Sandra Levy, Associate Editor09.15.10

Wipes makers are jockeying to have their products stand apart in an environment where competition is intensifying and they are employing some new packaging tricks that razzle and dazzle.

From soft pack delivery systems to stand-up pouch packs to convenient “on the go” travel packs to pop-up dispensers to one-push button to touchless dispensers, there are a slew of awesome innovations for packing wipes that are ecofriendly and offer consumers convenience, portability and value.

Soft Pack

One of the hottest ideas in wipes packaging is Nice-Pak Products Inc.’s Eco-Pak, a portable, soft pack delivery system that holds high-efficacy surface disinfecting wet wipes. This resealable package, which has soft sides is able to stand on one of its sides, maximizing store shelf impact and minimizing storage space under a kitchen sink. The package also provides a more compact footprint than traditional canisters for more efficient storage and transportation, as well as a more comfortable fit in the consumer’s hand, according to Ruth Levy, vice president of strategic product development at Nice-Pak Products.

“As we go for more efficient packaging and less packaging per product, we wanted something that consumers could handle. The whole concept was how can we make this easier for consumers to use? Historically, canisters are a wonderful delivery system for wipes. Over time, more products have been moving to a more manageable soft pack that’s easier to hold and easier for the consumer to store.We wanted to make a product that historically couldn’t be made into a soft pack convenient and portable for consumers. It’s all about the consumer benefit and consumer value. Not only is Eco-Pak easier to store and easier to handle, the dispensing is easier,” said Ms. Levy.

Consumers don’t have to thread a canister lid and they don’t have to take the lid apart and rethread it every time there’s a drop back, Ms. Levy said. “With Eco-Pak it’s always easy to reach that first wipe because the package compresses to the height of the actual stack. It’s easy for consumers to dispense and it maintains better moisture all the way through.”

Solar Lids Are A Fave

The Solar Lid is one of the latest innovations in packaging that is becoming increasingly popular. Noting that Nice-Pak designed and patented the solar lid in 1981, Ms. Levy described the device as “putting a dispenser on top of a soft pack,” allowing users to dispense one wipe at a time and then seal the pack tokeep the moisture in. The idea has exploded. The patents have run out and even Huggies and Pampers offer wipes with solo-type lids. There has been a movement from canisters to tubs to solo lids, which allows you to have a pack of wipes anywhere you go whether for face, hands or baby. Now with Eco-Pak for household surface disinfection, you can have them in your car or in different rooms of the house and you can take them when you travel. It has changed people’s ability to have portable cleaning products,” said Ms. Levy.

Hot Trends

Nice-Pak is busy pioneering other hot trends so don’t be surprised if you see more wipes packaged in cups that fit in car cup holders.

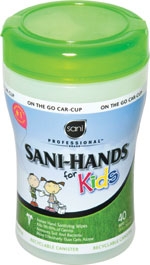

Nice-Pak offers Sani Hands for Kids in a cup and the company is expanding distribution under various brand name labels. People are more concerned about hand hygiene. Our goal is not just to provide people with product that they can carry around—these wipes have full hand sanitization properties. This was specially designed to give consumers a product that met their needs when they are out for a soccer game or ice cream so you can sanitize those hands in your back seat,” said Ms. Levy.

Individual packets for wipes are not new but their popularity is growing as consumers’ awareness about germs and viruses has increased. “Not only do you get the microbial kill from the alcohol but you also get the mechanical friction that the wipe provides,” said Ms. Levy. Independent university- and pathogen-sponsored studies show wiping hands with hand sanitizing wipes is more effective than gels, said Ms. Levy.

Belt dispensing packs are the latest thing to hit restaurants. Nice-Pak’s sister company, PDI specializes in hospital and restaurant business and designed the patented wet wipe belt dispensing pack to offer a convenient alternative to cleaning tables with a rag and a bucket. “The wipe can be used and thrown away. The Table Turner wipe packages fit into a belt dispense pack,” said Ms. Levy.

