Karen McIntyre, Editor11.10.17

Advanced Absorbent Technologies is a new hygiene products company dedicated to developing new choices in the adult incontinence market. Its founders have decades of experience in the absorbent hygiene market having developed absorbent product design changes while working at Covidien Retail Group.

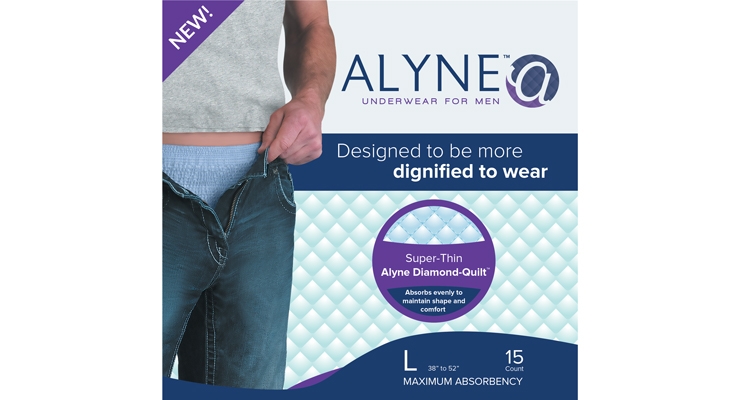

The company’s Alyne absorbent underwear manages fluid absorption differently by using multiple layers of different superabsorbent polymers (SAPs) that absorb at different rates, from quick absorption to complete absorption without bulkiness. The SAP layers are diamond quilted in a pocketed structure, sandwiched between layers of polypropylene spunbond and then ultrasonically bonded together.

This design can provide stability, excellent SAP absorbency management, thinness, dryness for more comfort and discretion that provides the wearer confidence through protection. Alyne was one of three finalists for INDA’s Hygienix Innovation Award earlier this month in Austin, TX.

AAT CEO Joe Howard led Covidien’s retail incontinence business for over 14 years. During that time, he introduced protective underwear to North America, breaking existing paradigms and growing the entire business from a 22% to 38% share.

Howard spoke with Nonwovens Industry about the new company and its vision for the adult incontinence market.

Nonwovens Industry (NWI): Can you give me little bit of background on AAT and how it was formed?

Joe Howard (JH): My two partners, Don Sheldon and Bill Terenzoni, and I were executives at Covidien’s Retail Group. We helped to sell that division to a competitor. For the next few years, we all went about doing other things, mostly consulting. We happened to get together for lunch and realized the adult incontinence category was woefully lacking in innovation since we left it. (We were the ones who introduced underwear, compressed packaging, and high-count bags.) We decided to focus on the key need for users in this category by designing a product that would be more dignified to wear. To do that, we came up with the concept of eliminating all the thick wood pulp used by traditional products. In addition, we decided to use colored fit threads to provide unique aesthetics, and opted to establish our own product sizes to better fit all consumers.

NWI: What expertise did your founders bring to this operation?

JH: Don is an expert in R&D for absorbent products with 40 years’ experience; he is also a patent expert with 25 of his own and has overseen hundreds of others. He has also been an expert witness in many patent cases.

I’m an experienced marketer and strategist with a strong financial background. I’ve been in the absorbent products business for more than 20 years and started my career in marketing at Heinz.

Bill’s expertise surrounds purchasing all the materials that we use in our design as well as logistics and contract manufacturer relations.

NWI: How are your efforts in developing absorbent products different from other companies in the absorbent hygiene area?

JH: We are not tied to any single technology, manufacturing process or encumbered with legacy converting assets. That is why after numerous prototypes, we focused on a pulpless design. We realized from the very beginning that we had to deliver comparable or better speed of absorbency without using pulp, not an easy hurdle. That’s why we developed the four-layer diamond quilt embossing system which uses multiple absorbents, each completing a specific task. We think this concept will completely change the way pull-on underwear is manufactured, over time, significantly reducing the cost of converting equipment.

NWI: How is AAT able to achieve things like innovation, speed to market and flexibility?

