Steve Katz, Managing Editor12.02.11

A diaper isn’t just a diaper, and the same can be said for the wide range of hygiene products produced in the nonwovens industry. While the bulk of many nonwoven products are made from the engineered fabrics that are the hallmark of the industry, there are a host of other materials working with nonwovens, whose role is to improve upon, add value and facilitate the efficacy of these products’ end uses.

Take the diaper, for example. Some are adorned with graphics designed to make the product visually appealing to both baby and Mom. Others feature fabrics to create a certain look, like the recent camouflage and jeans-themed diaper lines from Huggies.

Aesthetics aside, all diapers – and other hygiene products, like incontinence and feminine hygiene – need specific components to make them work as the manufacturer intends. The closures, films and tapes affixed to these hygiene products are of critical importance. No matter how good the nonwoven fabric may be in doing its job, if the corresponding components don’t work well, chances are, customers will be lost. Among the trends at the forefront of the hygiene components market is comfort, in conjunction with a product that’s visually appealing. With this in mind, manufacturers are developing components that make hygiene products more fashionable and stylish, while maintaining softness. Meanwhile, keeping costs down with low basis weight nonwovens is another market trend.

“We note the trend to thinner diapers and napkins enabled by new core technology and a growth in the use of bulkier, softer nonwoven topsheets enhanced with apertures and embossing, and elastic features continue to grow,” says Bill Norman, director of hygienic products for Clopay. Growth, he says, is clearly evident across the board. “There is continued opportunity for growth in emerging markets and regions. In addition, growth is available for innovative materials and technologies that enhance performance, aesthetics or sustainability – in a cost effective way.”

Pantex innovation

Pantex International is an example of a company that’s achieving the sought after combination of comfort, performance, fashion and affordability. “In order to satisfy the market’s requirements, we have in place several different activities that are mainly based on designing new products and features, while downgauging our product range accordingly,” says Gianluigi Fornoni, CEO for Pantex.

Recently, Pantex launched its innovative low basis weight (22-24gsm), perforated laminated films, the CL6, CL8 and CL18. These materials combine soft feel, dryness and visual appearance throughout different perforation patterns, with high runnability capabilities on high speed converting machines. In addition, the company has also launched a new“Ultra Soft” range of products that include embossed and perforated materials that satisfy the current market needs for softness and visual appearance. “The products are also available with lenitive additives and printing,” Fornoni explains. “High elastic properties, high strength and low basis weight is our response, with a cost effective elastic laminate for the increasing demand of elasticized components on baby diapers and adult care products.”

Fornoni points out the effect today’s global financial situation is having on the market. He says, “Due to the current global financial and economic situation, there is a continuous request for price reduction, which is challenging our developmental ability and, in order not to lose marketshare, we deliver to the market significant basis weight reduction on our traditional products without sacrificing the required performances.”

From a technical point of view, Fornoni has noticed an increase in attention for the fluid handling properties of the products where improvement, he says, is a must. “In addition, we notice the request for higher softness touch/feel, together with visual properties, like printing and embossing and for lenitive properties having additives like aloe, chamomile, vitamin E, etc. In particular, for baby diapers, we see the application of elasticized components growing.”

Berry Plastics: Sonic bonding and components with color

There continue to be advancements made when it comes to all areas related to printing, and this is the case with baby diapers, adult incontinence and feminine hygiene absorbent products.

“Bright and decorative colors are pleasing and stimulate positive consumer responses,” explains Keith Brechtelsbauer,vice president and general manager, Specialty Films Division, Berry Plastics Corp. He cites the recent success U by Kotex is having with teens and the introduction of new printed baby diapers with dots, bears and patterns that are pleasing to families. “Hygiene is becoming fashionable and products are being designed that reflect this,” he says.

Brechtelsbauer also emphasizes a continued trend towards work in sonic bonding of hygiene components to improve the form, fit and function of various materials. “Sonic bonding requires new film developments to ensure that nonwoven structures are bonded adequately to the film portion of the component. For example, Berry Plastics has partnered with Hermann Ultrasonics to marry both companies’ technologies together for optimum performance,” he adds.

