price points. Companies interested in exploring licensing or co-development for the HeatCoat system can contact Vicki Barbur, Commercial Business/Battelle at barbur@battelle.org.

Amy M. Heintz Ph.D., Technical Fellow, Materials Science, Battelle

Nonwoven materials are increasingly popular for both consumer and industrial applications, from hospital gowns to heavy-duty construction materials. How many of these nonwoven products could benefit from a lightweight, integrated heat source?

Carbon nanotube (CNT) coatings are lightweight, conductive and can be applied in a thin layer that does not interfere with the performance characteristics of nonwoven materials. A new heater coating system from Battelle brings the benefits of CNT technology to the nonwoven materials industry.

The Rise of Intelligent Nonwovens

“Smart” or “functional” nonwoven materials are gaining ground across several industries. These high-tech nonwovens incorporate smart coatings or interior layers that provide added functionality such as conductivity, sensor capabilities or antimicrobial characteristics.

Smart nonwovens combine the advantages of nonwoven materials with the functional characteristics of smart coatings and laminates. Nonwovens are an attractive alternative for many applications due to their high strength and durability and relatively low manufacturing costs compared to woven textiles. These characteristics have made nonwovens a popular choice for a wide variety of products, including materials used in the medical, personal care, transportation, home goods and construction sectors.

Nonwovens themselves can be made from a broad range of base materials, including both natural starches and synthetic or oil-based filaments, which are bonded using heat or resin to form polymeric meshes. Some may be created using a blend of base materials, which can include microfibers or nanofibers. Other nonwovens may be manufactured with both a core and a shell, each made using a different blend of base materials. Depending on the materials and manufacturing processes used, nonwovens can be created to deliver specific performance characteristics such as absorbency, liquid repellence, flame retardance, stretch, softness, insulation or filtration capabilities.

Adding a functional coating to a nonwoven material retains some or all of the initial performance characteristics of the nonwoven, while adding new functionality. Smart coatings can be created using resins, polymers and high-tech materials such as carbon nanotubes that can deliver unique functionality. The resulting coated nonwoven fabric will have combined properties that cannot be offered by either component individually. The base nonwoven fabric provides the tear and tensile strength, elongation and dimensional stability of the composite material and supports the layer of coating applied to it. The coating controls the chemical properties and features such as abrasion resistance and resistance to penetration by liquids and gases. By carefully selecting the combination of base fabric and functional coating, manufacturers can produce intelligent fabrics with many different possible combinations of desirable performance characteristics. In general, properties that can be altered using a coating include general fabric properties, appearance and aesthetics, and barrier properties. Smart coatings offer a broader range of performance characteristics, including conductivity, bacterial resistance or sensing capabilities.

Smart coated nonwoven materials are already creating new market opportunities in several markets. For example, antimicrobial properties could be added to disposable hospital gowns and other medical and personal care products. Moisture-sensing nonwoven materials have potential applications for construction and building materials as well as agricultural and environmental purposes. Heated nonwoven materials likewise have potential market opportunities in a variety of industries, including medical, transportation, construction, marine and military.

Creating Coated Nonwoven Fabrics

Coated fabrics are created by combining two or more layers into a composite material. The Textile Institute has two definitions of a coated fabric. The first is “a material composed of two or more layers, at least one of which is a textile fabric, and at least one of which is a substantially continuous polymeric layer. The layers are bonded closely together by means of an added adhesive or by the adhesive properties of one or more of the component-layers.” The second definition is “a textile fabric on which there has been formed in situ, on one or both surfaces, a layer or layers of adherent coating material.” They define a laminated fabric (or bonded fabric) as “a material composed of two or more layers, at least one of which is a textile fabric, bonded closely together by means of an added adhesive, or by the adhesive properties of one or more of the component layers.” While nonwovens are not considered textiles, they can be similarly coated or laminated to create composite materials.

Coated or laminated nonwoven fabrics can be created using a variety of methods, including knife coating, transfer, Zimmer coating, roll-to roll and spray coating. All of these processes share the same basic steps: feeding the textile material from rolls under tension to a coating zone where the coating is applied, heating the coated fabric to cure or gel the coating and volatize the solvents, cooling the coated fabric, and finally winding it into rolls.

For smart coated fabrics, the quality of the base fabric is critical. The purity and physical properties of materials used in the coating and the process sequence of the coating technology are also important factors to consider when creating a high-performance nonwoven coated fabric. The process used to deposit and bond the coating to the nonwoven must be carefully considered to ensure that the final product delivers the performance characteristics desired.

HeatCoat Technology: A Heated Coating for Flexible and Irregular Surfaces

Battelle has created a smart conductive coating that can be used on nonwoven fabrics and other flexible or irregular substrates. Battelle’s HeatCoat technology offers a unique blend of performance characteristics that can be used to create nonwoven fabrics that generate even, gentle warming without negatively impacting the properties of the fabric itself.

While there are many potential applications for heated or conductive fabrics, most conductive coatings are not ideal for use on soft, irregular or flexible substrates. Heater coatings are most commonly used on rigid substrates. Existing technologies do not allow for bending and flexing with a flexible substrate such as a nonwoven fabric, either losing conductivity during the bend, changing the surface properties to make the substrate more rigid, or both.

For this reason, most heated fabric technologies, including heating for nonwoven materials, rely on methods such as integrating wires between layers of fabric that generate heat when electricity is applied. Wires add weight and bulk, impact the drape of the material and are vulnerable to breakage. They also result in hot spots and uneven warming.

Gentler and more even warming can be achieved by pumping heated air in between layers of fabric, a method sometimes used for patient warming during surgery. This solves the hot spot problem and provides consistent warmth, but adds bulk and reduces the flexibility and drapability of the fabric. Forced air systems also require considerable power and must be hooked up to a fan, which limits the environments in which their use is practical.

