09.12.18

Karen Winkowski, Ph.D, Global Technical Director, Preservatives & Microbial Technology

Andrea Wingenfeld, Global Marketing Manager, Preservatives

Functional materials are becoming an important tool for formulators. The skillful selection of these materials can help resolve many formulation challenges. Preservatives are typically added to wipes products to protect them against microbial spoilage. This helps to prolong the shelf life of the product and protect the consumer from potential contamination. Preserving wipes products is very challenging especially, when coupled with the desire to formulate sustainable wipes products. The use of a functional sustainable ingredient, based on a blend of fragrances with antimicrobial benefits can help the formulator build and stabilize the formulation against microbial growth while enhancing the olfactory perception of the product and creating brand loyalty from its inception.

The ingredient Conarom b aromatic, is based on a naturally derived hops extract and the nature identical Phenylpropanol. It adds a gentle flowery-to-spicy fragrance to differentiate and impart additional allure to the end use cosmetic formulation. As a secondary benefit it also contributes to microbial stabilization of the product, providing broad protection. Formulators will appreciate its liquid state, good formulation compatibility and broad pH applicability. Conarom b aromatic is an effective solution that addresses the growing consumer demand for functional ingredients.

Introduction

Preserving wet wipes products is often challenging for formulators, as wet wipes provide an excellent venue for microbial growth. Formulators need to overcome interactions between the liquid (lotion) and the various types of wipes substrates that may reduce preservative efficacy. The use of natural fibers or the introduction natural materials that provide additional features to the nonwoven (e.g. wood-pulp or cellulose) often increase the microbial susceptibility of a wet wipe product. The ratio of the liquid/wipes, which changes from product to product, is also important. The amount of liquid and its distribution on the wipes substrate influences the preservation efficacy. The formulation of the liquid (emulsion vs. solution), the reduction or elimination of alcohols and the use of more biodegradable raw material also increases the microbial susceptibility of wipes products.

Additional variations in types of packaging further complicate the preservation strategy. Some wipes are packaged in individual sachets (singles), which can prevent microbial re-contamination without a loss in moisture. However, most frequently, wipes are packed in bulk in different type of containers (flexible flat packs with resalable opening (e.g., facial cleansers), tubs with easy opening lid (e.g., baby wipes) or canisters with pull through lids (e.g., household wipes)). Over time, the removal of wipes via the different container openings results in different migration patterns of the liquid from the wipes, as well as different patterns of exposure of the wipes to microbial contamination. As users extract wipes from their container, they also can introduce microbial contaminants into the package. And packaging with large openings that can be left open can increase the likelihood of microbial contamination and may require a more robust preservation strategy to mitigate that risk.

To add to these challenges, formulators also face significant pressure to formulate without using controversial preservative ingredients, must contend with constantly-changing regulatory guidelines and trying to address consumers’ demands based on perceptions that may have little or no scientific basis.

The use of functional materials to enhance the effect of traditional preservatives is becoming a common trend for formulators. Based on the “hurdle technology concept”, which has been used to control product safety in the food industry since the 1970s, the use of functional materials is employed today as a non-classical approach to boost a substrate’s resistance to microbial growth in many personal care products. Multifunctional ingredients, such as plant-derived essential oils, extracts with antimicrobial properties, glycols that reduce the water activity and/or chelators, are part of this approach [1, 2]. For example, some wipes products currently use acids combined with glycols and emollients as a preservative strategy. However, this strategy is limited by pH, as the use of acids requires a low pH in the liquid phase for efficacy (only the protonated form of the acids – uncharged, lipophilic species – can diffuse through the microbial cytoplasmic membrane, where it de-protonates to exert their action; thus, the pH of the system needs to be maintained below the pKa of the acid throughout the shelf life of the product). Thus, this preservative strategy is not suitable for all product types.

The trend for more inherently sustainable products that have a smaller environmental impact is also very prevalent in the wipes industry. Sustainable wipes are a natural choice for environmentally conscious consumers and responsible industry partners provided they have a robust preservation strategy.