Increasing diaper backsheet film softness at lower basis weights, while simultaneously maintaining converting speeds is an ongoing trend, Brechtelsbauer explains. “New resin developments hold some excellent promise for meeting value and cost targets going forward.”

As consumers look to extend usage cycles and minimize costs, and as the economy in the US has impacted hygienic article sales, this has had an impact on Berry’s research and development. “We at Berry continue to develop ‘high value polypropylene’ co-extrusions as a way to reduce basis weight while maintaining key properties around hole detection and winding integrity. This is a highly capital intensive development,” Brechtelsbauer says. Berry management recently approved $2 million in co-extrusion equipment upgrades to address this need.

Berry Plastics family of films called Touch of Silk (TOS) has been a top development priority. “This technology deploys new resin, embossing and extrusion technologies that impart tactile improvements while also allowing for the printing of graphics and the incorporation of nonwoven laminations. This Berry Plastics TOS technology is being applied in both article and packaging applications for personal care and medical fabrics,” says Brechtelsbauer.

Berry Plastics’ commitment to the printing and packaging of personal care products is unwavering. “We recently installed a new state-of-the-art, 10-color ‘quick change’ press in our McAlester, OK, site coupled with a new investment in two-sided printing. We are also adding additional bag converting capabilities to round out our dedicated investments in hygiene.”

Avery Dennison gets closure with tape

While diaper closures make up just a small portion of the final product, for obvious reasons their importance is immense. A recent innovation from Avery Dennison Corporation is a closure that simplifies diaper handling by applying the closure directly to the backsheet. This type of closure follows a trend where producers are switching from a polyethylene plastic backsheet to a nonwoven backsheet, thus permitting use of a closure that has excellent peel and shear.

“Unlike hook-and-loop systems that require a more coordinated application effort by the user, the new closure more directly hooks to the nonwoven backsheet,” explains Birgitta Van den Driessche, global product manager, personal care, Avery Dennison Performance Tapes. “Our diaper closure innovations also benefit diaper marketing and manufacturing. We offer extensive customization options that enhance the look and feel of a diaper. Customized closures offer diaper manufacturers a powerful way to brand their products. Beyond that, Avery Dennison also offers diaper manufacturers engineering assistance to make sure the tape closures run well on their equipment.”

Another innovation that supports diaper manufacturers’ processing efficiency is the ability of Avery Dennison Performance Tapes to supply closures for baby diapers and other nonwoven products on large-capacity spools. “The greater capacity increases the amount of tape that can be placed into diaper manufacturing lines, which can reduce the frequency of change-overs and the number of splices needed during diaper production,” Van den Driessche adds.

Avery Dennison has also picked up a distinct trend in emerging markets, where the company says there’s been an evolution from adhesive systems to mechanical closure systems.

“For mature markets, such as Europe and the US, as well as a few sectors in emerging markets, manufacturers are producing thinner and softer diapers, often with printing on the closure. Plus, premium diapers are gaining in popularity.”

It’s worth noting that nonwoven diaper closure innovations from Avery Dennison Performance Tapes are designed and developed based on input from mothers and fathers. Van den Driessche says, “Our interviews with parents revealed that comfort and ease-of-use remain high among their customer satisfaction priorities. In response, we are making it easier for users to find and open a tab on a diaper and we are looking at alternative materials to make closures even softer.

Netting it right with Conwed

Conwed, a maker of stretchable netting for hygiene products, is another components company that pays close attention to end users’ wants and needs in developing its product. According to Ivan Soltero, Conwed’s strategic marketing manager – Industrial, Conwed Global Netting Solutions, providing superior comfort is key. “End users keep influencing the industry and manufacturers are designing products with relevant characteristics such as breathability, smoothness, softness, drapeability, flexibility, high absorbency, etc.,” Soltero says.“End users seem to set expectations for obtaining good performance but also an affordable, comfortable product.”

