09.09.14

Weinheim, Germany

www.freudenberg.com

2014 Nonwovens Sales: $1.54 billion

Freudenberg Nonwovens: $825.2 million

Freudenberg Politex Nonwovens: $269.8 million

Freudenberg Filtration Technologies $451 billion

Key Personnel

Bruce Olson, CEO; René Wollert, CFO; Frank Heislitz, CTO, Richard Shaw, COO

Plants

Weinheim, Germany; Neuenburg, Germany; Kaiserslautern, Germany; Greetland, UK; Swindon, UK; Littleborough, U.K.; Colmar, France; Barcelona, Spain; Nizhiniy, Novgorod, Russia; Sant´ Omero, Italy; Cossato, Italy; Novedrate, Italy; Pisticci, Italy; Hong Kong, China; Suzhou, China; Nantong, China; Chennai, India; Pyungtaek, South Korea; Yang Mei, Taiwan; Tayuan, Taiwan; San Martin/Buenos Aires, Argentina; Durham, NC, U.S.; Jacarei, Brazil; Cape Town, South Africa

ISO Status

All locations are ISO 9001 and ISO 14001 certified; locations serving the automotives industry are TS 16469 certified; all sites are OHSAS 18001 certified

Processes

Drylaid staple fiber, wetlaid, spunbond, meltblown, needle punched, thermal bond, chemical bond, water entanglement

Brands

Celestia, Comfortemp, Evolon, Lutradur, Lutrasil, SoundTex, Vildona, Viledon, Vilene, Vilmed, Vlieseline, Marelli & Berta Major

Markets

Automotive interiors, apparel, energy, geotextiles, building interiors, medical, hygiene and special applications.

A new name and a new structure were among the top headlines for Freudenberg, which ranks number two on the list of top manufacturers this year after being edged out by Avintiv. At the start of the year, its parent company merged Freudenberg Nonwovens with its roofing and construction outfit Freudenberg Politex Nonwovens to create Freudenberg Performance Materials. The combined company now reports sales of €905 million and supplies materials in various markets and applications including automotive interiors, apparel, building materials, hygiene, medical, shoe components and specialties.

“Many products from former Freudenberg Nonwovens and Freudenberg Politex Nonwovens are very similar concerning their production and their application,” says CEO Bruce Olson. “Therefore we can use synergies along the entire value chain, for example concerning the material expertise.”

At Techtextil in Germany this year, Olson discussed the new company. On the one hand, he says, it is a very young company—due to its January launch—but at the same time, the company is looking back on “a long and successful history” developed by the previous groups.

“Together, we believe we are headed to an even brighter and more successful future,” Olson says.

The new business group will continue to be driven by the same set of values and guiding principles, he explains, and while nonwovens is a core technology platform for the company, the creation of Freudenberg Performance Materials will strengthen nonwovens further as a core technology platform.

“But our vision does not stop there,” he continues. “The name Performance Materials stands for more than just the name of a new business group. It represents a new strategic orientation and a mandate from our shareholders and hopefully from our customers to look beyond nonwovens in providing customers with solutions they need to remain successful and profitable.”

On the same day Freudenberg Performance Materials began operations, it also acquired 100% ownership of Polymer Health Technology, Wales, U.K., a leading supplier of polyurethane foams for advanced wound care applications.

With the acquisition of Polymer Health Technology, Freudenberg Performance Materials is able to offer its globally active customers additional innovative solutions for modern wound management. The hydrophilic polyurethane foam systems from Polymer Health Technology absorb wound exudate, creating an ideal environment for healing the wound and protecting it from drying out.

Freudenberg’s woundcare business in general has been earmarked a strong growth area in which different material groups—all supporting the healing process—are used. “Our substrates for advanced wound care dressings are used in the treatment of complex hard-to-heal wounds, e.g. diabetic foot, leg and pressure ulcers,” Olson says. “The nonwovens and foams designed by Freudenberg offer numerous constructions and raw material options to provide customized and innovative product solutions in advance wound care: hydroactive nonwovens, high absorbing nonwovens, hydrophilic foams and other tailor made solutions. One of the latest nonwoven developments with a thickness of two millimeters can even absorb wound exudates of up to 25 times of its own weight.”