We have found that the combination of hops extract with 3-phenyl-1-propanol offers a functional solution for wipes formulators. Hops extract is a well-known and widely used ingredient. It is one of the few ingredients used in the beer-brewing process; beer is one of the earliest human inventions and globally the most consumed alcoholic beverage in terms of volume [3]. Beer is often considered to be a “functional beverage”, in that has a prolonged shelf life and the absence of microbial contamination through the use of hops. The extracts of hops contain an abundance of polyphenols (flavonoids, prenylflavonoids and phenolic acids), bitter acids like humulone and lupulone and essential oils (monoterpenes, sesquiterpenes and oxygenated terpenes) [4]. These compounds have been shown to possess various anti-bacterial, anti-inflammatory, anti-oxidative, anti-angiogenic, anti-melanogenic, anti-osteoporotic and anti-carcinogenic effects. Potential uses of beer compounds in dermatology have been discussed recently and include treatment of skin diseases such as atopic dermatitis, dry skin, skin aging and hair loss, pigmentary disorders, etc. [3]

Phenyl propanol, though naturally identical in the Conoarom B aromatic, can be found naturally in strawberries, styrax benzoin resin (Deutsch: Benzoetinktur), tea, peru balsam, cassia leaf oil, cinnamon oil and other sources. [6] It is used in foods as a flavor ingredient (e.g., strawberry, apricot, peach flavors), and as a fragrance component (e.g., lilac, hyacinth, lily of the valley) because of its balsamic odor character. [6] The specific rich, slightly spicy aroma from hops results, when combined with the very harmonic phenyl propanol, in a mild flowery to spicy fragrance.

This functional material, sold under the tradename Conarom b aromatic, can offer the formulator a tool to enhance the olfactory perception of their product, as it imparts a subtle gentle fragrance to the wipes product, while delivering antimicrobial protection to the wipe product as a secondary effect. It can enhance consumers’ experience of the wipes and help to foster brand loyalty while helping to prevent microbial spoilage and prolonging the shelf life of the product.

Jane Henderson, global president of Beauty and Personal Care Division at Mintel, says: “We are living in exciting times with revolutionary advancements in technology, brand partnerships and product development. However, we think the coming years will bring stark contrasts in personal technology and natural ingredients that will drive beauty innovation over the next decade. Already, beauty manufacturers are working on new generations of beauty products that will satisfy consumers needs for speed and efficacy.” [7]. This underlines the importance of innovation, using ingredients that meet consumer needs.

Performance Data and Formulation Guidelines

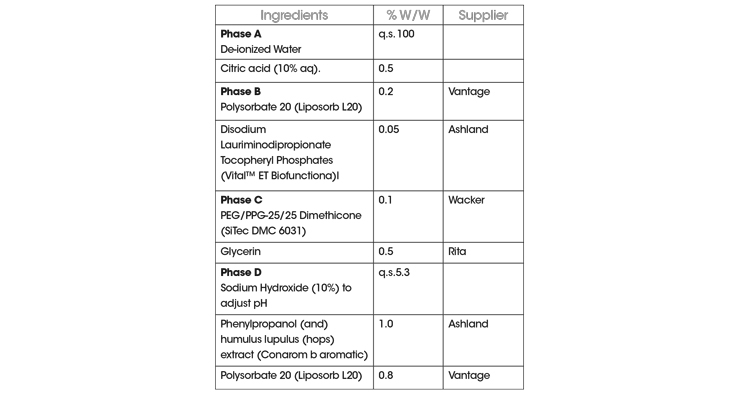

To evaluate the performance of Conarom B, we formulated a baby wipe liquid as described in Table I. The ingredients of Phase A were dissolved in water at room temperature with a sweep blade. The ingredients of Phase B were combined and mixed separately until clear. Phase B was then added to Phase A and mixed well. Thereafter, the ingredients of Phase C were added to the mixture of Phase A and Phase B in order and mixed well after each addition. The pH was then adjusted (5.2 – 5.4) and the last two ingredients were added and mixed until the solution was uniform.

