Wolfgang Siegert, Technical Support Manager International, Schulke & Mayr GmbH, Special Additives International09.04.12

Consumers have come to expect certain key attributes from wet cleaning wipes relative to their intended use, such as soil removal capacity, anti-static properties, streak-free shine, etc. Additionally, environmental acceptability, including the sustainable use of raw materials, is becoming a decisive factor for many customers.

The synergistic combination of benzisothiazolinone (BIT), methylisothiazolinone (MIT) and bis(3-aminopropyl)dodecylamine (BDA) has been shown to minimize the level of biocidal actives needed for preservation. With this new sustainable “full-life” protection concept, it is possible to control waterborne contaminations and microbially polluted natural nonwovens by adding a single, optimized dosage of preservative. Along with the economic and product safety improvements, this approach fulfills the demand for eco-labels, like European Flower and the White Swan, as well as the stringent requirements of the German Öko Test magazine.

The Goal of ‘Green’ Products

Sustainability is being systematically integrated into many companies’ principles and business processes. Often, the use of biocides is an essential point of discussion. Despite some consumer concerns about the use of biocides, the use of these materials has enabled a shift toward products with greater biodegradability. In a sense, the value of biocides to the quality of our lives is beyond price. Their function is preventative, primarily, minimizing waste of natural and limited resources while reducing exposure to harmful microorganisms.

The wish to produce “green” products should not result in insufficiently preserved, unsafe products. Proliferation of pathogenic microorganisms, product spoilage and visible growth of mold on the wet wipes are the risk of inadequately protected products.

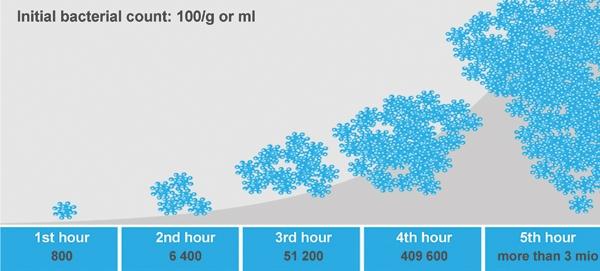

Microorganisms live in all parts of the biosphere where there is liquid water; they are critical to nutrient recycling in ecosystems as they act as decomposers. Populations of microorganisms undergo exponential growth. Figure 1 demonstrates the growth of Escherichia coli at optimal conditions with a generation time of 20 minutes.

Figure 1

Wet tissues are an excellent medium for the growth of bacteria, yeast and mold. The wet tissue liquids are mostly aqueous; the cellulose is a good nutrient; the nonwoven is always moderately contaminated with microorganisms; and the storage temperature is nearly optimal for microbial growth. Environmental requirements (e.g., from the EU Detergent Directive) to use only biodegradable detergents increase the susceptibility of wet tissues to microbial infection. The demand for flushable wipes and the increased use of natural fibers make mold growth, with its easily visible staining, more likely.

To ensure consumer safety and product stability, the addition of preservatives to wet wipes is necessary. Preservatives should protect the product by preventing biological degradation for a certain period. However, at the end of the lifecycle of a wet wipe (the disposal) the biocide should be biodegradable.

Biocidal properties and biodegradability are not in conflict. For example, a concentration of ethanol between 50% and 90% is a good disinfectant. It acts between 13% and 50% as preservative. Below 13% ethanol will be degraded biologically to acetic acid.

Conflict & Balance

From a marketing perspective, preservation should be as “green” as possible. Some consumers would prefer preservative-free.

From the view of plant management, preservation should control any microbial contamination during production. This would save costs for cleaning and sanitizing. ISO 22716 (Cosmetics—Good Manufacturing Practices (GMP)—Guidelines on Good Manufacturing Practices) gives guidelines for the production, control, storage and shipment of cosmetic wipes. While manufacturing in a simpler production line, ignoring hygienic design, may be acceptable for hard surface cleaning wipes, it is advisable to follow the same GMP rules for the manufacture of cosmetic wipes to minimize potential microbial contamination.

The target for product development is to select a preservative system balancing marketing and production demands to achieve an eco–friendly, sustainable product.

Contamination Sources

Microbial contamination of wet wipes can occur during their manufacture. The majority of the contaminants are present in the source of water and in the raw materials, including the nonwoven as well as in equipment and plumbing lines (tanks and pipes). Certain microorganisms produce biofilms that can adhere to the surfaces of plumbing systems containing water, to processing tanks and to other environments in the factory. These biofilms are in general resistant to treatment with biocides.

