Tara Olivo, associate editor09.14.15

The wipes market has grown at a steady pace over the last decade, and this trend is likely to continue over the next several years as consumers continue seek convenience. While baby wipes continue to comprise the largest piece of the market, nonwovens producers are refining their technologies for other areas such as moist toilet tissue, cosmetics, automotives and more.

And, to stay competitive in the market, product differentiation is key among these suppliers. Offering specific and unique products and adding value with creativity and innovation are ways nonwovens producers all across the globe are making their substrates stand out.

The nonwovens industry has seen a number of new substrates debut during the first half of 2015, so here’s a look at what’s new.

Truly Flushable

In January, nonwovens producer Suominen of Helsinki, Finland, introduced an upgraded version of its Hydraspun flushable substrate—Hydraspun Dispersible Plus. According to the company, the material breaks up more than three times faster than the standard Hydraspun Dispersible substrate and clearly passes the INDA/EDANA third edition flushability assessment test protocols.

Alistair Brown, director of marketing and communications, Suominen, says, “New Hydraspun Dispersible Plus substrates are similar to other spunlace or traditional offerings for wipes in terms of their cleaning and softness attributes, but unlike them in that they are truly flushable in domestic toilet systems and engineered precisely for that purpose.”

Hydraspun Dispersible Plus offers customers the same conversion runnability as the original Hydraspun, he explains, but because of its proven dispersion rate of breaking up three times faster than Hydraspun, the new product gives its customers and consumers “the added security of knowing that they can safely flush wipe products” made from it.

“In addition, Suominen has designed a simple yet effective logo, tested with consumers, to indicate that the wipes in the purchased package are indeed proven to be flushable in global wastewater systems,” he continues.

With all of the hurdles companies are facing in the flushable market, requests for better technology are increasing significantly. Brown suggests it’s important to respond to these calls.

“Product diversification is vital in wipes to ensure the changing and ever more demanding requirements for wipes from consumers are met with more and more new and specific products,” he says.

New Spunlace Launched at WOW

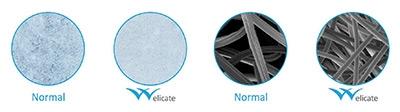

At this year’s World of Wipes (WOW) Conference held by INDA, the Association of the Nonwovens Fabrics Industry, Welspun India Ltd. introduced Welicate spunlace to the wipes market.

Welspun launched Welicate at the WOW conference this year. Its properties include softness, nice feel and strength.

Welicate can be applied to wipes for baby care, cosmetics, electronics, household, moist toilet tissue and medical use. Pranay Sahu, head – sales and marketing (Hygiene) for Welspun’s Advanced Textiles Business says, “Welspun’s Welicate spunlace is developed through a unique process using distinctive fibers and thus the developed spunlace exhibits exceptionally soft hand feel and improved functional properties like higher strength and reduced absorbency time when compared with straight spunlace.”

Because of the material’s higher strength, Sahu says converters can run it at higher speeds. Also, its functional properties allow for raw material cost savings, as brands and converters can optimize on the GSM of the material.

“Wipes developed from Welicate have extremely soft hand feel and delicate touch. Improved functional properties also lead to enhanced cleaning efficiency of wipes. When compared to similar GSM, Welicate wipes look and feel like a richer product”

In addition to Welicate, Welspun has introduced a substrate for hospital use this year, for patients getting sponge baths. Made of a polyester/viscose blend, the new material is double sided, with one side scrubby and the other smooth. Sahu says it’s a high strength and low elongation product with a GSM from 120-160, and it was made without using chemicals or polymer dots.

A Substrate Made without Water

Italian producer Albis Nonwovens recently launched Curacell using the company’s patented Strato5 technology. The material is a sandwich construction nonwoven that can be manufactured without a single drop of water. This method saves energy and lessens the threat of mold, fungus and bacteria, either during the production cycle or due to incorrect storage or while being converted into wipes.

Made from two external layers of polypropylene spunbond containing two well-linked internal layers of cellulose, ensuring a completely lint-free substance, Curacell is suitable for both wet and dry wipes, towels, pads and several industrial applications.