The liquid was added to a cellulosic nonwoven fabric at a ratio of 3:1 (liquid: nonwoven) and allowed to equilibrate for two days in the dark. The resulting wipes formulation offered a gentle spicy fragrance.

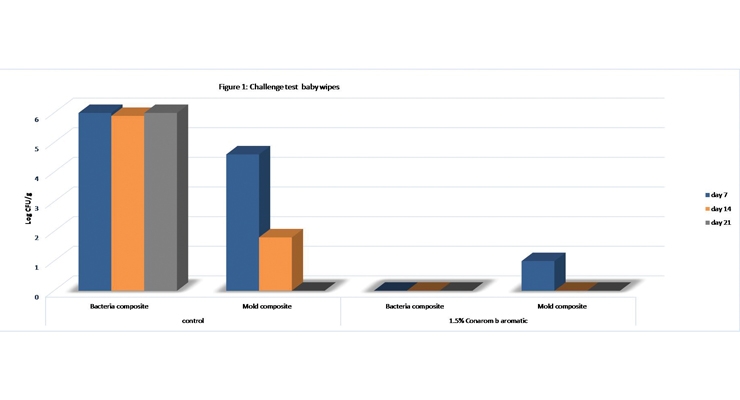

The system was then inoculated with a microbial suspension (about 107 cfu/ml) with a bacterial composite containing: Pseudomonas aeruginosa, Staphylococcus aureus, Escherichia coli and Burkholderia cepacia or a mold composite containing Aspergillus brasiliensis and Candida albicans. To reduce the loss of humidity, the bag containing the inoculated wipes was heat sealed. The wipes were incubated at room temperature under dark conditions for the duration of the tests. At day 7, 14 and 21 after inoculation, the microbial content of the sample was measured by plate count.

As shown in Figure 1, the control sample, containing no Conarom b aromatic, supported the growth of the bacteria, while the mold composite died off by day 21 (left panel). The sample containing Conarom b aromatic exhibited no microbial growth; bacteria were not recovered throughout the experiment and mold was not recovered by day 14 (right panel).

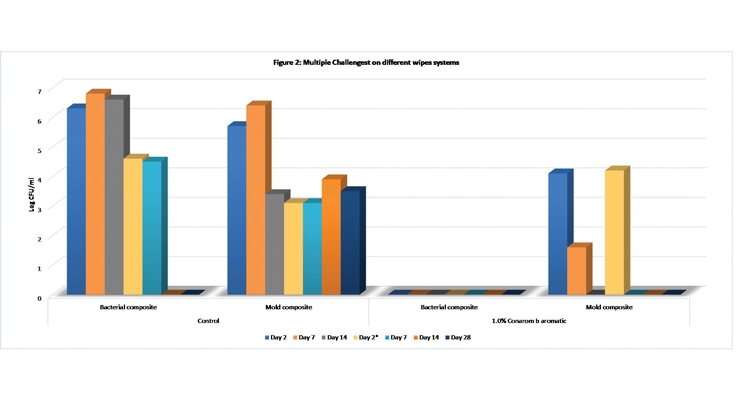

In another example, a wipes system (pH 4.1 – 4.2) was inoculated at two different time intervals: day 0 and day 14. The microbial content of the wipes was analyzed after 2, 7 and 14 days after the first inoculation and after 2, 7, 14 and 28 days after the second inoculation.

As shown in Figure 2, the addition of Conarom b aromatic exhibited no bacterial growth in this system, and mold growth was not detected by day 14 after the first inoculation and by day 7 after the second inoculation.

Conarom b can be added at various phases of production, when worked into products at ambient temperature. Heating processes up to 40°C will usually be well tolerated. To minimize interaction with an emulsifier system, it is recommended to incorporate it after the emulsion has formed. When diluted with water, fine dispersed droplets will be formed. Increased agitation often improves dispersion of the ingredient in aqueous products with low contents of emulsifiers.

It is recommended to evaluate the olfactoric behaviour in the individual formulations and to incorporate this feedback into the chosen dosage for microbial testing. Conarom b aromatic is usually added to products at concentrations in the range of 0.2 % to 2.0 %.