More Innovations

Tarry Paul Zielinski, vice president of sales at Guy & O’Neill, who recently spoke at the WOW conference in Chicago, discussed a number of packaging trends shaping the wipes market. For example, recent consumer research has revealed that consumers like wet wipe products with a pop-up feature, which means that when an individual wipe is dispensed from a package, the tail of the next wipe pops up through the dispensing orifice. “They’ve been conditioned based on the Kleenex facial tissue wipe dispensing device that continually pops up one tissue at a time. These products look good and consumers will leave them out (in sight) for home use,” said Mr. Zielinski.

Ms. Levy agreed that the pop-up feature is convenient. It provides one-hand dispensing, but she emphasized that this feature is application specific. “There are some products where the pop-up feature is important and some products where it is not important. It really depends on the specific application whether it’s more appropriate for it to pop up or not,” said Ms. Levy.

One hand or touchless operation is another trend that is taking hold, according to Mr. Zielinski, who provided the example of a consumer product—Lysol’s hand sanitizing soap dispenser. “It’s something that is important to customers. If you have one touch or no touch there are no germs left over or transferred to the next person who is using it,” said Mr. Zielinski.

Joseph Hotchkiss director, School of Packaging, Center for Packaging Innovation and Sustainability at Michigan State University agreed that touchless operation is a positive trend with benefits for the consumer. “If you touch the container and the next person touches it, they may have the contamination. If the container has a way of dispensing a wipe you break that kind of communication,” he said.

When it comes to canisters there are many awesome improvements that are noteworthy. “There have been many improvements in canisters in the form of large and unique shapes such as oval, flex pack sizes and the latest innovation, which are large domed- shaped canisters. There’s also flexible style canisters that use post consumer materials, polylactic acid materials,” said Mr. Zielinski.

Higher Counts

Catering to institutional centers, wipes makers are making larger count canister-style packages. Nice Pak recently launched a 300-count canister targeting healthcare and restaurant settings.

“There are a lot of products where the canister design is well suited to maintaining the efficacy of the formula. For surface disinfectants and hand antisepsis the canister really is technically a wonderful design. The higher counts are perfect for institutional settings, such as schools, hospitals and restaurants. In industry, people are certainly going to higher and higher counts because you want to have the minimum amount of plastic and the minimum amount of packaging per product and it allows for high traffic in hospitals and restaurants. We’re the market leader in surface disinfecting wipes in hospitals and hand antisepsis wipes in the hospital and food industry. Those are areas where we produce large canisters. We have special brackets to be mounted on walls and general areas,” said Ms. Levy.

Tamper Evident

These days consumers are increasingly demanding tamper evident features on packaging. According to Mr. Hotchkiss packaging tampering is a problem for all manufacturers including wipes makers. “This is a major problem for every industry.We are looking at new technologies that might indicate that a package has been in some way violated or may be a knockoff. It is a brand protection activity.The thing is to make it too expensive to knock off a product so that if someone wanted to duplicate your packaging system it would cost them more money than they could make on ripping off your product. Whenever you have a product that if tampered with could injure a consumer you are prudent to consider ways to protect your product,” he said.

Sustainability

When it comes to packing wipes, sustainability continues to be a trend that is showing no signs of dissipating.

“We absolutely recognize the opportunity to use less packaging material—to minimize the environmental impact and to have more product per shipping pallet for retailer shipping and storage efficiencies, as well as a smaller footprint for consumer storage convenience.Products that have disinfectant sanitization efficacy are technically challenging to put in soft packs so we came around some great hurdles for that. We had a consumer benefit that was good for the environment and it had all sorts of benefits for retailers in shipping and transportation. We aren’t just looking at less packaging. It isn’t just the material you put in that you can reduce, it’s all of the handling of that material before it even gets to you. We went all the way upstream to recognize how we were going to be better for the environment,” said Ms. Levy.