An added benefit to this technology is its ability to meet a worldwide trend toward saving water and preventing pollution and waste.

Future generations of Curacell will have an even more attractive environmental profile. By next year, in some products, the polypropylene layers will be replaced with polylactic acid, according to the company.

Silky Smooth

This spring, Sandler of Schwarzenbach/Saale, Germany, introduced two new wipes substrates for the cosmetics industry—sawatex classy silk and sawatex tactile TriLace.

A special fiber composition gives sawatex classy silk a particularly smooth, silky touch, and this exceptional feel enhances the materials’ high cleaning efficiency, says Carolin Weber, sales director hygiene and wipes.

Sandler’s second cosmetic substrate—sawatex tactile TriLace—is comprised of two nonwoven layers. The first is an exfoliating layer that removes makeup and dirt, while eliminating dead skin cells. Weber says this provides a gentle massage during use. The soft side refines the cleaning effect and leaves the skin feeling refreshed and revived. “This double-action effect helps speed up cell-renewal and thereby helps maintain a healthy skin,” Weber explains.

Sandler created these substrates due to increasing demand for more comfort in use. “They add a certain something to everyday care, transforming makeup removal into a ‘mini-wellness treatment.’”

When it comes to wipes substrates, Sandler does not take a one-size-fits-all approach. Product differentiation is key for them, and Weber says it is essential for them to gain a competitive edge.

“Cleaning efficiency and absorbency are basic requirements which customers arguably take for granted,” she explains.

“‘Added value’ in terms of design, haptics or additional functionalities is important. Sandler offers product differentiation through different printing and embossing designs, but also through product structure or fiber composition. Sawatex classy silk and sawatex tactile TriLace are examples of the latter, demonstrating the potential for innovation in the versatile wipes market.”

An Upgraded Microfilament Fabric

In May, Freudenberg Performance Materials unveiled Evolon 3D, a variation of its Evolon microfilament fabric. The original Evolon

Freudenberg has introduced a three-dimensional version of its Evolon fabric that can find use in the wipes market.

features smoothness, softness and uniformity, and has succeeded in replacing traditional textiles in areas such as bedding, decoration or even acoustics, according to Freudenberg Performance Materials. The new three-dimensional version’s surface has increased in volume and has become more refined, paving the way for other possible applications.

“Thanks to microfilaments, which are 30 to 100 times thinner than a human hair, Evolon’s worldwide patented technology provides outstanding anti-scratch cleaning performance and freedom from lint,” says Jean-Francois Kerhault, business segment manager for Evolon. “Furthermore, endless microfilaments make Evolon strong, mechanically stable and isotropic, providing extended durability for lightweight wipes and frequent wash resistance for heavier weights. Boosted by the microfilament technology, wipes as light as 30gsm can be made thanks to the brand new 3D version of Evolon.”

Evolon 3D is ideal for “highly demanding applications requiring the best surface preservation” such as the automotive, aerospace and other high-tech industries, but its distinct aesthetic and innovative features make it also applicable for consumer wet wipes, according to Kerhault.

“The 3D structure reinforces the uniformity of the microfilaments and increases ease of handling, making it possible to supply 3D microfilament wipes which are one-and-a-half to two times lighter than the lightweight wipes traditionally obtained using competing processes,” he says.

Additionally, in its 100gsm version, Freudenberg Performance Materials says Evolon 3D enables a new generation of sports towels to be produced that are just as ultra-compact, lightweight and effective, but with a traditional fabric look, like honeycomb or other patterns, that consumers are used to. Designers can also use Evolon 3D in decoration, where Evolon is already used because of its matte look, lightness, ease of handling and its acoustic properties.

According to Freudenberg Performance Materials, the Evolon 3D structure is achieved without post-treatment and without the addition of chemicals.

New Technology for Moist Toilet Tissue

Israeli-based Albaad has launched a new dispersible moist toilet tissue for the wipes category called HydroFINE. According to Asaf Izraely, Albaad’s vice president of R&D, the substrate if very different from carded spunlace. “It is a wetlaid hybrid technology with two bonding-unbinding mechanisms,” he says. “Web formation starts with wet laying a mix of wood pulp and short cut staple fibers on an incline wire and then binding by hydroentanglement and chemical binder applications.”

