When you settle into the seat for a roller coaster ride, you assume the car will stay on the track and you will stay safely in place for the duration of the ride. You might not think about the science behind every twist and turn. You expect every component to function well so you can enjoy the ride.

Likewise, most consumers do not think about the pad attachment adhesives used in their feminine hygiene and light incontinence products, or the science behind the security. They expect a pad that is easy to place, stays in place reliably through life’s twists and turns, and removes cleanly and easily after use, every time.

Fortunately, the team at Bostik is doing the behind-the-scenes thinking, focusing on the science behind pad performance. Bostik has a long history of creating, testing, and refining products that target consumer satisfaction while meeting operational criteria. Now, the Bostik team has zeroed in on stay-in-place performance, a key factor in consumer satisfaction.

What impact do adhesives have on stay-in-place performance? Answering this question could help producers choose the right adhesive and develop noticeably better products that track with consumer expectations.

A better hold on data

When developing and refining products, test data is a good place to start. Typical pad attachment adhesive testing includes initial peel tests, “in use” peel tests, and residue tests, among others. These tests are usually performed using fabrics such as cotton, nylon, microfibre, and more on a variety of weaves, surface treatments, and elongations.

For a long time, initial peel test data has been used to approximate stay-in-place performance. Here’s the rub: The forces involved with peel testing are not the same as the forces during actual use.

To help ensure a pad will stay in place throughout all her movements, day or night, the industry needs a way to specifically and accurately test stay-in-place performance. Bostik saw an opportunity to innovate. If better testing could lead to better product development, the team wanted to create a better test.

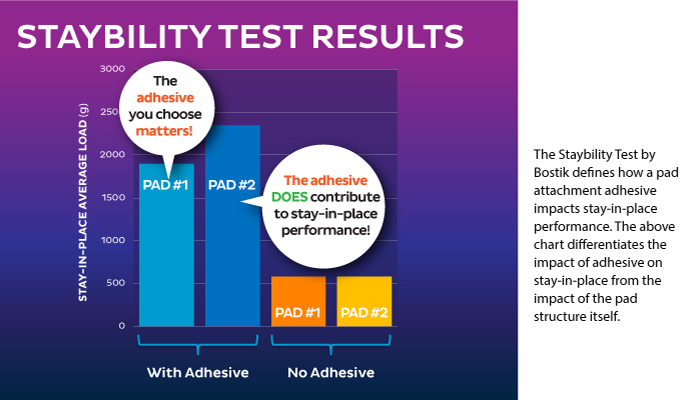

The new, patent-pending Staybility Test by Bostik gives producers the ability to test how well a pad stays in place during movements that simulate a woman’s daily motion. It can also predict the adhesive’s contribution to stay-in-place earlier in the product development process, before the expensive in-use testing phase. This allows producers to choose the right adhesive for their product development goals, saving time and reducing costs.

Noticeable impact, noticeable value

Can pads with higher Staybility scores deliver higher levels of consumer satisfaction?

Once again, better data points to “yes.” The analytics team from Bostik’s parent company, Arkema, compared results of Staybility testing with consumer reviews for the same pads. Pads with high Staybility scores also received more positive reviews, suggesting that better stay-in-place performance correlates with higher consumer satisfaction.

The results of this new test method by Bostik are clear: Pad attachment adhesives contribute to stay-in-place performance, and the contribution is measurable. Further, improving stay-in-place performance improves the consumer’s experience.

Noticeably better performance is sure to gain traction with consumers, which in turn will keep producer business objectives on track.

Contact Bostik to access smart thinking and learn more about noticeably better adhesive products and services.