Conwed is also noticing the trend to develop lighter-weight end products. “Companies are really trying to decrease costs while keeping good value in their product offerings,” Soltero says. “Whether it is to reduce volume, weight or layers, we see companies reinventing their processes to find a better alternative for their product line. This has just supported our efforts to work with our R&D and production departments to look for innovation that generates lighter weight products and more efficient and sustainable production processes.”

Soltero says companies today are dedicating a more significant share of their resources and focus to adult incontinence applications. “The demographics in North America call for giving extra attention to the steady growth of the adult incontinence segment. We have seen increased interest in our elastomeric netting for waistbands in incontinence underwear, which leads us to believe that this trend will still enjoy future growth,” Soltero says.

Addressing the need for lighter-weight products, Conwed recently improved upon its Rebound elastomeric netting, a product line introduced to the hygiene industry almost a decade ago, but was heavier and less developed than its most recent version. “Our R&D team has made great improvements to our processes in recent years and has been able to produce lighter weight elastomeric netting while keeping optimal tensile strength and stretch performance. With these enhancements, we have experienced renewed interest from hygiene manufacturers as our value proposition is now very competitive with that of other stretch engine materials such as spandex, films and stretchable nonwovens,” Soltero explains.

Soltero says the new Rebound netting features superior hysteresis versus other stretch engine materials which means it is highly stretchable and has excellent recovery with less energy loss. “It’s also flexible and strong due to its web structure, which allows customization of machine direction (MD), cross direction (CD) or bi-directional stretch capabilities, all while offering superior breathability and fit while providing comfort and durability.”

Soltero emphasizes that Rebound offers specific benefits to both manufacturers and end users alike. “Rebound elastomeric netting creates a superior stretch engine that allows products to expand while maintaining dimensional stability and compression. Its consistent integral joints form a web structure that provides stretch properties in one or all directions. So, manufacturers can customize stretch properties to fit final application. For end users, Rebound allows for a Tailored fit for products that demand to stay in place without restricting range of motion, and it’s designed to enhance flexibility and strength while delivering exceptional comfort, shape, durability and breathability.”

Stretching with Creora spandex

Hyosung, with its signature Creora brand, is the largest producer of spandex in the world with plants in Korea, China, Turkey, Vietnam and Brazil. Ria Stern, global marketing and brand director, emphasizes that, globally, the disposable hygiene market is a growth market, as population is increasing in emerging markets.

“Economic conditions in these countries are improving and with more women working outside their homes, the convenience of disposable diapers (and their affordability) is increasing,” Stern says, “Similarly as the population ages, and more people are living longer, the need for adult incontinent diapers is increasing.”

Stern says that Hyosung’s Creora C-100 has become an increasingly popular product among its customers. She emphasizes that its unique polymer chemistry provides for softer stretch, higher elongation than the competition, and 300% working elongation. Also, she says, higher draftability translates into reduced elastic cost per unit.

“We offer a wide range of deniers, in over and rolling take off with transfer tails for increased productivity and continuous processing,” Stern explains, adding that Hyosung can provide uniform unwinding, package to package uniformity and larger package sizes for up 150% longer run times.

Stern points out an important fact regarding the relationship between the components they provide and the end use product – the diaper. “Spandex is a small component of the overall diaper, however, if there is breakage in the spandex, the waste generated is the entire diaper.”

Velcro’s hook

Velcro is another brand that can offer keen insight, particularly when it comes to today’s closure market trends. Rebecca Morel, Velcro’s product manager personal care, says, “The trends in closure systems reflect trends we see across many categories of the hygiene components market. Of these, the demand for softness and flexibility are clearly on the rise. In developing and emerging markets, effective performance of the component is still the most valued aspect, now followed closely by qualities such as softness.In mature markets, softness, flexibility and aesthetics rate on par with performance, with growing expectations in terms of the primary function – that the component‘just works’.”