Another important division for Freudenberg Performance Materials is its spunlaid business which primarily serves the automotives, construction and bedding markets, which has assets serving this business on three continents—North America, Europe and Asia.

“Freudenberg Performance Materials has an excellent position in the spunlaid business. All three markets show specific opportunities for growth,” Olson says. “The customer base in our core segments is becoming more globalized, which drives us to ensure that we offer the same product range worldwide. The tiles sub-segment (construction market) shows the highest growth rates globally. “

In January 2014, Freudenberg announced a plan to upgrade its spunlaid operations in Durham, NC and Kaiserslautern, Germany. According to the company, the projects—both line enhancements—will improve product quality, allowing them to make nonwovens with high quality and improved performance. In Durham, three spunlaid lines were retrofitted with advanced production technology, while in Kaiserslautern an existing pilot line, which provides a good platform for product development at the planning level was upgraded. This project led to improvements in the quality of the product’s physical properties, allowing the business group to proactively serve the needs of its customers. “We continue to evaluate options for capacity expansions globally. If we realize an investment, it will be in next generation technology,” Olson adds.

Freudenberg’s spunlaid facility in Taiwan was not affected by the project. This site received a new line in 2012 to help increase the company’s profile in Asia.

Another important growth market for Freudenberg is Evolon, its microfilament nonwoven material, which was developed more than a decade ago but continues to evolve.

“Thanks to microfilaments which are around 100 times thinner than a human hair, Evolon’s worldwide patented technology provides outstanding lint-free, anti-scratch cleaning performance,” Olson says. “Furthermore, endless microfilaments make Evolon strong and mechanically stable. The isotropic fabric provides extended durability starting from lightweight wipes and frequent wash resistance for heavier weights.”

In May, Freudenberg launched Evolon 3D. This three-dimensional version of the material features increased surface volume and has become more refined, paving the way for other possible applications. Evolon 3D preserves the high performance of original Evolon, while increasing its bulkiness and volume and by taking on a feel and a look that are even more like fabric, according to Freudenberg. Like the original Evolon, Evolon 3D can be washed again and again without losing its structure. It can be kept white or dyed various colors. Transfer printing multiplies the possibilities for design and personalization and also produces very good results on Evolon 3D, according to company literature.

The applications are many and varied. In the ultralight category (as low as 30gsm), the 3D structure reinforces the uniformity of the microfilaments and increases ease of handling, making it possible to supply 3D microfilament wipes, which are 1.5 to 2 times lighter than the lightweight wipes traditionally obtained using competing processes. In addition, in its 100gsm version, Evolon 3D enables a new generation of sports towels to be produced that are just as ultra-compact, lightweight and effective but with a traditional fabric look that consumers know well.

Lastly, designers can use Evolon 3D in decoration, where Evolon is already valued for its matte look, lightness, ease of handling and its acoustical properties.

In keeping with Evolon’s clean production—free of solvents and chemical binders and with a minimum of production stages—the Evolon 3D structure is achieved without post-treatment and without the addition of chemicals.

In 2014, Freudenberg’s Interlinings Division recorded moderate growth in Europe, benefiting from market recovery in southern Europe, in particular Italy and Spain. Sales of woven, knit and nonwoven interlinings in the industrial apparel segment rose while a project known as the menswear initiative resulted in increased sales of woven and knit products.

A series of product innovations contributed to growth in the year under review. The main growth drivers were elastic interlinings and innovative paddings as a substitute for down as well as optimized product positioning in key markets.

In 2015, the Interlinings Division has returned to operating as a global division, bringing together all regions. The creation of this global management team has allowed Freudenberg Nonwovens to serve its customers in the global apparel industry more effectively and efficiently, according to Olson.