Conclusion

Conarom b aromatic represents a functional fragrance blend that contains nature-identical (synthetic in origin, but chemically identical to naturally-occurring molecules) and naturally derived (derived from naturally occurring source) ingredients. It adds a mild flowery to spicy fragrance to wipes formulations and delivers broad antimicrobial protection as a secondary effect. Its liquid form and wide pH acceptance make it a preferred technology for formulators that are searching for functional ingredients with both antimicrobial properties and a gentle fragrance to heighten the characteristic of their product.

References:

[1] Varvaresou A, Papageorgiou S, Tsirivas E, Protopapa E, Kintziou H, Kefala V, Demetzos C. (2009). Self-preserving cosmetics. Int J Cosmet Sci. Jun;31(3):163-175.

[2] https://www.personalcaremagazine.com/story/8736/new-alternatives-to-cosmetics-preservation

[3] Chen W, Becker T, Qian F, Ring J. (2013). Beer and beer compounds: physiological effects on skin health. JEAVD:1-9.

[4] Karabin M, Hudcova T, Jelinek L and Dostalek P. (2016). Biologically active compounds from Hops and prospects for their use. Comprehensive reviews in food science and food safety 15:542-567.

[5] http://www.chemicalbook.com/ChemicalProductProperty_EN_CB9690882.htm

[6] https://www.perfumersworld.com/product/phenyl-propyl-alcohol-3GN00379

[7] http://www.mintel.com/press-centre/beauty-and-personal-care/mintel-announces-four-beauty-trends-set-to-impact-global-markets-by-2025

Andrea Wingenfeld, Global Marketing Manager, Preservatives

Functional materials are becoming an important tool for formulators. The skillful selection of these materials can help resolve many formulation challenges. Preservatives are typically added to wipes products to protect them against microbial spoilage. This helps to prolong the shelf life of the product and protect the consumer from potential contamination. Preserving wipes products is very challenging especially, when coupled with the desire to formulate sustainable wipes products. The use of a functional sustainable ingredient, based on a blend of fragrances with antimicrobial benefits can help the formulator build and stabilize the formulation against microbial growth while enhancing the olfactory perception of the product and creating brand loyalty from its inception.

The ingredient Conarom b aromatic, is based on a naturally derived hops extract and the nature identical Phenylpropanol. It adds a gentle flowery-to-spicy fragrance to differentiate and impart additional allure to the end use cosmetic formulation. As a secondary benefit it also contributes to microbial stabilization of the product, providing broad protection. Formulators will appreciate its liquid state, good formulation compatibility and broad pH applicability. Conarom b aromatic is an effective solution that addresses the growing consumer demand for functional ingredients.

Introduction

Preserving wet wipes products is often challenging for formulators, as wet wipes provide an excellent venue for microbial growth. Formulators need to overcome interactions between the liquid (lotion) and the various types of wipes substrates that may reduce preservative efficacy. The use of natural fibers or the introduction natural materials that provide additional features to the nonwoven (e.g. wood-pulp or cellulose) often increase the microbial susceptibility of a wet wipe product. The ratio of the liquid/wipes, which changes from product to product, is also important. The amount of liquid and its distribution on the wipes substrate influences the preservation efficacy. The formulation of the liquid (emulsion vs. solution), the reduction or elimination of alcohols and the use of more biodegradable raw material also increases the microbial susceptibility of wipes products.

Additional variations in types of packaging further complicate the preservation strategy. Some wipes are packaged in individual sachets (singles), which can prevent microbial re-contamination without a loss in moisture. However, most frequently, wipes are packed in bulk in different type of containers (flexible flat packs with resalable opening (e.g., facial cleansers), tubs with easy opening lid (e.g., baby wipes) or canisters with pull through lids (e.g., household wipes)). Over time, the removal of wipes via the different container openings results in different migration patterns of the liquid from the wipes, as well as different patterns of exposure of the wipes to microbial contamination. As users extract wipes from their container, they also can introduce microbial contaminants into the package. And packaging with large openings that can be left open can increase the likelihood of microbial contamination and may require a more robust preservation strategy to mitigate that risk.

