MS Ultraschall to Showcase MS sonxSYS Combine Ultrasonic System

04.23.24

Technology increases efficiency and saves energy

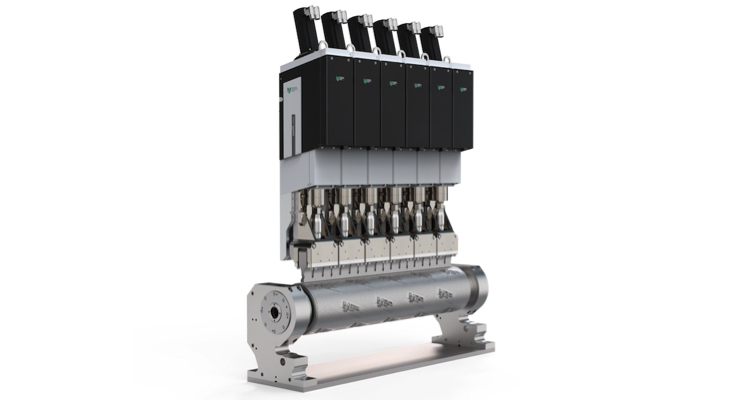

MS Ultraschall’s MS sonxSYS Combine ultrasonic system provides advantages for the nonwovens processing industry.

The increasing demands from the industry for faster and faster production lines then inevitably lead to technical requirements for maximum mechanical precision, high ultrasonic power and fast process control.

Quality and reliability are the key to success. Considering that the equipment in the nonwovens processing industry produces 24 hours a day, almost 360 days a year results in the requirements for high reliability of the components.

The ultrasonic welding process is a very good alternative to other joining and separating processes with high efficiency and further pioneering possibilities. In contrast to other processes, the ultrasonic process - whether cutting, sealing, welding, cut-off welding, punching or riveting—does not cause any damage to the product itself.

Continuous ultrasonic welding has many advantages:

With the MS sonxSYS Combine ultrasonic system, MS Ultraschall Technologie GmbH offers everything from a single source: ultrasonic, control technology, mechanical engineering and engraving rollers, robust mechanical engineering and high process speeds. Whether new production systems or the replacement of existing systems or outdated technologies in existing systems, the customer benefits from over 30 years of experience in the development and manufacture of high-quality and innovative ultrasonic components and machines.

The increasing demands from the industry for faster and faster production lines then inevitably lead to technical requirements for maximum mechanical precision, high ultrasonic power and fast process control.

Quality and reliability are the key to success. Considering that the equipment in the nonwovens processing industry produces 24 hours a day, almost 360 days a year results in the requirements for high reliability of the components.

The ultrasonic welding process is a very good alternative to other joining and separating processes with high efficiency and further pioneering possibilities. In contrast to other processes, the ultrasonic process - whether cutting, sealing, welding, cut-off welding, punching or riveting—does not cause any damage to the product itself.

Continuous ultrasonic welding has many advantages:

- Increased productivity—Increased efficiency due to immediate availability as soon as it is switched on compared to other joining processes

- Energy saving—No preheating of rollers required, no radiant heat

- Environmentally friendly by dispensing with “chemicals.” No additional material (e.g. adhesive) required, therefore environmentally friendly and allergy-friendly

With the MS sonxSYS Combine ultrasonic system, MS Ultraschall Technologie GmbH offers everything from a single source: ultrasonic, control technology, mechanical engineering and engraving rollers, robust mechanical engineering and high process speeds. Whether new production systems or the replacement of existing systems or outdated technologies in existing systems, the customer benefits from over 30 years of experience in the development and manufacture of high-quality and innovative ultrasonic components and machines.