Velcro focuses on a variety of specialized hook components along with its nonwoven FNL landing zone materials. “Our FNL technology enables us to manufacture nonwoven materials that eliminate the use of films in landing zones for a softer look and feel,” Morel explains. “This is combined with a manufacturing process that delivers a consistent weight, resulting in a more secure fastening system. The translucence of these products allows graphics to be visible through the backsheet material. This can cut manufacturer costs by reducing print on multiple components. We also offer printed FNL materials to help differentiate the landing zone of products.”

The integrated solution of Velcro’s Flex-Zone technology is another of the brand’s offerings within the hygiene market. These systems allow for a more flexible product by eliminating the need to adhesively bond the hook to a variety of substrates. Morel says, “We are able to offer a product that extrudes the hook zone directly onto the customer’s tab material. In addition to improving the flexibility of a diaper tab, for example, Flex-Zone technology reduces the likelihood of hook delamination and can reduce complexity in the manufacturer’s process.”

Morel points out that as private label further penetrates the market, competition will becomemuch more fierce, with a great effect on pricing. “As private label brands continue to have success, the steadily increasing intensity of competition in the hygiene components market is putting a premium on price reductions and operational efficiencies. This effect is compounded by rising raw material costs, economic pressure in most developed regions and growth in emerging markets.

“We’re challenged like never before to provide more for less, while maintaining our standards for world-class quality and industry-leading performance. The thirst for innovation is at an all-time high as well. We’ve increased up-front investment to continually turn out products that keep our customers at the forefront of their industries and achieving incremental cost savings,” Morel says.

Texsus and airthrough bonding

Barbara Bulleri, sales manager, Texsus, a provider specialized in the production of high loft ADL (acquisition distribution layer) material produced by air-through bonding technology, says that the prevailing trend in the market is to reduce core thickness. “We have foreseen and followed up on this trend with highly evolved loft ADL, specifically engineered,” she says. “Our Acquitex (ADL) is particularly suitable to produce thin/fluffless baby diapers as well as sanitary napkins and adult diapers,”Bulleri notes, adding that the main benefit to using a high loft ADL is the dryness that can be achieved through the main functions of the product.This dryness, she points out, is achieved through fast acquisition of the fluid, wide distribution (spreading) of the liquid and a buffer function. Bulleri explains:“The high loft ADL acts as a barrier between the wet mass and the skin. Acquitex products are available in a wide range of basis weights, colors and fiber mixing as well as multilayered structures and biodegradable compositions.”

Texsus also features topsheet products such as its Softex range, available in an array of basis weights and fiber mixing. “The main benefits to using an airthrough bonded topsheet are the softness and textile touch that cannot be achieved with alternative technologies such as spunbonded or perforated plastic film,” Bulleri says. “Main areas of application are femcare and incontinence. Softex is also available with different botanical treatments and embossed patterns,” she says. Softex layers can be treated with a wide range of natural finishes including aloe vera, vitamin E, silk protein, chamomile and additional substances.

There’s also Texsus Multitex, which combines topsheet and ADL. It’s a multilayer nonwoven combined in one unique, easy-to work structure made of soft topsheet and high loft ADL. “The Multitex concept pays close attention to sustainability, as it allows to use lighter materials and avoids any need of glue,” Bulleri says, emphasizing the increasing role environmental sustainability is playing in the hygiene market. The ultimate goal, she says, is to achieve zero waste to landfill, and notes the company is working on finished product recycling and use of renewable and recyclable raw materials, to be offered at a sustainable price for customers.

“In general, we think it is of primary importance to fulfill present needs without compromising the life of future generations. Environmental protection is an important part of our sustainability program,” Bulleri says. “We are committed to produce more green products focusing on the improvement of our process efficiency with the consequent reduction of energy consumption, recycling of production wastes, usage of renewable and recyclable raw materials.”

Texsus has recently doubled his airthrough bondingproduction capacity adding an additional line fully equipped with the latest modern technologies, the new capacity is mainly dedicated to the production of Acquitex High Loft ADL , including high grammage and multilayer materials, and Softex soft topsheets.

