09.28.20

Lydall, a leading global manufacturer of value-added engineered materials and specialty filtration solutions, announced its partnership with XPRIZE, a nonprofit organization that uses global competitions to crowdsource solutions to some of the world’s biggest challenges. Lydall will supply fine fiber meltblown filtration media, the critical component of N95 respirators and surgical masks that traps harmful particles, to the 25 qualified teams of XPRIZE’s Next-Gen Mask Challenge. Launched in July 2020, this four-month challenge invites young adults around the world to develop the next generation of surgical-grade consumer face masks. In addition to sharing a one-million-dollar prize, the three winning teams will be connected to rapid manufacturing opportunities in the U.S. to bring their designs to life.

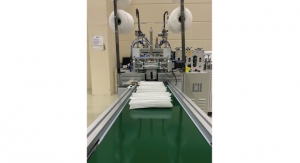

A global market leader in specialty filtration solutions for 100 years, Lydall is one of only a few companies in the U.S. and the world capable of manufacturing fine fiber meltblown filtration media for face masks and high-efficiency air filtration systems. Doing so requires extensive technical expertise, deeply ingrained supplier relationships and access to the right equipment. For decades, Lydall has produced filtration media at its facilities in Rochester, NH, and Saint-Rivalain, France.

Although the material has a variety of applications, in response to Covid-19, Lydall quickly pivoted to meet the explosive demand for meltblown filtration media for N95 respirators, surgical masks and other personal protective equipment (PPE). The company also announced investments in two new production lines in New Hampshire and one in France. The first new production line will be operational by the beginning of 2021, with the other two coming on line in mid-2021, increasing Lydall’s output of meltblown filtration media many times over.

“Innovation is core to who we are, and that means not only challenging ourselves to advance filtration science, but also supporting the next generation of innovators,” says Ashish Diwanji, president of Lydall Performance Materials, who will also serve on the judging panel for the challenge. “We’re honored to use our knowledge and resources to support XPRIZE and the young adults who are passionate about addressing the greatest global health crisis in over a century. I speak on behalf of all my colleagues at Lydall when I say that we can’t wait to see what kinds of solutions the teams come up with.”

Participants in XPRIZE’s Next-Gen Mask Challenge are tasked with designing face masks that offer a level of performance comparable to that of a surgical mask. This means that the mask must block 95% of particles while letting in enough air to allow the wearer to breathe comfortably. Lydall’s meltblown filtration media enables mask manufacturers to meet rigorous standards for quality and efficiency set in the U.S. by NIOSH, a division of the CDC, and ASTM. The material is even imbued with an electric charge that attracts particles, keeping them away from the wearer’s nose and mouth.

“We’re thrilled to have found such a strong partner for the XPRIZE Next-Gen Mask Challenge in Lydall,” says Sarah Saenz, XPRIZE Next-Gen Mask Lead. “We are challenging young innovators across the world to shift the perception around mask-wearing behavior by reimagining face masks entirely, but the most important aspect is safety. Lydall is providing the critical filtration media that makes N95 and surgical masks effective, and just as importantly, its team of engineers and material scientists will provide counsel and support to young adults around the world who want to build a better face mask. Their participation will help ensure that real solutions to a very real crisis are made available to our communities.”

A global market leader in specialty filtration solutions for 100 years, Lydall is one of only a few companies in the U.S. and the world capable of manufacturing fine fiber meltblown filtration media for face masks and high-efficiency air filtration systems. Doing so requires extensive technical expertise, deeply ingrained supplier relationships and access to the right equipment. For decades, Lydall has produced filtration media at its facilities in Rochester, NH, and Saint-Rivalain, France.

Although the material has a variety of applications, in response to Covid-19, Lydall quickly pivoted to meet the explosive demand for meltblown filtration media for N95 respirators, surgical masks and other personal protective equipment (PPE). The company also announced investments in two new production lines in New Hampshire and one in France. The first new production line will be operational by the beginning of 2021, with the other two coming on line in mid-2021, increasing Lydall’s output of meltblown filtration media many times over.

“Innovation is core to who we are, and that means not only challenging ourselves to advance filtration science, but also supporting the next generation of innovators,” says Ashish Diwanji, president of Lydall Performance Materials, who will also serve on the judging panel for the challenge. “We’re honored to use our knowledge and resources to support XPRIZE and the young adults who are passionate about addressing the greatest global health crisis in over a century. I speak on behalf of all my colleagues at Lydall when I say that we can’t wait to see what kinds of solutions the teams come up with.”

Participants in XPRIZE’s Next-Gen Mask Challenge are tasked with designing face masks that offer a level of performance comparable to that of a surgical mask. This means that the mask must block 95% of particles while letting in enough air to allow the wearer to breathe comfortably. Lydall’s meltblown filtration media enables mask manufacturers to meet rigorous standards for quality and efficiency set in the U.S. by NIOSH, a division of the CDC, and ASTM. The material is even imbued with an electric charge that attracts particles, keeping them away from the wearer’s nose and mouth.

“We’re thrilled to have found such a strong partner for the XPRIZE Next-Gen Mask Challenge in Lydall,” says Sarah Saenz, XPRIZE Next-Gen Mask Lead. “We are challenging young innovators across the world to shift the perception around mask-wearing behavior by reimagining face masks entirely, but the most important aspect is safety. Lydall is providing the critical filtration media that makes N95 and surgical masks effective, and just as importantly, its team of engineers and material scientists will provide counsel and support to young adults around the world who want to build a better face mask. Their participation will help ensure that real solutions to a very real crisis are made available to our communities.”