Content From Dukane Center of Excellence for Personal Care, Nonwovens and Packaging

-

Single Step Ultrasonic Cut & Seal with Servo Control

Dukane Ultrasonics presents the Servo Controlled Ultrasonic Welder with patented Melt-Match® Technology.Videos Released on 02.26.2021

-

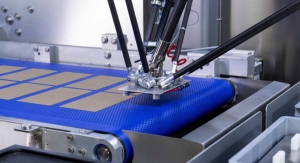

Adhesive-Free Ultrasonic Elastic Attachment for Nonwovens

The system utilizes rotary ultrasonics to attach elastic to nonwovens without glue.Videos Released on 02.26.2021

-

Ear Loop Attachment to Mask

Clean, Consistent, and strong bonds with ultrasonic weldingVideos Released on 02.26.2021

-

Multilayer Surgical Mask Construction

Surgical Mask Sealing with Ultrasonic BondingVideos Released on 02.26.2021

Related Content

-

Nonwoven Network to Install Ultrasonic Tea Packaging Machine

Machine can package 100 bags per minute09.21.21

-

Chemicals/Adhesives

H.B. Fuller to Focus on Sustainability at INDEX20

Adhesives specialist will discuss how its next generation technologies and solutions can reduce the overall ecological footprint09.17.21

-

Facilities/Capacity | India | Spunlace | Wipes

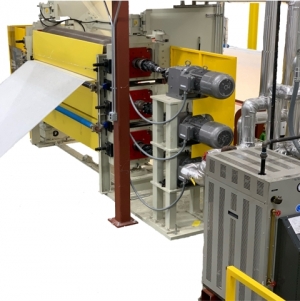

Tufropes to Install Spunlace Line in India

A.Celli Nonwovens will supply technologies for the new patent-pending spunlace line09.16.21

-

Hyperion Materials & Technologies Acquires Precision Manufacturer

GLE Precision specializes in high-precision small parts, extreme surface finishes and tolerances09.10.21

-

Precision Textiles Launches New Website

Enhancements include manufacturing capabilities, expanded product details and easier site navigation09.09.21

-

-

-

-

Machinery and Equipment

Maxcess Europe Expands Rotary Die Repair Services

Company opens sales office in Brasov, Romania09.01.21

-

Wipes

-

Electronics | Machinery and Equipment

Optima Develops Fuel Cell Production Lines

Company provides machine solutions for all process stages involved in manufacturing membrane electrode assembly08.30.21

-

Beckmann Converting Launches New Website

New site features a leaner presentation and easier navigation08.30.21

-

Fibers

Fiberpartner Launches Bico Biodegradable Low-Melt Fiber

PrimaLoft Bio fibers biodegrade by hydrodegradation08.19.21

-

Medical | Meltblown | Mergers and Acquisitions | North America

Precision ADM Acquires Canadian Meltblown Nonwovens Producer

Roswell DHT and Precision will produce 100% compostable nonwoven fabrics for use in PPE08.16.21

-

Machinery and Equipment | Shows/Events

Andritz to Exhibit Nonwovens Production Technologies at Techtextil Russia

Company will highlight air-through bonding, needlepunch, spunlace, spunbond and other technologies08.10.21

-

Filtration

H&V Selects Superior Felt & Filtration as Distributor for Trupor Membrane Media

SFF will distribute and convert Nylon grades08.09.21

-

Nonwovens in Food Packaging

Makers of food pads and beverage filtration focus on sustainabilityTara Olivo, Associate Editor 08.04.21

-

Machinery and Equipment

2021 Machinery & Equipment Review

A look at the latest technological developments from the major suppliers of nonwovens related machineryTara Olivo, Associate Editor 08.04.21

-

-

RISE to be Held Virtually Next Month

Research-based conference to highlight a myriad of topics07.29.21

-

Machinery and Equipment

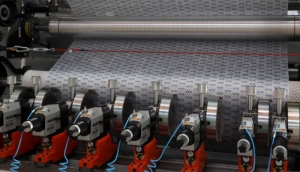

Maxcess Launches RotoMetrics RD300 NW D2 Solid Rotary Die

Tool specifically engineered for nonwoven applications including diapers, feminine care, wipes and medical/PPE materials07.22.21

-

Adult Incontinence | Diaper, Baby | Feminine Hygiene | Hygiene Film/Components

-

Associations | Shows/Events | Wipes

World of Wipes to Focus on Sustainability, Covid-19 Consumer Wipes Buying Trends

Event will be held next week in AtlantaTara Olivo, associate editor 07.07.21

-

Wipes

Innovation Award To Be Presented at WOW

Companies to vie for honor at Atlanta conference in July07.06.21

-

-

-

Airlaid | Facilities/Capacity | Western Europe

Magic Srl Installs Airlaid Line in Italy

Line supplied by Campen can produce several types of thermal bonded airlaid products07.01.21