Furthermore, Texsus has improved its packaging services, thanks to two modern spooling lines able to produce spool rolls that handle up to 50 km of High Loft ADL.

Take the diaper, for example. Some are adorned with graphics designed to make the product visually appealing to both baby and Mom. Others feature fabrics to create a certain look, like the recent camouflage and jeans-themed diaper lines from Huggies.

|

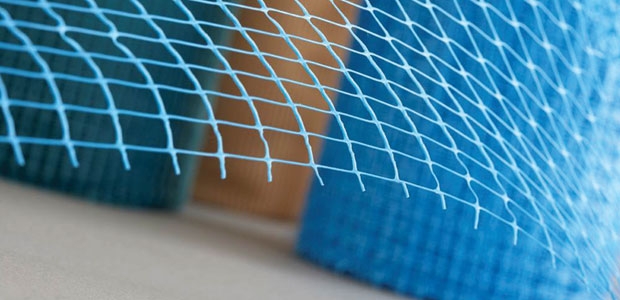

Conwed's Rebound elastomeric netting |

“We note the trend to thinner diapers and napkins enabled by new core technology and a growth in the use of bulkier, softer nonwoven topsheets enhanced with apertures and embossing, and elastic features continue to grow,” says Bill Norman, director of hygienic products for Clopay. Growth, he says, is clearly evident across the board. “There is continued opportunity for growth in emerging markets and regions. In addition, growth is available for innovative materials and technologies that enhance performance, aesthetics or sustainability – in a cost effective way.”

Pantex innovation

Pantex International is an example of a company that’s achieving the sought after combination of comfort, performance, fashion and affordability. “In order to satisfy the market’s requirements, we have in place several different activities that are mainly based on designing new products and features, while downgauging our product range accordingly,” says Gianluigi Fornoni, CEO for Pantex.

Recently, Pantex launched its innovative low basis weight (22-24gsm), perforated laminated films, the CL6, CL8 and CL18. These materials combine soft feel, dryness and visual appearance throughout different perforation patterns, with high runnability capabilities on high speed converting machines. In addition, the company has also launched a new“Ultra Soft” range of products that include embossed and perforated materials that satisfy the current market needs for softness and visual appearance. “The products are also available with lenitive additives and printing,” Fornoni explains. “High elastic properties, high strength and low basis weight is our response, with a cost effective elastic laminate for the increasing demand of elasticized components on baby diapers and adult care products.”

Fornoni points out the effect today’s global financial situation is having on the market. He says, “Due to the current global financial and economic situation, there is a continuous request for price reduction, which is challenging our developmental ability and, in order not to lose marketshare, we deliver to the market significant basis weight reduction on our traditional products without sacrificing the required performances.”

From a technical point of view, Fornoni has noticed an increase in attention for the fluid handling properties of the products where improvement, he says, is a must. “In addition, we notice the request for higher softness touch/feel, together with visual properties, like printing and embossing and for lenitive properties having additives like aloe, chamomile, vitamin E, etc. In particular, for baby diapers, we see the application of elasticized components growing.”

Berry Plastics: Sonic bonding and components with color

There continue to be advancements made when it comes to all areas related to printing, and this is the case with baby diapers, adult incontinence and feminine hygiene absorbent products.

“Bright and decorative colors are pleasing and stimulate positive consumer responses,” explains Keith Brechtelsbauer,vice president and general manager, Specialty Films Division, Berry Plastics Corp. He cites the recent success U by Kotex is having with teens and the introduction of new printed baby diapers with dots, bears and patterns that are pleasing to families. “Hygiene is becoming fashionable and products are being designed that reflect this,” he says.

Brechtelsbauer also emphasizes a continued trend towards work in sonic bonding of hygiene components to improve the form, fit and function of various materials. “Sonic bonding requires new film developments to ensure that nonwoven structures are bonded adequately to the film portion of the component. For example, Berry Plastics has partnered with Hermann Ultrasonics to marry both companies’ technologies together for optimum performance,” he adds.