To add to these challenges, formulators also face significant pressure to formulate without using controversial preservative ingredients, must contend with constantly-changing regulatory guidelines and trying to address consumers’ demands based on perceptions that may have little or no scientific basis.

The use of functional materials to enhance the effect of traditional preservatives is becoming a common trend for formulators. Based on the “hurdle technology concept”, which has been used to control product safety in the food industry since the 1970s, the use of functional materials is employed today as a non-classical approach to boost a substrate’s resistance to microbial growth in many personal care products. Multifunctional ingredients, such as plant-derived essential oils, extracts with antimicrobial properties, glycols that reduce the water activity and/or chelators, are part of this approach [1, 2]. For example, some wipes products currently use acids combined with glycols and emollients as a preservative strategy. However, this strategy is limited by pH, as the use of acids requires a low pH in the liquid phase for efficacy (only the protonated form of the acids – uncharged, lipophilic species – can diffuse through the microbial cytoplasmic membrane, where it de-protonates to exert their action; thus, the pH of the system needs to be maintained below the pKa of the acid throughout the shelf life of the product). Thus, this preservative strategy is not suitable for all product types.

The trend for more inherently sustainable products that have a smaller environmental impact is also very prevalent in the wipes industry. Sustainable wipes are a natural choice for environmentally conscious consumers and responsible industry partners provided they have a robust preservation strategy.

We have found that the combination of hops extract with 3-phenyl-1-propanol offers a functional solution for wipes formulators. Hops extract is a well-known and widely used ingredient. It is one of the few ingredients used in the beer-brewing process; beer is one of the earliest human inventions and globally the most consumed alcoholic beverage in terms of volume [3]. Beer is often considered to be a “functional beverage”, in that has a prolonged shelf life and the absence of microbial contamination through the use of hops. The extracts of hops contain an abundance of polyphenols (flavonoids, prenylflavonoids and phenolic acids), bitter acids like humulone and lupulone and essential oils (monoterpenes, sesquiterpenes and oxygenated terpenes) [4]. These compounds have been shown to possess various anti-bacterial, anti-inflammatory, anti-oxidative, anti-angiogenic, anti-melanogenic, anti-osteoporotic and anti-carcinogenic effects. Potential uses of beer compounds in dermatology have been discussed recently and include treatment of skin diseases such as atopic dermatitis, dry skin, skin aging and hair loss, pigmentary disorders, etc. [3]

Phenyl propanol, though naturally identical in the Conoarom B aromatic, can be found naturally in strawberries, styrax benzoin resin (Deutsch: Benzoetinktur), tea, peru balsam, cassia leaf oil, cinnamon oil and other sources. [6] It is used in foods as a flavor ingredient (e.g., strawberry, apricot, peach flavors), and as a fragrance component (e.g., lilac, hyacinth, lily of the valley) because of its balsamic odor character. [6] The specific rich, slightly spicy aroma from hops results, when combined with the very harmonic phenyl propanol, in a mild flowery to spicy fragrance.

This functional material, sold under the tradename Conarom b aromatic, can offer the formulator a tool to enhance the olfactory perception of their product, as it imparts a subtle gentle fragrance to the wipes product, while delivering antimicrobial protection to the wipe product as a secondary effect. It can enhance consumers’ experience of the wipes and help to foster brand loyalty while helping to prevent microbial spoilage and prolonging the shelf life of the product.

Jane Henderson, global president of Beauty and Personal Care Division at Mintel, says: “We are living in exciting times with revolutionary advancements in technology, brand partnerships and product development. However, we think the coming years will bring stark contrasts in personal technology and natural ingredients that will drive beauty innovation over the next decade. Already, beauty manufacturers are working on new generations of beauty products that will satisfy consumers needs for speed and efficacy.” [7]. This underlines the importance of innovation, using ingredients that meet consumer needs.