Mr. Hotchkiss agreed. “Anybody who produces a product designed to clean something has to pay attention to having more sustainable packaging. The changes will reduce the product’s carbon footprint, which means it uses fewer petrochemical-derived polymers and using more bio-derived polymers. It will mean using less material not only in the primary package but also in the distribution system, the secondary cartons and the tertiary palletizing systems will become much more efficient.”

Emphasizing that for most consumer products, the packaging and packaging process costs exceed the cost of ingredients, Mr. Hotchkiss said, “Nano cellulose is simply very small particles of cellulosic materials—cellulose being derived from plant sources. It is also biodegradable, readily available and typically cheaper than most polymers. If you added 20% nano cellulose to a standard polymer, you would reduce the carbon footprint of that package by 20%. You are very likely to decrease the cost of that package and you might have the same or better performance from that package. If you really look at this carefully and do the right kind of changes, you reduce the carbon footprint, you have a greener package and by the way, save some money.”

In terms of mechanical or bulk properties, Mr. Hotchkiss explained that by adding solid materials like nano cellulose or micro cellulose you may improve some of the strength properties of the polymer. If you improve the strength property, you use less material.

“If I can double the strength of a polymer, then in essence that allows me to reduce the amount of polymer used to make a package. I’ve replaced part of the polymer with a renewable material. I may have improved the properties to the point where I can actually use less material and get the same performance and I’ve reduced the carbon footprint so I’ve done some good things for that package,” said Mr. Hotchkiss.

Labels

There’s good news when it comes to labels on wipes packaging. “Labels are increasingly being done better—application labels allows for recyclability and better graphics are available,” said Mr. Zielinski.

Mike Rekitzke president N.E.W. Plastics Corp., which specializes in injection blow molding, extrusion blow molding and plastic profile extrusion took Mr. Zielinski’s sentiments one step further. “Packaging is becoming not just a means of holding the wipe and liquid, many customers are finding it a great way to advertise and market their productS on the store shelf as well. New labeling options like shrink sleeves allow for some very unique and attractive visuals for on-shelf displays rather than just silk screening or front and rear labels. This change in labeling alone offers more options for product marketing techniques to the consumer goods manufacturers,” he said.

Reducing Costs

Lighter weight canisters are increasingly being used to help reduce costs associated with wipes packaging. “We are seeing trends to move to lighter weight canisters in an effort to remove some of the costs. Unfortunately, the cost of petroleum-based plastic resins can be quite volatile. Reducing the grammageof the canister is one way for a customer to decrease the cost of their package. Our expertise is in designing the mold to make sure the reduced weight means we can still meet the critical side wall thickness and bottom for strength against drop,” said Mr. Rekitzke.

Customers are also starting to source more recycled content in their products as a means of controlling raw material costs, but Mr. Rekitzke cautioned that too much can cause manufacturing issues. “The consistency in the material can pose problems in the actual molding process. Inconsistency in the material due to melt index can cause streaking, holes, poor neck formation and poor cycle times. Potential levels of increased dirt particles that are generally found in recycled materials, which challenge dirt specifications, can cause holes in canisters. Because of potential contamination of recycled resin, a number of these options are not available due to FDA and other facility standards.

Peering in the Crystal Ball

Where is wipes packaging headed in the future?

Mr. Zielinski said consumers desire upscale attractive designer packaging to match different home and bathroom décors that they can leave out on counter top dispensers. They are also interested in tamper-evident, tear-away inner seals, pop-up dispensers for next towel dispensing and one-touch operation. He foresees use of task specific prints available on plastic tubs to match specific cleaning applications.

Meanwhile, Mr. Hotchkiss foresees the use of square wipes packaged flat in a square container and dispensed from the side rather than the top. “That would probably use less material per given number of wipes. Maybe you’d save 10-15% of the polymer used in the container. That would be an absolutely huge savings. To a large manufacturer that would be worth millions of dollars a year,” he said.

Finally Mr. Zielinski summed up the importance of continued innovation in wipes packaging in these words: “Getting creative with the packaging allows for better opportunity in trade and toward the consumers themselves. The net result is to gain market share by coming up with innovation which fuels differentiation, protection and profitability of your brand. The trade wants package differentiation. Make the product new again and different from the competition,” he said.