Increasing diaper backsheet film softness at lower basis weights, while simultaneously maintaining converting speeds is an ongoing trend, Brechtelsbauer explains. “New resin developments hold some excellent promise for meeting value and cost targets going forward.”

As consumers look to extend usage cycles and minimize costs, and as the economy in the US has impacted hygienic article sales, this has had an impact on Berry’s research and development. “We at Berry continue to develop ‘high value polypropylene’ co-extrusions as a way to reduce basis weight while maintaining key properties around hole detection and winding integrity. This is a highly capital intensive development,” Brechtelsbauer says. Berry management recently approved $2 million in co-extrusion equipment upgrades to address this need.

Berry Plastics family of films called Touch of Silk (TOS) has been a top development priority. “This technology deploys new resin, embossing and extrusion technologies that impart tactile improvements while also allowing for the printing of graphics and the incorporation of nonwoven laminations. This Berry Plastics TOS technology is being applied in both article and packaging applications for personal care and medical fabrics,” says Brechtelsbauer.

Berry Plastics’ commitment to the printing and packaging of personal care products is unwavering. “We recently installed a new state-of-the-art, 10-color ‘quick change’ press in our McAlester, OK, site coupled with a new investment in two-sided printing. We are also adding additional bag converting capabilities to round out our dedicated investments in hygiene.”

Avery Dennison gets closure with tape

While diaper closures make up just a small portion of the final product, for obvious reasons their importance is immense. A recent innovation from Avery Dennison Corporation is a closure that simplifies diaper handling by applying the closure directly to the backsheet. This type of closure follows a trend where producers are switching from a polyethylene plastic backsheet to a nonwoven backsheet, thus permitting use of a closure that has excellent peel and shear.

“Unlike hook-and-loop systems that require a more coordinated application effort by the user, the new closure more directly hooks to the nonwoven backsheet,” explains Birgitta Van den Driessche, global product manager, personal care, Avery Dennison Performance Tapes. “Our diaper closure innovations also benefit diaper marketing and manufacturing. We offer extensive customization options that enhance the look and feel of a diaper. Customized closures offer diaper manufacturers a powerful way to brand their products. Beyond that, Avery Dennison also offers diaper manufacturers engineering assistance to make sure the tape closures run well on their equipment.”

Another innovation that supports diaper manufacturers’ processing efficiency is the ability of Avery Dennison Performance Tapes to supply closures for baby diapers and other nonwoven products on large-capacity spools. “The greater capacity increases the amount of tape that can be placed into diaper manufacturing lines, which can reduce the frequency of change-overs and the number of splices needed during diaper production,” Van den Driessche adds.

Avery Dennison has also picked up a distinct trend in emerging markets, where the company says there’s been an evolution from adhesive systems to mechanical closure systems.

“For mature markets, such as Europe and the US, as well as a few sectors in emerging markets, manufacturers are producing thinner and softer diapers, often with printing on the closure. Plus, premium diapers are gaining in popularity.”

It’s worth noting that nonwoven diaper closure innovations from Avery Dennison Performance Tapes are designed and developed based on input from mothers and fathers. Van den Driessche says, “Our interviews with parents revealed that comfort and ease-of-use remain high among their customer satisfaction priorities. In response, we are making it easier for users to find and open a tab on a diaper and we are looking at alternative materials to make closures even softer.

Netting it right with Conwed

Conwed, a maker of stretchable netting for hygiene products, is another components company that pays close attention to end users’ wants and needs in developing its product. According to Ivan Soltero, Conwed’s strategic marketing manager – Industrial, Conwed Global Netting Solutions, providing superior comfort is key. “End users keep influencing the industry and manufacturers are designing products with relevant characteristics such as breathability, smoothness, softness, drapeability, flexibility, high absorbency, etc.,” Soltero says.“End users seem to set expectations for obtaining good performance but also an affordable, comfortable product.”