Other products, such as home health products or consumer goods, may use a layer of gel in between the fabric layers that can be heated in an oven or microwave. These products provide an even layer of heat, but are very heavy and bulky. The gel layer also cools down quickly, often becoming too hot when initially warmed but rapidly losing heat once the product is removed from the warming source. Some products use chemicals that react to produce heat when a barrier between them is broken. These products retain their heat longer but are single use only and have the same drawbacks in terms of weight and bulk, with additional consumer risks due to the chemicals involved.

Battelle’s HeatCoat technology uses an entirely different approach. The coating consists of a formulation of dispersed single walled carbon nanotubes. When applied to the nonwoven fabric, it forms a thin conductive layer that generates heat when power is applied. The CNT coating is applied in a very thin layer that does not change the flexibility or drape of the fabric it is applied to and does not add unwanted weight or bulk to the final product. The HeatCoat technology maintains conductivity even when bent and delivers uniform, predictable heat on soft, flexible and irregular substrates. It offers several advantages over traditional heater coating solutions (see Table 1).

Power Budget Limited? HeatCoat technology is applied directly to the substrate. Combined with a closed loop temperature control and low resistance electrical interfaces, HeatCoat technology delivers only the heat needed, minimizing the power required

Flexibility or Repeated Bending Needed? HeatCoat technology is flexible and maintains conductivity during bend. When applied to even the most flexible substrates like memory foam or fabric, it does not affect durometer and moves with the substrate.

Soft or irregular surface? HeatCoat technology can be applied to nonwovens using a variety of methods, including knife coating, transfer, Zimmer coating, roll-to roll and spray coating. Once applied, it provides good thermal contact even on flexible or irregular surfaces, which prevents hot spots.

Thermally Sensitive Substrate? HeatCoat technology delivers power to the surface, allowing precise control of the temperature profile and eliminating unintentional overheating of the substrate or underlying objects. This makes it safe for use in fabrics that will come in contact with people and in other temperature-sensitive applications.

Optical, NIR, or Radar Transparency Needed? HeatCoat technology can be formulated as a transparent conductor and has no effect on RF communications.

Battelle developed and optimized the coating over more than a decade of internally-funded research into CNT coatings. Through these efforts, Battelle has optimized the properties, stability, manufacturing, integration and sustainment of CNT coatings and their products. HeatCoat technology incorporates design elements that enhance thermal uniformity, reduce wasted power, and enable zonal-control of separate heaters by closed loop feedback. These design elements can be incorporated as needed to create a spectrum of products from low-cost, flexible heaters for consumer applications to sophisticated, purpose-engineered heaters for use in aviation or industrial applications.

HeatCoat technology has already been proven in the aviation industry for anti-icing and de-icing for aircraft and drones. Applying the technology to nonwovens opens up possibilities for many new applications for medical, consumer, industrial and military use. The technology has been demonstrated in several nonwoven applications, including a fabric warming system for thermoregulation therapy and a durable fiberglass mat suitable for wind turbine or proprotor anti-icing or de-icing.

How HeatCoat Technology Works

HeatCoat technology is an integrated heater coating system based on CNT coatings. A resistive heater is created by passing current through a conductor. At fixed voltage, the heat generated is determined by Joule’s law and depends on the square of the applied voltage and the inverse of the heater’s resistance; low resistance is a requirement for resistive heaters. The high conductivity/low resistivity of CNT coatings means that heat can be generated from extremely thin films, which can be flexible and even transparent.

The CNT coating can be sprayed, painted or roll-to-roll coated onto surfaces. The resulting coating is very thin and conformable, typically no more than 3 µm thick, resulting in a surface that adheres closely to the substrate’s surface characteristics. The coating can be readily spray-applied or printed onto any substrate, including thermally stable and/or sensitive substrates. It can also be patterned into heater zones or arrays, something that is difficult with a carbon veil or similar system.

A minimal configuration for the HeatCoat technology systems includes (see Figure 2):

- Coating stack-up: heater coating and protective topcoat, often to provide water or dielectric barrier

- Electrical leads that connect the power to the conductive coating

- Power supply and controller

Market Opportunities for Conductive Nonwoven Materials: Heating and Beyond

Nonwoven fabric heaters created using CNT coating technology could be used in a broad range of commercial and industrial applications. These heaters are lighter, thinner and more flexible than existing fabric heater technologies on the market, offering significant advantages for current applications and opening up new possibilities in areas where weight, thickness or conformability requirements have made heating difficult.

Possible applications for HeatCoat technology include:

- Medical: Surgical drapes and patient warming fabrics, surgical clothing for medical personnel working in cold ORs, or wraps for thermoregulation therapy.

- Automotive: Heated seat covers with warming integrated right into the fabric.

- Construction: Heated underlayment for de-icing in roofing, laying concrete and other building applications.

- Agriculture: Heated seed-impregnated fabrics for use in green houses and cold frames.

- Energy: Wind-turbine anti-icing or de-icing or heated insulating materials for wind turbines and other applications.

- While HeatCoat technology has been optimized to deliver heat to the substrates it is applied to, there are many other potential applications for conductive CNT coatings. This is an enabling technology for a whole host of wearable technologies or integrated sensors. For example, integrated sensors could be used to detect and quantify: moisture levels, motion, weight, orientation, light level and vital statistics.

In Summary

Battelle has been awarded several patents for the technologies used in our HeatCoat technology. Now, the system is ready for the next phase of development. It is highly customizable for a variety of potential nonwoven applications requiring different thermal or conductive properties and price points. Companies interested in exploring licensing or co-development for the HeatCoat system can contact Vicki Barbur, Commercial Business/Battelle at barbur@battelle.org.