The incoming water in factory pipe systems can originate from various sources. Each source supplies a different, usually specific composition of organic and inorganic constituents of chemical ingredients in the water. Additionally, the hardness of the water can play an important role. Possible water sources include:

• Town water from a single public well

• Town water from various public wells

• Water from (river) shore filtrates

• Water from (sea) shore filtrates

• Water from reservoirs

• Water from a privately owned source

• Water from a privately owned well

Ion exchangers are often sources of contamination. The ion exchanger resins can be colonized by biofilms, which are unharmed even after regeneration with sodium hydroxide solution or hydrochloric acid. An exchanger plant fed with drinking water (organism count <100/ml) often produces demineralized water with a count of 10,000 organisms/ml.

Additional problems arise as a result of intermediate storage of water in tanks where access may be difficult. Maintenance on these can lapse, resulting in insufficient cleaning and sanitization. In some cases, these storage tanks are installed under a roof exposed to warming. As a result, during the first use on a Monday morning, stored water with an organism count of up to 10 million/ml may be used for production, leading to an unacceptable initial organism count in freshly manufactured products.

A ‘Fresh’ Approach

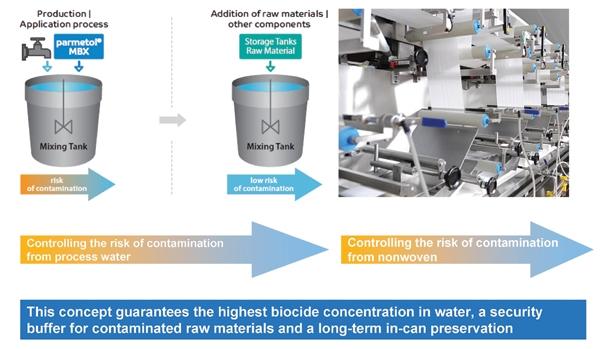

The addition of a fast-acting preservative with long-term protection at the beginning of the production process to sanitize the water used for bulk production is a possible solution to this problem. The killing of bacteria by such a preservative must occur within a few minutes. The best situation would be adding it before other ingredients. The principle of adding the full amount of biocide during the first water addition to the vessel is shown in Figure 2.

Figure 2

Extensive research has shown bis(3-aminopropyl)dodecylamine (BDA) to be an excellent enhancer for today’s standard “soft” preservatives based on methylisothiazolinone (MIT) in combination with benzisothiazolinone (BIT). This combination of actives is able to reduce markedly the contact time necessary to sanitize the water within the normal production process to a few minutes, significantly decreasing holding times.

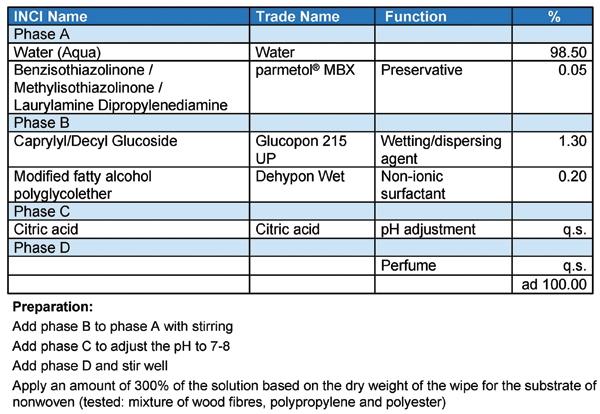

This combination allows very low use concentrations to preserve wet tissues adequately. Figure 3 shows an example of an all-purpose wet wipe that passes microbial challenge testing (schülke FeuTukoTest) using this preservative combination.

Figure 3

Labels & Legislation

The European Ecolabel is a voluntary scheme established in 1992 to encourage businesses to market eco-friendly products and services. Products and services awarded the Ecolabel carry the flower logo, allowing consumers, both public and private—to identify them easily.

Established product groups include all-purpose cleaners and cleaners for sanitary facilities; detergents for dishwashing machines; hand dishwashing detergents; laundry detergents and soaps, shampoos and hair conditioners.

The ecological criteria required to receive the EU Ecolabel for all-purpose cleaners and sanitary cleaners are published in the Commission Decision 2011/383/EU.

The formulation shown in Figure 3 would fulfill the demands of this Commission Decision. Additionally, the packaging criteria for these products must be taken into account. According to the European Chemicals Agency (ECHA) “Guidance on requirements for substances in articles,” a wet cleaning wipe is a combination of an article (functioning as a container or a carrier material) and a substance or mixture.

