Kin Ohmura05.04.18

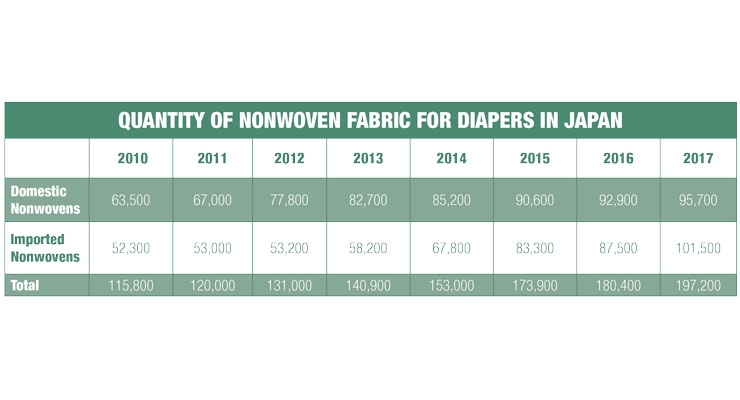

Diaper production has greatly increased in Japan and this has led to growth in demand for nonwovens—both in terms of amount and quality. However, many diaper makers are using imported materials, meaning that growth of imported nonwovens has surpassed that of domestic material in 2017. The table below shows the quantity of demand for domestic nonwovens fabric and those of imported ones used for diapers.

The numerical value in the table shows the total demand for spunbonded nonwovens and thermal bonded nonwovens. Demand for spunbond nonwoven fabric is 158,500 tons and this amount is broken down between 61,500 tons of domestic products and 97,000 tons of imported materials.

Meanwhile, in thermal bonded nonwovens, demand was reported at 34,200 tons of domestic products and 4500 tons of imported materials. In total, 38,700 tons of thermal bonded nonwovens are used in the Japanese diaper market, and most of them are produced domestically, while the imports are stronger in the spunbond market, representing 61% of demand. The increase in the imported nonwovens in the table shows the expansion of the imported spunbonded nonwovens.

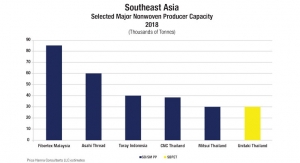

Imported spunbonded nonwoven fabrics includes two forms. On one hand, the diaper makers are importing directly via trading companies, and on the other hand, nonwoven fabric makers such as Mitsui Chemicals, Asahi Kasei and Toray are importing and selling nonwoven fabric that is produced by their overseas subsidiaries. Toray has imported and sold all of its spunbonded nonwoven fabrics, not has produced domestically but also in China and Indonesia. Mitsui Chemicals and Asahi Kasei both have operations in Thailand and have produced and sold both domestic and imported nonwoven fabrics.

Although the quantity of demand for imported nonwoven fabrics has increased, these materials tend to be more general-purpose type with a lower added value than imported materials. The diaper makers are emphasizing the development of high quality products with high functionality corresponding to the demand for high performance type of products. Therefore, spunbond nonwoven producers are developing new high performance product to better compete with thermal bonded nonwovens.

Japanese diapers have a good reputation in China and in the ASEAN countries thanks to their high quality, and demand for them has significantly increased abroad. This reputation can largely be attribted to the high quality of the diapers’ main ingredient—the nonwoven fabric— and to the customer it doesn not matter if they are made in Japan or not.

The numerical value in the table shows the total demand for spunbonded nonwovens and thermal bonded nonwovens. Demand for spunbond nonwoven fabric is 158,500 tons and this amount is broken down between 61,500 tons of domestic products and 97,000 tons of imported materials.

Meanwhile, in thermal bonded nonwovens, demand was reported at 34,200 tons of domestic products and 4500 tons of imported materials. In total, 38,700 tons of thermal bonded nonwovens are used in the Japanese diaper market, and most of them are produced domestically, while the imports are stronger in the spunbond market, representing 61% of demand. The increase in the imported nonwovens in the table shows the expansion of the imported spunbonded nonwovens.

Imported spunbonded nonwoven fabrics includes two forms. On one hand, the diaper makers are importing directly via trading companies, and on the other hand, nonwoven fabric makers such as Mitsui Chemicals, Asahi Kasei and Toray are importing and selling nonwoven fabric that is produced by their overseas subsidiaries. Toray has imported and sold all of its spunbonded nonwoven fabrics, not has produced domestically but also in China and Indonesia. Mitsui Chemicals and Asahi Kasei both have operations in Thailand and have produced and sold both domestic and imported nonwoven fabrics.

Although the quantity of demand for imported nonwoven fabrics has increased, these materials tend to be more general-purpose type with a lower added value than imported materials. The diaper makers are emphasizing the development of high quality products with high functionality corresponding to the demand for high performance type of products. Therefore, spunbond nonwoven producers are developing new high performance product to better compete with thermal bonded nonwovens.

Japanese diapers have a good reputation in China and in the ASEAN countries thanks to their high quality, and demand for them has significantly increased abroad. This reputation can largely be attribted to the high quality of the diapers’ main ingredient—the nonwoven fabric— and to the customer it doesn not matter if they are made in Japan or not.