From soft pack delivery systems to stand-up pouch packs to convenient “on the go” travel packs to pop-up dispensers to one-push button to touchless dispensers, there are a slew of awesome innovations for packing wipes that are ecofriendly and offer consumers convenience, portability and value.

Soft Pack

One of the hottest ideas in wipes packaging is Nice-Pak Products Inc.’s Eco-Pak, a portable, soft pack delivery system that holds high-efficacy surface disinfecting wet wipes. This resealable package, which has soft sides is able to stand on one of its sides, maximizing store shelf impact and minimizing storage space under a kitchen sink. The package also provides a more compact footprint than traditional canisters for more efficient storage and transportation, as well as a more comfortable fit in the consumer’s hand, according to Ruth Levy, vice president of strategic product development at Nice-Pak Products.

“As we go for more efficient packaging and less packaging per product, we wanted something that consumers could handle. The whole concept was how can we make this easier for consumers to use? Historically, canisters are a wonderful delivery system for wipes. Over time, more products have been moving to a more manageable soft pack that’s easier to hold and easier for the consumer to store.We wanted to make a product that historically couldn’t be made into a soft pack convenient and portable for consumers. It’s all about the consumer benefit and consumer value. Not only is Eco-Pak easier to store and easier to handle, the dispensing is easier,” said Ms. Levy.

Consumers don’t have to thread a canister lid and they don’t have to take the lid apart and rethread it every time there’s a drop back, Ms. Levy said. “With Eco-Pak it’s always easy to reach that first wipe because the package compresses to the height of the actual stack. It’s easy for consumers to dispense and it maintains better moisture all the way through.”

Solar Lids Are A Fave

The Solar Lid is one of the latest innovations in packaging that is becoming increasingly popular. Noting that Nice-Pak designed and patented the solar lid in 1981, Ms. Levy described the device as “putting a dispenser on top of a soft pack,” allowing users to dispense one wipe at a time and then seal the pack tokeep the moisture in. The idea has exploded. The patents have run out and even Huggies and Pampers offer wipes with solo-type lids. There has been a movement from canisters to tubs to solo lids, which allows you to have a pack of wipes anywhere you go whether for face, hands or baby. Now with Eco-Pak for household surface disinfection, you can have them in your car or in different rooms of the house and you can take them when you travel. It has changed people’s ability to have portable cleaning products,” said Ms. Levy.

Hot Trends

Nice-Pak is busy pioneering other hot trends so don’t be surprised if you see more wipes packaged in cups that fit in car cup holders.

Nice-Pak offers Sani Hands for Kids in a cup and the company is expanding distribution under various brand name labels. People are more concerned about hand hygiene. Our goal is not just to provide people with product that they can carry around—these wipes have full hand sanitization properties. This was specially designed to give consumers a product that met their needs when they are out for a soccer game or ice cream so you can sanitize those hands in your back seat,” said Ms. Levy.

Individual packets for wipes are not new but their popularity is growing as consumers’ awareness about germs and viruses has increased. “Not only do you get the microbial kill from the alcohol but you also get the mechanical friction that the wipe provides,” said Ms. Levy. Independent university- and pathogen-sponsored studies show wiping hands with hand sanitizing wipes is more effective than gels, said Ms. Levy.

Belt dispensing packs are the latest thing to hit restaurants. Nice-Pak’s sister company, PDI specializes in hospital and restaurant business and designed the patented wet wipe belt dispensing pack to offer a convenient alternative to cleaning tables with a rag and a bucket. “The wipe can be used and thrown away. The Table Turner wipe packages fit into a belt dispense pack,” said Ms. Levy.