“The apparel business is truly global and business between regions is closely interlinking,” he says. “With its long established global presence, it was the next logical step for Freudenberg Apparel to evolve into a global division.”

Olson adds that the new organizational structure will enable the company to fully exploit the synergies between operational and strategic structures. The goal is to drive growth in the apparel market segment by engaging with customers at a global level.

“The global apparel market is growing in line with GDP. Apparel is a competitive business but Freudenberg has a strong position in most core markets,” Olson adds. “With its customized product and service packages, global network and broad product range globally available, Freudenberg Apparel is well positioned to serve the specific customer demands and further strengthen its global marketshare.”

In July 2014, Freudenberg expanded its interlinings business through the acquisition of the Hänsel brand from Hänsel Textil in Iserlohn, Germany. As a leading global manufacturer of highly-developed textiles, Hänsel has allowed Freudenberg to offer additional sophisticated interlining solutions. Hänsel offers numerous special interlinings for manufacturers of ladies and men’s outer garments, childrenswear and sports clothing. Products include genuine horsehair canvas, multi-zone interlinings or extremely light wovens and knits.

“The Hänsel brand stands for quality and innovation. With the textile interlinings used throughout the fashion industry, we are extending our comprehensive portfolio and our know-how in the field of knitted fabrics in a future-oriented manner,” Olson adds.

In new product news, Freudenberg has developed the world’s first nonwoven interlining made from 100% biodegradable polyester fiber, which made it the first company to be issued with a certificate for the biodegradation of a PES interlining by the German Hohenstein Institute, an accredited test laboratory.

ECO 123 degrades twice as fast as a standard polyester interlining. In an alkaline composting environment, degradation would already be completed in approximately six to nine months. The lightweight nonwoven interlining has good resistance to washing and drycleaning and is suitable for ironing.

Freudenberg Politex Nonwovens

In January 2015, Freudenberg Politex Nonwovens—the Freudenberg´s roofing and construction specialist, which makes polyester-based nonwovens using both staple and spunbonded technology—merged with company’s nonwovens business group to become Freudenberg Performance Materials.

Recent developments from this arm of the company include an expansion of its product range through the addition of innovative special products for roofing materials and the construction industry. Central to these developments were the modification of two production lines in Pisticci, Italy.

One of these lines now makes fiberglass-reinforced spunbonded nonwovens for flat roof applications and the other can manufacture nonwoven roofing reinforcements for pitched slate roofs. Freudenberg Politex also operations production sites in Spain, Russia and Georgia.

Freudenberg Filtration Technologies

Freudenberg Filtration Technologies reported sustained growth in 2014 with sales increasing to €373.1 million. The business group made good progress in profitability on the back of the higher sales volume, increased productivity at plants, systematic costs, inventory and receivables management as well as continuous improvement programs.

In 2014, good sales growth in Europe and China contrasted with developments in South America, Australia and South Africa which were characterized by challenging economic factors. In industry filtration, Freudenberg Filtration Technologies further expanded its business with Viledone filter elements and service contracts. Furthermore, the group won and concluded key major orders for system solutions. Projects included complete air filtration systems for offshore oil platforms in Brazil, filtration systems for a hospital in Spain and several project orders for efficient resource-saving wastewater treatment in the U.K. food and beverage industry.

Demand for micronAir cabin air filters, which are sold as original equipment in new vehicles and on the aftermarket, increased in all regions, with appreciable growth in China, North America and Europe. In response to this increased demand, the group has commissioned a new logistics center at its Kaiserslautern, Germany site. The newly created close proximity of production and logistics is one contributory factor in meeting customers’ growing demands regarding product availability and delivery flexibility.

