09.08.15

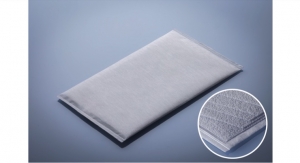

Freudenberg Performance Materials has started a pilot line at its global competence site in Kaiserslautern, Germany. The spunlaid nonwovens made by Freudenberg, both on this plant and elsewhere, are used in a wide variety of applications and markets ranging from carpets for car interiors, fitted carpets for buildings and cabin air filters for vehicles to bedding and mattress covers for allergy sufferers. Freudenberg is continuously developing its spunlaid manufacturing processes at the Kaiserslautern site. This latest investment was reported at €3 million.

New processes are developed and tested on pilot lines before they are transferred to production plants, and this pilot line will takes one of Freudenberg Performance Materials' current innovation projects to its next stage of development. “We produce spunlaid nonwovens with a patented process developed in-house that has considerable advantages over competing technologies,” says Michael Ehret, head of Operations, regional business unit Europe and plant manager at Kaiserslautern.

The benefits of this technology include tailor-made products, homogeneous quality and high productivity.

“The commissioning of this pilot line will allow us to open up entirely new areas of application and to develop further innovative products to meet individual customers’ requirements,” says Dr. Volker Röhring, manager process development.

The new line will be operated by the current workforce at Kaiserslautern, which comprised about 630 people at last count and also contains parts of Freudenberg's filtration and medical businesses.

New processes are developed and tested on pilot lines before they are transferred to production plants, and this pilot line will takes one of Freudenberg Performance Materials' current innovation projects to its next stage of development. “We produce spunlaid nonwovens with a patented process developed in-house that has considerable advantages over competing technologies,” says Michael Ehret, head of Operations, regional business unit Europe and plant manager at Kaiserslautern.

The benefits of this technology include tailor-made products, homogeneous quality and high productivity.

“The commissioning of this pilot line will allow us to open up entirely new areas of application and to develop further innovative products to meet individual customers’ requirements,” says Dr. Volker Röhring, manager process development.

The new line will be operated by the current workforce at Kaiserslautern, which comprised about 630 people at last count and also contains parts of Freudenberg's filtration and medical businesses.