03.11.19

Booth 820

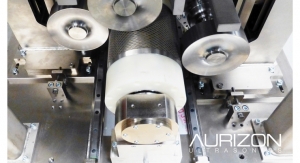

Aurizon Ultrasonics makes high power ultrasonic systems for a variety of nonwoven processing applications including bonding, elastic entrapment, feature attachement, embossing, sheet lamiantion and custting.

Many nonwoven product manufacturers use adhesives for these steps, but Aurizon is proving that there is a better way to produce elasticized fabric – ultrasonic technology!

In the past, Aurizon Ultrasonics exclusively provided rotary sonotrodes with their technology. However, in 2019 they are expanding their offerings by including the option of fixed blade horn technology. This technology can reduce equipment cost by leveraging an increased blade width as compared to rotary. It is not suitable as a replacement for all rotary horn applications, yet there are many less demanding applications where it is an effective solution such as material lamination and edge sealing.

The company’s patented technology provides a solid foundation for delivering increased productivity, reduced costs, and a more sustainable process. Additionally, ultrasonic technology has aesthetic benefits including odorless, softer, more breathable fabric and the potential for using lighter materials and reduced elastic decitex. Elasticized fabric created by ultrasonic methods has more drape, bend and crush conformability than products using adhesive.

Aurizon Ultrasonics makes high power ultrasonic systems for a variety of nonwoven processing applications including bonding, elastic entrapment, feature attachement, embossing, sheet lamiantion and custting.

Many nonwoven product manufacturers use adhesives for these steps, but Aurizon is proving that there is a better way to produce elasticized fabric – ultrasonic technology!

In the past, Aurizon Ultrasonics exclusively provided rotary sonotrodes with their technology. However, in 2019 they are expanding their offerings by including the option of fixed blade horn technology. This technology can reduce equipment cost by leveraging an increased blade width as compared to rotary. It is not suitable as a replacement for all rotary horn applications, yet there are many less demanding applications where it is an effective solution such as material lamination and edge sealing.

The company’s patented technology provides a solid foundation for delivering increased productivity, reduced costs, and a more sustainable process. Additionally, ultrasonic technology has aesthetic benefits including odorless, softer, more breathable fabric and the potential for using lighter materials and reduced elastic decitex. Elasticized fabric created by ultrasonic methods has more drape, bend and crush conformability than products using adhesive.