Dealing with slower growth rates, particularly in mature geographies, has been a challenge facing suppliers to the global hygiene industry for years. These companies have also been tasked with responding to product design changes like lower basis weights and thinner cores. The increased balance between efficacy and safety, brought on by the Covid-19 pandemic, and sustainability also introduced a unique set of challenges.

To ensure it is the company its customers need it to be, Bostik has continued to invest in communication tools, manufacturing assets and innovation. The company continues to run webinars and other information sessions to help its customers understand market trends. Meanwhile, its new plant in Nara, Japan, puts it close to its customers in the Asia-Pacific region, the fastest growing market for hygiene products.

Taking time to illustrate the efforts Bostik has made to stay relevant and connected, Jeffrey Merkt, senior vice president, Bostik North America & Bostik’s Global Nonwovens Division, talks about how Bostik has operated throughout the Covid-19 pandemic and how it plans to move forward.

Karen McIntyre: I know we are not here to talk specifically about Covid-19 but we can’t really avoid the topic in September 2020. How has it affected Bostik?

Jeffrey Merkt: As the world, our customers and their customers’ behaviors change and adapt to a new normal we need to behave even smarter. At Bostik we have always put safety first – the safety of our products of course but also our employees. In North America, the production of chemicals was classed as an essential business. Yes, the pandemic has impacted how we need to operate but due to our scale and the support from our parent company Arkema we have continued to supply our valued customers around the globe. This support as well as our global production footprint, processes and agility provides us with the flexibility needed to provide a seamless service to producers of hygiene articles many of whom were also considered as essential businesses themselves.

We have contingency plans in place in the event of any sustained issue that might impact our ability to produce or supply. These plans are not just there for Covid-19 but form the basis of our business continuity plans in any event, from a natural disaster, raw material shortage to a pandemic.

On top of this, our customers continue to benefit not only from the performance and consistency of our products but the expertise that we bring (albeit delivered differently). The culture we have at Bostik has really been a positive factor. We thank our customers for their continued support and recognition of the value that Bostik brings them during these more difficult times.

McIntyre: You mentioned the need to behave ‘even smarter’ and that you are bringing expertise differently. Please can you explain?

Merkt: Yes, obviously getting to see our customers in person is more challenging so we have had to look at ways to reach them and to provide our support effectively but remotely. This means that we will need to make important decisions about where we are present in person. We decided this year not to participate at large group events that are still going ahead and that would potentially put our employees at risk. These are not easy decisions; as one of the world’s largest adhesive providers we want to support industry events but we do have to be responsible.

McIntyre: How do you see technology playing a part in your future relationships with customers?

Merkt: We are really taking advantage of available technology to remain close to our customers. Bostik launched its new website in the summer of 2020. We have and continue to run webinars to support our customers with their understanding of market trends, sustainability, SOIs for example and also with the optimisation of their use of glue. We are already successfully using and will continue to explore the use of virtual tools to provide our individual customers with our support for adhesive trials, the roll out of products and maintain the momentum on mutual projects. We will continue to use current tools but also investigate different ways to reach our customers to provide the support that they need and that differentiate us from our competition. As a result we have some exciting things planned for later in 2020 and into 2021.

McIntyre: Where do you see most growth coming from in the future?

Merkt: I think it’s well recognized that the hygiene market is not experiencing the unit growth that it once was, particularly in the more mature geographies. We do still expect to see organic growth in the adult incontinence market globally (light incontinence as well as in adult briefs and protective underwear) and also in all segments in the emerging geographies albeit from a lower base. In addition, we expect to see product design changes that will result in the need for additional adhesives or adhesive with different performance requirements. Take diaper cores for example, developments in these areas have resulted in additional adhesive requirements that we are well placed to support, not only with products but also knowledge to support our customers with their understanding of the needs.

The whole sustainability’ topic is huge right now and you can’t miss the growth in the number of hygiene products that are making claims in this area, incorporating renewable materials, considered biodegradable, compostable or recyclable. I think we can expect to see this growth continue and the various approaches move from what was once considered niche into more and more mainstream products. We want to be part of this growth.

McIntyre: How do the market growth rates impact your ability to invest?

Merkt: Although the market growth numbers are lower than we have enjoyed in the past, it is important that we continue to invest, not just to add capacity but to increase efficiencies, quality and improve the overall supply chain. We are excited to announce the opening of a brand new plant in Nara, Japan. This is Bostik and Arkema’s first plant in Japan and the investment was really made for three reasons, that all contribute to an enhanced customer experience:

- It puts us closer to our customers to better address their specific needs.

- Asia Pacific is the fastest growing market for disposable hygiene products.

- It gives us not only best-in-class quality and productivity it provides the flexibility needed to support our customers growth in Japan, in the region and globally.

Outside of this new plant in Japan we are investing in upgrades to our manufacturing equipment, packaging lines, in our laboratories and we invest in our people. We continue to grow our investment in technology research and in product development.

In the area of technology research we are working closely with our parent company to develop & then use analytical tools that predict adhesive performance based on a number of real production and material variables. We know that best results will come from analysing adhesive performance in the earliest phases of our customer’s product development. Combining material science with a computational capability enables our customers to bring better-performing, more profitable products to market faster and with a minimum of disruption to their own operations.