Performance Data and Formulation Guidelines

To evaluate the performance of Conarom B, we formulated a baby wipe liquid as described in Table I. The ingredients of Phase A were dissolved in water at room temperature with a sweep blade. The ingredients of Phase B were combined and mixed separately until clear. Phase B was then added to Phase A and mixed well. Thereafter, the ingredients of Phase C were added to the mixture of Phase A and Phase B in order and mixed well after each addition. The pH was then adjusted (5.2 – 5.4) and the last two ingredients were added and mixed until the solution was uniform.

The liquid was added to a cellulosic nonwoven fabric at a ratio of 3:1 (liquid: nonwoven) and allowed to equilibrate for two days in the dark. The resulting wipes formulation offered a gentle spicy fragrance.

The system was then inoculated with a microbial suspension (about 107 cfu/ml) with a bacterial composite containing: Pseudomonas aeruginosa, Staphylococcus aureus, Escherichia coli and Burkholderia cepacia or a mold composite containing Aspergillus brasiliensis and Candida albicans. To reduce the loss of humidity, the bag containing the inoculated wipes was heat sealed. The wipes were incubated at room temperature under dark conditions for the duration of the tests. At day 7, 14 and 21 after inoculation, the microbial content of the sample was measured by plate count.

As shown in Figure 1, the control sample, containing no Conarom b aromatic, supported the growth of the bacteria, while the mold composite died off by day 21 (left panel). The sample containing Conarom b aromatic exhibited no microbial growth; bacteria were not recovered throughout the experiment and mold was not recovered by day 14 (right panel).

In another example, a wipes system (pH 4.1 – 4.2) was inoculated at two different time intervals: day 0 and day 14. The microbial content of the wipes was analyzed after 2, 7 and 14 days after the first inoculation and after 2, 7, 14 and 28 days after the second inoculation.

As shown in Figure 2, the addition of Conarom b aromatic exhibited no bacterial growth in this system, and mold growth was not detected by day 14 after the first inoculation and by day 7 after the second inoculation.

Conarom b can be added at various phases of production, when worked into products at ambient temperature. Heating processes up to 40°C will usually be well tolerated. To minimize interaction with an emulsifier system, it is recommended to incorporate it after the emulsion has formed. When diluted with water, fine dispersed droplets will be formed. Increased agitation often improves dispersion of the ingredient in aqueous products with low contents of emulsifiers.

It is recommended to evaluate the olfactoric behaviour in the individual formulations and to incorporate this feedback into the chosen dosage for microbial testing. Conarom b aromatic is usually added to products at concentrations in the range of 0.2 % to 2.0 %.

Conclusion

Conarom b aromatic represents a functional fragrance blend that contains nature-identical (synthetic in origin, but chemically identical to naturally-occurring molecules) and naturally derived (derived from naturally occurring source) ingredients. It adds a mild flowery to spicy fragrance to wipes formulations and delivers broad antimicrobial protection as a secondary effect. Its liquid form and wide pH acceptance make it a preferred technology for formulators that are searching for functional ingredients with both antimicrobial properties and a gentle fragrance to heighten the characteristic of their product.

References:

[1] Varvaresou A, Papageorgiou S, Tsirivas E, Protopapa E, Kintziou H, Kefala V, Demetzos C. (2009). Self-preserving cosmetics. Int J Cosmet Sci. Jun;31(3):163-175.

[2] https://www.personalcaremagazine.com/story/8736/new-alternatives-to-cosmetics-preservation

[3] Chen W, Becker T, Qian F, Ring J. (2013). Beer and beer compounds: physiological effects on skin health. JEAVD:1-9.

[4] Karabin M, Hudcova T, Jelinek L and Dostalek P. (2016). Biologically active compounds from Hops and prospects for their use. Comprehensive reviews in food science and food safety 15:542-567.

[5] http://www.chemicalbook.com/ChemicalProductProperty_EN_CB9690882.htm

[6] https://www.perfumersworld.com/product/phenyl-propyl-alcohol-3GN00379

[7] http://www.mintel.com/press-centre/beauty-and-personal-care/mintel-announces-four-beauty-trends-set-to-impact-global-markets-by-2025