Karen McIntyre, editor11.11.15

Meltblown nonwovens are largely known for their role in SMS technology where they are manufactured in tandem with spunbond to be used in hygiene applications. The combination of meltblown and spunbond improved the barrier function of the fabric economically.

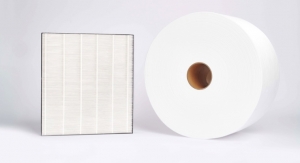

While this is certainly a big usage for meltbown, comprising about 60% of its overall output, meltblown is an important technology in its own right, finding its place in a range of applications including filtration, medical, wipes and more.

Meltblown is one of nonwovens’ oldest manufacturing processes and, some say, its most turbulent. The process extrudes thermoplastic fiber-forming polymer through a linear die containing several hundred small orifices. Streams of hot air—exiting from the left and right sides of the die nosepiece—rapidly attenuating the extruded polymer stream to form extremely fine filaments. They are then blown onto a collector screen forming a fine-filtered, self-bonded nonwoven web.

“Of the various fiber equipment markets we are involved with, meltblown is the most volatile with surges in demand linked to global health fears (SARS, H1N1, etc.) or oil spills impacting demand,” says Timothy Robson of machinery manufacturer Hills Inc.

However, Robinson reports he is seeing a shift towards smaller fibers and fabrics with more features that can be achieved with unique polymers (chemical resistance), small diameters (overall efficiency and filter “quality factor”) and bicomponent construction (charge retention, compatibility or additives). This has helped ease cost concerns in the meltblown market.

“From Hills’ perspective we’ve seen the interest in small fibers starting to catch up with the supply,” Robson adds. “Various methods of making very small fibers at commercially viable throughputs have existed for close to a decade but the industry has had difficulty justifying the additional cost,” he says.

Stricter indoor air quality regulations as well as the focus on highly efficient filters that do not rely on electrostatic charging are two major drivers of this phenomenon. “Additionally the availability of very small fibers have allowed other unique applications of meltblown, for example by utilizing its very high surface area,” Robinson adds.

Hills offers all types of meltblown equipment including conventional diameters, throughput and polymers, but its strongest focus in on bicomponent and submicron (nanomeltblown) webs.

“Unique polymers continue to hit the market requiring corrosion resistant metals in the extrusion portion and higher temperature capabilities,” Robson adds. “Additionally continued R&D in sub-micron or ‘nano’ fibers is slowly resulting in products being commercialized using the higher capacity methods for producing the same.”

Supplier Side

One of the nonwovens industry’s oldest suppliers of meltblown nonwovens and the first company to combine it with spunbond nonwovens to form SMS, Kimberly-Clark Professional Partnership Products, offers two forms of meltblown nonwovens. The company’s fine-fiber meltblown provides high absorbent capacity and low lint with a cloth-like feel and is available with a variety of surface patterns and surface treatment options, while the dual-texture meltblown provides dual-sided performance with one scrubby side and one smooth side.

Jessica Berger, customer market manager, Kimberly-Clark Professional Partnership Products, calls K-C meltblown an ideal base selection for wet wipes thanks to its metered fluid release, which is superior to cellulosic nonwovens like spunlaced rayon.

“It delivers just the right amount of chemical to a surface—not too much and not too little. Its uniform bond structure also makes our meltblown an excellent choice for providing fine particulate barrier and superior absorbent capacity in advanced personal nonwovens, including patient warming blankets, table towels, and surface disinfecting wipes,” she says.

“Plus it can be thermally laminated and/or treated with liquid surfactants.”

K-C uses its meltblown nonwovens internally to fuel its billion-dollar brands but also works with customers to create exceptional products.

“Our customers can count on us to deliver a product with a 99.9% first-time quality rating, thanks to our highly automated manufacturing, advanced control systems, and stringent statistical quality controls,” Berger adds. “And our manufacturing capabilities enable us to meet our customer’s needs, including regulatory compliance. Our ability to use different and unique fibers and proprietary fabric construction can help our customers achieve their desired product properties.”

The Machinist’s View

Mohammad Hassan, senior research engineer, Biax-Fiberfilm, credits meltspun technology’s growth to its ability to offer a lot to the nonwovens market. Recent technology advances are largely targeting higher throughput, finer fiber size and better web uniformity, allowing nonwovens manufacturers to bridge the gap between conventional single-row meltblowing technology and spunbond technology by offering high-strength microfibers and the capability of spinning high molecular weight resins that have higher viscosities.

Biax-Fiberfilm offers an advanced the multi-row spinneret technology to handle much higher operating pressure and pushed the limit of nozzle density to 266 nozzle/inch. In addition to this, Biax offers spinnerettes with small capillaries down to 0.006 inch to achieve small fibers—all with significant advantages in throughput.

“Such advancement would enable our customers to develop niche products with a new class of materials,” Hassan says. “Meltspun technologies are continuously improving and winning new markets from the mature technologies such as wetlaid and carding. In addition to this, we see many technical products that are taking advantage of the meltspun technologies in the medical and electronics field because they are easier to tailor and it is becoming more economical to make.”

Other market drivers are primarily better web formation that is more uniform, free of roping and shots, higher production capacity to lower manufacturing costs and smaller fiber size to offer lighter products with higher performance.

All of these advancements are helping meltblown expand its role in a number of markets. For filtration, a market where meltblown has always been valued, increased fiber size control and material selection have created new opportunities.

“We see many products are being developed for high temperature and chemical resistance application beside some products for sophisticated medical applications.”

Meanwhile, in the medical field, meltblown fabrics can offer new products to prevent or reduce healthcare acquired infections (HAIs). Thanks to their excellent barrier properties in elastic laminates for the hygiene market, meltblown technology is replacing film-based laminates with the new elastic resins and the robust multirow meltblowing technology.