-

-

Meltblown | Spunbond/Spunmelt

Avgol to Add Three Lines In Russia

Multi-tier investment includes R5, meltblown and lamination lines06.29.21

-

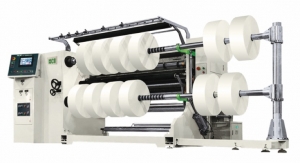

Machinery and Equipment | Medical | Meltblown

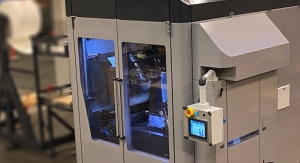

HCI Offers Slitting Machine for Medical Grade Meltblown

Slitting and rewinding speeds of up to 100 m/min increases production capacity06.28.21

-

Market Data

Smithers Releases Report on Nonwovens Supply Chain Disruptions

Study examines how Covid-19 has impacted the industry worldwide06.23.21

-

Machinery and Equipment | Mergers and Acquisitions

-

Filtration | Mergers and Acquisitions | North America

Unifrax to Acquire Lydall

Combination of companies creates a global specialty materials platform in advanced filtration, EV battery systems and energy saving applications06.21.21

-

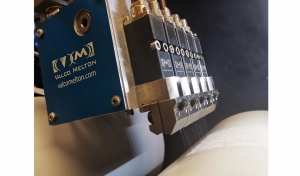

Chemicals/Adhesives

Bostik Expands Hot Melt Offering

Following two acquisitions company is offering pellet, powder, web and film adhesives06.14.21

-

-

Machinery and Equipment | Meltblown | North America | Product Improvement/Innovation | Wipes

-

Machinery and Equipment

Heytex USA Orders New Era Thermal Laminating and Embossing Line

Line will be installed in Pulaski, VA06.02.21

-

INDA Launches Updated Nonwoven Material Sampler

178-page publication contains 124 material swatchesKaren McIntyre, editor 05.25.21

-

Airlaid | Machinery and Equipment

PulPac, Dan-Web Form Partnership

Companies develop standardized machinery for Dry Molded FiberTara Olivo, associate editor 05.25.21

-

Joint Q+A: Defender Safety & Premier Guard USA

Teddy Haggerty of Defender Safety and Howard Sherman of Premier Guard USA share insights on the state of PPE manufacturing.

-

Maxcess Acquires OneBox Vision

Vision inspection specialist will add to capabilitiesKaren McIntyre, editor 05.21.21

-

Apparel | Green/Sustainability

Freudenberg Shoe Components Certified to GRS

Certification makes company an officially-confirmed supplier of sustainable shoe componentsTara Olivo, associate editor 05.20.21

-

Filtration

Neenah Filtration Launches HVAC Filter Media Solution

NeenahPure is available for pleatable and bag filter elementsTara Olivo, associate editor 05.12.21

-

Meltblown

-

Machinery and Equipment

New Edelmann Technology Delivers Increased Speed

Slit rolls of about 1 m. in diameter can be produced at a top speed of 2500 m./min.Tara Olivo, associate editor 05.10.21

-

-

Diaper, Baby | Wipes

Millie Moon Debuts Luxury Diapers at Target

Diapers and sensitive baby wipes are certified with the Target Clean iconTara Olivo, associate editor 04.26.21

-

Facilities/Capacity | Machinery and Equipment | North America

Jessup Installs New Era Coating and Laminating Line

Line successfully built in Lake Bluff, IL, facility amid pandemic04.16.21

-

Construction

Roofing & Construction Update

Nonwovens producers offer a range of innovative products to protect homes and buildingsTara Olivo, Associate Editor 04.12.21

-

Meltblown | Spunbond/Spunmelt

Spunmelt Nonwovens Surge

New lines are popping up all over the globe to help ease shortages for medical fabrics and other key applicationsKaren McIntyre, Editor 04.12.21

-

Wipes

Jacob Holm's SoftFlush Receives Fine to Flush Certification

Wipes substrate offers dispersibility and softnessKaren McIntyre, editor 03.25.21

-

China | Facilities/Capacity | Needlepunch

Chongqing Double Elephant to Install Four Needlepunch Lines

Andritz technology will create microfiber nonwovensKaren McIntyre, editor 03.25.21

-

Apparel

Freudenberg Performance Materials Launches Online Shop for Apparel Industry

Range of interlinings, tapes, canvas and preformed materials, linings and comfortemp thermal insulation availableTara Olivo, associate editor 03.24.21

-

Associations | Shows/Events | Wipes

World of Wipes Returns as In-Person Event

Wipes conference to be held in Atlanta July 12-15Tara Olivo, associate editor 03.18.21

-

Automotive and Transportation | Facilities/Capacity | Filtration

Bondex Adds Needlepunch Line in SC

Investment will meet demand for filtration and other industrial applicationsKaren McIntyre, editor 03.10.21

-

India

-

Machinery and Equipment | Medical

Autefa Solutions Offers Fully Automated Line for Protective Mask Production

HiPerMask produces masks in accordance with the EU FFP2 and FFP3 standards as well as the U.S. N95 and N98 standardsTara Olivo, associate editor 03.04.21

-

Single Step Ultrasonic Cut & Seal with Servo Control

Dukane Ultrasonics presents the Servo Controlled Ultrasonic Welder with patented Melt-Match® Technology.

