03.15.19

One product – countless packaging types and sizes: a common practice with today’s paper hygiene products. Incontinence products for men are a relatively new market segment. But here, too, there is already great variety. Ideally, a system should be capable of packaging large and small packs and almost every size in between. And of course, a system needs to master a wide range of product variants, which are equivalent to product formats.

When it comes to packaging sizes, the paper hygiene product manufacturers’ marketing experts know exactly whether consumers prefer to buy products in cartons or plastic bags and precisely how the products should be aligned inside the packaging. The color of the sales packaging is also immensely important in the case of incontinence products for men. Bulk packs for care facilities are a further variant for which there is growing demand. Last but not least, marketing campaigns further increase the range of variants.

On the other side, there is the manufacturing and packaging process that has to map this diversity. Together with the multi-stage packaging process, the converter forms an integrated line with high output. How is it possible to implement this wide range of requirements into highly flexible processes without a loss of performance?

(R)Evolution

An initial user already employed a previous version of the new stacker, it also allowed packaging both in cartons and bags. But the new project represents a major step forward, especially in the form of increased output. Today’s system processes 80 cycles per minute, an increase of around 250% compared to the previous performance.

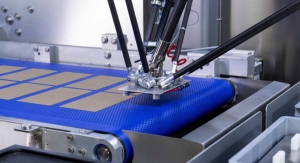

That kind of increase is not possible simply by adjusting a few set screws. One challenge of the new design is that on one side of the stacker, the incontinence products flow in a continuous stream from the converter into the paddle chain. On the opposite side of the stacker, the paddle chain with the product stack (count) needs to be stopped briefly for transfer and transport into the packaging process. The challenge is that there is continuous movement on one side of the stacker and brief stopping of the paddle chain on the other side to allow discharging of the count. This is achieved with the help of a new, improved intermediate storage system within the stacker. The larger this buffer is, the higher the output.

The stacker itself is equipped with two discharges positioned diagonally. They mark the transition points to an Optima OS2 packaging machine for plastic bags or to an Optima CM 180/10 cartoner. The advantage of this diagonal constellation is that it ensures the ‘right’ direction of processing in each case. The bagger receives the products in a linear fashion. In contrast, the products are pushed laterally onto the cartoner, which docks on at a 90-degree angle. This makes an additional change in direction at this point superfluous.

Processing Stability Times Three

The customer also profits from greatly increased processing stability and from an expanded product format range. To achieve this, for the first time, Optima Nonwovens has integrated a height adjustment in the bridging conveyor between the stacker and cartoner. The correct lateral guide can now be quickly set up for each product size. In this way, incontinence products with the current product dimensions (additional formats will be added in the future) are transported onward with high reliability into the next process station.

The stacker is equipped with another new feature at the transition point in the cartoning process; a second compression station has been added after the initial pre-compression process. The second compression process takes place at the end of the bridging conveyor which is shortly before the product stack is pushed into the carton. This also increases tolerances for the product dimensions that can be processed. Incontinence products, in particular, vary greatly in thickness, with a maximum product thickness of 14 mm, tolerances of plus/minus 4 mm are now possible with the new system. This further increases processing stability.

Process reliability has also been clearly increased during cartoning. To do this, the Optima developers have decoupled the process. The carton blanks are extracted, then spread, erected and inserted into the transport system. Previously, this was virtually one continuous procedure. This, however, meant that minor deviations from the defined parameters triggered errors. The clear separation of this sequence has slightly increased the dimensions of the cartoner, but the process is now extremely robust. Although there is no long-term experience to fall back on, the paper hygiene product manufacturer is currently in the process of conducting Product Acceptance Tests (PAT) and the possibility of retrofitting existing lines with these new, improved features is already being discussed. The new systems are convincing from start to finish, which is confirmed by the error-free PATs.

Interlinking: An Overview of the Process

Today, the converter and the packaging process are closely linked. After leaving the converter, the incontinence products travel first into an Optima quality gate with a flipper. The converter has no separate reject after the folding functions, but it does contain monitoring functions where signals are sent to the quality gate. This allows a rejected product to be discharged independent of the process and manufacturer.

The quality gate itself checks the dimensions of the products, which also allows conclusions to be drawn with regards to correct folding and quality. In addition, the required spacing is monitored, without slowing the process down. The stacker picks up the products in its paddle chain and positions them as ‘counts’ ready for discharge.

These pre-compressed product stacks exit the machine toward the cartoner or bagger, where additional compression is performed. Then the actual packaging of the products takes place, according to the respective principle. Finally, the two lines converge in a case packer. (A second case packer would not be cost-efficient).

Here, the paper hygiene product manufacturer profited from the close collaboration between the three suppliers involved. The interfaces between converter, packaging machines and case packer were coordinated without problems. And if any problems should occur, the quality gate offers the user a further advantage. All product parameters, that could have negative effects on the process, are precisely documented. This means that sources of error can be pinpointed or ruled out.

What’s the Bottom Line?

On the new stacker, the changeover between packaging in cartons or plastic bags is virtually seamless. Processing switches from one direction to the other and back again with little time required. The manufacturer of paper hygiene products makes use of changeover times on the bagger or cartoner, for example in order to configure different product or packaging formats, for manual packaging.

In summary, the user benefits from the very high process stability and, with the new stacker type, greatly increased flexibility. The flexibility to react quickly to the current market, customer or marketing requirements, but also the flexibility within the company that comes from the optimum deployment of personnel and machines without periods of inactivity. And last but not least, the new stacker does away with the need for a (conventional) complete line (plus operating personnel) that could package products only in cartons or only in plastic bags.

