03.24.15

Freudenberg & Vilene Nonwovens, a partnership between Freudenberg Performance Materials and Vilene Nonwovens, is building a new state-of-the-art production line for automotive headliners as its Suzhou, China facility. The line is scheduled to begin production in summer 2016.

The automotive market in Asia is growing, and is particularly dynamic in China. According to figures published by the German Association of the Automotive Industry (VDA), some 1.9 million vehicles were sold in China in January 2015 alone, a 13% increase compared to the same month last year. Demand for high-quality products is rising steadily, with automotive headliners enjoying a particularly strong trend. Asian OEMs prefer printed headliners that meet the high design standards of Japanese and Korean car manufacturers.

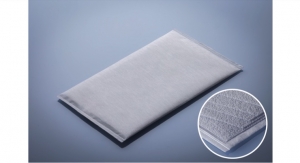

Freudenberg & Vilene introduced printed headliners in 2010 and is currently the only manufacturer with this capability in-house. This allows the company to offer nonwoven-based headliners that are innovative and individualized with additional features. Apart from excellent abrasion resistance, outstanding acoustic properties and improved stain resistance, these products in combination with other vehicle components contribute to a marked reduction in vehicle weight. “Our commitment in China underscores the fact that we are a leading reliable partner for our customers worldwide and at the same time reaffirms our headliner expertise,” Bruce Olson, President and CEO of Freudenberg Performance Materials, comments.

In addition to automotives, Freudenberg & Vilene's Chinese site also makes industrial nonwovens for apparel and electronic applications as well as the energy and storage sectors.

The automotive market in Asia is growing, and is particularly dynamic in China. According to figures published by the German Association of the Automotive Industry (VDA), some 1.9 million vehicles were sold in China in January 2015 alone, a 13% increase compared to the same month last year. Demand for high-quality products is rising steadily, with automotive headliners enjoying a particularly strong trend. Asian OEMs prefer printed headliners that meet the high design standards of Japanese and Korean car manufacturers.

Freudenberg & Vilene introduced printed headliners in 2010 and is currently the only manufacturer with this capability in-house. This allows the company to offer nonwoven-based headliners that are innovative and individualized with additional features. Apart from excellent abrasion resistance, outstanding acoustic properties and improved stain resistance, these products in combination with other vehicle components contribute to a marked reduction in vehicle weight. “Our commitment in China underscores the fact that we are a leading reliable partner for our customers worldwide and at the same time reaffirms our headliner expertise,” Bruce Olson, President and CEO of Freudenberg Performance Materials, comments.

In addition to automotives, Freudenberg & Vilene's Chinese site also makes industrial nonwovens for apparel and electronic applications as well as the energy and storage sectors.