More Innovations

Tarry Paul Zielinski, vice president of sales at Guy & O’Neill, who recently spoke at the WOW conference in Chicago, discussed a number of packaging trends shaping the wipes market. For example, recent consumer research has revealed that consumers like wet wipe products with a pop-up feature, which means that when an individual wipe is dispensed from a package, the tail of the next wipe pops up through the dispensing orifice. “They’ve been conditioned based on the Kleenex facial tissue wipe dispensing device that continually pops up one tissue at a time. These products look good and consumers will leave them out (in sight) for home use,” said Mr. Zielinski.

PDI designed the patented wet wipe belt dispensing pack. |

Ms. Levy agreed that the pop-up feature is convenient. It provides one-hand dispensing, but she emphasized that this feature is application specific. “There are some products where the pop-up feature is important and some products where it is not important. It really depends on the specific application whether it’s more appropriate for it to pop up or not,” said Ms. Levy.

One hand or touchless operation is another trend that is taking hold, according to Mr. Zielinski, who provided the example of a consumer product—Lysol’s hand sanitizing soap dispenser. “It’s something that is important to customers. If you have one touch or no touch there are no germs left over or transferred to the next person who is using it,” said Mr. Zielinski.

Joseph Hotchkiss director, School of Packaging, Center for Packaging Innovation and Sustainability at Michigan State University agreed that touchless operation is a positive trend with benefits for the consumer. “If you touch the container and the next person touches it, they may have the contamination. If the container has a way of dispensing a wipe you break that kind of communication,” he said.

When it comes to canisters there are many awesome improvements that are noteworthy. “There have been many improvements in canisters in the form of large and unique shapes such as oval, flex pack sizes and the latest innovation, which are large domed- shaped canisters. There’s also flexible style canisters that use post consumer materials, polylactic acid materials,” said Mr. Zielinski.

Higher Counts

Catering to institutional centers, wipes makers are making larger count canister-style packages. Nice Pak recently launched a 300-count canister targeting healthcare and restaurant settings.

“There are a lot of products where the canister design is well suited to maintaining the efficacy of the formula. For surface disinfectants and hand antisepsis the canister really is technically a wonderful design. The higher counts are perfect for institutional settings, such as schools, hospitals and restaurants. In industry, people are certainly going to higher and higher counts because you want to have the minimum amount of plastic and the minimum amount of packaging per product and it allows for high traffic in hospitals and restaurants. We’re the market leader in surface disinfecting wipes in hospitals and hand antisepsis wipes in the hospital and food industry. Those are areas where we produce large canisters. We have special brackets to be mounted on walls and general areas,” said Ms. Levy.

Tamper Evident

These days consumers are increasingly demanding tamper evident features on packaging. According to Mr. Hotchkiss packaging tampering is a problem for all manufacturers including wipes makers. “This is a major problem for every industry.We are looking at new technologies that might indicate that a package has been in some way violated or may be a knockoff. It is a brand protection activity.The thing is to make it too expensive to knock off a product so that if someone wanted to duplicate your packaging system it would cost them more money than they could make on ripping off your product. Whenever you have a product that if tampered with could injure a consumer you are prudent to consider ways to protect your product,” he said.

Sustainability

When it comes to packing wipes, sustainability continues to be a trend that is showing no signs of dissipating.

“We absolutely recognize the opportunity to use less packaging material—to minimize the environmental impact and to have more product per shipping pallet for retailer shipping and storage efficiencies, as well as a smaller footprint for consumer storage convenience.Products that have disinfectant sanitization efficacy are technically challenging to put in soft packs so we came around some great hurdles for that. We had a consumer benefit that was good for the environment and it had all sorts of benefits for retailers in shipping and transportation. We aren’t just looking at less packaging. It isn’t just the material you put in that you can reduce, it’s all of the handling of that material before it even gets to you. We went all the way upstream to recognize how we were going to be better for the environment,” said Ms. Levy.

Mr. Hotchkiss agreed. “Anybody who produces a product designed to clean something has to pay attention to having more sustainable packaging. The changes will reduce the product’s carbon footprint, which means it uses fewer petrochemical-derived polymers and using more bio-derived polymers. It will mean using less material not only in the primary package but also in the distribution system, the secondary cartons and the tertiary palletizing systems will become much more efficient.”