Finally, the new stacker is always an interesting option when you want to increase capacities but it is not possible to clearly assess future market potential. The stacker’s second discharge, whether for packaging in cartons or plastic bags, does not have to be used right away, if the potential for a second packaging method materializes, the financial threshold is considerably lower.

When it comes to packaging sizes, the paper hygiene product manufacturers’ marketing experts know exactly whether consumers prefer to buy products in cartons or plastic bags and precisely how the products should be aligned inside the packaging. The color of the sales packaging is also immensely important in the case of incontinence products for men. Bulk packs for care facilities are a further variant for which there is growing demand. Last but not least, marketing campaigns further increase the range of variants.

On the other side, there is the manufacturing and packaging process that has to map this diversity. Together with the multi-stage packaging process, the converter forms an integrated line with high output. How is it possible to implement this wide range of requirements into highly flexible processes without a loss of performance?

(R)Evolution

An initial user already employed a previous version of the new stacker, it also allowed packaging both in cartons and bags. But the new project represents a major step forward, especially in the form of increased output. Today’s system processes 80 cycles per minute, an increase of around 250% compared to the previous performance.

That kind of increase is not possible simply by adjusting a few set screws. One challenge of the new design is that on one side of the stacker, the incontinence products flow in a continuous stream from the converter into the paddle chain. On the opposite side of the stacker, the paddle chain with the product stack (count) needs to be stopped briefly for transfer and transport into the packaging process. The challenge is that there is continuous movement on one side of the stacker and brief stopping of the paddle chain on the other side to allow discharging of the count. This is achieved with the help of a new, improved intermediate storage system within the stacker. The larger this buffer is, the higher the output.

The stacker itself is equipped with two discharges positioned diagonally. They mark the transition points to an Optima OS2 packaging machine for plastic bags or to an Optima CM 180/10 cartoner. The advantage of this diagonal constellation is that it ensures the ‘right’ direction of processing in each case. The bagger receives the products in a linear fashion. In contrast, the products are pushed laterally onto the cartoner, which docks on at a 90-degree angle. This makes an additional change in direction at this point superfluous.

Processing Stability Times Three

The customer also profits from greatly increased processing stability and from an expanded product format range. To achieve this, for the first time, Optima Nonwovens has integrated a height adjustment in the bridging conveyor between the stacker and cartoner. The correct lateral guide can now be quickly set up for each product size. In this way, incontinence products with the current product dimensions (additional formats will be added in the future) are transported onward with high reliability into the next process station.

The stacker is equipped with another new feature at the transition point in the cartoning process; a second compression station has been added after the initial pre-compression process. The second compression process takes place at the end of the bridging conveyor which is shortly before the product stack is pushed into the carton. This also increases tolerances for the product dimensions that can be processed. Incontinence products, in particular, vary greatly in thickness, with a maximum product thickness of 14 mm, tolerances of plus/minus 4 mm are now possible with the new system. This further increases processing stability.

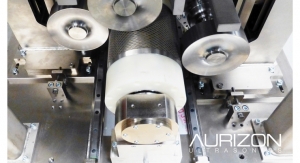

Process reliability has also been clearly increased during cartoning. To do this, the Optima developers have decoupled the process. The carton blanks are extracted, then spread, erected and inserted into the transport system. Previously, this was virtually one continuous procedure. This, however, meant that minor deviations from the defined parameters triggered errors. The clear separation of this sequence has slightly increased the dimensions of the cartoner, but the process is now extremely robust. Although there is no long-term experience to fall back on, the paper hygiene product manufacturer is currently in the process of conducting Product Acceptance Tests (PAT) and the possibility of retrofitting existing lines with these new, improved features is already being discussed. The new systems are convincing from start to finish, which is confirmed by the error-free PATs.

Interlinking: An Overview of the Process

Today, the converter and the packaging process are closely linked. After leaving the converter, the incontinence products travel first into an Optima quality gate with a flipper. The converter has no separate reject after the folding functions, but it does contain monitoring functions where signals are sent to the quality gate. This allows a rejected product to be discharged independent of the process and manufacturer.

The quality gate itself checks the dimensions of the products, which also allows conclusions to be drawn with regards to correct folding and quality. In addition, the required spacing is monitored, without slowing the process down. The stacker picks up the products in its paddle chain and positions them as ‘counts’ ready for discharge.

These pre-compressed product stacks exit the machine toward the cartoner or bagger, where additional compression is performed. Then the actual packaging of the products takes place, according to the respective principle. Finally, the two lines converge in a case packer. (A second case packer would not be cost-efficient).

Here, the paper hygiene product manufacturer profited from the close collaboration between the three suppliers involved. The interfaces between converter, packaging machines and case packer were coordinated without problems. And if any problems should occur, the quality gate offers the user a further advantage. All product parameters, that could have negative effects on the process, are precisely documented. This means that sources of error can be pinpointed or ruled out.

What’s the Bottom Line?

On the new stacker, the changeover between packaging in cartons or plastic bags is virtually seamless. Processing switches from one direction to the other and back again with little time required. The manufacturer of paper hygiene products makes use of changeover times on the bagger or cartoner, for example in order to configure different product or packaging formats, for manual packaging.

In summary, the user benefits from the very high process stability and, with the new stacker type, greatly increased flexibility. The flexibility to react quickly to the current market, customer or marketing requirements, but also the flexibility within the company that comes from the optimum deployment of personnel and machines without periods of inactivity. And last but not least, the new stacker does away with the need for a (conventional) complete line (plus operating personnel) that could package products only in cartons or only in plastic bags.

Finally, the new stacker is always an interesting option when you want to increase capacities but it is not possible to clearly assess future market potential. The stacker’s second discharge, whether for packaging in cartons or plastic bags, does not have to be used right away, if the potential for a second packaging method materializes, the financial threshold is considerably lower.