JH: Our 100 years of cross functional experience in the category combined with the fact we’re not encumbered with a giant complex organization drives speed to market. It’s no secret that speed to market is the No. 1 determinant of success in new products.

The industry is not so fast to change. I mean today’s absorbent structure (pulp and SAP) was introduced 45 years ago. You might say many of today’s incontinence consumers have literally been waiting a lifetime for a product like Alyne to give them a truly dignified wearing experience.

NWI: Has it been difficult to enter the hygiene space as a smaller company?

JH: Given that we had long standing relationships with most material suppliers and converters, our most difficult issue was finding a way to make a new to the world absorbent core efficiently and effectively. So, we decided to work with non-traditional manufacturers and designed our own equipment. That combination is working great.

NWI: Why was the time right for a new company in this market?

JH: Great innovation is always timely. The notion of pulpless cores has been kicked around for 20 or more years. Why the big manufacturers never addressed it is likely due to be married to legacy assets, risk avoidance and never developing a solution which could deliver unsurpassed absorbency, dryness and leakage protection in a core that is 50% thinner.

NWI: What can you tell me about Alyne Protective underwear? How is this product and the technology different from existing AI products?

JH: Our vision has been to develop a product that would clearly be “Designed to be more dignified to wear.” What makes Alyne different is the combination of its unique absorbent core (50% thinner with a cube that is about 30% smaller) combined with premium features including better, more comfortable fit threads. We use two times as many fit threads as most competitors (108). The fit threads are colored for differentiation and provide a certain elegance in the design.

We’re implementing what we refer to as ‘right sizing’ where each product better fits consumers whether they have a small frame or larger one. And we’re delivering excellent value to the consumer by pricing the same per bag as the leading brand.

As Steve Jobs would say, we do have “One more thing” ... Alyne is the sustainability champion in the category because it meets the EPA’s No. 1 goal of reducing the amount of materials used (about 30% on average). Retailers love the space savings in their warehouses, trucks and store shelves. Plus, once the market fully converts to pulpless products globally, countless trees will be saved, over time.

NWI: Is adult incontinence the key focus of AAT or are you examining other absorbent markets?

JH: Adult incontinent underwear is our first focus. We feel consumers will see and feel the difference immediately and will become brand loyal to Alyne. Having said that, it’s no secret that our technology is applicable to many personal care absorbent categories. The potential is virtually unlimited.

NWI: Can you tell me little bit about the rest of your product range?

JH: No, we don’t talk about our future plans. However, our pull-on underwear product range is super-efficient. Our full line of products for women and men is only 10 SKUs. That, combined with the cube reduction has really resonated with retailers and ecommerce partners.

The company’s Alyne absorbent underwear manages fluid absorption differently by using multiple layers of different superabsorbent polymers (SAPs) that absorb at different rates, from quick absorption to complete absorption without bulkiness. The SAP layers are diamond quilted in a pocketed structure, sandwiched between layers of polypropylene spunbond and then ultrasonically bonded together.

This design can provide stability, excellent SAP absorbency management, thinness, dryness for more comfort and discretion that provides the wearer confidence through protection. Alyne was one of three finalists for INDA’s Hygienix Innovation Award earlier this month in Austin, TX.

AAT CEO Joe Howard led Covidien’s retail incontinence business for over 14 years. During that time, he introduced protective underwear to North America, breaking existing paradigms and growing the entire business from a 22% to 38% share.

Howard spoke with Nonwovens Industry about the new company and its vision for the adult incontinence market.

Nonwovens Industry (NWI): Can you give me little bit of background on AAT and how it was formed?

Joe Howard (JH): My two partners, Don Sheldon and Bill Terenzoni, and I were executives at Covidien’s Retail Group. We helped to sell that division to a competitor. For the next few years, we all went about doing other things, mostly consulting. We happened to get together for lunch and realized the adult incontinence category was woefully lacking in innovation since we left it. (We were the ones who introduced underwear, compressed packaging, and high-count bags.) We decided to focus on the key need for users in this category by designing a product that would be more dignified to wear. To do that, we came up with the concept of eliminating all the thick wood pulp used by traditional products. In addition, we decided to use colored fit threads to provide unique aesthetics, and opted to establish our own product sizes to better fit all consumers.