Again, the support provided by Arkema based on their confidence in the hygiene market and Bostik’s Nonwoven division to deliver growth is fundamental to our ability to invest.

McIntyre: You mentioned the whole ‘sustainability’ topic is huge right now. How do you view this topic at Bostik?Merkt: We believe that Sustainability, or sustainable development, is best defined by the vision written in the Brundtland commission report in 1987: “meeting the needs of the present without compromising the ability of future generations to meet their own needs. Today, Corporate Social Responsibility, or CSR, is the terminology that most would use to describe how they consider Sustainable Development challenges and translate them into a strategy, a vision and commitments, a program, a culture, or goals. Bostik, as part of Arkema, has a strategy that is based on three pillars:

(1) Deliver sustainable solutions driven by innovation

(2) Manage our activities as a responsible manufacturer

(3) Cultivate an open dialogue and close relations with our stakeholders

For the first objective, Bostik R&D is aligned with the Arkema strategic innovation platforms that are delivering benefits to one or more UN Sustainable Development goals. Bostik has also worked on a Sustainability Assessment of our current portfolio of products so we have a baseline on which to work to strengthen the benefits of our solutions while transitioning away from solutions that have a negative impact.

For the second objective, we have a strong safety program in place (for our employees and our processes) and we defined with Arkema a climate plan that is aligned with the Paris Agreement. This plan includes energy reduction programs, as well as defined targets to move to low-carbon energy.

Having an open dialogue and close relations with our stakeholders is absolutely critical. When defined according to our sustainability strategy, a ‘sustainable adhesive’ is one which is manufactured responsibly but is also designed to meet the sustainability objectives of our customer. This is why it is important that we have a proper dialogue with customers so we work on and deliver innovative sustainable solutions that are considered sustainable for the customer, based on their strategy, their goals and objectives.

Within Bostik, there have been interesting developments and our colleagues in the packaging area have developed a fully compostable adhesive for a specific application. In the Nonwovens division we are working on a number of projects, both short and long term to deliver solutions that are not only considered ‘sustainable’ but meet the needs in other areas considered essential in today’s market.

McIntyre: So what new product launches can we expect from Bostik in the future?

Merkt: We are continually quietly adding products to our global and regional product lines. These are products that would typically provide incremental improvements to the features and benefits of product lines offered today. You may have heard us talking before about adhesives being the enabler. Hot melt adhesives have been used in the production of disposable hygiene products for generations yet we know that quite often the article producers talk about adhesives being a necessary evil. We strongly believe that they are still the best, the most adaptable, most flexible bonding solution today and will continue to be the best to meet the needs of the article producer in the future. However, to keep meeting these needs for reliable and flexible bonding solutions, as well as enabling our customers to address & satisfy the requirements their consumer, we have to keep innovating.

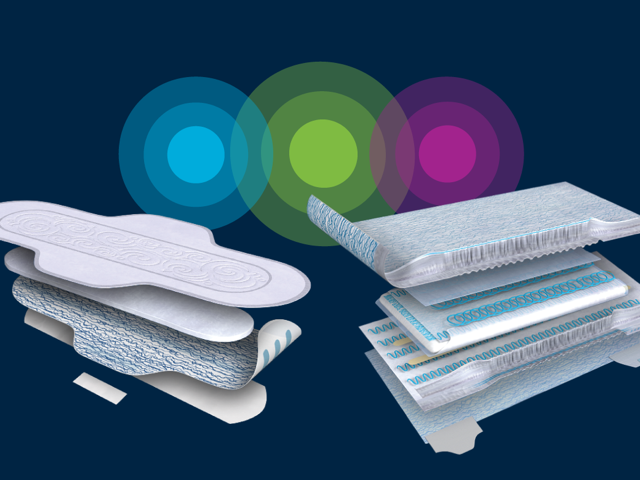

Beyond these products that offer the incremental benefits in areas such as processability, odor reduction or the ability to reduce cost-in-use, we are pursuing opportunities for adhesive innovation in other ways. In many cases, we are creating next-level products for all three market segments, baby care, feminine care and adult incontinence. These types of smart innovations go beyond the incremental improvements that I just spoke about and provide a more fundamental opportunity for our customers to improve their own processes (such as adhesive handling) as well as their own products and the satisfaction levels of their consumer. We recognize that there are adhesive applications that impact the confidence & satisfaction levels of the consumer in the end product. The consumer needs to be confident that the product will do its job comfortably, consistently, conveniently and all at a price they are happy to pay. Their choices however have become greater, they are less forgiving and more demanding particularly in the areas that they care about or affect them personally.

If you look at some of the hygiene product or market trends, we see opportunities here in many areas; from supporting the growth in the use of indicators or sensors in adult incontinence to enabling our customers to offer more sustainable solutions (based on their own definitions of compostability, biodegradability or improving the environmental impact of their own production) that we just talked about. We clearly have an exciting period ahead of us and one in which we can all expect to see new smart solutions coming from Bostik.