For such ready-to-use products, the weight utility ratio (WUR) of the primary packaging must be below 150 grams packaging per liter of cleaning solution. For example, with a 120 grams per square-meter spunlace three-layer structure (67% viscose, 33% PET, sawatex TriLace), a maximum water absorption capacity of approximately 1,000% is possible8. In practice, it was found that the actual absorption capacity was 830%. This allows for the application of 1,000 grams of cleaning solution on 120 grams of nonwoven, so there is still some space for a soft pack. Production of an Ecolabel-conforming wet wipe product is possible.

In Summary…

A limited number of biocidal actives are available for the preservation of household wet cleaning wipes. Many actives are under public discussion and harsh actives may lead to negative reviews in test magazines. New concepts in preservation are required. Minimizing the use of preservatives is essential according to the philosophy “as little as possible, but as much as technically necessary.”

The utilization of boosting effects of actives helps to reduce use concentrations. An optimized dosage concept improves and helps to ensure product safety, even with low use concentrations of in-can preservatives. Optimized preservative application, combined with special nonwoven qualities, allow products to fulfill EU Ecolabel criteria.

About the author: Wolfgang Siegert is technical support manager with Schülke & Mayr GmbH. He can be reached at +49 40 52100 528; wolfgang.siegert@schuelke.com; www.schuelke.com.

The synergistic combination of benzisothiazolinone (BIT), methylisothiazolinone (MIT) and bis(3-aminopropyl)dodecylamine (BDA) has been shown to minimize the level of biocidal actives needed for preservation. With this new sustainable “full-life” protection concept, it is possible to control waterborne contaminations and microbially polluted natural nonwovens by adding a single, optimized dosage of preservative. Along with the economic and product safety improvements, this approach fulfills the demand for eco-labels, like European Flower and the White Swan, as well as the stringent requirements of the German Öko Test magazine.

The Goal of ‘Green’ Products

Sustainability is being systematically integrated into many companies’ principles and business processes. Often, the use of biocides is an essential point of discussion. Despite some consumer concerns about the use of biocides, the use of these materials has enabled a shift toward products with greater biodegradability. In a sense, the value of biocides to the quality of our lives is beyond price. Their function is preventative, primarily, minimizing waste of natural and limited resources while reducing exposure to harmful microorganisms.

The wish to produce “green” products should not result in insufficiently preserved, unsafe products. Proliferation of pathogenic microorganisms, product spoilage and visible growth of mold on the wet wipes are the risk of inadequately protected products.

Microorganisms live in all parts of the biosphere where there is liquid water; they are critical to nutrient recycling in ecosystems as they act as decomposers. Populations of microorganisms undergo exponential growth. Figure 1 demonstrates the growth of Escherichia coli at optimal conditions with a generation time of 20 minutes.

Figure 1

Wet tissues are an excellent medium for the growth of bacteria, yeast and mold. The wet tissue liquids are mostly aqueous; the cellulose is a good nutrient; the nonwoven is always moderately contaminated with microorganisms; and the storage temperature is nearly optimal for microbial growth. Environmental requirements (e.g., from the EU Detergent Directive) to use only biodegradable detergents increase the susceptibility of wet tissues to microbial infection. The demand for flushable wipes and the increased use of natural fibers make mold growth, with its easily visible staining, more likely.

To ensure consumer safety and product stability, the addition of preservatives to wet wipes is necessary. Preservatives should protect the product by preventing biological degradation for a certain period. However, at the end of the lifecycle of a wet wipe (the disposal) the biocide should be biodegradable.

Biocidal properties and biodegradability are not in conflict. For example, a concentration of ethanol between 50% and 90% is a good disinfectant. It acts between 13% and 50% as preservative. Below 13% ethanol will be degraded biologically to acetic acid.

Conflict & Balance

From a marketing perspective, preservation should be as “green” as possible. Some consumers would prefer preservative-free.

From the view of plant management, preservation should control any microbial contamination during production. This would save costs for cleaning and sanitizing. ISO 22716 (Cosmetics—Good Manufacturing Practices (GMP)—Guidelines on Good Manufacturing Practices) gives guidelines for the production, control, storage and shipment of cosmetic wipes. While manufacturing in a simpler production line, ignoring hygienic design, may be acceptable for hard surface cleaning wipes, it is advisable to follow the same GMP rules for the manufacture of cosmetic wipes to minimize potential microbial contamination.

The target for product development is to select a preservative system balancing marketing and production demands to achieve an eco–friendly, sustainable product.