In 2014, Freudenberg Filtration Technologies acquired the industrial activated carbon corrosion protection business of U.S.-based MeadWestvaco Corporation. The air purification product portfolio comprises activated carbon pellets, Honeycomb modules, which include the innovative Versacomb technology and system solutions. These new products complement the company’s existing range of quality gas phase filtration solutions.

www.freudenberg.com

2014 Nonwovens Sales: $1.54 billion

Freudenberg Nonwovens: $825.2 million

Freudenberg Politex Nonwovens: $269.8 million

Freudenberg Filtration Technologies $451 billion

Key Personnel

Bruce Olson, CEO; René Wollert, CFO; Frank Heislitz, CTO, Richard Shaw, COO

Plants

Weinheim, Germany; Neuenburg, Germany; Kaiserslautern, Germany; Greetland, UK; Swindon, UK; Littleborough, U.K.; Colmar, France; Barcelona, Spain; Nizhiniy, Novgorod, Russia; Sant´ Omero, Italy; Cossato, Italy; Novedrate, Italy; Pisticci, Italy; Hong Kong, China; Suzhou, China; Nantong, China; Chennai, India; Pyungtaek, South Korea; Yang Mei, Taiwan; Tayuan, Taiwan; San Martin/Buenos Aires, Argentina; Durham, NC, U.S.; Jacarei, Brazil; Cape Town, South Africa

ISO Status

All locations are ISO 9001 and ISO 14001 certified; locations serving the automotives industry are TS 16469 certified; all sites are OHSAS 18001 certified

Processes

Drylaid staple fiber, wetlaid, spunbond, meltblown, needle punched, thermal bond, chemical bond, water entanglement

Brands

Celestia, Comfortemp, Evolon, Lutradur, Lutrasil, SoundTex, Vildona, Viledon, Vilene, Vilmed, Vlieseline, Marelli & Berta Major

Markets

Automotive interiors, apparel, energy, geotextiles, building interiors, medical, hygiene and special applications.

A new name and a new structure were among the top headlines for Freudenberg, which ranks number two on the list of top manufacturers this year after being edged out by Avintiv. At the start of the year, its parent company merged Freudenberg Nonwovens with its roofing and construction outfit Freudenberg Politex Nonwovens to create Freudenberg Performance Materials. The combined company now reports sales of €905 million and supplies materials in various markets and applications including automotive interiors, apparel, building materials, hygiene, medical, shoe components and specialties.

“Many products from former Freudenberg Nonwovens and Freudenberg Politex Nonwovens are very similar concerning their production and their application,” says CEO Bruce Olson. “Therefore we can use synergies along the entire value chain, for example concerning the material expertise.”

At Techtextil in Germany this year, Olson discussed the new company. On the one hand, he says, it is a very young company—due to its January launch—but at the same time, the company is looking back on “a long and successful history” developed by the previous groups.

“Together, we believe we are headed to an even brighter and more successful future,” Olson says.

The new business group will continue to be driven by the same set of values and guiding principles, he explains, and while nonwovens is a core technology platform for the company, the creation of Freudenberg Performance Materials will strengthen nonwovens further as a core technology platform.

“But our vision does not stop there,” he continues. “The name Performance Materials stands for more than just the name of a new business group. It represents a new strategic orientation and a mandate from our shareholders and hopefully from our customers to look beyond nonwovens in providing customers with solutions they need to remain successful and profitable.”

On the same day Freudenberg Performance Materials began operations, it also acquired 100% ownership of Polymer Health Technology, Wales, U.K., a leading supplier of polyurethane foams for advanced wound care applications.

With the acquisition of Polymer Health Technology, Freudenberg Performance Materials is able to offer its globally active customers additional innovative solutions for modern wound management. The hydrophilic polyurethane foam systems from Polymer Health Technology absorb wound exudate, creating an ideal environment for healing the wound and protecting it from drying out.

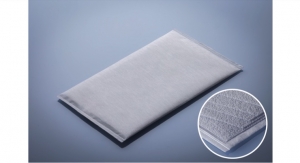

Freudenberg’s woundcare business in general has been earmarked a strong growth area in which different material groups—all supporting the healing process—are used. “Our substrates for advanced wound care dressings are used in the treatment of complex hard-to-heal wounds, e.g. diabetic foot, leg and pressure ulcers,” Olson says. “The nonwovens and foams designed by Freudenberg offer numerous constructions and raw material options to provide customized and innovative product solutions in advance wound care: hydroactive nonwovens, high absorbing nonwovens, hydrophilic foams and other tailor made solutions. One of the latest nonwoven developments with a thickness of two millimeters can even absorb wound exudates of up to 25 times of its own weight.”