These two mechanisms give HydroFINE better controllability on strength, dispersibility, patterns and other performances, and better flexibility to use different raw materials and mixes, he adds. This technology also allows for a wider range of basis weights.

“The technology was designed to offer a solution of better flexibility needed to meet the changing and diverse requirements and flushability standards in this globally growing market,” Izraely says.

And, to stay competitive in the market, product differentiation is key among these suppliers. Offering specific and unique products and adding value with creativity and innovation are ways nonwovens producers all across the globe are making their substrates stand out.

The nonwovens industry has seen a number of new substrates debut during the first half of 2015, so here’s a look at what’s new.

Truly Flushable

In January, nonwovens producer Suominen of Helsinki, Finland, introduced an upgraded version of its Hydraspun flushable substrate—Hydraspun Dispersible Plus. According to the company, the material breaks up more than three times faster than the standard Hydraspun Dispersible substrate and clearly passes the INDA/EDANA third edition flushability assessment test protocols.

Alistair Brown, director of marketing and communications, Suominen, says, “New Hydraspun Dispersible Plus substrates are similar to other spunlace or traditional offerings for wipes in terms of their cleaning and softness attributes, but unlike them in that they are truly flushable in domestic toilet systems and engineered precisely for that purpose.”

Hydraspun Dispersible Plus offers customers the same conversion runnability as the original Hydraspun, he explains, but because of its proven dispersion rate of breaking up three times faster than Hydraspun, the new product gives its customers and consumers “the added security of knowing that they can safely flush wipe products” made from it.

“In addition, Suominen has designed a simple yet effective logo, tested with consumers, to indicate that the wipes in the purchased package are indeed proven to be flushable in global wastewater systems,” he continues.

With all of the hurdles companies are facing in the flushable market, requests for better technology are increasing significantly. Brown suggests it’s important to respond to these calls.

“Product diversification is vital in wipes to ensure the changing and ever more demanding requirements for wipes from consumers are met with more and more new and specific products,” he says.

New Spunlace Launched at WOW

At this year’s World of Wipes (WOW) Conference held by INDA, the Association of the Nonwovens Fabrics Industry, Welspun India Ltd. introduced Welicate spunlace to the wipes market.

Welspun launched Welicate at the WOW conference this year. Its properties include softness, nice feel and strength.

Because of the material’s higher strength, Sahu says converters can run it at higher speeds. Also, its functional properties allow for raw material cost savings, as brands and converters can optimize on the GSM of the material.

“Wipes developed from Welicate have extremely soft hand feel and delicate touch. Improved functional properties also lead to enhanced cleaning efficiency of wipes. When compared to similar GSM, Welicate wipes look and feel like a richer product”

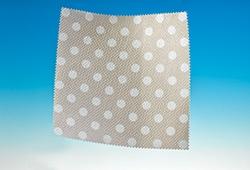

In addition to Welicate, Welspun has introduced a substrate for hospital use this year, for patients getting sponge baths. Made of a polyester/viscose blend, the new material is double sided, with one side scrubby and the other smooth. Sahu says it’s a high strength and low elongation product with a GSM from 120-160, and it was made without using chemicals or polymer dots.

A Substrate Made without Water

Italian producer Albis Nonwovens recently launched Curacell using the company’s patented Strato5 technology. The material is a sandwich construction nonwoven that can be manufactured without a single drop of water. This method saves energy and lessens the threat of mold, fungus and bacteria, either during the production cycle or due to incorrect storage or while being converted into wipes.

Made from two external layers of polypropylene spunbond containing two well-linked internal layers of cellulose, ensuring a completely lint-free substance, Curacell is suitable for both wet and dry wipes, towels, pads and several industrial applications.

An added benefit to this technology is its ability to meet a worldwide trend toward saving water and preventing pollution and waste.

Future generations of Curacell will have an even more attractive environmental profile. By next year, in some products, the polypropylene layers will be replaced with polylactic acid, according to the company.