Contamination Sources

Microbial contamination of wet wipes can occur during their manufacture. The majority of the contaminants are present in the source of water and in the raw materials, including the nonwoven as well as in equipment and plumbing lines (tanks and pipes). Certain microorganisms produce biofilms that can adhere to the surfaces of plumbing systems containing water, to processing tanks and to other environments in the factory. These biofilms are in general resistant to treatment with biocides.

The incoming water in factory pipe systems can originate from various sources. Each source supplies a different, usually specific composition of organic and inorganic constituents of chemical ingredients in the water. Additionally, the hardness of the water can play an important role. Possible water sources include:

• Town water from a single public well

• Town water from various public wells

• Water from (river) shore filtrates

• Water from (sea) shore filtrates

• Water from reservoirs

• Water from a privately owned source

• Water from a privately owned well

Ion exchangers are often sources of contamination. The ion exchanger resins can be colonized by biofilms, which are unharmed even after regeneration with sodium hydroxide solution or hydrochloric acid. An exchanger plant fed with drinking water (organism count <100/ml) often produces demineralized water with a count of 10,000 organisms/ml.

Additional problems arise as a result of intermediate storage of water in tanks where access may be difficult. Maintenance on these can lapse, resulting in insufficient cleaning and sanitization. In some cases, these storage tanks are installed under a roof exposed to warming. As a result, during the first use on a Monday morning, stored water with an organism count of up to 10 million/ml may be used for production, leading to an unacceptable initial organism count in freshly manufactured products.

A ‘Fresh’ Approach

The addition of a fast-acting preservative with long-term protection at the beginning of the production process to sanitize the water used for bulk production is a possible solution to this problem. The killing of bacteria by such a preservative must occur within a few minutes. The best situation would be adding it before other ingredients. The principle of adding the full amount of biocide during the first water addition to the vessel is shown in Figure 2.

Figure 2

Extensive research has shown bis(3-aminopropyl)dodecylamine (BDA) to be an excellent enhancer for today’s standard “soft” preservatives based on methylisothiazolinone (MIT) in combination with benzisothiazolinone (BIT). This combination of actives is able to reduce markedly the contact time necessary to sanitize the water within the normal production process to a few minutes, significantly decreasing holding times.

This combination allows very low use concentrations to preserve wet tissues adequately. Figure 3 shows an example of an all-purpose wet wipe that passes microbial challenge testing (schülke FeuTukoTest) using this preservative combination.

Figure 3

Labels & Legislation

The European Ecolabel is a voluntary scheme established in 1992 to encourage businesses to market eco-friendly products and services. Products and services awarded the Ecolabel carry the flower logo, allowing consumers, both public and private—to identify them easily.

Established product groups include all-purpose cleaners and cleaners for sanitary facilities; detergents for dishwashing machines; hand dishwashing detergents; laundry detergents and soaps, shampoos and hair conditioners.

The ecological criteria required to receive the EU Ecolabel for all-purpose cleaners and sanitary cleaners are published in the Commission Decision 2011/383/EU.

The formulation shown in Figure 3 would fulfill the demands of this Commission Decision. Additionally, the packaging criteria for these products must be taken into account. According to the European Chemicals Agency (ECHA) “Guidance on requirements for substances in articles,” a wet cleaning wipe is a combination of an article (functioning as a container or a carrier material) and a substance or mixture.

For such ready-to-use products, the weight utility ratio (WUR) of the primary packaging must be below 150 grams packaging per liter of cleaning solution. For example, with a 120 grams per square-meter spunlace three-layer structure (67% viscose, 33% PET, sawatex TriLace), a maximum water absorption capacity of approximately 1,000% is possible8. In practice, it was found that the actual absorption capacity was 830%. This allows for the application of 1,000 grams of cleaning solution on 120 grams of nonwoven, so there is still some space for a soft pack. Production of an Ecolabel-conforming wet wipe product is possible.

In Summary…

A limited number of biocidal actives are available for the preservation of household wet cleaning wipes. Many actives are under public discussion and harsh actives may lead to negative reviews in test magazines. New concepts in preservation are required. Minimizing the use of preservatives is essential according to the philosophy “as little as possible, but as much as technically necessary.”

The utilization of boosting effects of actives helps to reduce use concentrations. An optimized dosage concept improves and helps to ensure product safety, even with low use concentrations of in-can preservatives. Optimized preservative application, combined with special nonwoven qualities, allow products to fulfill EU Ecolabel criteria.

About the author: Wolfgang Siegert is technical support manager with Schülke & Mayr GmbH. He can be reached at +49 40 52100 528; wolfgang.siegert@schuelke.com; www.schuelke.com.