Emphasizing that for most consumer products, the packaging and packaging process costs exceed the cost of ingredients, Mr. Hotchkiss said, “Nano cellulose is simply very small particles of cellulosic materials—cellulose being derived from plant sources. It is also biodegradable, readily available and typically cheaper than most polymers. If you added 20% nano cellulose to a standard polymer, you would reduce the carbon footprint of that package by 20%. You are very likely to decrease the cost of that package and you might have the same or better performance from that package. If you really look at this carefully and do the right kind of changes, you reduce the carbon footprint, you have a greener package and by the way, save some money.”

In terms of mechanical or bulk properties, Mr. Hotchkiss explained that by adding solid materials like nano cellulose or micro cellulose you may improve some of the strength properties of the polymer. If you improve the strength property, you use less material.

“If I can double the strength of a polymer, then in essence that allows me to reduce the amount of polymer used to make a package. I’ve replaced part of the polymer with a renewable material. I may have improved the properties to the point where I can actually use less material and get the same performance and I’ve reduced the carbon footprint so I’ve done some good things for that package,” said Mr. Hotchkiss.

Labels

There’s good news when it comes to labels on wipes packaging. “Labels are increasingly being done better—application labels allows for recyclability and better graphics are available,” said Mr. Zielinski.

Mike Rekitzke president N.E.W. Plastics Corp., which specializes in injection blow molding, extrusion blow molding and plastic profile extrusion took Mr. Zielinski’s sentiments one step further. “Packaging is becoming not just a means of holding the wipe and liquid, many customers are finding it a great way to advertise and market their productS on the store shelf as well. New labeling options like shrink sleeves allow for some very unique and attractive visuals for on-shelf displays rather than just silk screening or front and rear labels. This change in labeling alone offers more options for product marketing techniques to the consumer goods manufacturers,” he said.

Reducing Costs

Lighter weight canisters are increasingly being used to help reduce costs associated with wipes packaging. “We are seeing trends to move to lighter weight canisters in an effort to remove some of the costs. Unfortunately, the cost of petroleum-based plastic resins can be quite volatile. Reducing the grammageof the canister is one way for a customer to decrease the cost of their package. Our expertise is in designing the mold to make sure the reduced weight means we can still meet the critical side wall thickness and bottom for strength against drop,” said Mr. Rekitzke.

Customers are also starting to source more recycled content in their products as a means of controlling raw material costs, but Mr. Rekitzke cautioned that too much can cause manufacturing issues. “The consistency in the material can pose problems in the actual molding process. Inconsistency in the material due to melt index can cause streaking, holes, poor neck formation and poor cycle times. Potential levels of increased dirt particles that are generally found in recycled materials, which challenge dirt specifications, can cause holes in canisters. Because of potential contamination of recycled resin, a number of these options are not available due to FDA and other facility standards.

Peering in the Crystal Ball

Where is wipes packaging headed in the future?

Mr. Zielinski said consumers desire upscale attractive designer packaging to match different home and bathroom décors that they can leave out on counter top dispensers. They are also interested in tamper-evident, tear-away inner seals, pop-up dispensers for next towel dispensing and one-touch operation. He foresees use of task specific prints available on plastic tubs to match specific cleaning applications.

Meanwhile, Mr. Hotchkiss foresees the use of square wipes packaged flat in a square container and dispensed from the side rather than the top. “That would probably use less material per given number of wipes. Maybe you’d save 10-15% of the polymer used in the container. That would be an absolutely huge savings. To a large manufacturer that would be worth millions of dollars a year,” he said.

Finally Mr. Zielinski summed up the importance of continued innovation in wipes packaging in these words: “Getting creative with the packaging allows for better opportunity in trade and toward the consumers themselves. The net result is to gain market share by coming up with innovation which fuels differentiation, protection and profitability of your brand. The trade wants package differentiation. Make the product new again and different from the competition,” he said.