Silky Smooth

This spring, Sandler of Schwarzenbach/Saale, Germany, introduced two new wipes substrates for the cosmetics industry—sawatex classy silk and sawatex tactile TriLace.

A special fiber composition gives sawatex classy silk a particularly smooth, silky touch, and this exceptional feel enhances the materials’ high cleaning efficiency, says Carolin Weber, sales director hygiene and wipes.

Sandler’s second cosmetic substrate—sawatex tactile TriLace—is comprised of two nonwoven layers. The first is an exfoliating layer that removes makeup and dirt, while eliminating dead skin cells. Weber says this provides a gentle massage during use. The soft side refines the cleaning effect and leaves the skin feeling refreshed and revived. “This double-action effect helps speed up cell-renewal and thereby helps maintain a healthy skin,” Weber explains.

Sandler created these substrates due to increasing demand for more comfort in use. “They add a certain something to everyday care, transforming makeup removal into a ‘mini-wellness treatment.’”

When it comes to wipes substrates, Sandler does not take a one-size-fits-all approach. Product differentiation is key for them, and Weber says it is essential for them to gain a competitive edge.

“Cleaning efficiency and absorbency are basic requirements which customers arguably take for granted,” she explains.

“‘Added value’ in terms of design, haptics or additional functionalities is important. Sandler offers product differentiation through different printing and embossing designs, but also through product structure or fiber composition. Sawatex classy silk and sawatex tactile TriLace are examples of the latter, demonstrating the potential for innovation in the versatile wipes market.”

An Upgraded Microfilament Fabric

In May, Freudenberg Performance Materials unveiled Evolon 3D, a variation of its Evolon microfilament fabric. The original Evolon

Freudenberg has introduced a three-dimensional version of its Evolon fabric that can find use in the wipes market.

“Thanks to microfilaments, which are 30 to 100 times thinner than a human hair, Evolon’s worldwide patented technology provides outstanding anti-scratch cleaning performance and freedom from lint,” says Jean-Francois Kerhault, business segment manager for Evolon. “Furthermore, endless microfilaments make Evolon strong, mechanically stable and isotropic, providing extended durability for lightweight wipes and frequent wash resistance for heavier weights. Boosted by the microfilament technology, wipes as light as 30gsm can be made thanks to the brand new 3D version of Evolon.”

Evolon 3D is ideal for “highly demanding applications requiring the best surface preservation” such as the automotive, aerospace and other high-tech industries, but its distinct aesthetic and innovative features make it also applicable for consumer wet wipes, according to Kerhault.

“The 3D structure reinforces the uniformity of the microfilaments and increases ease of handling, making it possible to supply 3D microfilament wipes which are one-and-a-half to two times lighter than the lightweight wipes traditionally obtained using competing processes,” he says.

Additionally, in its 100gsm version, Freudenberg Performance Materials says Evolon 3D enables a new generation of sports towels to be produced that are just as ultra-compact, lightweight and effective, but with a traditional fabric look, like honeycomb or other patterns, that consumers are used to. Designers can also use Evolon 3D in decoration, where Evolon is already used because of its matte look, lightness, ease of handling and its acoustic properties.

According to Freudenberg Performance Materials, the Evolon 3D structure is achieved without post-treatment and without the addition of chemicals.

New Technology for Moist Toilet Tissue

Israeli-based Albaad has launched a new dispersible moist toilet tissue for the wipes category called HydroFINE. According to Asaf Izraely, Albaad’s vice president of R&D, the substrate if very different from carded spunlace. “It is a wetlaid hybrid technology with two bonding-unbinding mechanisms,” he says. “Web formation starts with wet laying a mix of wood pulp and short cut staple fibers on an incline wire and then binding by hydroentanglement and chemical binder applications.”

These two mechanisms give HydroFINE better controllability on strength, dispersibility, patterns and other performances, and better flexibility to use different raw materials and mixes, he adds. This technology also allows for a wider range of basis weights.

“The technology was designed to offer a solution of better flexibility needed to meet the changing and diverse requirements and flushability standards in this globally growing market,” Izraely says.