Another important division for Freudenberg Performance Materials is its spunlaid business which primarily serves the automotives, construction and bedding markets, which has assets serving this business on three continents—North America, Europe and Asia.

“Freudenberg Performance Materials has an excellent position in the spunlaid business. All three markets show specific opportunities for growth,” Olson says. “The customer base in our core segments is becoming more globalized, which drives us to ensure that we offer the same product range worldwide. The tiles sub-segment (construction market) shows the highest growth rates globally. “

In January 2014, Freudenberg announced a plan to upgrade its spunlaid operations in Durham, NC and Kaiserslautern, Germany. According to the company, the projects—both line enhancements—will improve product quality, allowing them to make nonwovens with high quality and improved performance. In Durham, three spunlaid lines were retrofitted with advanced production technology, while in Kaiserslautern an existing pilot line, which provides a good platform for product development at the planning level was upgraded. This project led to improvements in the quality of the product’s physical properties, allowing the business group to proactively serve the needs of its customers. “We continue to evaluate options for capacity expansions globally. If we realize an investment, it will be in next generation technology,” Olson adds.

Freudenberg’s spunlaid facility in Taiwan was not affected by the project. This site received a new line in 2012 to help increase the company’s profile in Asia.

Another important growth market for Freudenberg is Evolon, its microfilament nonwoven material, which was developed more than a decade ago but continues to evolve.

“Thanks to microfilaments which are around 100 times thinner than a human hair, Evolon’s worldwide patented technology provides outstanding lint-free, anti-scratch cleaning performance,” Olson says. “Furthermore, endless microfilaments make Evolon strong and mechanically stable. The isotropic fabric provides extended durability starting from lightweight wipes and frequent wash resistance for heavier weights.”

In May, Freudenberg launched Evolon 3D. This three-dimensional version of the material features increased surface volume and has become more refined, paving the way for other possible applications. Evolon 3D preserves the high performance of original Evolon, while increasing its bulkiness and volume and by taking on a feel and a look that are even more like fabric, according to Freudenberg. Like the original Evolon, Evolon 3D can be washed again and again without losing its structure. It can be kept white or dyed various colors. Transfer printing multiplies the possibilities for design and personalization and also produces very good results on Evolon 3D, according to company literature.

The applications are many and varied. In the ultralight category (as low as 30gsm), the 3D structure reinforces the uniformity of the microfilaments and increases ease of handling, making it possible to supply 3D microfilament wipes, which are 1.5 to 2 times lighter than the lightweight wipes traditionally obtained using competing processes. In addition, in its 100gsm version, Evolon 3D enables a new generation of sports towels to be produced that are just as ultra-compact, lightweight and effective but with a traditional fabric look that consumers know well.

Lastly, designers can use Evolon 3D in decoration, where Evolon is already valued for its matte look, lightness, ease of handling and its acoustical properties.

In keeping with Evolon’s clean production—free of solvents and chemical binders and with a minimum of production stages—the Evolon 3D structure is achieved without post-treatment and without the addition of chemicals.

In 2014, Freudenberg’s Interlinings Division recorded moderate growth in Europe, benefiting from market recovery in southern Europe, in particular Italy and Spain. Sales of woven, knit and nonwoven interlinings in the industrial apparel segment rose while a project known as the menswear initiative resulted in increased sales of woven and knit products.

A series of product innovations contributed to growth in the year under review. The main growth drivers were elastic interlinings and innovative paddings as a substitute for down as well as optimized product positioning in key markets.

In 2015, the Interlinings Division has returned to operating as a global division, bringing together all regions. The creation of this global management team has allowed Freudenberg Nonwovens to serve its customers in the global apparel industry more effectively and efficiently, according to Olson.

