|

CAPABILITY |

POLYMER |

ADVANTAGE |

CAUSE / CAUSED BY … |

COULD BE INTERESTING FOR e.g. … |

|

|

Cellulose Spunlaid can be produced by our process, if taken for solvent spinning (lyocell process) |

Natural polymer cellulose |

Saving costs for cellulose NW production |

No need to produce fibers first, which are later arranged to a carded NW |

Companies, who really want to sell NW made of renewable and sustainable material (trees), which also biodegrades in the soil and not in a so-called industrial composting plant at 60° like PLA: no greenwashing |

|

|

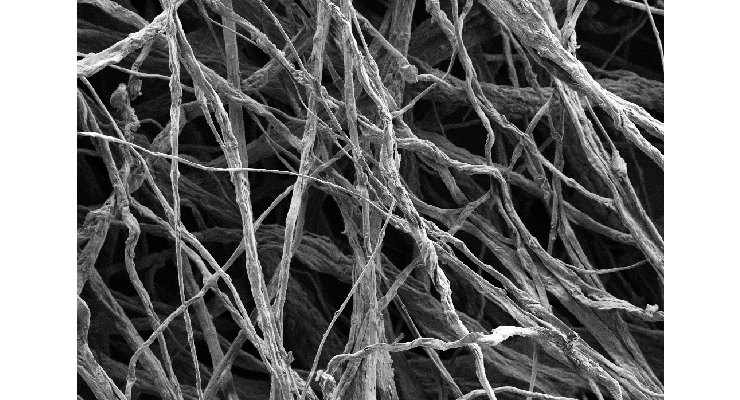

NW consisting of endless filaments, which are fine |

Natural polymer cellulose |

Flexible system adjustable by process parameters |

Split-swing effect from Nanoval results in much finer filaments than the large spinning nozzle (abt. 0.6 mm) |

Companies who want to produce NW material consisting of finer filaments, than the usual staple fibers produced by known fiber producers, which have diameters of abt. 10 - 15 µm |

|

|

Large spinning nozzles |

Natural polymer cellulose |

Robust system for paper pulp, dissolving pulp, cotton linters, waste paper, wood particles or other additives (such as catalysts etc.) |

Split-swing effect from Nanoval is a gas dynamic effect, performed by process parameters rather than by a small nozzle diameter |

a) Companies, who want to put in additives into the fibers, as we did with wood particles, only to show the possibility and to save pulp, since wood is cheaper and does not need to be dissolved |

|

|

Self-intermingling of filaments of adjacent spinning nozzels |

Natural polymer cellulose |

Even unbonded webs are quite strong in both MD and CD. NW made of staple fibers always nee a bonding - our cellulose spunlaid is a textile already direct after spinning |

Gas-dynamic Nanoval-effect, really something special |

The bonded NW should have a higher tenacity than cellulose NW made of staple fibers |

|

|

Spunlaid fully flushable |

Natural polymer cellulose |

We have improved our system and are also able to spin directly cellulose NW, which are fully flushable |

A new process idea, which cannot be revealed here |

Companies, who want to produce flushable wipes |

|

|

Robust process for Nanoval's synthetic spunlaid, an alternative to MB |

Many polymers have been spun, such as PP, PE, PA, PET, PPS, PBT, PC, PAN or PLA and more (also Vistamax and Kraton were tested) |

Flexible system |

Precisely defined gas-dynamics due to laminar flow |

Companies, who are looking for a robust and flexible system or generally are interested for something new |

|

|

Stronger web, higher elongation compared to MB |

PP, PE, PA, PET, PPS, PBT, PC, PAN or PLA and more |

Generally a higher web tenacity and higher elongation compared to MB even in unbonded state |

Gas-dynamic Nanoval-effect, really something special |

For applications, where strong NW is required |

|

|

Less energy consumption than MB in terms of |

PP, PE, PA, PET, PPS, PBT, PC, PAN or PLA and more |

Higher profits for the NW producer or lower prices can be offered |

Circular and individual air nozzles have a smaller cross-section than a long gap as in MB, the throughputs per hole are larger |

Every NW producer |

|

|

Wide adjustable range of filament diameters, mixed nano/micro filaments |

PP, PE, PA, PET, PPS, PBT, PC, PAN or PLA and more |

New types of NW material, e.g. for filters, can be produced |

The fine diameters of filaments are generated by a special gas-dynamic effect, which can be adjusted by the process parameters |

Every NW producer, who wants to step-out from the MB-corridor |

|

|

Higher productivity in terms of kg/h/m (belt width) compared to MB |

PP, PE, PA, PET, PPS, PBT, PC, PAN or PLA and more |

Reduced specific investment costs |

A good process with large throughputs per hole |

Every NW producer |

|

|

Higher air throughput through the NW compared to MB |

PP, PE, PA, PET, PPS, PBT, PC, PAN or PLA and more |

Reduced energy costs for the air fan e.g. in filter applications |

A special structure of Nanoval's NW since we have a kind of stochastic effect due to the special gas-dynamics in our laval nozzle for spinning (up to sonic speed at the outlet) |

Filter applications or venting purposes of NW |

|

|

Spinning nozzles arranged in many rows |

PP, PE, PA, PET, PPS, PBT, PC, PAN or PLA and more |

Each row could be supplied by another polymer |

Every row of nozzle can have its own supply distribution of polymer |

a) Special new NM products can be developed consisting of various polymers, which cause special effects due to different shrinkage etc. |

|