Adhesive-Free Ultrasonic Elastic Attachment for Nonwovens

Videos

Adhesive-Free Ultrasonic Elastic Attachment for Nonwovens

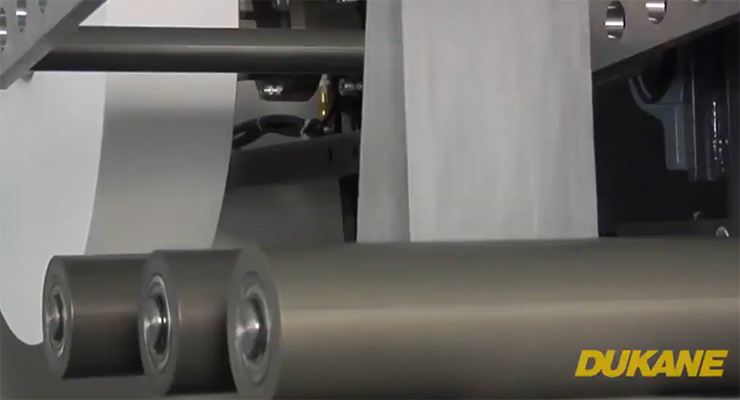

The system utilizes rotary ultrasonics to attach elastic to nonwovens without glue.

02.26.21

Ultrasonic Elastic Attachment technology provides a robust, high-speed process solution for creating elasticized materials that have zero creep and eliminate the need for costly and messy adhesives. Products can range from narrow containment flaps up to large waste panels and can be constructed with lighter-weight materials without concern for adhesive bleed-through.

The system utilizes rotary ultrasonics to attach elastic to nonwovens without glue. Manufacturers can avoid all the production issues associated with using glue. The process supports line speeds up to 600 mpm. Even when line disruptions occur, the ultrasonic continuously attach the elastic strands. The end result allows for maximum product performance.

By eliminating glue, the end-user experiences a softer feel and a more comfortable feel, improved elastic performance, eliminated creep. The production line does not need to shut down to clean glue residue. Avoid the costs associated with buying and storing glue.

More Videos by Dukane Center of Excellence for Personal Care, Nonwovens and Packaging

-

Videos

Single Step Ultrasonic Cut & Seal with Servo Contr

Dukane Ultrasonics presents the Servo Controlled Ultrasonic Welder with patented Melt-Match® Technology.Videos02.26.21

-

Videos

Ear Loop Attachment to Mask

Clean, Consistent, and strong bonds with ultrasonic weldingVideos02.26.21

-

Videos

Have a password?

Cookies help us to provide you with an excellent service. By using our website, you declare yourself in agreement with our use of cookies.

You can obtain detailed information about the use of cookies on our website by clicking on "More information”.

Copyright © 2025 Rodman Media. All rights reserved. Use of this constitutes acceptance of our privacy policy The material on this site may not be reproduced, distributed, transmitted, or otherwise used, except with the prior written permission of Rodman Media.