NWI: What expertise did your founders bring to this operation?

JH: Don is an expert in R&D for absorbent products with 40 years’ experience; he is also a patent expert with 25 of his own and has overseen hundreds of others. He has also been an expert witness in many patent cases.

I’m an experienced marketer and strategist with a strong financial background. I’ve been in the absorbent products business for more than 20 years and started my career in marketing at Heinz.

Bill’s expertise surrounds purchasing all the materials that we use in our design as well as logistics and contract manufacturer relations.

NWI: How are your efforts in developing absorbent products different from other companies in the absorbent hygiene area?

JH: We are not tied to any single technology, manufacturing process or encumbered with legacy converting assets. That is why after numerous prototypes, we focused on a pulpless design. We realized from the very beginning that we had to deliver comparable or better speed of absorbency without using pulp, not an easy hurdle. That’s why we developed the four-layer diamond quilt embossing system which uses multiple absorbents, each completing a specific task. We think this concept will completely change the way pull-on underwear is manufactured, over time, significantly reducing the cost of converting equipment.

NWI: How is AAT able to achieve things like innovation, speed to market and flexibility?

JH: Our 100 years of cross functional experience in the category combined with the fact we’re not encumbered with a giant complex organization drives speed to market. It’s no secret that speed to market is the No. 1 determinant of success in new products.

The industry is not so fast to change. I mean today’s absorbent structure (pulp and SAP) was introduced 45 years ago. You might say many of today’s incontinence consumers have literally been waiting a lifetime for a product like Alyne to give them a truly dignified wearing experience.

NWI: Has it been difficult to enter the hygiene space as a smaller company?

JH: Given that we had long standing relationships with most material suppliers and converters, our most difficult issue was finding a way to make a new to the world absorbent core efficiently and effectively. So, we decided to work with non-traditional manufacturers and designed our own equipment. That combination is working great.

NWI: Why was the time right for a new company in this market?

JH: Great innovation is always timely. The notion of pulpless cores has been kicked around for 20 or more years. Why the big manufacturers never addressed it is likely due to be married to legacy assets, risk avoidance and never developing a solution which could deliver unsurpassed absorbency, dryness and leakage protection in a core that is 50% thinner.

NWI: What can you tell me about Alyne Protective underwear? How is this product and the technology different from existing AI products?

JH: Our vision has been to develop a product that would clearly be “Designed to be more dignified to wear.” What makes Alyne different is the combination of its unique absorbent core (50% thinner with a cube that is about 30% smaller) combined with premium features including better, more comfortable fit threads. We use two times as many fit threads as most competitors (108). The fit threads are colored for differentiation and provide a certain elegance in the design.

We’re implementing what we refer to as ‘right sizing’ where each product better fits consumers whether they have a small frame or larger one. And we’re delivering excellent value to the consumer by pricing the same per bag as the leading brand.

As Steve Jobs would say, we do have “One more thing” ... Alyne is the sustainability champion in the category because it meets the EPA’s No. 1 goal of reducing the amount of materials used (about 30% on average). Retailers love the space savings in their warehouses, trucks and store shelves. Plus, once the market fully converts to pulpless products globally, countless trees will be saved, over time.

NWI: Is adult incontinence the key focus of AAT or are you examining other absorbent markets?

JH: Adult incontinent underwear is our first focus. We feel consumers will see and feel the difference immediately and will become brand loyal to Alyne. Having said that, it’s no secret that our technology is applicable to many personal care absorbent categories. The potential is virtually unlimited.

NWI: Can you tell me little bit about the rest of your product range?

JH: No, we don’t talk about our future plans. However, our pull-on underwear product range is super-efficient. Our full line of products for women and men is only 10 SKUs. That, combined with the cube reduction has really resonated with retailers and ecommerce partners.