Conwed is also noticing the trend to develop lighter-weight end products. “Companies are really trying to decrease costs while keeping good value in their product offerings,” Soltero says. “Whether it is to reduce volume, weight or layers, we see companies reinventing their processes to find a better alternative for their product line. This has just supported our efforts to work with our R&D and production departments to look for innovation that generates lighter weight products and more efficient and sustainable production processes.”

Soltero says companies today are dedicating a more significant share of their resources and focus to adult incontinence applications. “The demographics in North America call for giving extra attention to the steady growth of the adult incontinence segment. We have seen increased interest in our elastomeric netting for waistbands in incontinence underwear, which leads us to believe that this trend will still enjoy future growth,” Soltero says.

Addressing the need for lighter-weight products, Conwed recently improved upon its Rebound elastomeric netting, a product line introduced to the hygiene industry almost a decade ago, but was heavier and less developed than its most recent version. “Our R&D team has made great improvements to our processes in recent years and has been able to produce lighter weight elastomeric netting while keeping optimal tensile strength and stretch performance. With these enhancements, we have experienced renewed interest from hygiene manufacturers as our value proposition is now very competitive with that of other stretch engine materials such as spandex, films and stretchable nonwovens,” Soltero explains.

Soltero says the new Rebound netting features superior hysteresis versus other stretch engine materials which means it is highly stretchable and has excellent recovery with less energy loss. “It’s also flexible and strong due to its web structure, which allows customization of machine direction (MD), cross direction (CD) or bi-directional stretch capabilities, all while offering superior breathability and fit while providing comfort and durability.”

Soltero emphasizes that Rebound offers specific benefits to both manufacturers and end users alike. “Rebound elastomeric netting creates a superior stretch engine that allows products to expand while maintaining dimensional stability and compression. Its consistent integral joints form a web structure that provides stretch properties in one or all directions. So, manufacturers can customize stretch properties to fit final application. For end users, Rebound allows for a Tailored fit for products that demand to stay in place without restricting range of motion, and it’s designed to enhance flexibility and strength while delivering exceptional comfort, shape, durability and breathability.”

Stretching with Creora spandex

Hyosung, with its signature Creora brand, is the largest producer of spandex in the world with plants in Korea, China, Turkey, Vietnam and Brazil. Ria Stern, global marketing and brand director, emphasizes that, globally, the disposable hygiene market is a growth market, as population is increasing in emerging markets.

“Economic conditions in these countries are improving and with more women working outside their homes, the convenience of disposable diapers (and their affordability) is increasing,” Stern says, “Similarly as the population ages, and more people are living longer, the need for adult incontinent diapers is increasing.”

Stern says that Hyosung’s Creora C-100 has become an increasingly popular product among its customers. She emphasizes that its unique polymer chemistry provides for softer stretch, higher elongation than the competition, and 300% working elongation. Also, she says, higher draftability translates into reduced elastic cost per unit.

“We offer a wide range of deniers, in over and rolling take off with transfer tails for increased productivity and continuous processing,” Stern explains, adding that Hyosung can provide uniform unwinding, package to package uniformity and larger package sizes for up 150% longer run times.

Stern points out an important fact regarding the relationship between the components they provide and the end use product – the diaper. “Spandex is a small component of the overall diaper, however, if there is breakage in the spandex, the waste generated is the entire diaper.”

Velcro’s hook

Velcro is another brand that can offer keen insight, particularly when it comes to today’s closure market trends. Rebecca Morel, Velcro’s product manager personal care, says, “The trends in closure systems reflect trends we see across many categories of the hygiene components market. Of these, the demand for softness and flexibility are clearly on the rise. In developing and emerging markets, effective performance of the component is still the most valued aspect, now followed closely by qualities such as softness.In mature markets, softness, flexibility and aesthetics rate on par with performance, with growing expectations in terms of the primary function – that the component‘just works’.”