-

Adhesive-Free Ultrasonic Elastic Attachment for Nonwovens

The system utilizes rotary ultrasonics to attach elastic to nonwovens without glue.

-

Ear Loop Attachment to Mask

Clean, Consistent, and strong bonds with ultrasonic welding

-

Multilayer Surgical Mask Construction

Surgical Mask Sealing with Ultrasonic Bonding

-

Filtration

Fiber Bond VE3 Technology Inactivates SARS-CoV-2 in HVAC Filtration Systems

New technology was tested by Microbac Laboratories02.24.21

-

Ultrasonics Fuel Mask Production

Emerson's Branson welding technology has been used in mask production02.11.21

-

One Earth Coffee Bags Ideal for Single Serve and Cold Brew

Compostable material made from sugar cane02.09.21

-

Wipes

-

Turkey | Wipes

-

CHECK OUT ALLIANCE'S NEW WEBSITE!

Located in Richmond, VA, Alliance Machine and Engraving, LLC is recognized as experts in the engraving and embossing industry, both within and outside the U.S

-

Automotive and Transportation

Nonwovens in Automotives

New mobility, sustainability create more opportunities for nonwovens producersTara Olivo, Associate Editor 12.11.20

-

Absorbent Core | Hygiene Film/Components

Hygiene Suppliers Go Natural

Demand for safer ingredients, transparency guide innovation in a highly competitive marketKaren McIntyre, Editor 12.11.20

-

Machinery and Equipment | Mergers and Acquisitions

Andritz to Buy Laroche

Deal enhances scope of supply in spunlace, wetlaid and needlepunch machinery12.04.20

-

Hygiene Film/Components | Medical

New Elastic Laminate for Masks Solves Elongation Challenges

Elamask by Texol provides for high speed production and long term user comfort12.02.20

-

Chemicals/Adhesives

H.B. Fuller Launches Adhesive for Natural-Based Hygiene Products

Full Care 5885 is Eco Passport-certified11.30.20

-

Machinery and Equipment

IHSAN Sons Partners with A Celli for Defect Control and Production Enhancement

Installs A.Celli’s Doctor Rewinder11.20.20

-

Facilities/Capacity | Medical | North America

United Sewing Automation Produces U.S.-Sourced and Manufactured PPE Face Masks

Mt. Airy, NC, facility gets a visit from U.S. Representative Patrick McHenry11.17.20

-

-

Henkel is thinking ahead for even purer and safer personal hygiene products

As a leading global supplier of adhesives for various personal hygiene applications, Henkel is constantly innovating to create unique value for its customers.

-

Wipes

Wet Wipes Increased Prevalence in Drug Development

A number of factors including patient preference are driving the growth of wet wipes in pharma.John Waddell, Business Development Director – Pharma, PDI Contract Manufacturing 10.20.20

-

What you need for the perfect slitting process of a printed reel

In the hygiene industry, it is crucial that the slitting of the printed reel is perfectly aligned with the printing machine if you want to achieve...

-

Contract Services | Facilities/Capacity

-

Schott & Meissner Air-Through Drum Oven for Auria’s US-Plant

Schott & Meissner, a leading specialist for Thermal Bonding equipment.

-

GDM Receives INDEX Innovation Award

Expandable Welding Wheel honored in machinery and equipment category10.08.20

-

China

Chinese Nonwovens Outlook

As hygiene products continue to evolve in sophistication and design, nonwovens manufacturers continue to invest in new technologiesKaren McIntyre, Editor 10.08.20

-

Contracts/Awards | Shows/Events

EDANA Announces INDEX Innovation Award Winners

Companies honored across seven categories in virtual ceremony10.07.20

-

ExxonMobil Introduces High-Loft, Ultra-Soft Nonwovens for Hygiene

Blend is easily processed via spunbond09.28.20

-

Machinery and Equipment | North America

Jessup Manufacturing Adds Coating and Laminating Line

Line supplied by New Era Converting Machinery is being installed in Illinois09.17.20

-

Hygiene Components Suppliers Adapt to Change

The supply chain evolves to meet new consumer demandsTara Olivo, Associate Editor 12.10.19

-

Wipes

-

Dukane Buys Aurizon Ultrasonics

Companies have worked together to develop continuous ultrasonic bonding, sealing and converting08.05.19

-

-