“The apparel business is truly global and business between regions is closely interlinking,” he says. “With its long established global presence, it was the next logical step for Freudenberg Apparel to evolve into a global division.”

Olson adds that the new organizational structure will enable the company to fully exploit the synergies between operational and strategic structures. The goal is to drive growth in the apparel market segment by engaging with customers at a global level.

“The global apparel market is growing in line with GDP. Apparel is a competitive business but Freudenberg has a strong position in most core markets,” Olson adds. “With its customized product and service packages, global network and broad product range globally available, Freudenberg Apparel is well positioned to serve the specific customer demands and further strengthen its global marketshare.”

In July 2014, Freudenberg expanded its interlinings business through the acquisition of the Hänsel brand from Hänsel Textil in Iserlohn, Germany. As a leading global manufacturer of highly-developed textiles, Hänsel has allowed Freudenberg to offer additional sophisticated interlining solutions. Hänsel offers numerous special interlinings for manufacturers of ladies and men’s outer garments, childrenswear and sports clothing. Products include genuine horsehair canvas, multi-zone interlinings or extremely light wovens and knits.

“The Hänsel brand stands for quality and innovation. With the textile interlinings used throughout the fashion industry, we are extending our comprehensive portfolio and our know-how in the field of knitted fabrics in a future-oriented manner,” Olson adds.

In new product news, Freudenberg has developed the world’s first nonwoven interlining made from 100% biodegradable polyester fiber, which made it the first company to be issued with a certificate for the biodegradation of a PES interlining by the German Hohenstein Institute, an accredited test laboratory.

ECO 123 degrades twice as fast as a standard polyester interlining. In an alkaline composting environment, degradation would already be completed in approximately six to nine months. The lightweight nonwoven interlining has good resistance to washing and drycleaning and is suitable for ironing.

Freudenberg Politex Nonwovens

In January 2015, Freudenberg Politex Nonwovens—the Freudenberg´s roofing and construction specialist, which makes polyester-based nonwovens using both staple and spunbonded technology—merged with company’s nonwovens business group to become Freudenberg Performance Materials.

Recent developments from this arm of the company include an expansion of its product range through the addition of innovative special products for roofing materials and the construction industry. Central to these developments were the modification of two production lines in Pisticci, Italy.

One of these lines now makes fiberglass-reinforced spunbonded nonwovens for flat roof applications and the other can manufacture nonwoven roofing reinforcements for pitched slate roofs. Freudenberg Politex also operations production sites in Spain, Russia and Georgia.

Freudenberg Filtration Technologies

Freudenberg Filtration Technologies reported sustained growth in 2014 with sales increasing to €373.1 million. The business group made good progress in profitability on the back of the higher sales volume, increased productivity at plants, systematic costs, inventory and receivables management as well as continuous improvement programs.

In 2014, good sales growth in Europe and China contrasted with developments in South America, Australia and South Africa which were characterized by challenging economic factors. In industry filtration, Freudenberg Filtration Technologies further expanded its business with Viledone filter elements and service contracts. Furthermore, the group won and concluded key major orders for system solutions. Projects included complete air filtration systems for offshore oil platforms in Brazil, filtration systems for a hospital in Spain and several project orders for efficient resource-saving wastewater treatment in the U.K. food and beverage industry.

Demand for micronAir cabin air filters, which are sold as original equipment in new vehicles and on the aftermarket, increased in all regions, with appreciable growth in China, North America and Europe. In response to this increased demand, the group has commissioned a new logistics center at its Kaiserslautern, Germany site. The newly created close proximity of production and logistics is one contributory factor in meeting customers’ growing demands regarding product availability and delivery flexibility.

In 2014, Freudenberg Filtration Technologies acquired the industrial activated carbon corrosion protection business of U.S.-based MeadWestvaco Corporation. The air purification product portfolio comprises activated carbon pellets, Honeycomb modules, which include the innovative Versacomb technology and system solutions. These new products complement the company’s existing range of quality gas phase filtration solutions.