Velcro focuses on a variety of specialized hook components along with its nonwoven FNL landing zone materials. “Our FNL technology enables us to manufacture nonwoven materials that eliminate the use of films in landing zones for a softer look and feel,” Morel explains. “This is combined with a manufacturing process that delivers a consistent weight, resulting in a more secure fastening system. The translucence of these products allows graphics to be visible through the backsheet material. This can cut manufacturer costs by reducing print on multiple components. We also offer printed FNL materials to help differentiate the landing zone of products.”

The integrated solution of Velcro’s Flex-Zone technology is another of the brand’s offerings within the hygiene market. These systems allow for a more flexible product by eliminating the need to adhesively bond the hook to a variety of substrates. Morel says, “We are able to offer a product that extrudes the hook zone directly onto the customer’s tab material. In addition to improving the flexibility of a diaper tab, for example, Flex-Zone technology reduces the likelihood of hook delamination and can reduce complexity in the manufacturer’s process.”

Morel points out that as private label further penetrates the market, competition will becomemuch more fierce, with a great effect on pricing. “As private label brands continue to have success, the steadily increasing intensity of competition in the hygiene components market is putting a premium on price reductions and operational efficiencies. This effect is compounded by rising raw material costs, economic pressure in most developed regions and growth in emerging markets.

“We’re challenged like never before to provide more for less, while maintaining our standards for world-class quality and industry-leading performance. The thirst for innovation is at an all-time high as well. We’ve increased up-front investment to continually turn out products that keep our customers at the forefront of their industries and achieving incremental cost savings,” Morel says.

Texsus and airthrough bonding

Barbara Bulleri, sales manager, Texsus, a provider specialized in the production of high loft ADL (acquisition distribution layer) material produced by air-through bonding technology, says that the prevailing trend in the market is to reduce core thickness. “We have foreseen and followed up on this trend with highly evolved loft ADL, specifically engineered,” she says. “Our Acquitex (ADL) is particularly suitable to produce thin/fluffless baby diapers as well as sanitary napkins and adult diapers,”Bulleri notes, adding that the main benefit to using a high loft ADL is the dryness that can be achieved through the main functions of the product.This dryness, she points out, is achieved through fast acquisition of the fluid, wide distribution (spreading) of the liquid and a buffer function. Bulleri explains:“The high loft ADL acts as a barrier between the wet mass and the skin. Acquitex products are available in a wide range of basis weights, colors and fiber mixing as well as multilayered structures and biodegradable compositions.”

Texsus also features topsheet products such as its Softex range, available in an array of basis weights and fiber mixing. “The main benefits to using an airthrough bonded topsheet are the softness and textile touch that cannot be achieved with alternative technologies such as spunbonded or perforated plastic film,” Bulleri says. “Main areas of application are femcare and incontinence. Softex is also available with different botanical treatments and embossed patterns,” she says. Softex layers can be treated with a wide range of natural finishes including aloe vera, vitamin E, silk protein, chamomile and additional substances.

There’s also Texsus Multitex, which combines topsheet and ADL. It’s a multilayer nonwoven combined in one unique, easy-to work structure made of soft topsheet and high loft ADL. “The Multitex concept pays close attention to sustainability, as it allows to use lighter materials and avoids any need of glue,” Bulleri says, emphasizing the increasing role environmental sustainability is playing in the hygiene market. The ultimate goal, she says, is to achieve zero waste to landfill, and notes the company is working on finished product recycling and use of renewable and recyclable raw materials, to be offered at a sustainable price for customers.

“In general, we think it is of primary importance to fulfill present needs without compromising the life of future generations. Environmental protection is an important part of our sustainability program,” Bulleri says. “We are committed to produce more green products focusing on the improvement of our process efficiency with the consequent reduction of energy consumption, recycling of production wastes, usage of renewable and recyclable raw materials.”

Texsus has recently doubled his airthrough bondingproduction capacity adding an additional line fully equipped with the latest modern technologies, the new capacity is mainly dedicated to the production of Acquitex High Loft ADL , including high grammage and multilayer materials, and Softex soft topsheets.

Furthermore, Texsus has improved its packaging services, thanks to two modern spooling lines able to produce spool rolls that handle up to 50 km of High Loft ADL.