Hassan says these are just some of the areas where meltblown will target thanks to new advances in the technology. “Using patented and proprietary technologies, we enable our customers to produce economically high-end nonwoven fabrics,” Hassan says. “The primary drivers are the continuous need for improvement of the existing products and the urgency to solve evolving customer needs,” he says.

While this is certainly a big usage for meltbown, comprising about 60% of its overall output, meltblown is an important technology in its own right, finding its place in a range of applications including filtration, medical, wipes and more.

Meltblown is one of nonwovens’ oldest manufacturing processes and, some say, its most turbulent. The process extrudes thermoplastic fiber-forming polymer through a linear die containing several hundred small orifices. Streams of hot air—exiting from the left and right sides of the die nosepiece—rapidly attenuating the extruded polymer stream to form extremely fine filaments. They are then blown onto a collector screen forming a fine-filtered, self-bonded nonwoven web.

“Of the various fiber equipment markets we are involved with, meltblown is the most volatile with surges in demand linked to global health fears (SARS, H1N1, etc.) or oil spills impacting demand,” says Timothy Robson of machinery manufacturer Hills Inc.

However, Robinson reports he is seeing a shift towards smaller fibers and fabrics with more features that can be achieved with unique polymers (chemical resistance), small diameters (overall efficiency and filter “quality factor”) and bicomponent construction (charge retention, compatibility or additives). This has helped ease cost concerns in the meltblown market.

“From Hills’ perspective we’ve seen the interest in small fibers starting to catch up with the supply,” Robson adds. “Various methods of making very small fibers at commercially viable throughputs have existed for close to a decade but the industry has had difficulty justifying the additional cost,” he says.

Stricter indoor air quality regulations as well as the focus on highly efficient filters that do not rely on electrostatic charging are two major drivers of this phenomenon. “Additionally the availability of very small fibers have allowed other unique applications of meltblown, for example by utilizing its very high surface area,” Robinson adds.

Hills offers all types of meltblown equipment including conventional diameters, throughput and polymers, but its strongest focus in on bicomponent and submicron (nanomeltblown) webs.

“Unique polymers continue to hit the market requiring corrosion resistant metals in the extrusion portion and higher temperature capabilities,” Robson adds. “Additionally continued R&D in sub-micron or ‘nano’ fibers is slowly resulting in products being commercialized using the higher capacity methods for producing the same.”

Supplier Side

One of the nonwovens industry’s oldest suppliers of meltblown nonwovens and the first company to combine it with spunbond nonwovens to form SMS, Kimberly-Clark Professional Partnership Products, offers two forms of meltblown nonwovens. The company’s fine-fiber meltblown provides high absorbent capacity and low lint with a cloth-like feel and is available with a variety of surface patterns and surface treatment options, while the dual-texture meltblown provides dual-sided performance with one scrubby side and one smooth side.

Jessica Berger, customer market manager, Kimberly-Clark Professional Partnership Products, calls K-C meltblown an ideal base selection for wet wipes thanks to its metered fluid release, which is superior to cellulosic nonwovens like spunlaced rayon.

“It delivers just the right amount of chemical to a surface—not too much and not too little. Its uniform bond structure also makes our meltblown an excellent choice for providing fine particulate barrier and superior absorbent capacity in advanced personal nonwovens, including patient warming blankets, table towels, and surface disinfecting wipes,” she says.

“Plus it can be thermally laminated and/or treated with liquid surfactants.”

K-C uses its meltblown nonwovens internally to fuel its billion-dollar brands but also works with customers to create exceptional products.

“Our customers can count on us to deliver a product with a 99.9% first-time quality rating, thanks to our highly automated manufacturing, advanced control systems, and stringent statistical quality controls,” Berger adds. “And our manufacturing capabilities enable us to meet our customer’s needs, including regulatory compliance. Our ability to use different and unique fibers and proprietary fabric construction can help our customers achieve their desired product properties.”

The Machinist’s View

Mohammad Hassan, senior research engineer, Biax-Fiberfilm, credits meltspun technology’s growth to its ability to offer a lot to the nonwovens market. Recent technology advances are largely targeting higher throughput, finer fiber size and better web uniformity, allowing nonwovens manufacturers to bridge the gap between conventional single-row meltblowing technology and spunbond technology by offering high-strength microfibers and the capability of spinning high molecular weight resins that have higher viscosities.

Biax-Fiberfilm offers an advanced the multi-row spinneret technology to handle much higher operating pressure and pushed the limit of nozzle density to 266 nozzle/inch. In addition to this, Biax offers spinnerettes with small capillaries down to 0.006 inch to achieve small fibers—all with significant advantages in throughput.

“Such advancement would enable our customers to develop niche products with a new class of materials,” Hassan says. “Meltspun technologies are continuously improving and winning new markets from the mature technologies such as wetlaid and carding. In addition to this, we see many technical products that are taking advantage of the meltspun technologies in the medical and electronics field because they are easier to tailor and it is becoming more economical to make.”

Other market drivers are primarily better web formation that is more uniform, free of roping and shots, higher production capacity to lower manufacturing costs and smaller fiber size to offer lighter products with higher performance.

All of these advancements are helping meltblown expand its role in a number of markets. For filtration, a market where meltblown has always been valued, increased fiber size control and material selection have created new opportunities.

“We see many products are being developed for high temperature and chemical resistance application beside some products for sophisticated medical applications.”

Meanwhile, in the medical field, meltblown fabrics can offer new products to prevent or reduce healthcare acquired infections (HAIs). Thanks to their excellent barrier properties in elastic laminates for the hygiene market, meltblown technology is replacing film-based laminates with the new elastic resins and the robust multirow meltblowing technology.